-

Posts

5,200 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

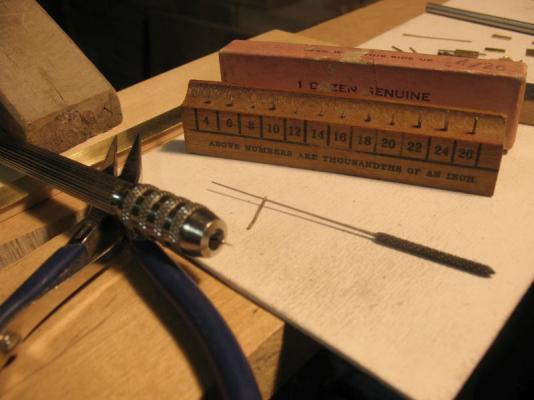

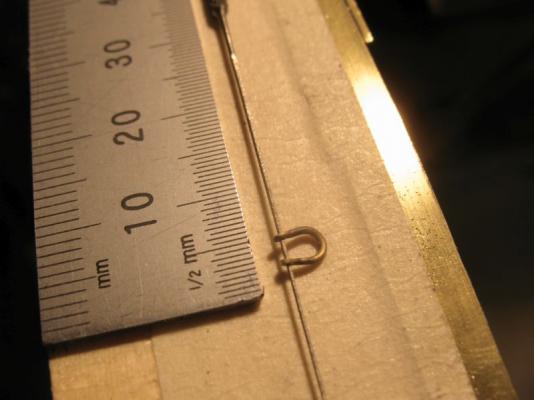

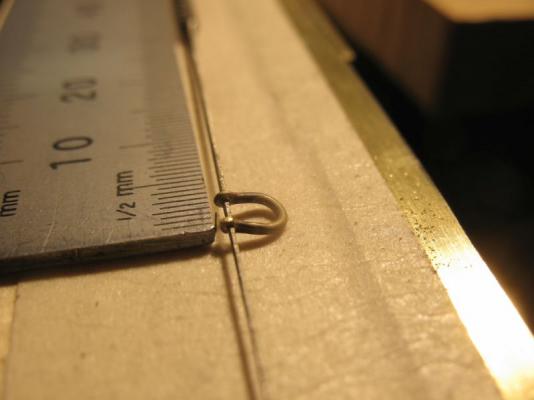

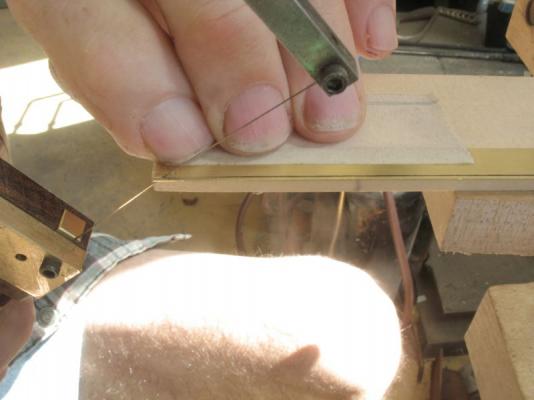

An Idea came to me reading on Keith's build log here regarding the flattening of the ends of fine gauge wire. By melting the end of the wire we also create an annealed ball which can be flattened with a pair of smooth pliers A watchmakers pivot drill was then used to drill the hole by hand the hole is .022" Drilling the holes was the hardes part of this project. I am pleased with the final outcome but this will need a little practice to finesse the shape of them for further use. This method will most likely work with some heavier gauge wire which will eliminate having to use the lathe to create the ball ends. Michael

-

The finished model looks really sharp Rusty, Congratulations on finishing. Michael

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Very Nice Pete, These small boat really do have a charm about them. Michael

- 153 replies

-

- musongus bay

- sloop

-

(and 1 more)

Tagged with:

-

Bob thanks for the update, things are looking very shipshape. Michael

- 420 replies

-

Hi Elia, a belated greeting for your B'day I look forward to seeing the next update. Russ thank you for your link your paintings are wonderful. Michael

-

Beautifully clean work on the channels Ed. Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Floyd Walmart, I paid $6 per tin for it, I don't normally shop there but they were the only supplier within 50 miles. michael

- 80 replies

-

- Americas Cup

- Endeavour

-

(and 1 more)

Tagged with:

-

Floyd, I don't know what to tell you about the decking, but I have a good friend who fixes fiberglass boats and he swears by Krylon Spectrum paint, I have purchased the same but have not had the warm weather yet to spray outside, also I need to finish other bits first. Michael

- 80 replies

-

- Americas Cup

- Endeavour

-

(and 1 more)

Tagged with:

-

Made me laugh Bob Now off to Jasper back in a few days. Michael

- 2,215 replies

-

Grant, Tom, Row, Pete and Edwin, Thanks for the kind words and for all the likes. I have not had a lot of time in the shop the last couple of days and tomorrow I will be taking a few days up at Jasper Park Lodge for the Alberta Libraries Conference. Will bring back pics of the mountains. I hope to catch up on some reading about sail making because that aspect is beginning to loom large (sorry Bob) and I need to learn quite a few things. I am sitting hear drooling over the cover photo of the August 2009 issue of Wooden Boat magazine The image of a Gill Smith look-a-like by Lance Lee some absolutely seductive lines on a boat if ever there was some. I have almost finished the second pair of hinges and have been taking a lot of pictures. I will be posting a step by step set in the metalwork area. This method of making hinges can apply to a lot of different hinge shapes. I will also detail the small countersink that I needed to make for them. Michael

- 2,215 replies

-

Hear Hear! The model is looking very nice Bob, those line show up very well, planking ought to just flow like butter. Michael

- 86 replies

-

- muscongus bay lobster smack

- Midwest Products

-

(and 1 more)

Tagged with:

-

Very nice straps Remco, did you heat treat (anneal) the brass or bend them hard? Michael

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Glad to see you back. Very sweet looking boat. Michael

- 153 replies

-

- musongus bay

- sloop

-

(and 1 more)

Tagged with:

-

the perseverance pays in the end, nice work Bob. Michael

- 420 replies

-

Cutting/Sanding Brass?

michael mott replied to esion's topic in Metal Work, Soldering and Metal Fittings

Rich since you are only cutting short lengths, you can also use a jewelers saw to cut the brass. The particular strip of .25mm brass was originally cut from a standard KS sheet of brass that you can purchase at the hobby shops. I needed some strips that were 3/8th by .010" which is basically the same as .25mm. I cut the bit strips on the table saw some time ago, by sandwiching the sheet between some plywood and using a sled. but that is another kettle of fish. Here is a step by step I just did to show what I mean using the jewelers saw. 1 tape the .25mm ( .010") to the edge of a piece of thin wood, leaving the 1mm+ overhanging the edge, this gives the metal a lot of support 2 using the finest blade you can find and then using a jewelers saw cut along the line holding the saw at an proximately 45 degree angle this makes the teeth seem closer together, (it's the geometry) cut with a smooth and gentle motion The set up of the camera took much longer than the cut which took about 30 - 40 seconds Anything much thinner than this you can cut with a good pair of scissors, in fact I did cut a small strip off the end of this brass strip with a pair of scissors. Michael -

The launch is looking very good Steve. Michael

- 625 replies

-

- bounty launch

- model shipways

-

(and 1 more)

Tagged with:

-

Ed it is great to read your methodology nice tip with the steel straight edge. Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Mauro, it is great that you have found some more time to work on your model. Good looking stitching on the sails. Michael

- 111 replies

-

AL's CNC Wood Milling Machine

michael mott replied to dewalt57's topic in Modeling tools and Workshop Equipment

An interesting bit of Kit, for sure. Michael -

A good looking start on a very nice looking hull shape, I will be following along as well. Michael

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.