-

Posts

5,198 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

Sherry Thanks, Bob the guy building this boat said he didn't know what a nail was so he could only work the way he was taught ;>)) Michael

- 2,215 replies

-

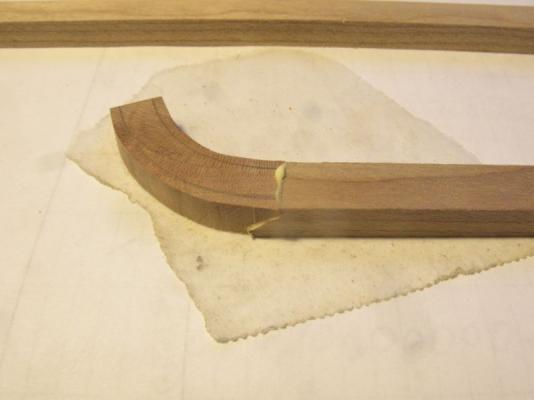

Thanks Mark, perhaps I will do a bit of careful editing at the first few pages over the next while and see about adding in some of the earlier pictures. I did not get much time in the shop today, I had to go get water and also dealt with some more computer configuring. Here are a few pictures of the progress on the doors for the companionway, They are still quite rough regarding the shape, but I am happy with the overall design I still need to shorten the panel and make the curved top rail the bottom rails are tennoned into the stiles. I thought I would see how things look in Black and white. I was doing some searching for images of Genesta and some of the early black and white photographs that were taken while some of the big yachts were racing are really stunning. they are sharp and well posed a true testament to the photographers and cameras of the time. Michael

- 2,215 replies

-

Cutty Sark by NenadM

michael mott replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Very nice fitting of the trim Nenad Michael- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

So where did you get those giant pegs Jay.... oh right this is a very small cannon very nice work. Michael

-

Thank you all for the interesting feed back, and for all the likes. Sailor said Sailor I will proceed with the doors for the access to the magnets Row said I have wondered a few times about slowly editing the first post to look at including a little more of the original build log information. I am not sure if it is possible to add pages at the front of the log though. Perhaps Mark can advise. S.os said It is because the floor of the cockpit is not yet resolved, the original configuration did have a solid bottom. I have considered but not net figured out the cockpit drainage. The latticed floor boards that were in the old cockpit need to be reshaped to fit the new cockpit as well. My original plan was to have the cockpit removable so as to access the RC gear for the rudder, I am now leaning toward setting the cockpit in more permanently and running some drains out through the hull this will mean I have to ensure that the floor is above the waterline of course. Now that I am not going to put a radio into her I really have no need to have the cockpit removable quickly. The obvious challenges of building on the fly and lacking in some forethought about these things, and the continuing changes of mind regarding the design of various elements. This entire build has become a lot more complicated in many more ways than I had originally imagined I will definitely have better knowledge about these things on the next build though. Michael

- 2,215 replies

-

Dan excellent attention and execution of the tree nailing details. The overall effect is certainly worth the effort. Michael

- 241 replies

-

- queen annes revenge

- pirate

-

(and 2 more)

Tagged with:

-

Bob I am guessing that yuo made the bowsprit piece from a long strip and folded it in four places wrapping it around and then soldering the closed spaces between the two side of each tab. I could be completely wrong of course. Michael

- 420 replies

-

Hmmm Sailor your questions are good ones for me to contemplate, initially I was thinking that it might be a simple small cabinet for a few tools , pliers wrench sort of things, The idea of it opening into a larger space had not occurred to me. Michael

- 2,215 replies

-

Keith, Remco has something like this in his signature and since adopting this attitude I have been able to stay much better focused. and less worried about moving to the next steps. Your deck planking looks great. Michael

- 84 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

Thank you everyone for the very kind remarks. and thank you to all of you who added the likes. Owen Welcome and I look forward to some pictures of your build, Do you have any pictures of your grandfathers boat? This evening I started to frame up the companionway and decided to add doors instead of hatch boards. The stops have been glued inplace, tomorrow i will notch out for the hinges and make them as well. also while looking at the compass I wondered about the location and then it came to me in a flash.... a little bit of cutting both wood and metal and this is the configuration, I am much happier with the location, it just did not look right sitting on the deck. The block of mahogany is just sitting there at the moment, I am thinking that a couple of curved doors so that there is some access under the binnacle it seems logical, I will think on it while I make the companionway doors. Michael

- 2,215 replies

-

The planking looks good Bob, will you be adding any support at the edges where the planks but up to the cover board? Michael

- 420 replies

-

Today I finished off the cap rail and gave it a coat of Tung oil the first picture shows the continuation of the joints at the corners. I used the old pencil lines trick to line things up All the pieces glued and doweled. Placed back on the boat tomorrow I will get back to the cabin hatch boards. Michael

- 2,215 replies

-

Does the hull have to be inserted in pieces? and the top down view looks great regarding the details of the deck. Michael

- 36 replies

-

- black pearl

- bottle

-

(and 1 more)

Tagged with:

-

Hi Ed tried to send you a PM, it would not work. michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Kannon, there is no such animal as a "purist" Dave and Mark of course are having fun with the term as you no doubt have realized. JB the fact that you are interested in funneling your carving ability into the hull of a ship model is perfect for inclusion on this wonderful site. You will find no end of very helpful advice from those who are skilled at the particular task you are doing. I would reccomend you start with a build log after deciding on a boat or ship, you ask what are the best power tools and steps, there are so many examples of just about every aspect of building a model ship here. Jump in and do not be afraid to ask a specific question about a task as you have already done. Check out the plans and research sections and also the threads that discuss planking some over solid wood and so on. Good luck with your new endeavour. Michael

-

I did see that not doing this at the time was due to a complete lack of knowledge in these matters, and that the way I approached it was more complicated than it needed to be. Ah... just need to train some little people. Gulliver probably thought the same thing! Michael

- 2,215 replies

-

Ed I do hope that you are considering a book for this type of ship model. From my limited knowledge of such things there seem to be quite a few monographs and how to's for the classic three masted battle ships but little on the clippers and merchant sailing ship models. I just thought I would add my name to the growing chorus. Respectfully Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

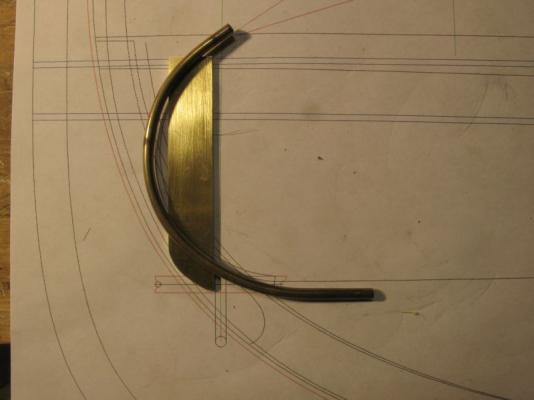

Row I am already ahead of you there. Before the crash of MSW 1.0 I had been documenting the build from the keel up and after I did not rebuild the log but just picked up where I had got too. I do have however hundreds of photographs of the entire build from the very begining. this picture shows the curved brass tube to carry the steering wire to the tiller. the first decking was white pine and the wires were set before the first planking was finished the wire was to have a stop fixed so that it would move back and forth tracking beneath the cockpit eventually I covered the first layer of planking with a layer of clear fir because I did not like the way the first layer looked plus there was the issue of the cover board and learning about the construction of the full sized practice as I was moving along. after the fir was scraped and given a rub down with steel wool the steel exit holes are virtually invisible but they are still there as marked by the red circle in this picture. Now this is a possibility that I am considering very seriously, and that is to not put any kind of radio in her at all but to sail it with the rigging set and cleated as if she was a classic pond yacht. the reason being, that the build is more important than the sailing of this model, My sailing will happen in Maria. the boat is set so that if I wanted to add the radio and other gear later I could do it. I would rather spend my time though building the next boat than sailing a model, as long as I know it will sail that is all that matters at this point, so it will get to the water and it will be documented for sure. And to answer you question about glue , I am using lepages carpenters glue and the cap will be varnished or oiled when finished. michael

- 2,215 replies

-

Nils, Bob, John, thanks for stopping by and your thoughts. Thanks for the likes. Today I took a little time out from computer transfer to work on the cockpit cap rail. The joints are small and a bit fiddly. I have the corners all made now and the stern pieces glued together Before finalizing I will add some dowel pins to locate the rails to the vertical boards. hopefully I can finish the shaping tomorrow. Michael

- 2,215 replies

-

Floyd, are still sure you are not going to put her in the water? Michael

- 80 replies

-

- Americas Cup

- Endeavour

-

(and 1 more)

Tagged with:

-

micro table saw stop

michael mott replied to michael mott's topic in Modeling tools and Workshop Equipment

Hi Richard, not a dumb question at all, and if you read the whole of the information on the Hobby mill site you will also notice that Jeff said that he was not endorsing his method or recommending it as a preferred method but that it worked for him. I might suggest that like all things there are a number of different ways to acheive the same results, what is comfortable for some is not for others, that said having a larger "vocabulary" enables one to be able to use more than just one word. Some times the particular piece of wood is more easily cut using one or the other methods or even types of saw. This has been my experience. michael

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.