-

Posts

5,200 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

Hi Egilman, yes the strap bolts were flattened in the vice they needed 4 annealings to get to the correct width. I created a small jig using some tool steel blanks as in the next picture. The bottom piece if steel has a piece of shimstock to create a slide fit for the top piece of tool steel that gets hit with a hammer using a piece of brass between the steel and hammer. The edge next to the bolt section has a small radius on the top anvil (tool steel) Michael

-

Thanks Ron, I ended up finishing the points or switch as some call them. I am progressing on the wagon ironwork. All the axleguards are now cut. next was to get the strapbolts made . Then the next piece of metalwork is the headstock and sole Knees These plates are part of the whole buffer and strengthening of the frame Now that I have a prototype I can set up to make the four needed. The strapbolts are turned from 1/8th brass rod with the bolt part being .060" and threaded 0x80 and the section that gets flattened is turned to .095" this eventually becomes .140" wide by approx .040". and the knees are .040" copper they have been blackened in some Jax Blackener. Michael

-

Hello Walter, lovely work on the carving of your hull the deck details look very sharp. I will continue to follow along. Michael

- 15 replies

-

- jolie brise

- pilot

-

(and 1 more)

Tagged with:

-

Now having finished the next few posts, all I can ad is to repeat what others have said that this is a wonderful example of the Art of model-making in all its guises. Michael

-

Gary this seem to affect all of us at some time or another. The model is looking superb. Michael

-

Kevin, your videos and explanations of the changes that you have made to correct the errors you pointed out were very informative. I have not watched all of them all the way through yet, but from watching all the way through the first one, I learned a lot, your casual and honest approach is so refreshing. I shall enjoy the rest of the videos at a leisurely pace. Thank you for taking the time to prepare them. Michael

- 72 replies

-

- fishing boat

- artisanal fishing boat

-

(and 1 more)

Tagged with:

-

Congratulations Vaddoc, you have done a wonderful job on this yacht! making all the rigging working as you have done is not for the feint of heart, it increases the amount of detailing and work that a static model does not have to contend with. A clever way of measuring the profile with the tooth pics as well. Michael

-

The shot from the bow really shows how extremely narrow this yacht was. She looks very nice in the daylight. Michael

-

Keith your work on the interior reminds me of what DeWitt H. Parker said in The Principles of Aesthetics In Thinking of the beauty of architecture, we are all to apt to consider the exterior exclusively, forgetting that the inside of a building , where we live, is even more important practically, and is capable of at least as great an aesthetic effect" Wonderful work on the cameo of the insides! Michael

-

Hi Martin the hull is looking rather sharp no pun intended. There was an article in Wooden boat quite a few years ago now that featured the development of the yachts of the era that your model is taken, I think that Vanity was one of the most extreme of the narrow yachts. I am wishing in may ways that I had not begun my own cutter at 1/8th scale your 1/16th scale seems so much more manageable regarding the space required for working on. I look forward to the rest of the build. Michael

-

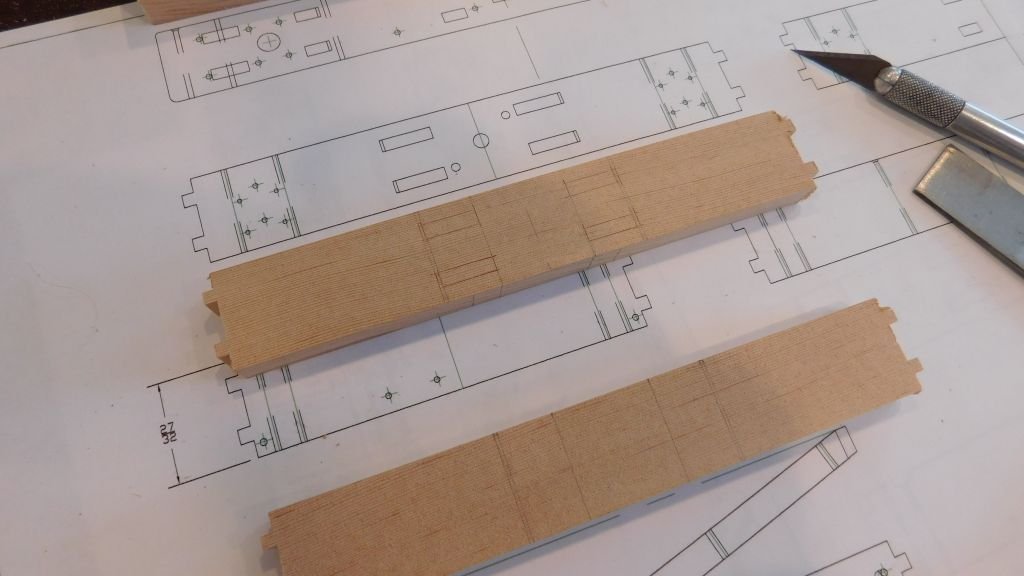

I had a very busy couple of days with no modelwork, yesterday I let Maria Go, it was a bit of work getting her out of the garage and onto the trailer. She went back to the chap I first got her from. I have no idea what will happen to her now. The chapter that was Maria and all the trials and tribulations that went with refurbishing the old sloop are now going to be fond memories. Today as I waited in line to take something to the Eco station here in Edmonton after a 1 hour crawl to the pay booth My car broke down and I had to be pushed out of the way because I was blocking the entrance for everyone. A second 1 hour wait for the tow truck. So then spent the last bit of the afternoon tidying up the garage and sorting wood. There was progress before all this though. I finished the mortises and tennons and dry assembled the frame then began cutting out the axleguards out of some .051" cold-rolled steel. I did one per day they took 2 1/2 hours each to cut with a #5 jewelers saw blade the blades only cut about 2 inches before wearing enough that to push them further they break. After cutting they were drilled out then had to have a double bend put into the top section this took tree tries to get right, bending then flattening it out again. After I figured out the technique it was plain sailing, the cutting did not get any faster or easier though. They actually get bolted to the inside of the sole bars and I will use the guards as templates to drill the holes through the wood. Just one more guard to make then all the other odd little bits of metal Nuts and bolts. Time to rest now it was a troublesome day today. Michael

-

Nice builds Larry, and for a great cause as well. Michael

- 84 replies

-

- nimblet

- knockabout

-

(and 1 more)

Tagged with:

-

Vaddoc Frustrating days can really test one's mettle! You are doing a fantastic job and the effort is most certainly worth it. Not long now it looks like you are on the home stretch. Michael

-

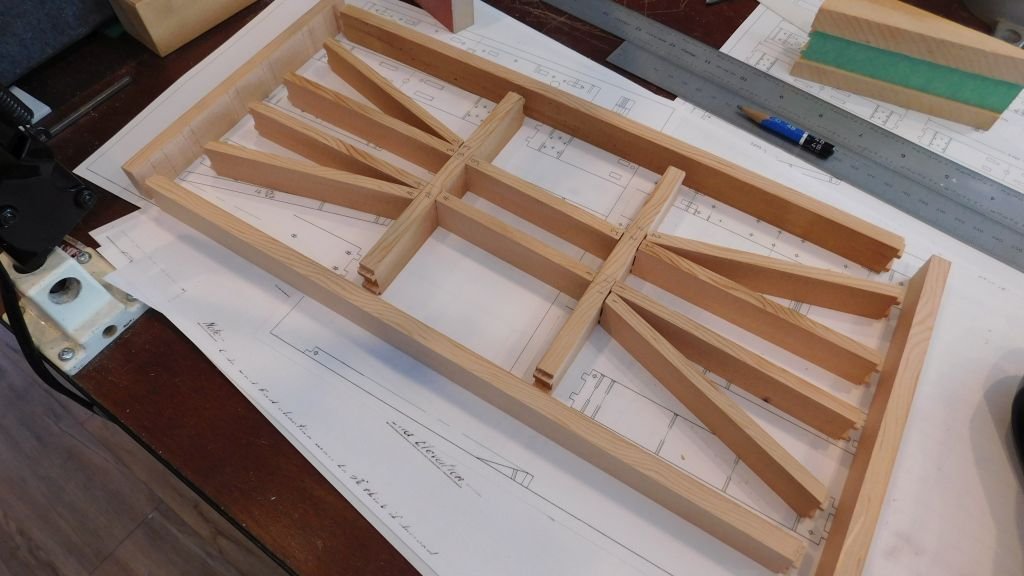

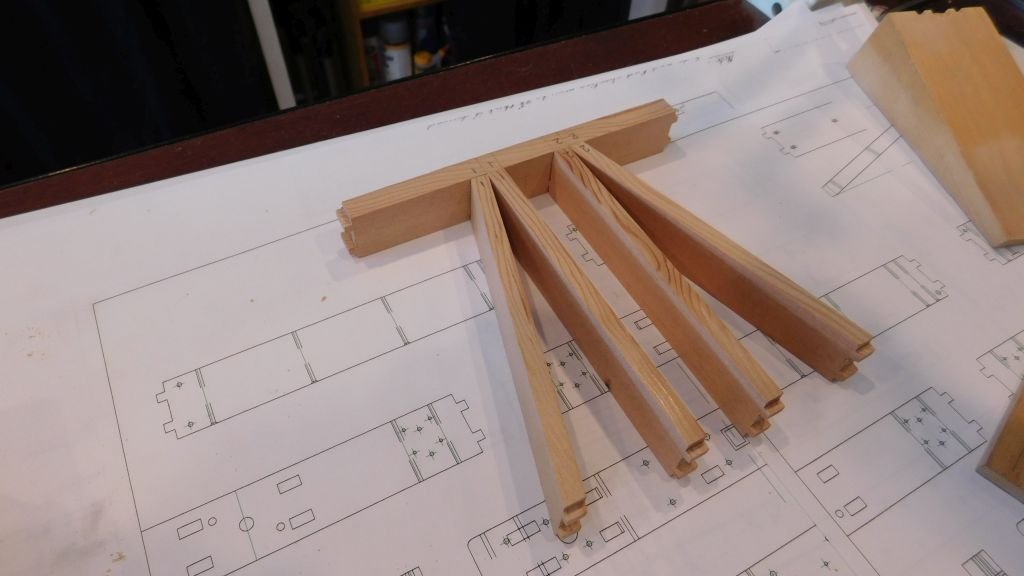

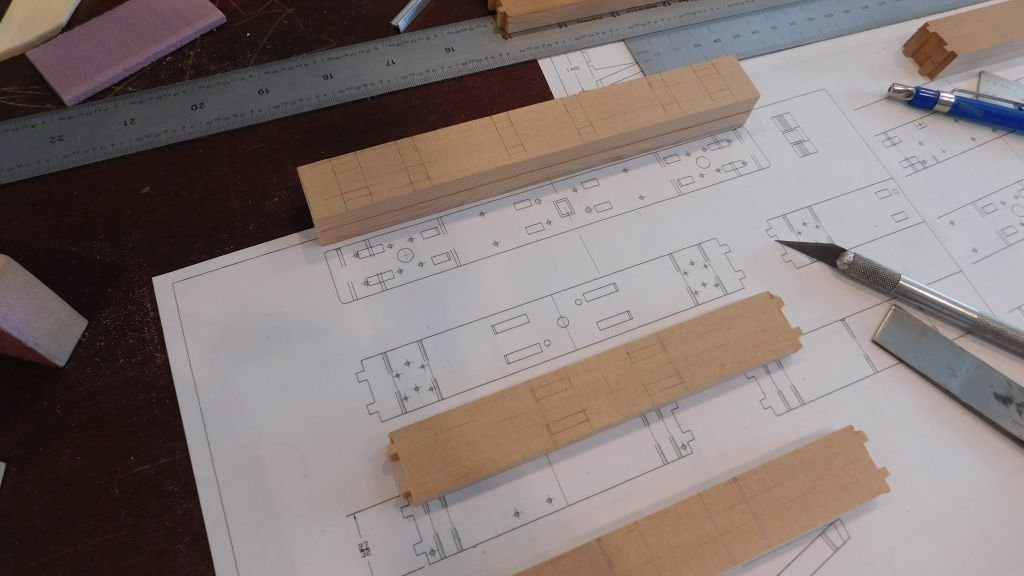

Thanks everyone for the likes and kind comments. A little progress . I had to make slight adjustment to the long side timbers due to a conversion compounding error they were about 7/64th too long, so set them up next to the centre beams and made the adjustment on the one end before cutting the cross member timbers. then cut the mortises in them and proceeded to do the same with the buffer beams. first shot is of the mortises being chopped out for the cross beams. next the four timbers in the buffer and then fitted I now take my hat off to all you folk who frame up the decks of your three deckers.... they would have to take me away in a straight jacket, I honestly do not know how you manage to do those decks as neat and clean as they are. It is very humbling indeed. Michael

-

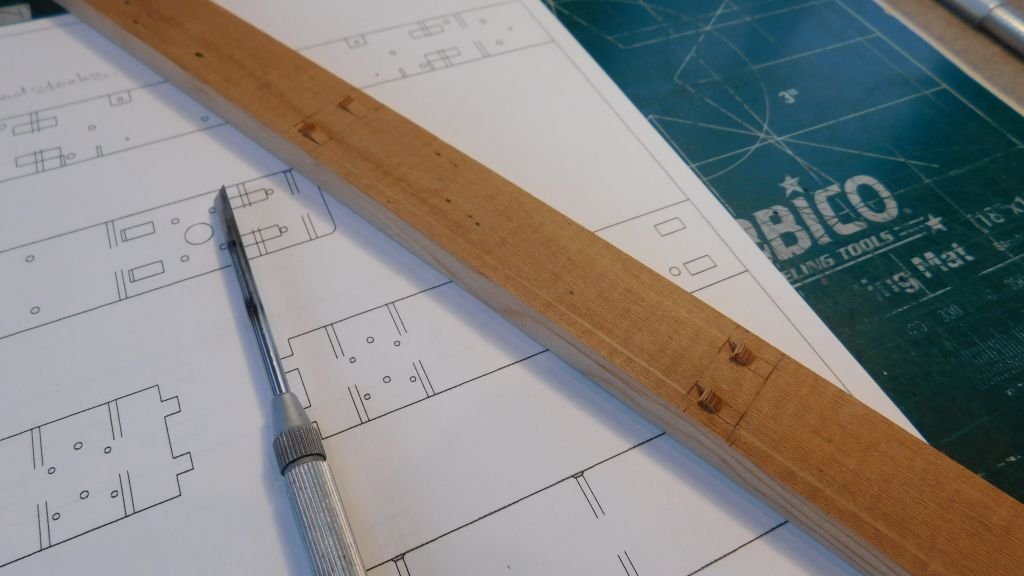

In order to maintain my sanity I have taken a break from the foam and started to build the standard gauge wagon that I am going to use to replicate the scene with the wagon on top of the little 18 inch gauge trolleys. I am using a bit of salvaged old growth clear fir that came from a soling paneled door. You could also say that I am practicing cutting the mortise and tenons that so many of you execute with such precision in the deck framing that many of the wonderful builds have. The sequence pretty much speaks for itself. first though I did a quick practice. And finally some blank tyres cut from some 2 3/4 x 1/4 solid drawn tube for the wheels that need to be machined to thickness and profiled . Time to some tea. Michael

-

Problem is you would also need to charter and aeroplane as well because Keith lives in the south of England. Michael

-

Keith your work continues to put a big smile on my face, it is such a delight to watch this yacht take shape. Michael

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.