-

Posts

2,246 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by EJ_L

-

I'm a big fan of the 17th and early 18th century ships of the line. Fortunately, a lot of the ships I am interested in are already in kit form but, a couple things I would like to see to improve what is out there. The first would be a less of the decorative parts being molded in metal. They rarely look good and are often replaced anyway. I know that to have them already carved in wood would make the kits extremely expensive but could the kits instead come with high quality images of what the decorations look like and then a supply of blank carving blocks to carve them out of. This would obviously be on advanced kits and not beginners but I think that would be a nice change. The other which may be harder to do is to try to uniform scale between the ships. I like to display my models side by side to compare but that can be hard to do when the scales are different. I do not know how hard it would be to try to make series of kits in the same scale so that all my 17th century French ships are all 1:100 scale for example. I know I wish my Constitution and Victory models were the same but at 1:96 and 1:200 respectively, they look odd next to each other. I guess this is more of a pet peeve of mine coming from model railroading where an entire layout is to scale and anything I build fits right in. With my ships, I don't have that luxury. As to other suggestions, like I already said, I like the large man of war ships. Would love to see more of them though I would have to research for name/country suggestions. Price is always a concern but as I am currently saving up the last couple of hundred I need to buy the Sergal Le Soleil Royal which is a $1200 kit, it doesn't worry me. If the quality is good, I will pay for it. I'm a fan of the longer builds as I like to be able to settle in and take my time but it is nice to have a faster build sometimes. Finally I would like to see more cross section kits. I would love to have one to match both my current build of La Couronne and my next of Le Soleil Royal. I think being able to display a cross section of a ship next to it's whole would be a great addition to any display as well as enriching our community in our education about ships. Cross sections give an extreme level of detail and information about the interior of a ship that a lot of us lack due to primarily modeling the outsides. Thanks, I hope this helps and I look forward to seeing what you all come up with next!

-

Bob, Elijah and Michael than you for the compliments and the likes from everyone else as well. As we all know it is always nice to see our work appreciated by others. I'm hard at work planking the spar deck now and the interior bulkheads. Once that is done I have lots of work to do building columns and arches to support the deck. I've been looking forward to building those and having them installed as to me they are the first of the interior decorative pieces.

- 608 replies

-

- la couronne

- corel

-

(and 1 more)

Tagged with:

-

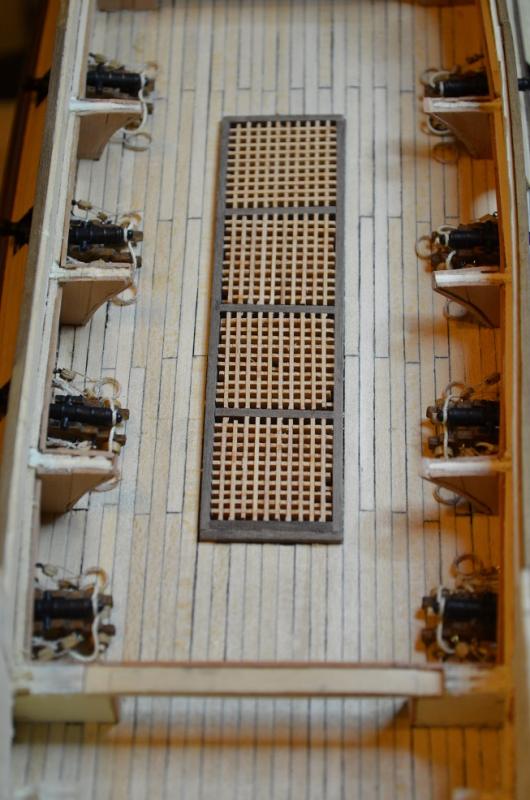

All canons have been installed on the upper gun deck. Most are on a simple carriage without rigging as details will not be seen once the remaining decks are in place. The four canons on either side of the cargo hatches are the only ones on this deck to receive full rigging since those will be the only ones visible from above. Granted even they will not be easy to see once the spar deck and ships boat are in place. There was a lot of learning and trial procedures that took place with these guns. Trying to find the best ways to rig the guns so the ones on the spar deck that will be completely visible will look awesome. Now that the canons are installed I will finish cleaning up a couple details and then I will be installing the spar deck and up another level I will go. It is an exciting step as this next deck is when I really start installing the heavy details. Support columns, arches, interior bulkhead planking, ladders and railings and many more items will be getting installed.

- 608 replies

-

- la couronne

- corel

-

(and 1 more)

Tagged with:

-

I really enjoy rigging my ships. It is very difficult and frustrating at times but the challenge is a welcome one. Every line I get installed I find myself sitting back and enjoying the new addition. Each ship I have built I try to do a better job with my rigging in making sure they are seized correctly, ran to the correct belaying pins or cleats, rigged through the blocks or that the blocks are the right ones. Each build I have learned something new and each has become better for it. Like any aspect of ship building where there is a lot of repetition it can become monotonous and I am ready to see the end of it after a while but that is no different then planking or any other phase really.

-

Wow! She really turned out looking great! Excellent job on the sails. Of course with all the fine work and effort you have been putting into her over the months I expected nothing less. Great job! I don't know what your grading criteria is but that is first class work to this community. So now that I am guessing school will be ending, are you planning on taking on a new project?

-

Mark, Thank you very much! Yes, the kit did contain blocks and rigging line as well as everything that a person would need to complete the kit. It was short some of the canons and I plan to order more soon though the ship could be completed with some of the gun ports closed. That being said I am using parts I have in my extras from past builds as well as custom built parts and some newly ordered parts. I don't think I have built a model, be it a car, train, building or ship in many long years that only used parts from the kit.

- 608 replies

-

- la couronne

- corel

-

(and 1 more)

Tagged with:

-

I stand corrected on the morhball ships. I knew that the Navy did return some ships with upgrades to service and that many museum ships are maintained in a "battle readiness" state and yes it is far less expensive than new ship construction. I was misinformed to the extent these upgrades were taken to. I was under te impression that they were upgraded with modern electronics and related systems as well as structural but, and I may be wrong again, are not the upgrades limited to what the ship can support? I would think that the ships structure would limit what can be done in terms of modernizing them. This is not an arguement but curiosity and looking for the correct information.

-

Ship museums are definitely more for people who have never been on a ship then us former sailors. That being said I'm glad there are some around and although I do not feel every ship needs to be preserved, I am glad some are. In the present we rarely think about what the future might want. The Constitution and Victory during their prime and even towards the end of their active service were probably not planned on becoming museums. It is largely due to luck that they survived long enough for someone to say that it would be a good idea to preserve them. Thankfully they did save them and many more for those of us interested in history. This is the same way we think now with modern ships. We don't need or want a museum as we can see them now. It is thinking 50-100 years from now that decides on if they should be a museum. Will future generations want to know what our battleships, carriers and subs look like? When we are exploring space will those people care how we explored the oceans? For the sake of our society as a whole I hope so but today if I'm given the choice between setting money aside to preserve a carrier or funding education for example, education will win and I will hope and pray that private money will become available for the museum. As for mothballing a ship, we have that. I have seen the Navy's mothball fleet. if we had to rely on that fleet to fight with we will be done. The time and money it would take to get them up and going and compatible with modern technology is unimaginable. I guess if we needed ships that didn't need to rely on modern technology we would be in good shape. Otherwise... I say pick a ship that has meaning be it the first of a revolutionary type or one that was instrumental in history and preserve those as a museum. Otherwise I almost hate to say it but either scrap them or sink them for reefs. Things should be preserved for history and education. I'm a firm believer but we can only save so much. Be smart and choose well. Put money where it it does the most good and will benefit the future generations the most.

-

She is looking real nice. Your framing is great. Clean and neat and once you finish fairing everything up she should be good to go for planking. I would agree with holding off on the rail till much later. If you are worried about stability you can always tack a temporary batten across the extensions. A lot of instructions say to put this on early but after breaking a few of them off on my first models and realizing that you gain nothing by doing it early other than rework later, I now skip that step. I have learned that building ships is much more than following directions. It is instead more of learning to read blue prints and schematics which typically tell you what needs to be there but it is up to you to know in what order this needs to happen. Experience is really the only way to learn this. Yes, read practicums, and build logs though keep in mind many things will be different based on the builder's experience and level of detail used. Combine that with the knowledge of the ship available at the time the information was written and you will find yourself with many different ways of achieving a great ship though rarely will any two look alike. With a more popular ship such as the one you are building that information is much more readily available but, the variances between sources will be greater. With a rarer ship, typically there is less information but what exists usually stays closer to each other unless something new is discovered. As a new ship builder, (and I count myself one) this can be very frustrating as you want to build a great ship but don't always know all the tricks and secrets and the order they need to happen. This is where you are succeeding in great strides. You are thinking things through, staying steps ahead and asking questions of those with more experience. Read, research, read and read some more. See what others have done and decide if that is what you want/need to do. Take full advantage of sites like this one where the wealth of the world of model ship building can teach and guide you on your journey. Above all though have fun. Enjoy your build for the fun it is and the knowledge will come.

- 117 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks. I don't know why they say to twist wire around the blocks. Its really not any easier to do that than to seize the block and its far from accurate.

- 608 replies

-

- la couronne

- corel

-

(and 1 more)

Tagged with:

-

More pieces being made ready for assembly. Should be able to start rigging the canons in place this weekend.

- 608 replies

-

- la couronne

- corel

-

(and 1 more)

Tagged with:

-

Very nice Bob. I too like the Walnut look better than the white wood. Very nice and clean again. Looking forward to seeing you move forward with not just one but two fantastic builds.

- 206 replies

-

- battle station

- panart

-

(and 1 more)

Tagged with:

-

French rigging practice in the days of spritsail topsail

EJ_L replied to cerberusjf's topic in Masting, rigging and sails

I too will be relying heavily on Anderson's book for my Couronne build as it seems to be the most thorough book for 17th century rigging that I have found so far. Of course there were always subtle changes in rigging from ship to ship and country to country so it is hard say if what is in there is 100% accurate to the ship being built. Thanks to everyone who helped to clear this up. I just hope that how I read that book and interpret the drawings I have that it does not offend to many people. -

Elijah, your adjustments look great. The spacing is much more even now. As for writing on tape, you can write on clear scotch tape with a pen. They make very fine pens, .5mm instead of the more common .7mm. They are easy to find in any office supply store just pay attention to the size on the packaging. Just be careful to not smear the ink once you have drawn on the tape. Another option I have seen is just to use the edge of a piece of card stock to transfer your marks with. The card stock is flexible enough to follow the shape of the hull and since it is paper you can write on it easily. Just make your tick marks on the edge of it as you would the tape then you can slide it along your template to get your sizes.

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

Every time you update I am again just amazed with what you have done. Fantastic work Michael. I should keep a log of how many hours I spend looking at your photos for inspiration and guidance for my own build.

-

Matt, your rivets are looking fantastic and you have a great idea. I may have to try that on a future build. As regards to sanity, every time I show one of my models and especially pictures of other people's models to friends and family they all just shake their heads and the most common phrase out of their mouths is along the lines of "that is crazy" or "you are insane". I think it must be a requirement then to be a little insane if you are going to be a scale model builder and especially a model ship builder. I mean really, who in their right mind would want to dedicate hundreds of hours to to the building of tiny parts all for something that just sits in a glass case if they even get finished in the first place?!?! That is right, us! If I had to choose a way to be insane this is one I am proud of.

- 117 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Canon building is progressing nicely. Only three more to build for the upper gun deck. Fortunately for this deck only 8 of the guns are visible and will receive full rigging. The others on this deck are covered up and so will not get as much detail. If my plans for the day continue as I hope I will have all the canons built and rigging well under way.

- 608 replies

-

- la couronne

- corel

-

(and 1 more)

Tagged with:

-

Matt, great job on those waterways. I agree that a lot can be accomplished using just hand tools. I do a have a full woodworking shop in my garage but I hardly use any of those tools. About the only power tool I really use on a regular basis is my Dremel Drill ans even it is only used for major sanding/drilling operations. Other wise I have a small hand miter saw and exact-o knives for cutting, chisels and hand planes for shaping, files and sandpaper for smoothing and pin vises for drilling. That being said, There are many things that are pushing me more and more towards using more power tools. The more I build and read about other ships the more I want to scratch build my own parts and rely on kit parts less. I am thinking that very soon I will be finding myself out in my shop milling, and scrolling more and more and I have already been practicing turning parts on my lathe. I do not think this will speed up anything. In fact, this will actually probably cause my builds to take longer but I think I will take even more pride in knowing that I made all the parts and not just installed ones premade.

- 117 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Very nice job on the figurehead Ken. She sure is coming together nicely.

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

It looks like you are on the right track. Your bottom band looks like you have almost twice the width at the stern then you do at the bow. As long as the math works out so that it is the same number of strakes at both ends you will be fine. I do agree with what Mike was saying earlier in that often what we lay out in the beginning changes as we progress. Work a small area at a time and recheck your measurements as you go along so you can adjust the widths as needed. Smaller changes throughout the hull are easier to hide than large changes at the end.

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

She is still looking very nice. We have all built models that we are not as proud of for many different reasons. Making mistakes is natural and sometimes we also find ourselves in over our heads when it comes to the skills needed. Don't give up. At least not permanently. Sometimes a break can be useful to clear out thoughts or do something less challenging to improve skills or even boost confidence. I will still pick up a generic car model from time to time and build it just to relax and show myself that I can do something awesome when I feel bogged down by the complexities of my other hobbies. Another thing I have learned, though admittedly I do not always follow, is to not compare your results to everyone else but instead only to your work. My dad, who restores classic Mustangs, always says that you are only failing if you are not improving your work. Of course this is coming from a man whose cars constantly win best of show awards. Still he is right. If I only compared my ships to some of the breath taking work I have seen on here I would have never completed the first one. Heck, I never would have done a second car model back when I was a child as the ones my dad built were incredible. No, I plow on and I only compare my work to my previous work. Every time I see things getting cleaner, more detailed, and the mistakes less glaring I am happy. Of course I wish my work was as good as others on here and perhaps one day it will be. Till then I continue to practice skills, learn new ways and fail. Then I fail again and again till a different result happens. You are doing good work. I enjoy seeing the updates. I plan on building that ship next. Mine will be out of wood but a lot of the same elements and trouble zones will be there. Your mistakes can teach as much as your successes. Please keep going and your skills will return and get even better and this site will have yet another very nice completed ship to add to it's collection.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.