-

Posts

2,156 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ian_Grant

-

Had a bit of a brain wave: how about two independent beams for the upper and lower remes? This would allow software to independently control the range of lift motion for each reme of oars, allowing the upper ones to be raised slightly higher without the lower ones necessarily going all the way up to horizontal. I like it! Ideally the vertical shafts could have two shorter linear bearings on them, one for each reme's oar beam. I would modify the interface board and software to add two more output servos for the two new lifts. Potential snag is we now have a long beam mounted on two 1.25" linear bearings more than 2 ft apart; could a single central servo move it up and down without the ends binding? Don't know. I have always had in the back of my mind that perhaps the beams would need servos at each end, so be it. But with four beams that would be eight servos doing the lifting which seems beyond the realm of reasonableness. Or, perhaps, two vertical shafts at each end, the inner pair for the lower oar beam, outer pair for the upper, and all four shafts sporting 2.25" bearings to better resist binding. I am going to order some parts from Servocity to build a partial model, and get a "feel" for how these bearings perform in my scenario. If central lift servos can't work, then back to Plan "A". More to come. Happy modelling.

- 536 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

I'm a bit late to this build, but very impressed! Between you and Chris I am thinking I should try a card model of some sort; will have to look around to see what appeals. Happy modelling!

- 23 replies

-

- card

- World of Paperships

-

(and 2 more)

Tagged with:

-

Yes, you need to be concerned about breathing in ultra-fine particles which will enter your lungs. Especially if a model has some exotic tropical wood species. The trick is to collect the dust before it scatters into the air. Have you heard of "suction boards"? Basically you build a box with a perforated top surface and a dust port to connect to some sort of shop vac. Simply sit your piece on the perforated surface and sand away. Dust disappears into the collector before it has a chance to scatter. Of course, this still requires a shop vac but some of the small units are relatively quiet. It must be able to filter sub-micron particles or it will send your collected dust straight back into your room. Hope this helps! Here is an example video:

-

Going to be beautiful. May I suggest you add "RADIO" to your title; that way all the RC enthusiasts will pull up chairs. 😀 Looked up Southern Cross Models. I see your 1/72 County class hull is 2.7 meters long !!!!!! RC enthusiasts will definitely want to follow this! Also, that deck and turret look very nice; are you 3D printing parts, or does Southern Cross models work up structure too?

- 88 replies

-

- Australia II

- Finished

-

(and 2 more)

Tagged with:

-

Good God Bill! So sorry to hear about all that.....hope you both are fully recovered soon! Best Regards, Ian

-

Marc, I see you went with a painted figurehead too, as opposed to all gilt. Nice!

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

While responding to Kevin, I noticed I hadn't posted in a month. Still moving from mast to mast adding backstays. To break the tedium I added the boom and gaffs to the jigger and also installed the cargo boom. The monkey gaff still lacks a pair of guys. Coils of pre-belayed running rigging accumulating. I'm glad I am omitting all buntlines! 😁

-

150 euro! I did not pay that but I did have to look hard for one, eventually getting it from France. If you would like to build a Preussen, a cheaper route is to buy a "Cap Horn" 5-mast barque kit and simply convert the jigger to square rig. This less popular kit is a made-up ship that never existed as far as I know but is otherwise identical to the kit Preussen. Kevin, if you go back to post #12 of this log, someone had a kit to sell. Maybe they still do? Or you can build Cap Horn as "Potosi" which did exist in the same Laeisz fleet as Preussen and was in fact handier to maneuver, being barque rigged. Bill Morrison is doing this as mentioned earlier in this log. The hull is about 9" longer than Victory's hull, but their overall lengths are about the same. Preussen is a more compact finished model than Victory, much narrower and shorter. Here is a pic.

-

Bruce, thankfully the Preussen lacks deadeyes which is a blessing at her scale. And these big windjammers had no studding sails. I like your Cutty Sark progress, keep up the good work!

-

Kevin, thank you for the kind words. Yes, these big steel windjammers are quite picturesque. I especially like the elevated storm gangways, for some reason. And from some of the photos I've seen of these ships in a storm I can see why they were needed! Her hull is about 9" longer than Victory's, but the bowsprit is very much shorter than Victory's. A model of her at 1/100 would be magnificent and fun to build. Yes the scale is smaller, but her rigging is much less intricate than 18th century practice, albeit with everything repeated five times on her five masts which does get a bit tedious. The repetition will get even worse when I start hanging six yards on each mast! I haven't looked for build plans, but a chap named Neville Wade has built an RC model of her so he must have found them somewhere. Here are Neville's ships, not as detailed as some but very pretty on the water. After I get the galley working I'd like to build an RC square rigger next. http://www.cocatrez.net/Water/NevilleWadeShips/index.html https://www.rcgroups.com/forums/showthread.php?2205250-Neville-Wade-s-Radio-Controlled-Square-riggers Thanks for the Newby book tips - I'll have a look for them. And do look for "The Last Grain Race" for yourself. It's interesting, vividly written, and funny at times.

-

Bill, just thought of the head sail rigging. Granted it's on the axis of the ship but the halliards need to be belayed on deck. You could usefully complete the various downhauls and halyards before moving to yards and other running rigging. In my case I am nearly done the standing rigging on my "Preussen", but in accordance with "The Ian Grant Method of Ship Rigging" all the running rigging is already belayed on deck to prevent a lot of special words while trying to tie off after all the backstays are in. See all the coils hanging over her bulwarks, here. Some from mast bitts, some from bulwark rails, some lower sheets and tacks.

-

3D printing is amazing, the way of the future for sure. I can't get over how quiet she is! I last launched an electric RC boat in the 70's using brushed Decaperm motors of the times; you could easily hear the motor whine from shore. I was thinking of maybe refurbishing my old WW I battlecruiser (which last sailed in 1980) with ESC's to replace the rheostat speed controllers but maybe I should change the motors too, having seen this. The Decaperms were geared motors; do you need to add a reduction box for these new brushless motors?

- 54 replies

-

- Liberty Ship

- Finished

-

(and 2 more)

Tagged with:

-

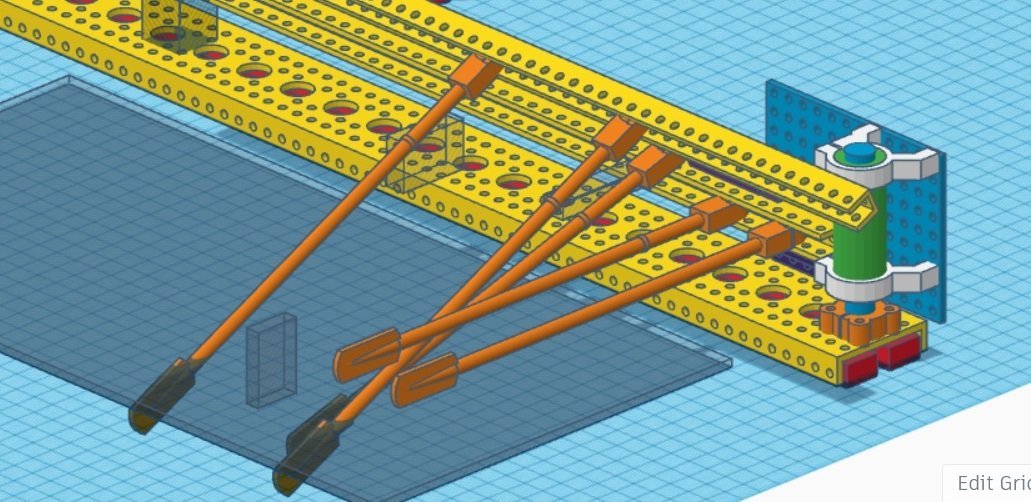

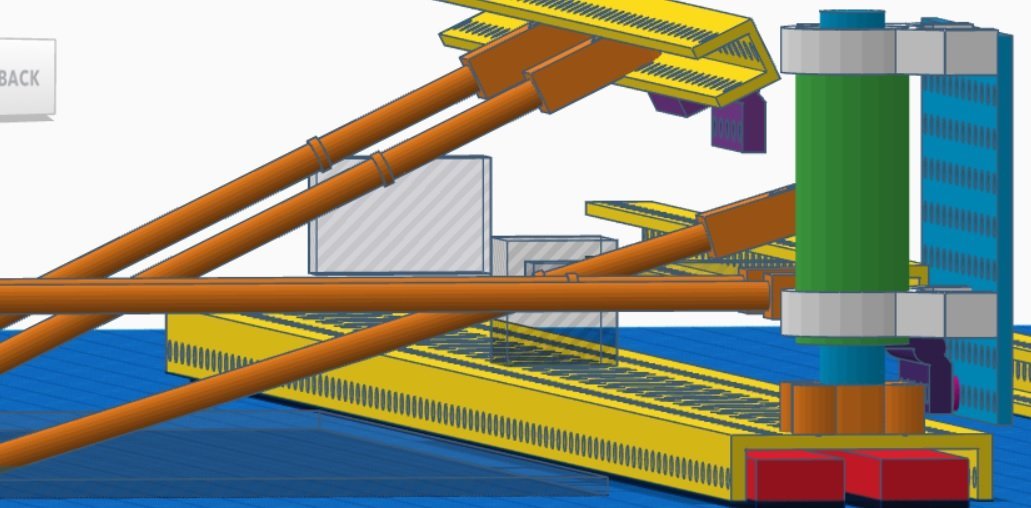

Servo selection done - the sweep servos will be Hitec's model HS-755MG, a "giant scale" or "1/4 scale" (depending on who you talk to) analog servo where "MG" stands for metal gears. The other contender was the HS-645MG standard-size servo, which would have had less margin over the expected RMS torque. The 755 rotates 90 degrees with the typical RC set's 1000 to 2000 usec pulse range but can rotate up to 200 degrees given a wider range (570 to 2400 usec is the extreme, according to Servocity). Since I have the Arduino controlling it I can easily provide 870 to 2130 usec or whatever, to get it to rotate 120 degrees. Then as discussed previously the arm can be short, minimizing the torque. The final nail in the 645's coffin was that the 755's different motor actually draws less current while providing 50% more torque. I think I said earlier that I'd rather have a bigger motor loafing along than a smaller motor labouring; with the bigger motor drawing less power it's a no-brainer. I then needed to design the oar position angles for power and return strokes. Pulling out my Pitassi I was reminded that his quadrireme interpretation had 88 oars, not 80, so my remes will be 22 not 20. This will increase torque 10% but I had already decided on smaller blades for appearance so torque is only about 3/4 of what I said in earlier posts. I spent some time manually drawing the oar angles wrt the waterline given the outrigger size. I found that it's not easy to have both remes of oars in the water for the power stroke and still have decent clearance above the water for the upper reme of oars during the return stroke; in a real ship the rowers in the upper reme could just lift their blades more than their buddies in the lower reme, but my mechanism will move the looms of both sets of oars the same distance vertically. It seems I will need to have the lower reme come up to horizontal in order to have clearance for the upper reme. Also, I'd like to have a little more freeboard than scale (which is only 3/4") but this makes the oar angles steeper which increases the above difficulty. I finally came up with a drawing with lower oar hole centres 1.25" above the water, with upper oar tholes spaced 13/16" higher, and 1.25" more outboard. This will lead to an upper deck somewhat higher than ancient writers imply for a quadrireme, but what the hell. I was surprised to find that I only need about 1/2" of vertical movement at the looms. Here is the drawing: I could go on forever making manual drawings so I decided to use tinkerCAD to model the mechanism with Servocity parts. I still can't figure out how to import Servocity's STEP files into tinkerCAD, and I don't want to spend months swearing at Fusion360, so I just drew the parts manually in tinkerCAD. Still required a few special words. 😁 I drew it with linear bearings since the available 2" long bearing now seems about right. My main purpose is twofold: (1) see how far below the waterline the drawer slides need to be, in order to design the central bulkheads, and (2) determine how far towards hull centreline the mechanism reaches i.e. how much space in the middle (needed!) for battery or servos? Here's what I have to this point. This drawing shows two upper reme oars and one lower reme oar with blades in water. Also two lower reme oars in horizontal position. Oar angles when in the water are 17 and 26 degrees respectively, a bit higher than Pitassi's 12 and 19, because I have the extra freeboard. From the bottom, we have the red drawer slides, a yellow "low side channel", an orange clamping hub, a blue SS shaft clamped in it, a green linear bearing, white clamping mounts around the bearing, a blue "back plate" which forms one end of the oar beam and which slides up and down the shaft thanks to the bearing, purple hinges connecting yellow u-channels to the beam, orange oar pivots within the u-channel, and orange oars. I haven't represented the other end (similar), or the L-channel beams which will connect them. The hinges on the upper reme will connect to the beam via standoffs (not shown) which will place the upper oar looms correctly relative to the lower (given the outrigger dimensions). So far I've concluded that the bottom faces of the drawer slides only need to be about 2mm below waterline, not as much as I had feared. The mechanism intrudes about 2.6" into the hull meaning that I only have about 1.8" free in the middle of the 7" beam hull. Probably ok for a battery and maybe the lift servos. I'm also finding that it is not so easy to place the second reme's hinges exactly as required; I had blithely assumed that if I tweaked the spacing from beam to hinges, and used washers as necessary between hinge and u-channel, I could get the oar looms to be anywhere I liked. Not quite that simple. Further tinkering required. It would be cool if I could animate this. Dream on.

- 536 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

Hey, I was born in Paisley! Parents emigrated when I was four. My brothers and I went to see our old address when we went backpacking years ago.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

Me again. Just thought about the mainstay tackles. They make an interesting little addition to the model. I don't think Longridge describes them in text, but there they are in the "Standing Rigging" pull-out, dangling from the main stay. If you want to add them, it may be easier now than with all the yard ends poking out at you. 😉

-

Bill, one thing that comes to mind is the numerous lines that tie off on "shroud cleats" especially at the fore mast. You should figure out what you're going to do about them. I formed shroud cleats from etched cleats and very small pieces of evergreen and tied the lines to them before attaching to shrouds; my usual reverse-rigging method. This avoids having to reach across the ship to tie the lines off. Of course you could just tie them to the shroud. At the end of the day it's very hard to see.

-

Over 3m long........gorgeous.........now we're talking. I drool over such large RC models in "Introduction to RC Scale Sailing Models" by Vaughn Williams.

- 454 replies

-

- Union Steamship Company

- Stepcraft 840

-

(and 3 more)

Tagged with:

-

All the guys I see at my local model shops are older. By and large the new generation just isn't interested, or has no exposure to dad at home making things. Nor do they get shop classes at school any more, at least here in Canada. Around 1970 or so, we were brazing with oxy-acetylene torches in grade 7 or 8 shop class. Today, nada; liability you know......... The world has moved on. My dad's trade of tool and die maker now features CAD'ed CNC-everything, not the experienced tradesman cutting from a drawing in such a way that the gear backlash effect is minimized. And you're now considered a cabinetmaker if you can lift melamine panels off the router table and run the edger machine to tape the exposed edges. There are maybe six people in Ottawa who make sailing ship models; I don't know any firsthand. I doubt manufacturers could recoup their tooling investment if they made a new ship model. It's sad, but 3D printing is on its way to help those interested. Soon we will make our own kits with software. Just the same route blazed in so many other areas.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

Being a teenage boy when I built the CS in the 70's, I painted Nanny with flesh colour and dark hair, and two tiny dots of red paint for nipples. Sheesh. If I ever refurbish her (the CS) job one after cleaning will be painting Nanny white. 😀

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

Thanks gentlemen for mentioning this. I've added a note on pg 1 of my SR instructions, for when (if?) I get to her. Cheers!

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.