-

Posts

6,761 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith Black

-

Lynn, the launch way looks great, the Phantom looks right at home. I didn't get interested in ship modeling till much later in life. What drew my interest when working for a salmon cannery my second season up north was my future/current wife. She was there working in the mess hall (her second season), when we met. She had originally gone up to check out her Alaskan Native heritage, I'd originally gone north to escape a bad marriage. Her mother was full blood Aleut born in the village (Egegik) where the cannery was located. Her mother left the village when she was about 15 to go to school in Anchorage. She stayed in Anchorage after her schooling was finished and eventually met my wife's father who was stationed there in the Navy. They moved to Michigan where my wife was born. It was a cannery romance that has stuck for 42 years.

-

HMCSS Victoria 1855 by BANYAN - 1:72

Keith Black replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

I hate gutters. When we had the roof replaced on our house 11 years ago I told the roofers to take down the gutters and throw them in the skip. I just wish I could come up with a good way of keeping water from pouring down our necks when entering the front and back porch doors.- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Dave, for the first time out I think you're doing grand. As to your question.... sand/file, fill, rinse, and repeat.

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

Yes and no. It requires the standing stays the backstays be tightened or loosened with deadeyes and blocks. It's a pretty big undertaking, it's feasible it could be done at sea if all the sails were temporarily hauled and the seas were calm but would be a task better done dockside.

-

Kramer, the angle of a mast is called "rake" and completely vertical would be no rake. Most ships sail with a bit of rake depending on the Captain's preference and how the ship performs.

-

Adrien, welcome to MSW.

-

HMCSS Victoria 1855 by BANYAN - 1:72

Keith Black replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Pat, fortunately our projects wait patiently for our attention. I look forward to your updates when circumstances permit.- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Keith, that's amazing. Because of your lathe work I thought that you were in and out of a shop your whole working career. I knew you were in engineering as well but I thought is was part and parcel. Kinda goofy me thinking that now that I stop and think about it.

-

LOL!........ I'm pretty sure your machine skills and maybe more importantly your ability to see the 'how to' made you one of their more valuable employees. The mast are gorgeous, spot on replication.

-

Siggi, beautiful work as always. I always enjoy seeing an update from you. Glad to see your workers practicing social distancing.

-

Glen, she's really looking swell. As the old saying goes, necessity is the mother of invention. Just a suggestion if I may, if you chuck the nail shank in your drill, you can use a metal file to make the nail heads smaller as the drill spins. Another use for the poor man's lathe.

-

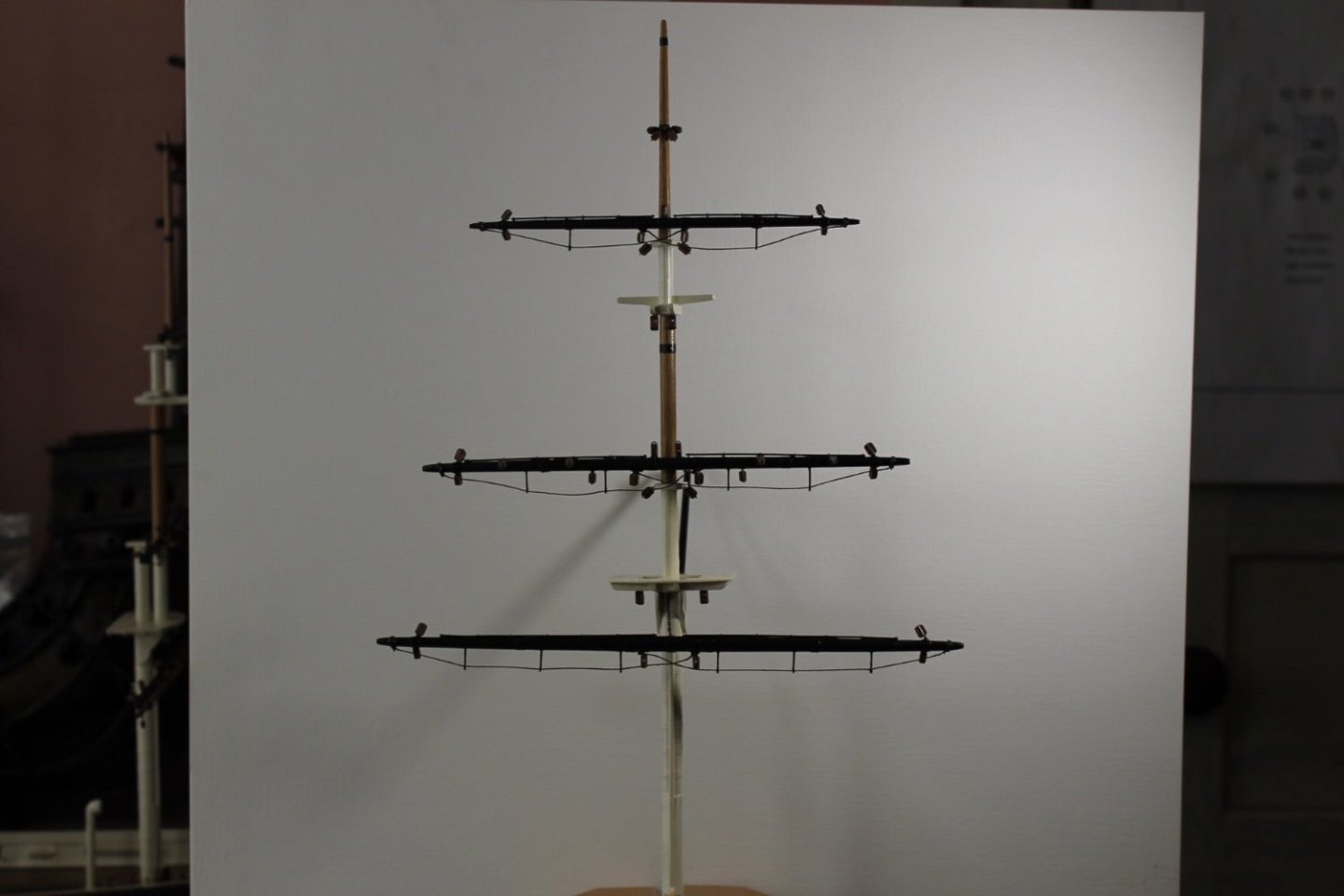

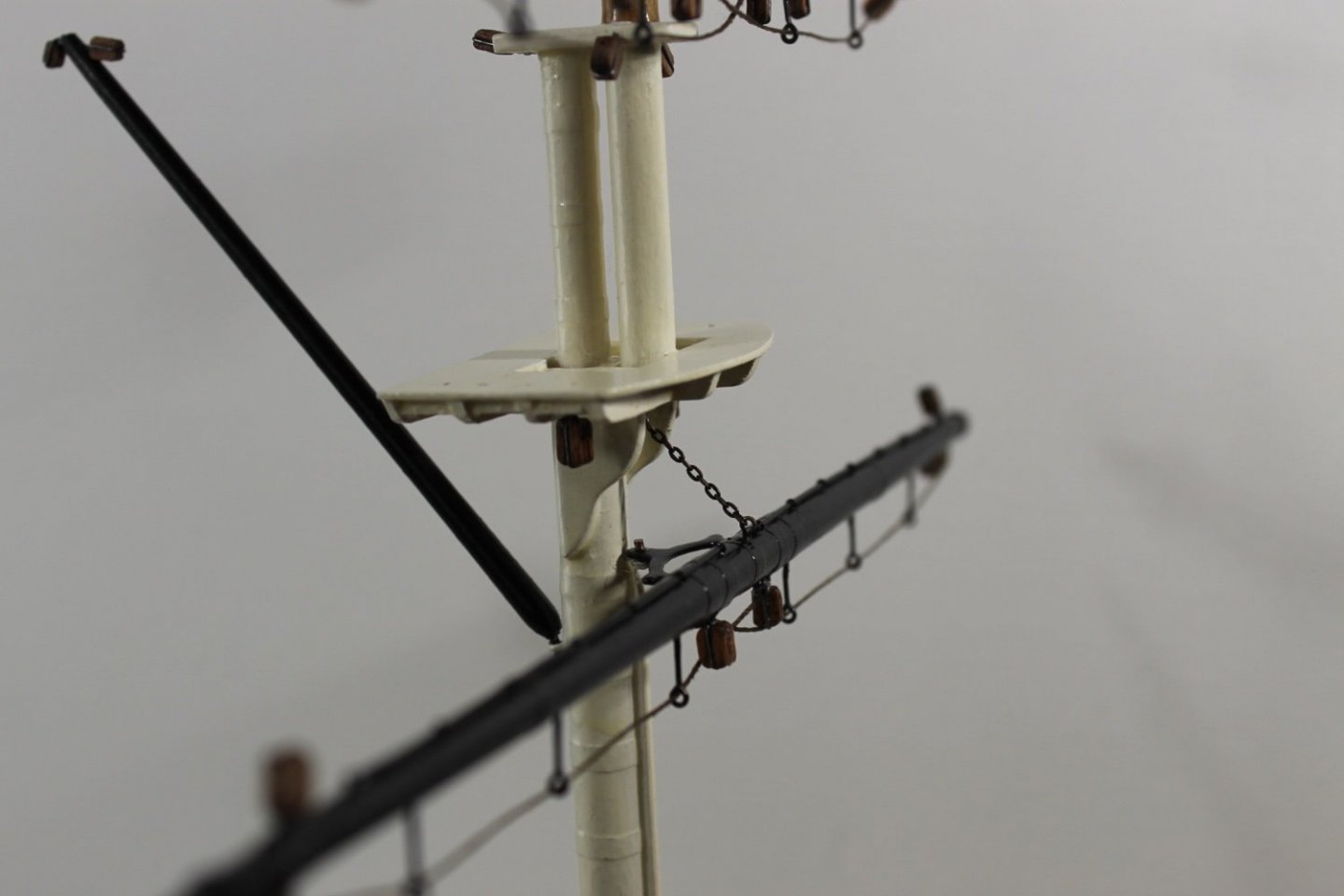

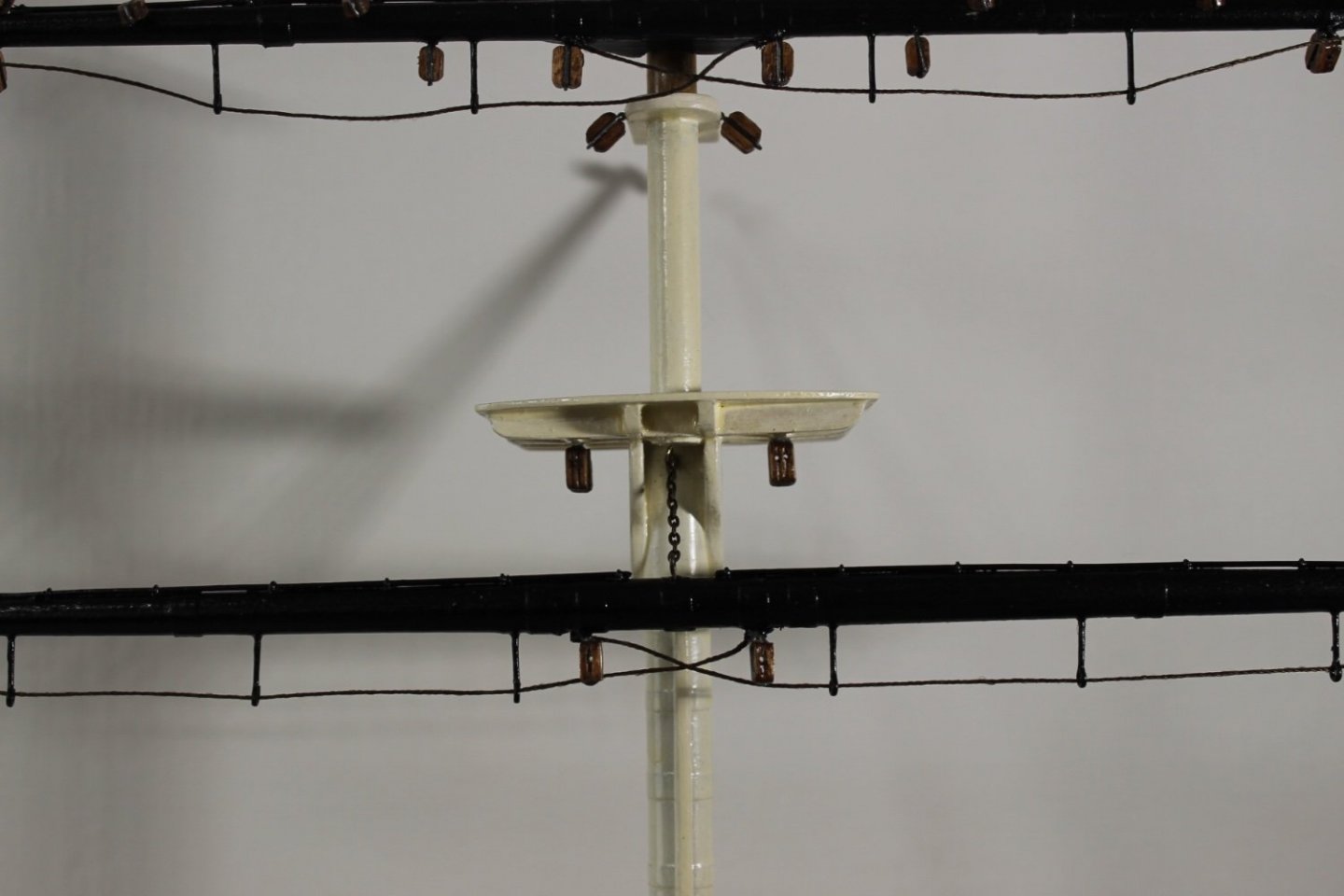

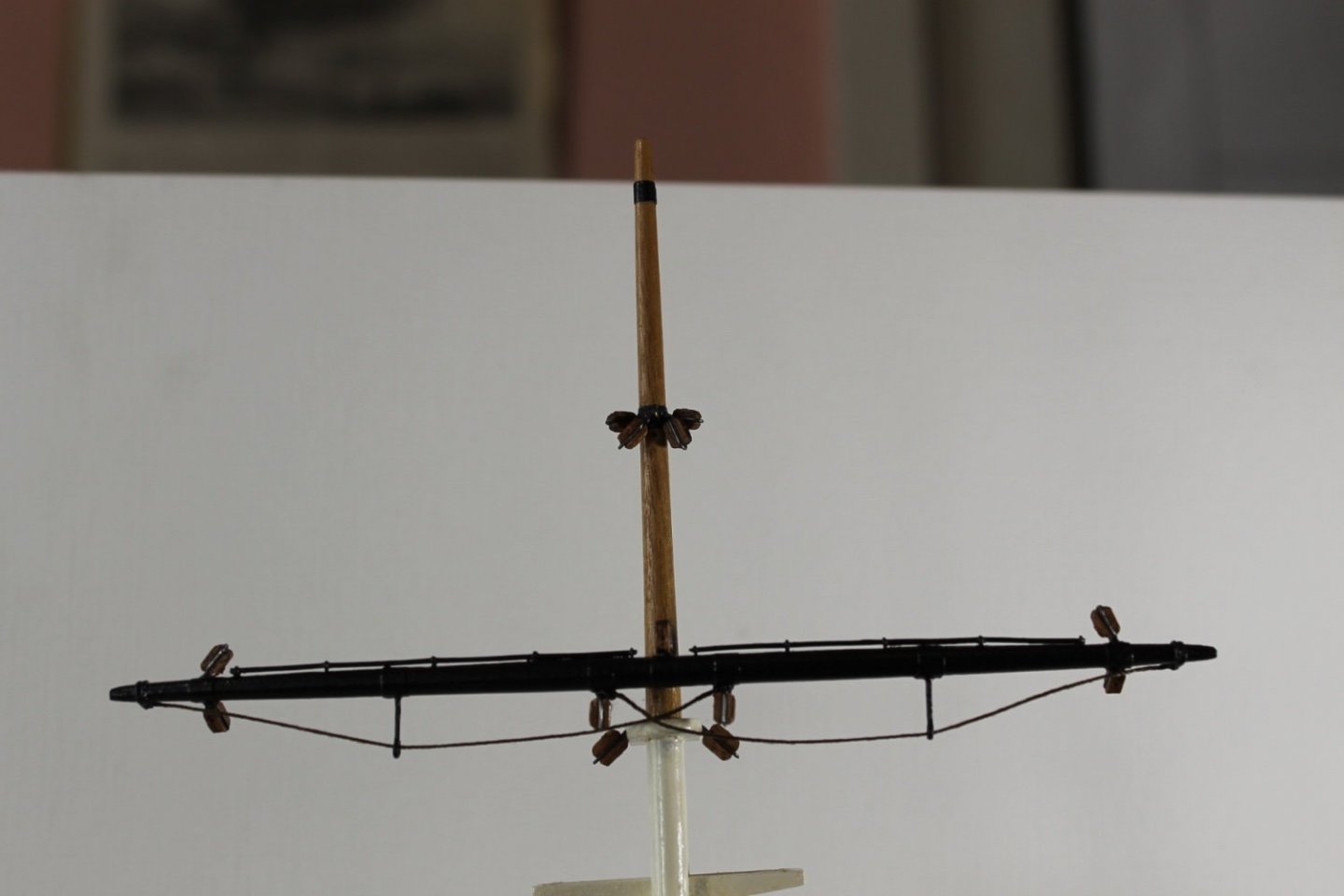

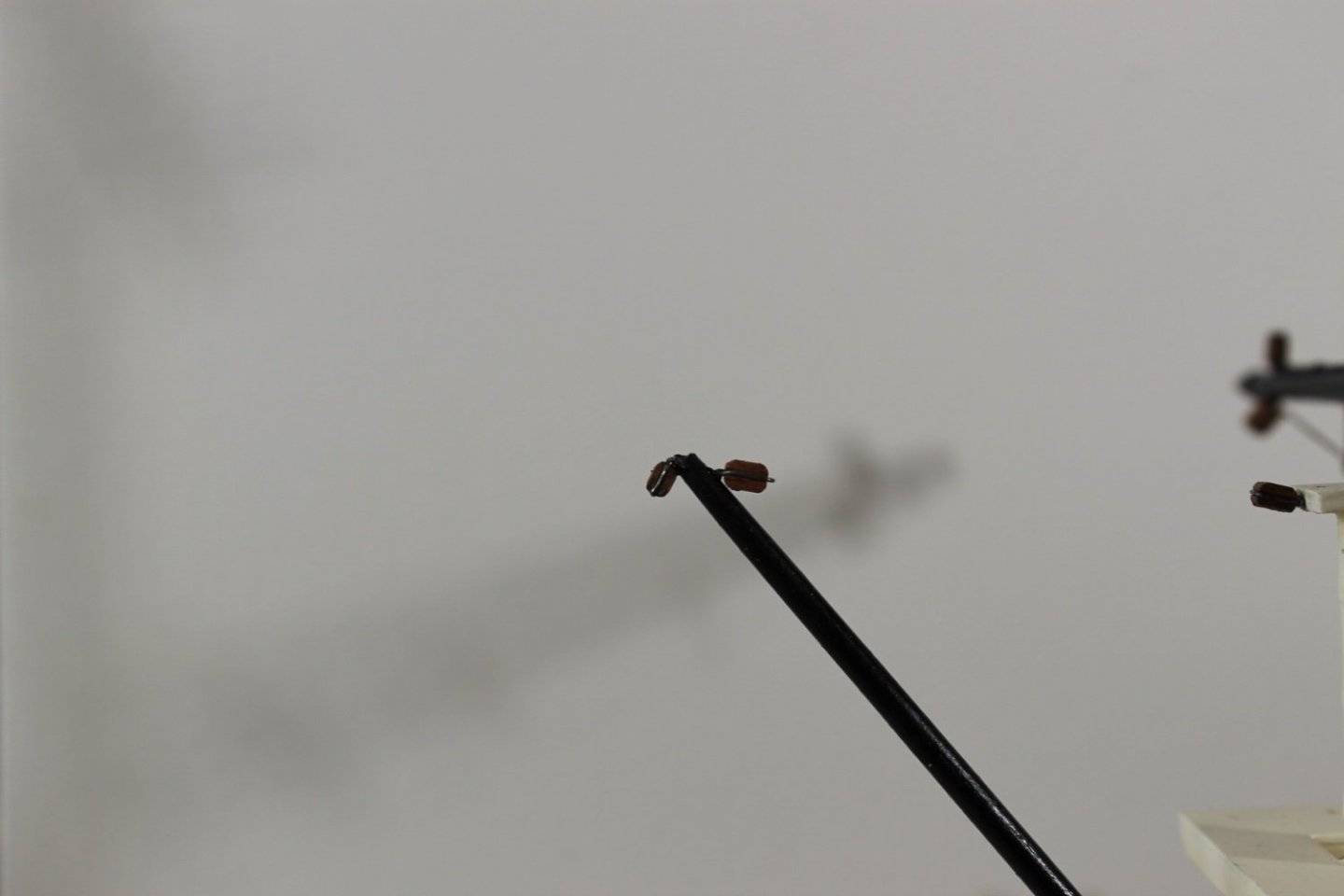

Thank you for all the comments and likes. Work continues populating the mizzen mast with blocks. I'm getting close but felt that an update was in order. Top most four blocks are the mizzen topgallant lifts and main topgallant brace blocks. Once again I'm drilling holes and glueing the blocks in place eliminating the need for eyebolts due to the small scale. Not a lot of wood to work with here. The preventer chain is .6 inches and was a pain in the backside getting the length correct. I've never gotten a chain length correct the first time, it usually takes three attempts and this guy was no exception. It's affixed at the point between the cheeks but is just placed in the yard where I can remove the yard and continue to work on the mast unencumbered. Blocks for the US flag and rear admiral's flag. I've tried to use graduating blocks sizes. Larger blocks on the lower areas where the loads would have been greater and then ever decreasing block sizes as I move upward where loads would be lighter. As I stated before I bought my blocks from Cornwall. They're perfectly fine for my project but they are not everyone's cuppa. If ordering the types of blocks I'm using, one should order about 20% more than needed. For those of you going the same route as myself, sort through your blocks. One, to eliminate culls and two, to sort sizes. Even though a bag is supposed to be one size, they're probably not and that's a good thing. I found that sizes were slightly smaller and larger than marked and I've taken advantage of that. It's given me the opportunity to try and portray a realistic distribution of blocks through the rigging. That's it till next time, thank you to all for looking in........Keith

-

Keith, absolutely top notch workmanship. I bet your former employer rued the day you retired.

-

I need help repairing an Artesania Latina Dallas 1:50 model

Keith Black replied to Zeus-cat's topic in Wood ship model kits

-

Steve, welcome to MSW. Glad to have you aboard.

-

Untangling and rerigging or start from scratch?

Keith Black replied to Rgpracer's topic in Masting, rigging and sails

Obviously, whoever drew up that plan didn't get the memo. -

Figureheads of English East Indiamen 1750

Keith Black replied to bruce d's topic in Nautical/Naval History

Bruce, it looks like a man riding a griffin, the griffin's head is center of the man's stomach. The man's right hand appears to be ready to cover or just uncovering the griffin's eyes while his left hand grasps the griffin's talon. But hey, I flunked the Rorschach test. -

I tried bifocals, not my cuppa. I've stuck with ever increasing strength reading glasses.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

You've been doing all this beautiful work with poor lighting?! Oh, to have younger eyes again.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Marc, more of the same beautiful work. absolutely gorgeous. Hey, do you do model work in the TV room? If so, I don't know you do it. After moving tools and blocks down stairs to the TV room last winter, I tried for six months to get work done stropping blocks, I failed miserably. I've lost two years to Covid at a time when two years of my almost 75 years is a lot! This maybe the new normal, the price we pay for destroying the environment/habitat of numerous animal species around the globe.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.