-

Posts

407 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Bitao

-

-

On 8/5/2021 at 5:51 PM, bruce d said:

Your work is immaculate. 👍

No one can be perfect.I'm just trying to do better。

- billocrates, mtaylor, Keith Black and 2 others

-

5

5

-

The saddest thing for me was that while everyone else was making progress in post construction, I was regressing in reconstruction and failure. But I'm glad you guys supported it, especially Greg and Druxey for their timely comments! I learned something. It's been specially modified today. Also feel harmonious and much better-looking!

-

On 7/17/2021 at 7:00 PM, druxey said:

Nice clean work. Don't forget the taper of the knee of the head!

After Greg made it clear that I was wrong, I realized how important your warning was. Because of my misunderstanding. . Now I have to find a way to change it .What a painful reality!😪

-

Greg, I finally understand what you're saying, and first of all, thank you so much for pointing that out. This is also the reason why I like MSW from the bottom of my heart, I have seen many masters including your excellent works and style of work, let me learn a lot of things, but also met many warm-hearted friends. Secondly, I have to admit that some mistakes are inevitable due to my lack of knowledge of the basic structure of ships and my language comprehension and reading difficulties. But it's also the process and opportunity for me to learn and improve. At present, the ribs have been laid to the seventh group, although it is more difficult to change, but I think it is also a test and an opportunity to improve my skills. I will do everything in my power to meet that standard. Thanks again for your detailed and patient answers!

-

Greg, is this what you meant by "the knee of the head permanently" ?

- Jeronimo, GrandpaPhil, KentM and 3 others

-

6

6

-

3 hours ago, dvm27 said:

Lovely remake Bitao. Just curious - is the knee of the head permanently affixed to the stem or just temporarily fitted? I'm asking because the knee of the head is usually tapered aft to fore and from the lower to the extreme upper tip. As well the standard usually narrower than the upper knee/stem junction.

Hello, Greg. I'm sorry, because my English is limited, I can't understand you. Can you draw this position and direction on the picture? From what I understand, you're referring to a change in the thickness of the top of the ribs?

- billocrates and mtaylor

-

2

2

-

4 hours ago, druxey said:

Certainly the plan under the model helps keep the frames to the correct spread or width.

Yes, druxey. That's the lowest mistake I've ever made. Too much confidence in their own vision and neglect of the positioning of the abduction edge.

- mtaylor, billocrates, druxey and 1 other

-

4

4

-

-

-

Hello. Moving on...

- Keith Black, JpR62, CaptnBirdseye and 18 others

-

20

20

-

1

1

-

-

-

Mark,That's very kind of you. In fact, my basic tools are comprehensive. But because the Chinese are so sorry, many of the world's best tools are scarce at home and often more expensive. Although the online shopping is very convenient, but involves the procedure, the transportation, the time, the assembly model processing gadget is nearly all blank (mainly is Proxxon) , after all, the domestic real player is not many. So many special tools, I am based on their actual needs of the design and production. It's another fun thing for me to do with models!

- Canute, FriedClams, mtaylor and 2 others

-

5

5

-

Mark, I admire a man who takes his job seriously. Because it's all about the details. And I've learned something from your work. Open-minded, friendly, discreet, all in your position. I noticed that the angle adjustment of the background inspired me a lot! Because I have several such accessories, although the accuracy is not high, but convenient, intuitive is the advantage. It is often more practical to deal with some common processes. Inspired me to design other tools. Thank you!

-

On 6/30/2021 at 9:04 AM, VTHokiEE said:

You are on a completely different plane from me (I can’t begin to see any errors). I can empathize with wanting to build it just right for yourself. I love watching your progress and also can’t wait to see the restart. Have fun!

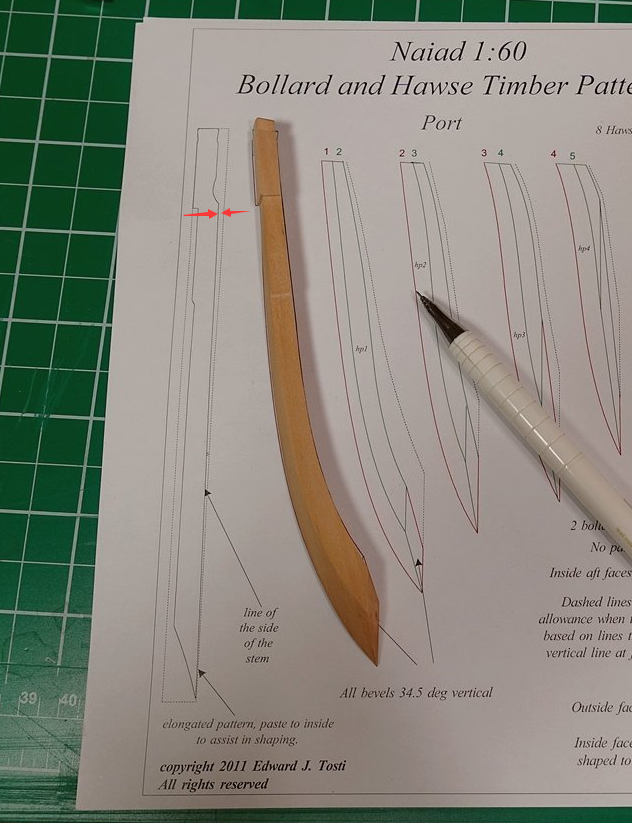

Thank you for your attention. In fact, some of the biases and omissions do not affect the overall structure of the layout. Maybe I was wrong about the painting. Maybe it's the painting. But I want to start over. In particular, the position of the bow trough of the bow slightly forward. If the hull is laid, it is in the wrong place (indicated by the Red Arrow) . Some parts used cherry wood, the effect is not good, so this start again, I will use all the pear mainly. In addition in the beginning of this period of time, I also have to process some of their own design of special fixture to assist processing, in order to improve the quality and accuracy of processing.

-

druxey,You're absolutely right! I never care what other people say about me, but my principles and bottom line don't change. Rather than destroying a work of art, it should be a adherence to a certain standard.

- billocrates, RichardG, Keith Black and 5 others

-

8

8

-

16 minutes ago, dvm27 said:

I have done the same Bitao. It will take you less time to reach the same point in the project and you will be happier with the results.

Mistakes are hard to live with. It affects the mood behind it. The fastest time to complete a piece of work is at least a year, compared with more than ten days of regret, it is nothing. Maybe it's better to start over.

-

27 minutes ago, druxey said:

I'm sorry that you are not happy with your work so far. It looks to be of very high quality to my eye. What exactly is unsatisfactory?

I'm a little OCD. It doesn't seem like much to others, but I can't forgive myself. So I don't want to leave it until the end, but it's only been 11 days, and I've worked really hard. But thinking that the process would take longer, I decided to give up and start over. Maybe I pushed too hard. It's a good time to take a few days off, get in the mood, and clean up the studio. I think every pursuit of perfection will have a bad time, to overcome their own is the greatest difficulty. Thank you for the attention and the likes, I will not give up, after a few days I will start again.

- Saburo, billocrates, druxey and 3 others

-

6

6

-

Today, I found some problems and mistakes. It doesn't affect the whole structure, but it does bother me. Also, some of the materials are not ideal. So I decided to start from scratch and throw everything away. I need to take a break and start over. This post will be deleted in three days. I'm sorry to disappoint you.

-

50 minutes ago, druxey said:

Part of the beauty of a wooden ship model is the hand craftsmanship, not a machine-perfect finish! Those bollard timbers and cross-chock look just fine.

I agree with you very much! In fact, in the eyes of many people, as long as the machine processing out of the precise parts can make the perfect work. In fact, in my opinion, this is wrong! Because it is not difficult to accurately process any single part, it is the assembly process that is difficult. In this process, machining deviation, material deformation deviation, positioning deviation must be effectively adjusted. This process can not be replaced by any machine. Any tool can not substantially improve personal technology will only improve efficiency and accuracy, otherwise with numerical control equipment is not easy to complete any work? But what I see is that a lot of people do not understand this basic knowledge, blindly trust the role of numerical control. Of course, I don't deny that some parts can not be processed without numerical control and have better results, such as engraving parts or some outfitting parts; these parts often do not need too precise assembly position but can be performed independently, so the effect will be better. But not only do we enjoy the process of making the model, but also the ability to adjust it manually, which is the most important thing. So I do not look forward to complete CNC machining of the kit, in my view, that is just complex building blocks, the final assembly will not have accurate results. After all, the precision of the final product can adjust the scope is too limited, and deviation is inevitable for anyone!

- Saburo, Keith Black, mtaylor and 3 others

-

6

6

-

Thanks for the likes and anticipation. This part of the progress seems very slow, but in fact because the operation of a bit more grinding, I failed three times to reach the standard. Because each plane radian changes greatly, the part clamps the difficulty, simply uses the spade knife manual repair. So it seems that surface finish is not as perfect as machine finish.

- mtaylor, aviaamator, popash42 and 18 others

-

21

21

-

Do a little bit every day to make sure I'm making progress. Some words and sentences have to be looked up by translation software to be understood because the English descriptions on the pictures are difficult to read. And I'm used to using MM units, each of which needs to be converted and double checked. Slow down. Strive to achieve every detail can meet the requirements of the drawings. Thank you for your attention.

-

Hello everyone, it's great to be back on this forum again. The original plan was to take at least half a month off after 《YOUNG AMERICA 》and move on to the next project. But I'm used to being in the studio every day, enjoying the intense and difficult process. I've been reading all THE books I've bought these days, and I've decided to start making 《THE NAIAD FRIGATE 1797》. I also chose it because I like a boat with a complicated interior. More importantly, the whole process and Mr. Edt's drawings made me feel very precise, very human, very easy to understand. At least I don't have to spend any more time doing research. I will have a holiday soon, the hot Beijing lets me bury in the home earnest manufacture, and the determination completes it! It took me more than three months to learn and prepare before I started building my last boat, and this time it took me only four days to build it. It's still a tough ship for me, but I'm willing to share my every move with you, even if it means going through the inevitable process of failure. But I think perfection is the goal of all of us.

-

12 hours ago, Thistle17 said:

I am still scratching my head bitao; incredible work in an incredibly short period. I used to work in a software development group and the manager I assumed responsibility from had a saying. "You can always tell the quality of the work by the sharpness of ones tools". So I look at your table saw top and see not a scratch or mar. I have studied your shop made tools. I have witnessed your execellence of work produc and I am dazzled by your speed of execution. What else can I say but well done indeed!

Joe

Thank you, Joe. In my opinion, any good tool can not be separated from anyone skilled operation, otherwise not only poor accuracy, but also bring potential danger. Usually before I make it, I plan the sequence of each part, and I back up 2-3 ways of processing each part to prevent failure and inefficiency. I also like to judge how I work by other people's marks, which is probably a habit I've developed over the years. Because not everyone is willing to show how it's done. I can see that you are a very careful person, I think your daily work is also very excellent! Have a good day.

NAIAD 1797 by Bitao - 1:60

in - Build logs for subjects built 1751 - 1800

Posted