-

Posts

407 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Bitao

-

-

11 hours ago, wefalck said:

That's a pretty big machine ...

What is the brass part on the middle of the x-y-slide, a steady to support long parts when milling in the dividing apparatus ?

Hello, wefalck. Nice to meet you. This milling attachment I completed last year was originally used on my vertical milling machine. But there are advantages to using a horizontal milling machine for some parts. So I built this machine myself. The upper brass support seat is adjustable and firmly locked, and when machining longer parts, the small support plate is always moved by rolling gears to ensure that the support seat is under the knife edge, only manual operation is required.

- mtaylor, wefalck and Keith Black

-

3

3

-

A small horizontal milling machine specially designed for working with model parts of sailboats.Completely meet the needs of processing copper and aluminum and wood. Using three-phase motor frequency conversion control; Speed 900-1850 adjustable; ER25 Chuck Spindle; accuracy 0.02; main table adopts screw feed, vice table for slide rail fast feed. The whole machine weighs 155KG. The production period is 17 days.

-

A number of micro-angle ruler to facilitate the construction of the internal structure behind the various beams, to avoid the accumulation of large deviation. The market does not sell such a small corner ruler can only be processed. After the whole milling of these small square feet, a great deal of time is spent in manual grinding on the reference platform. With near-zero grade.The Inner Right Angle Platform and locating hole are designed. The combined clamp can also be used as fixture locating and drawing lines.

- michael mott, wefalck, Mike Y and 12 others

-

15

15

-

During the last month, I stopped working and redesigned the table saw and all kinds of accessories. The table saw and upside-down milling into one; to meet the late precision of small parts sawing and wood processing.Rest for a few days while i continue with the hull construction.

-

Appreciate the attention to detail and perfection, which is exactly what we need. Come on, man!

- mtaylor, Keith Black and FriedClams

-

3

3

-

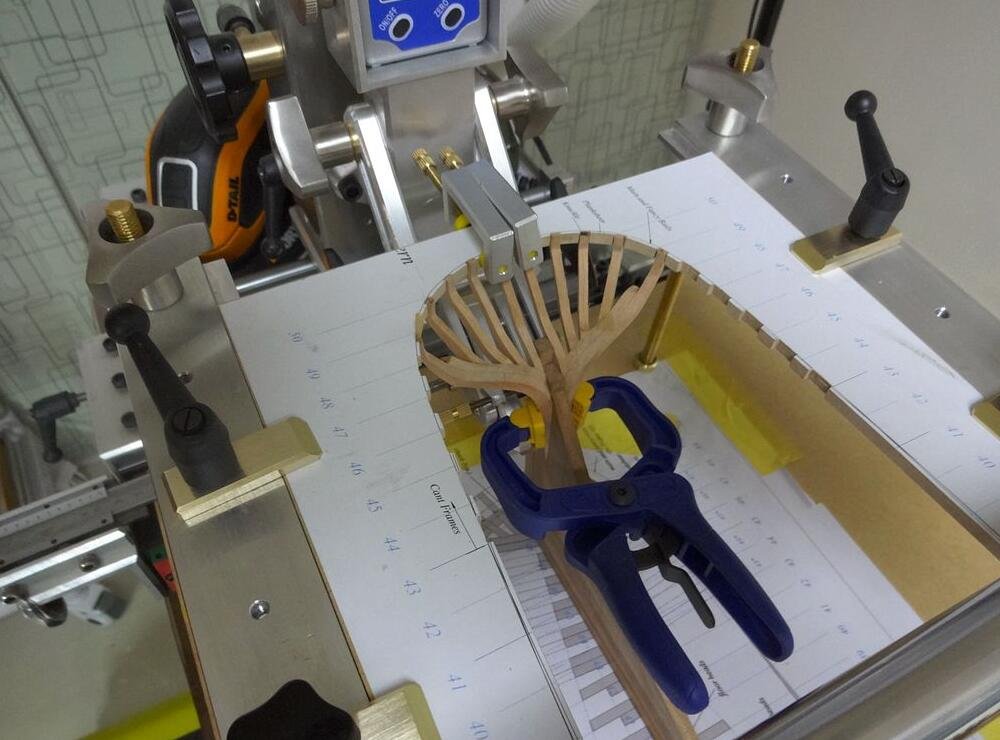

I've been on a break for the last month. But not idle, three weeks to the slipway for the eighth improvement, integrated a variety of functional accessories, to avoid the trouble of frequent replacement, but also the biggest improvement. Because the hull was laid out long after completion, some of the ribs were deformed and had to be recalibrated before the entire hull was sanded. This can have a huge impact on the rest of the production, so it will still take some time to iterate and correct this step before moving on to the next step to ensure that there are no large deviations.

-

15 hours ago, smotyka said:

According to the Seek truth from facts, an accurate set of drawings not only avoids the pitfalls of variations in the process, but also provides a good opportunity for the maker to improve efficiency and success; I think Ed did that. The reason why I put so much effort into designing and manufacturing a heavy-duty multifunction slide with a total weight of more than 200 kg, plus various accessories, is to produce a very good assistant for hull construction up to 1.3 m in length. Greatly improved efficiency, the use of all-metal materials, to avoid all kinds of deformation and material stiffness caused by the deviation and operating failure, so that the hull more easily. So far, it's a work in progress. To many incredible people, this may seem like a bit of a mountain out of a molehill. But for me, it was worth it to do better.

Thank you for your attention.

- druxey, Keith Black and mtaylor

-

3

3

-

1 hour ago, rwiederrich said:

You may have mentioned it earlier...but what do you do as a profession, if I may ask? If designing and creating the intricate tooling is one of your favorite things to do, then I can only assume you have engineering and machining in your background? There are other folks on this forum who are acute in fabricating their own tooling to create their models as well. What a skill......what a desire. I built telescopes too...but I don't always have to build the tools to build the telescopes. What a hobby. mmmmmmm

Rob

In the previous introduction, I have already introduced my occupation is the physical education teacher. All of my machining skills were acquired through self-study and constant trial and error. And that's what's surprising to many people. After all, I'm not a machining major, nor have I studied this systematically.

- gjdale, Keith Black, BANYAN and 1 other

-

4

4

-

1 hour ago, rwiederrich said:

Thank you for the explanation. *extra* tools? I am quite overly impressed with the amount of custom tooling you have already amassed. I can't wait to see what other genius you have imagined that you still need!

Rob

Some of the ribs have been deformed because the hull has been there for a long time. Before I go back to work, I need to make some more auxiliary parts on the slipway for recalibration. Only in this way, I can enter the internal and external grinding stage, start internal construction.

-

17 hours ago, rwiederrich said:

I'm on vacation. I haven't done anything in almost a month. All the images you see so far are from September to December 2018, including a month to do something else. In fact, it only took about 50 days. There are about 90 sets of ribs throughout the hull. At least one day, only four sets of ribs were completed; at most one day, 15 sets of ribs were completed! This may be difficult for many people to do. I often stay alone in the studio from morning till night to enjoy the fun of all kinds of production. Four to five hours of sleep are usually enough. More importantly, each process is a test of my skills and inspiration, and for each of the different parts, I have a variety of processing methods, in case of failure. Efficiency and accuracy are important to me! Otherwise, you won't see the tools I've designed and refined myself. It's my favorite thing to do. In order to finish the boat better, I need to make some extra tools before I go back to work. I want you to get an update on me as soon as possible. Thank you for your attention.

- mtaylor, druxey, Keith Black and 1 other

-

4

4

-

6 hours ago, Mark P said:

Beautiful work Hyw;

Your work bench and shop look like an operating theatre; I take it that Frankenstein was re-vivified there not too long ago!

Congratulations and all the best with the rest of the build. I shall watch with great interest.

Mark P

Hi, Mark P. Thank you for your attention. . The process of making a model ship is hard, but we should make it more interesting. . .😋

- mtaylor, Keith Black and Mark P

-

3

3

-

4 hours ago, Rik Thistle said:

Hi Richard .

According to public records, I've seen a lot of different slides. Four years ago, I first used aluminum alloy to make the first slide, in order to prevent wood deformation. Through the use of these years, gradually accumulated some experience, designed a more practical and flexible platform. This is the eighth improvement. It is a pity that the whole process of improvement is not documented, because it needs to be verified by follow-up practice to ensure that the idea is correct. Clamping, positioning, lifting and rotating, to meet the needs of the 72-48 scale, with the help of the gantry structure to achieve a simple drilling and milling, more accurate than the mere use of hands. Replace different accessories to facilitate marking of waterlines, stiffeners, rib locations and hull internal and external grinding. According to the actual needs, will further expand the function or the improvement. All for one purpose: to make it more fun and convenient.

- Mark P, mtaylor, Rik Thistle and 1 other

-

4

4

-

12 minutes ago, noel_colledge said:

Hi Hyw.

You mention 5 of your favourite ships you wish to build, what other 3 masterpieces can we look forward to seeing in the future.

Regards

Noel

Hi Noel,I like a boat with a complicated interior. The more exact details, the better. I'm not sure what's next. But Le Fleuron was the ship that had to be built.

- WalrusGuy, mtaylor and Keith Black

-

3

3

-

9 hours ago, Keith Black said:

hyw,sir.

You are a driven man who obviously settles for nothing short of perfection. Your tools are beautiful, the quality and quantity (clamps in particular) is amazing. Your work space is to die for, gleaming industrial functionality.

But what really impresses me is your tool management. If I had that many tools, I'd be spending half my day muttering "now where did I put that"

It's an honor to watch a master at work, thank you for sharing.

Keith

Thanks for the compliment, Keith. Tool making is also an area of interest to me in the modeling process. Not only can it improve efficiency and accuracy, but I also see it as a piece of work. I have three rooms of various tools, which I need to develop the habit of keeping in order at ordinary times, in order not to affect my use. And, no matter what tool processing, each complete a process or a component, I have to clean up and put back in place, even if again to take. That's what I've been doing for 20 years. It may seem like a compulsion to others, but I think a clean environment and orderly organization will make you more productive and more comfortable at work.Attitude is everything。

-

9 hours ago, rwiederrich said:

Magnificent!

By what means did you create the brass bands (Strips) for the iron lattice works? Hand scribed or with a paper cutter of sorts?

Uniformity can be a challenge...so too, to prevent *curling*. Good job.

Rob

I have tried many hand-cut tools, but none of them are up to my standards. Because the material we usually cut is very thin and very small, no hand tool can accurately size, no warping, no Burr, no deformation. So I bought a small CNC plate cutting machine, to solve the cutting problem. The dimensions can be accurate to a minimum of 0.1 mm. The stiffeners you see in the diagram are all 1.2 mm wide with a maximum deviation of plus or minus 0.04.

- mtaylor, druxey and Keith Black

-

3

3

-

-

14 hours ago, rwiederrich said:

Indeed..production imagery can induce production error if one is not particularly tasked with the imaging. Not to mention, as perfectionists, it is not within us to parrade our failures...even in process.

Production of finely crafted members is the ultimate goal anyway....it doesn't hurt our sensitive egos either.

I live by this motto: *Quality is never an accident, it is always the result of high intention, sincere effort, intelligent direction and skillful execution. It represents the wise choice of many alternatives*

From what I gather, you exhibit this motto in spades.

Rob

I couldn't agree with you more, Rwiederrich. In fact, I also have numerical control processing equipment, but rarely use, after all, design program for me is not an easy thing to do and there is no mass production (individual works will never repeat) . I don't accept favors from people who don't belong to me. According to their own ability, I still use the traditional machine tool manual processing. In order to concentrate on my own work, my private workspace is never open to the public. Sometimes for a small component, it may fail many times a day to get a satisfactory finished product. It was a beautiful piece of work, but I was the only one who knew how hard it was.

- mtaylor, druxey, michael mott and 1 other

-

4

4

-

16 hours ago, JpR62 said:

Wonderful ! From an another world !

Same world, different dreams...

- JpR62, Keith Black and mtaylor

-

3

3

-

9 hours ago, rwiederrich said:

What the H**L......Wait!

How are you producing these members...what was your process for creating the pumps and windless...everything is far too clean and shows no signs of soldering or casting.

The end results are amazingly astounding....perfection in miniature metallurgy........

Where are your fabrication steps.......? Your work is as perfect as can be imagined...but you are leaving out the manufacturing steps...Is that by design?

Rob

I must say, I'm impressed by your keen insight! Personal production follows the principle of "efficient, accurate, unique" , on the one hand, in the production process based on their own ideas constantly develop, improve tools; on the other hand, in the process of processing is also a trade-off between the use of a variety of processing methods. Before each component processing will have a variety of plans to implement; for example, you mentioned the component connection way, many people are usually glue, tin solder, the advantage is easy to operate, but also the disadvantage is very prominent: The connection strength is not enough to cause easy to fall off, affect the overall appearance. So I usually use structural connection way (negative difference with) , the whole again manual repair. The biggest benefit of this approach is to make parts look cleaner and more securely connected. But it has increased the processing difficulty and the technical request, especially the accurate localization is very important. This type of processing also carries a high risk of failure. To tell the truth, I do a lot of small parts in fact a high failure rate, after all, too small, processing a little deviation will lead to irreversible scrap. And I'll show you the most successful one! This is one of the reasons I rarely shoot in the production process, plus the processing process requires a high degree of concentration, too busy to take care of shooting. So delicate parts are often in the form of finished products in front of everyone.

-

Because, my friends, it will take me a few days to make the sixth structural improvement on the slipway. The update speed may be temporarily affected, thank you for your attention. I'll keep going until I finish it!

-

4 hours ago, rwiederrich said:

First of all, thank you for your appreciation and attention. I'm 52 years old, From Beijing, China; a former professional gymnast, and now a teacher. Because I have a lot of time, amateur likes to do various models for 23 years, in order to be able to do better, self taught a variety of basic processing skills and at least 10 years of practical experience. Most of the works are made of plastic and metal materials and have been transformed, covering a wide range of subjects (all are static models) . This also laid the foundation for my later sailboat building, although I had less than five years of sailboat building experience. My personality is a very demanding type of work, which is difficult for many people to understand. I set myself the goal of completing at least five of my favorite sailboats in the eight years leading up to my retirement, as well as designing and building special tools as needed in the production process, most of these tools are not available or even unique on the market, but they have greatly improved my productivity and accuracy. Perhaps a little more personal inspiration, coupled with years of hard work, has allowed me to show a certain ability. I don't like working with other people. After all, everyone has different perspectives and skill levels. Can't agree on a lot of things. As a hobby, I also get a lot of fun from it. I hope to show more of my work in the future.

cheers

-

-

In fact, I started working on the Gemma last September, and it took me less than a month to complete the hull and equipment for Young America. I was a little tired from all the work, and as a relief, the change of taste brought Gemma to an early end. Young America is back on track.

- mtaylor, JpR62 and Keith Black

-

3

3

-

Self-made small horizontal milling machine

in Modeling tools and Workshop Equipment

Posted

Yeah, and sometimes there's a problem with the clamps. In particular, the narrow components on the milling slot processing。