-

Posts

606 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Matt D

-

-

Thank you for your nice comments, Glenn, JJ, and Jim. And thank you to the people who clicked the "like" button. As Chuck describes at the end of the Chapter 7 instructions, that bow area sure looks empty now. I'm looking forward to filling it in with the beautiful Chapter 8 pieces. But first, I need to make more eye bolts and split rings.

- James G, scrubbyj427, FrankWouts and 1 other

-

4

4

-

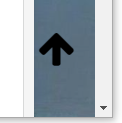

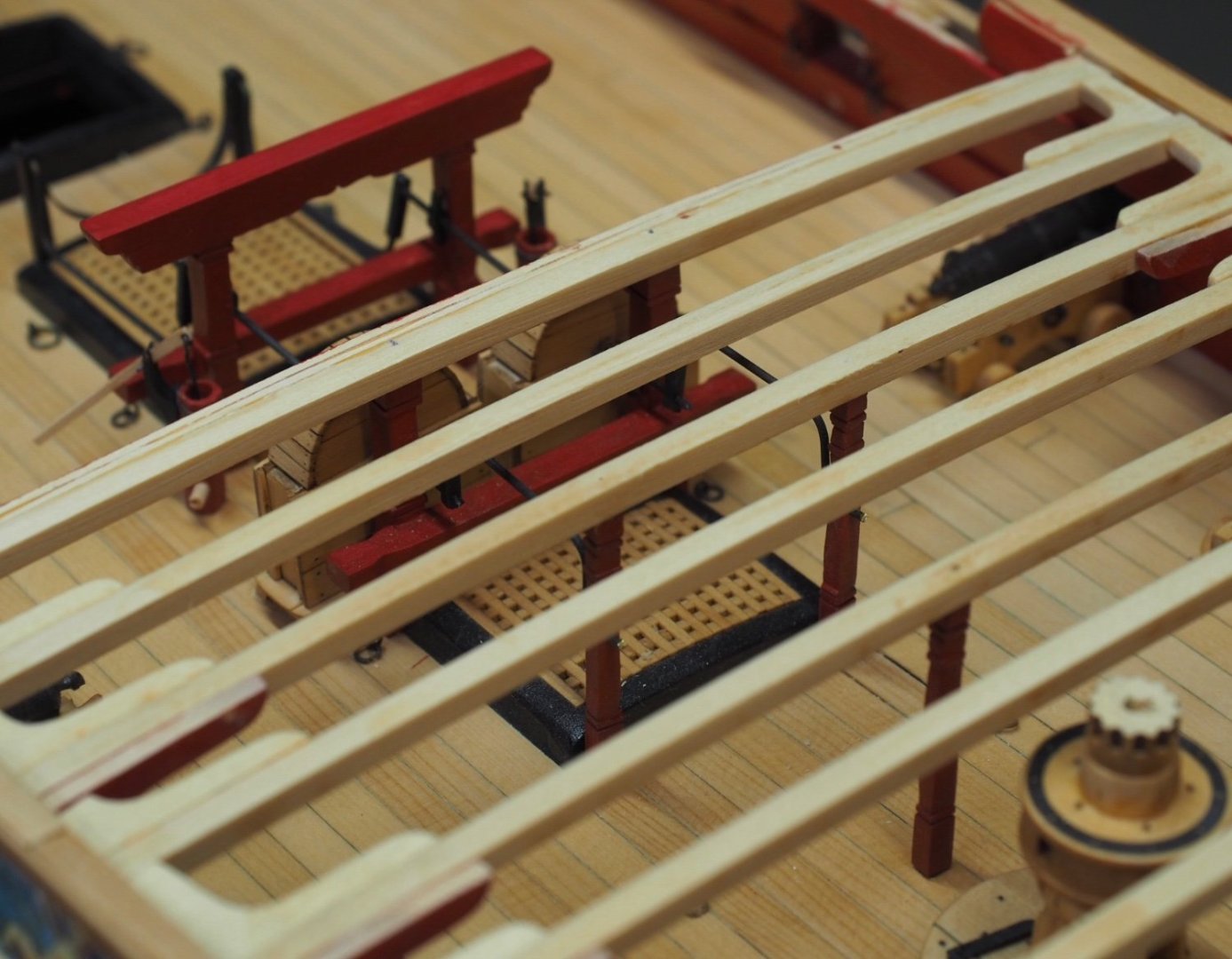

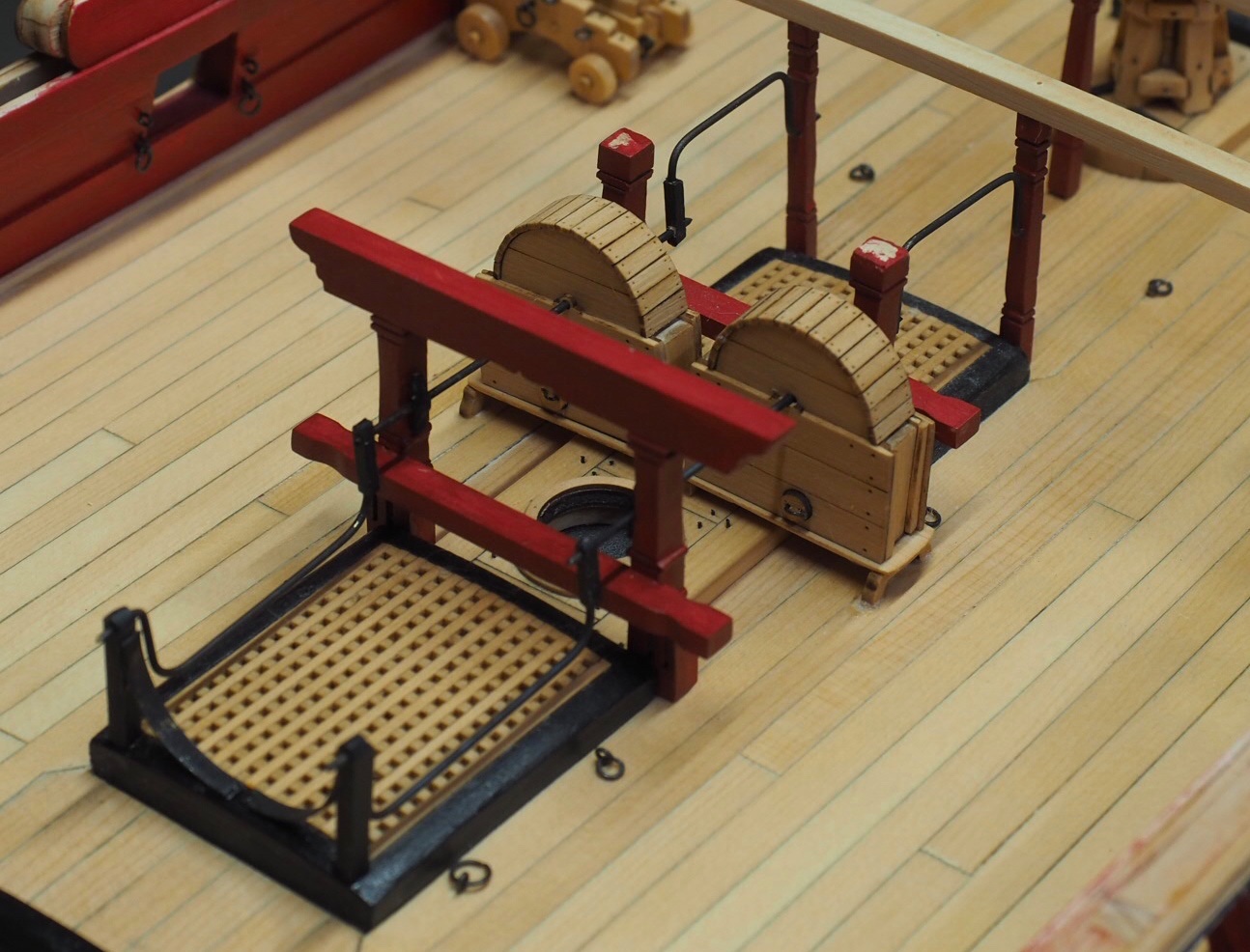

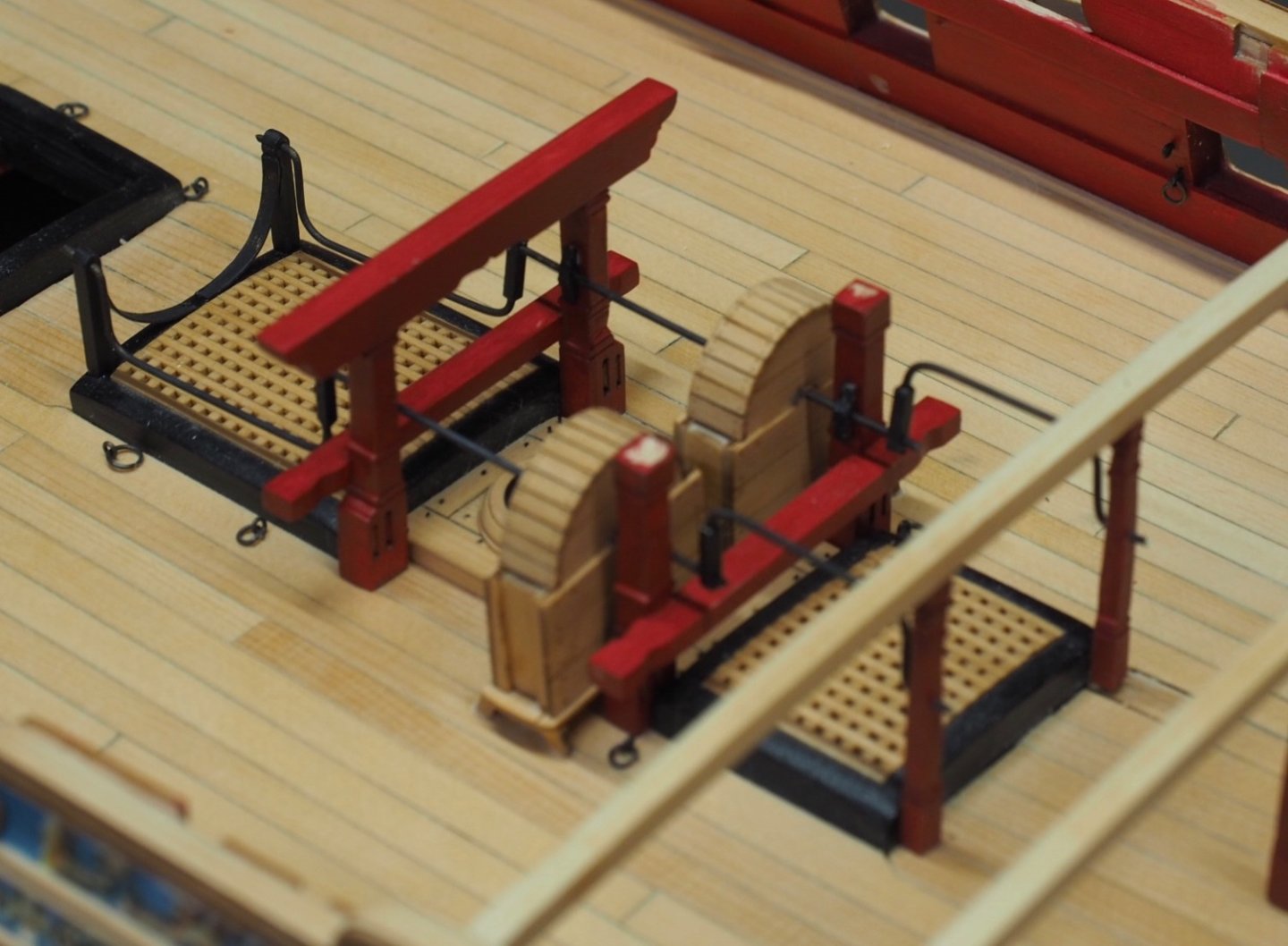

I completed chapter seven. My elm pumps are not glued in yet. The handles seem pretty fragile they might be in the way down the road, so I left them pinned but not glued. As you can see, I left the beams bright, rather than painting them. The only exception was the forward side of the front-most beam.

-

I look forward to watching your progress, Pavel. This is such a beautiful kit.

-

On 2/28/2023 at 9:33 AM, glbarlow said:

Thank you for your comments. Yesterday was spent drilling holes for the many ring bolts, I have to say it hurt a little bit to do so 😂

I hear what you're saying. Especially drilling such a nice deck as yours. But the ring bolts and eyes really add a lot and you'll be amazed at how they look when you get them installed.

- Rustyj, scrubbyj427, FrankWouts and 3 others

-

6

6

-

It looks like you've done a fantastic job on your bulkheads. I agree with you that buying Chuck's laser cut bulkheads would be much easier, but you can't beat the feeling of having done it yourself. Plus, your next model might not have that as an option, so now you know that you can make your own. My own had many errors that I didn't recognize until I was fairing the hull. I had to fill a few voids and file a few humps. From these photos, I think you're in great shape.

-

Thanks, Chuck, JJ, and Glenn. Chuck, I agree with you 100%. One think I didn't mention was that I pinned everything except the chain pumps. After I figured out how to get the holes drilled in the right spot using masking tape, I've been a pinning maniac. I thought about pinning the chain pumps, but decided the risk of splitting the feet was not worth any benefit. I'm certain they're not going anywhere with the 1mm brass crank rod holding them down. I'm away from home for work this week and looking forward to building the elm pumps this weekend after I get home. I have my 7-10-7 marks on the 3/16"x3/16" boxwood strip, so I can start filing right away.

- glbarlow, FrankWouts, Rustyj and 3 others

-

6

6

-

That looks amazing, Frank! You're the model of taking your time and doing a beautiful job!

-

- Saburo, Rustyj, scrubbyj427 and 6 others

-

9

9

-

Thanks Chuck and Frank. And thanks to all the “likes”! I deserve no credit for the quoins: I bought 8mm belaying pins from The Crafty Sailor to use there. The ones I tried to make were awful!

-

-

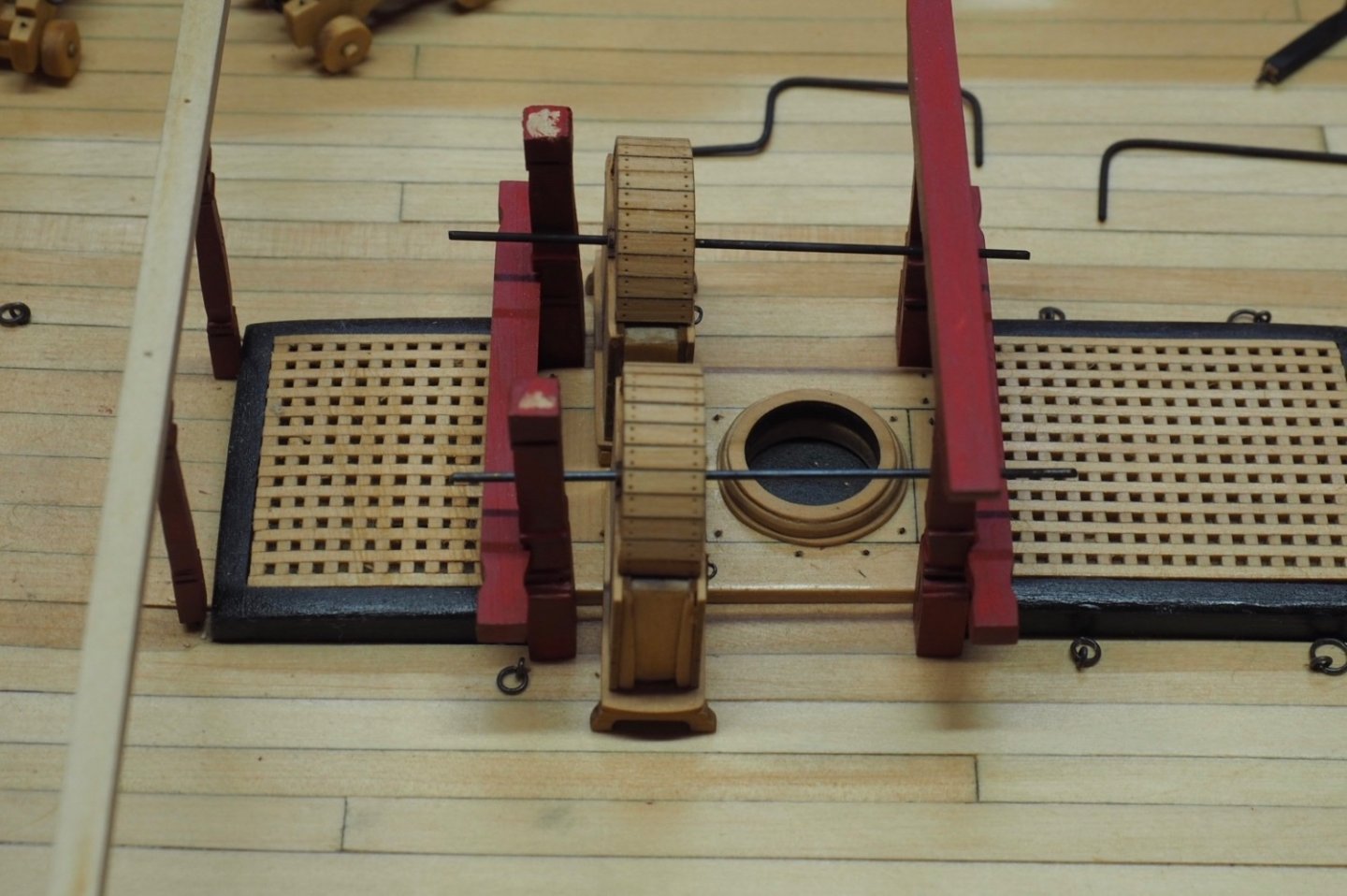

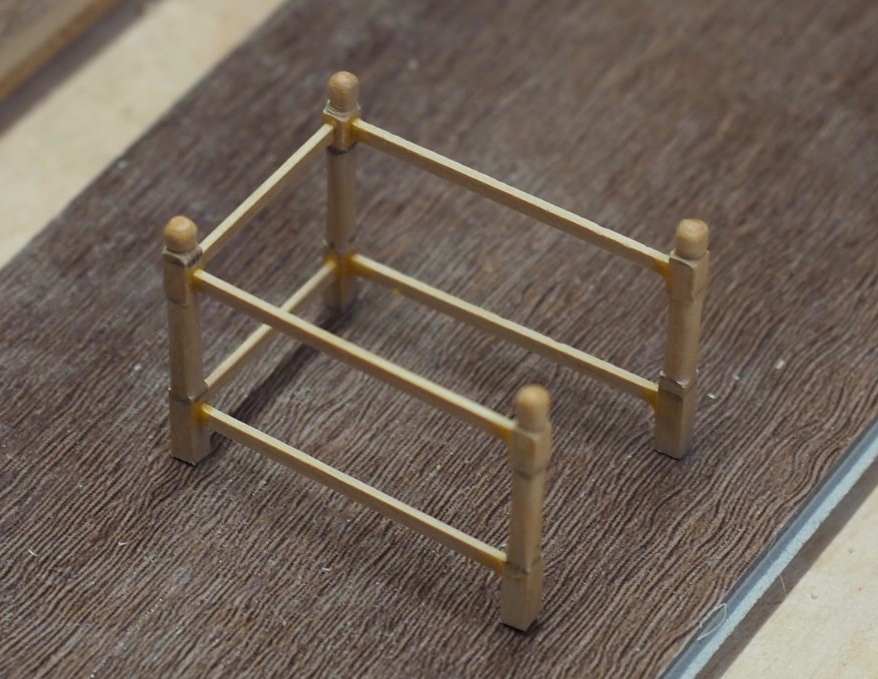

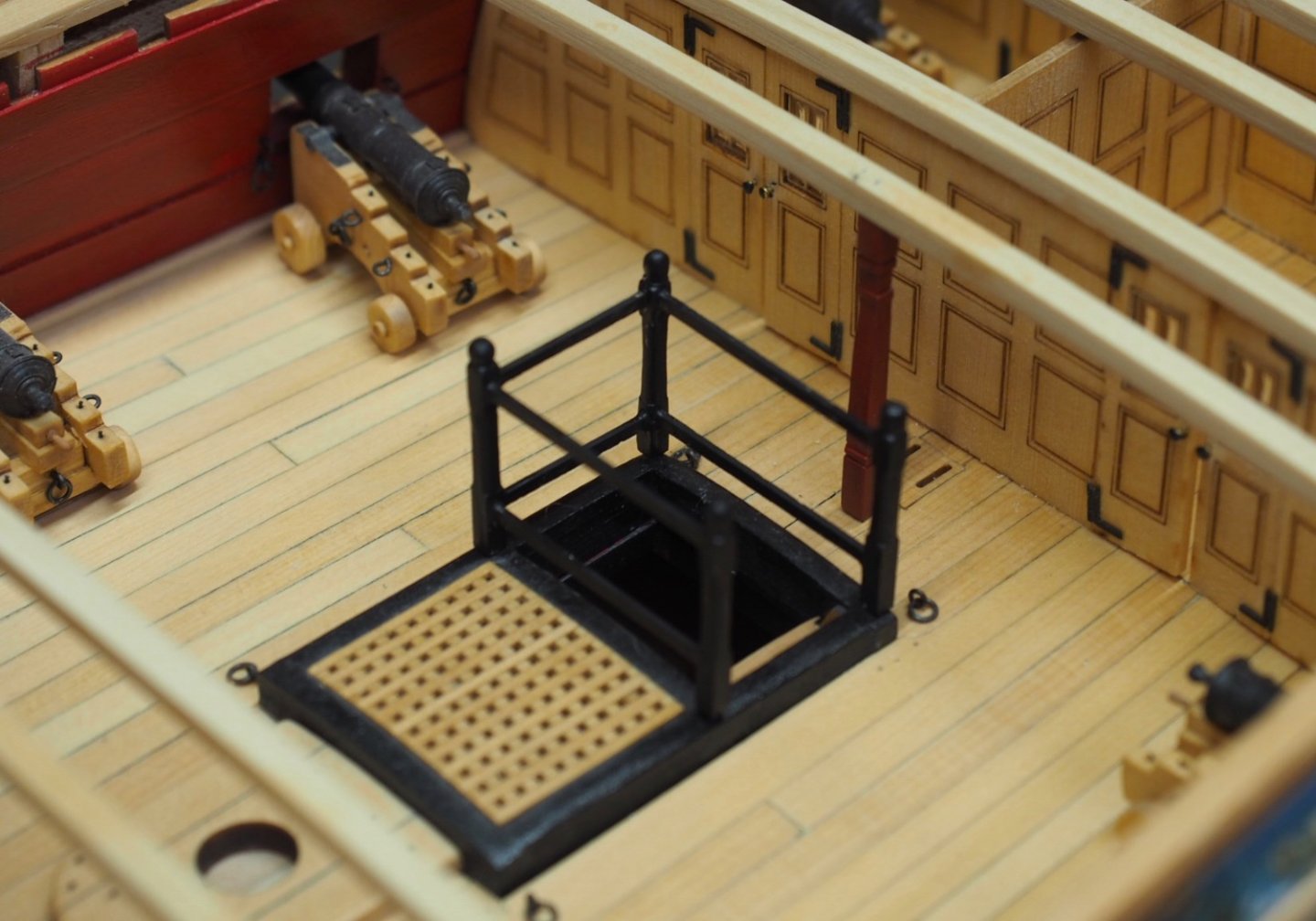

Here are a couple of shots of the railing around the companionway. I tried to do this exactly as described in chapter 7. Turning the stanchions was very easy using a Dremel tool and a small file. I glued it up using PVA. I expected it to be very fragile, but it’s surprising strong. I pinned it using 24 gauge steel wire. I’m pretty happy with how it turned out.

- scrubbyj427, bdgiantman2, FrankWouts and 14 others

-

16

16

-

1

1

-

Thanks, Chuck. That makes perfect sense.

- FrankWouts and Saburo

-

2

2

-

6 minutes ago, scrubbyj427 said:

Is the lower part sitting all the way down into its position on the gun deck?

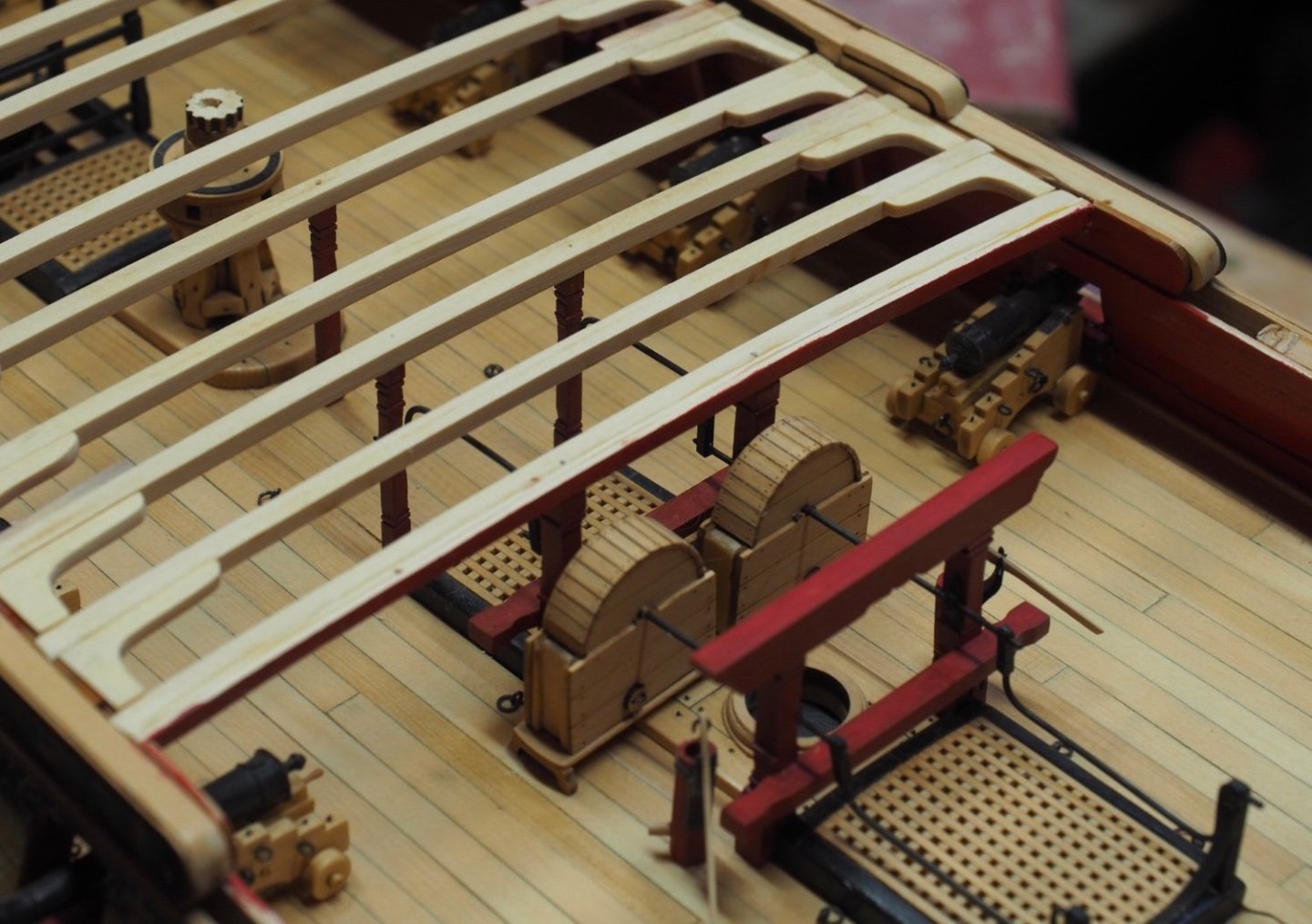

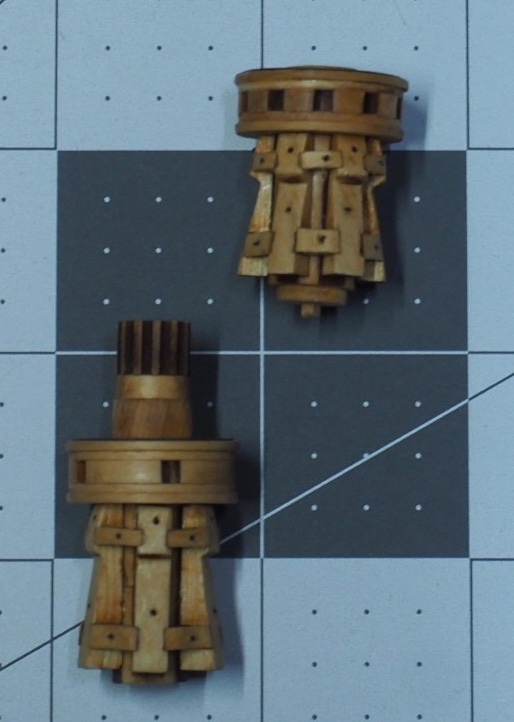

Thanks for looking, JJ. Yes, the lower part is all the way into the base below. Once I have a better idea of how high it should be, I can carefully cut or sand it down to fit. So this is a solvable problem.

- Edwardkenway, FrankWouts, glbarlow and 1 other

-

4

4

-

I think I have a problem with the height of my capstan. I can’t find a good view that shows how high above the quarterdeck beams the upper capstan should be. But I think mine is too high. I’ve carefully measured with my calipers and the top of the cog is 11/64” above the beam just forward of the capstan. Do any of you know if that’s too high as I suspect?

- ccoyle, Jack H, Edwardkenway and 2 others

-

5

5

-

-

-

Welcome aboard the Winchelsea project, my fellow Michigander! You’re definitely not too late to the party. You will see that we have someone working in every chapter at this moment, which is pretty amazing if you ask me. So there are many sources of good advice for you. As Joe has already mentioned, birch plywood is potentially a problem. Do you mean high quality Baltic Birch? Or are you talking about the birch plywood that they sell at Lowes and Home Depot, which is only veneered in birch and is much softer inside? The former is much more like hardened blue steel appropriate for the hull of a battleship. Fairing it will be a really hard job. The latter is just about perfect for this project. My first hull attempt was with Baltic Birch. My second was with Home Depot birch.

- Saburo, FrankWouts, scrubbyj427 and 2 others

-

4

4

-

1

1

-

3 hours ago, FrankWouts said:

I always shake my little bottle or tube with CA gleu before playing it.

or some reason the sticky part of the emulsion sinks when the bottle or tube is in rest for a longer period of time.

You then do not only apply only solvent instead of the full glue emulsion.I'll give that a try, Frank. Here I thought the Glue Gods were just frowning on me.

- Stuntflyer and FrankWouts

-

2

2

-

The "window maker" glass looks really nice, Gary. I used Micro Krystal Klear for mine, following Bob's lead @rafine . I had already installed and enclosed the acetate on the outboard stern, just as you have described. But with the Micro Krystal Klear, I was able to carefully put it over top using a toothpick to spread it around just like you would in an empty frame. One advantage (in addition to having a look you might like better) is that it gives some degree of protection against breaking the window pieces later in the build. You might be able to test it on one of the extra windows from Chapter 3 by gluing an acetate window on and then applying the window maker afterwards.

- FrankWouts and cdrusn89

-

2

2

-

Thanks, Rusty, and all of the likes, too. Chapter 7 has some neat stuff in it. But I'm a little freaked out by the beams. On the one hand, I can't wait to get them in and I love how they're going to look. On the other, I want to make sure everything is just right and the cannon are all very secure before I close her up. I'd hate to have to try to remove any of these beams down the road!

- Rustyj and FrankWouts

-

2

2

-

I’m with you on putting off the cannon as long as possible, brother! I still have 8 in the packages!

Also, your lights look really cool, JJ!

- FrankWouts and scrubbyj427

-

2

2

-

Thanks, JJ. It feels good to make some progress on her.

- FrankWouts and scrubbyj427

-

2

2

-

You’re the man, @James H!

- Knocklouder, Obormotov and mtaylor

-

3

3

-

I just want to say thank you to whoever came up with the new up arrow button at the lower right. I love not having to scroll all day to get back to the top of the page, now.

- mtaylor, druxey, thibaultron and 9 others

-

12

12

.thumb.jpg.6d6ee4bdbfaac2c58ecc77e7b80ae374.jpg)

Cutter Cheerful 1806 by Freebird - Syren Ship Model Company - 1/48

in - Build logs for subjects built 1801 - 1850

Posted

You're very smart to keep your pieces so well organized. It looks like you're off to an excellent start on your cannon parts. In my opinion, workflow is the key to getting them all done with consistent results.