-

Posts

611 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Matt D

-

-

Your bulkheads look great, Paul. You did a really good job on the false keel. I had a very hard time with the joints on mine.

-

I think what you’re asking for is the maximum theoretical force. That would simply be the dynamic pressure times the cross sectional area. Dynamic pressure is the pressure of air in the direction of flow, which is 1/2 rho x V^2, where rho is air density and V is velocity. It’s not possible for the force to be higher than that. The ratio between the actual force and the maximum theoretical force is the drag coefficient. This is an application of Burnoulli’s principle.

-

35 minutes ago, glbarlow said:

Then….wow!

That's what you do when you give up playing the piano in favor of building model ships.

- Jorge Diaz O, glbarlow, scrubbyj427 and 1 other

-

4

4

-

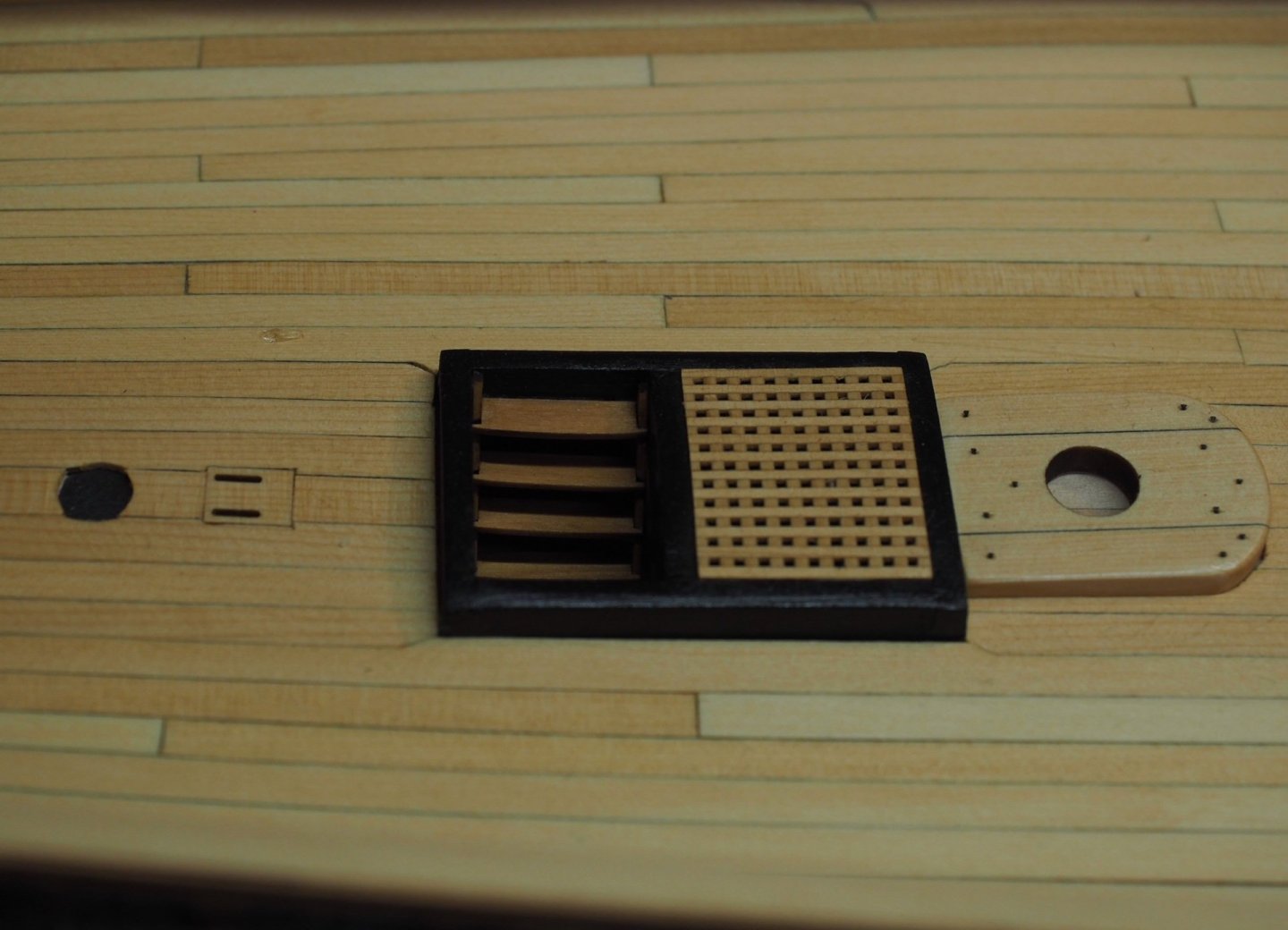

Those came our beautiful, Matthias! I'm still amazed that you can make those panels in 1/4" scale.

-

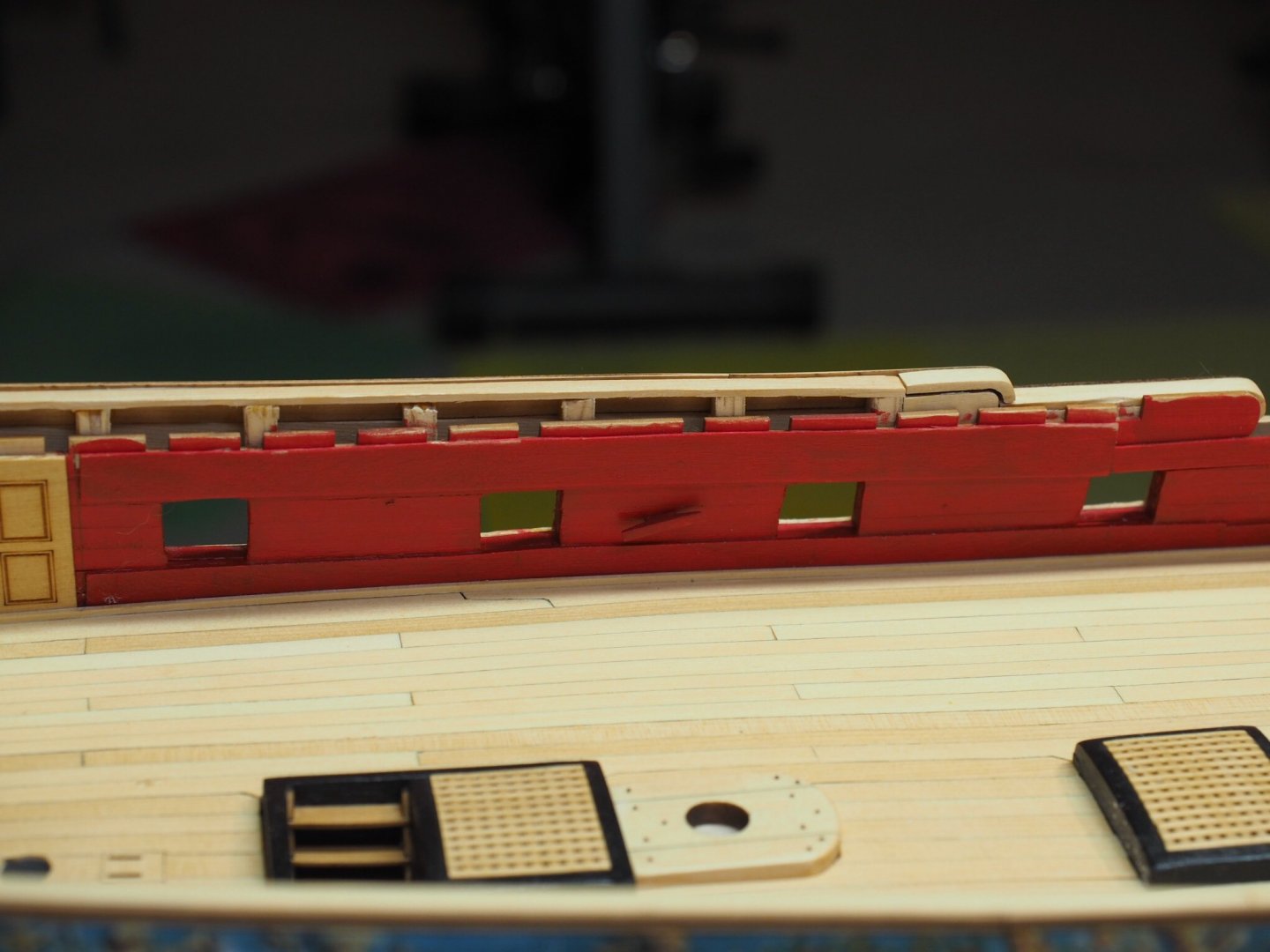

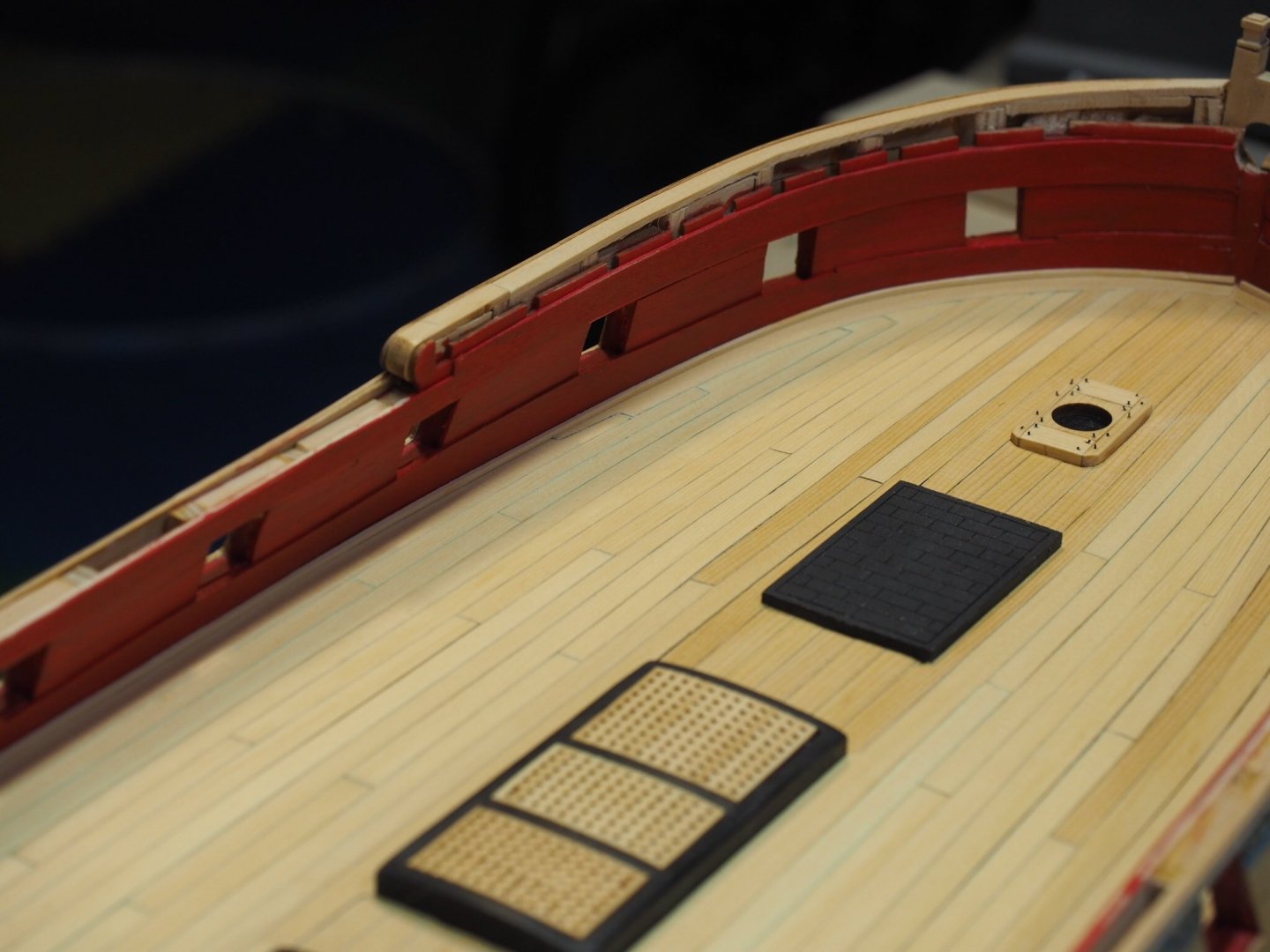

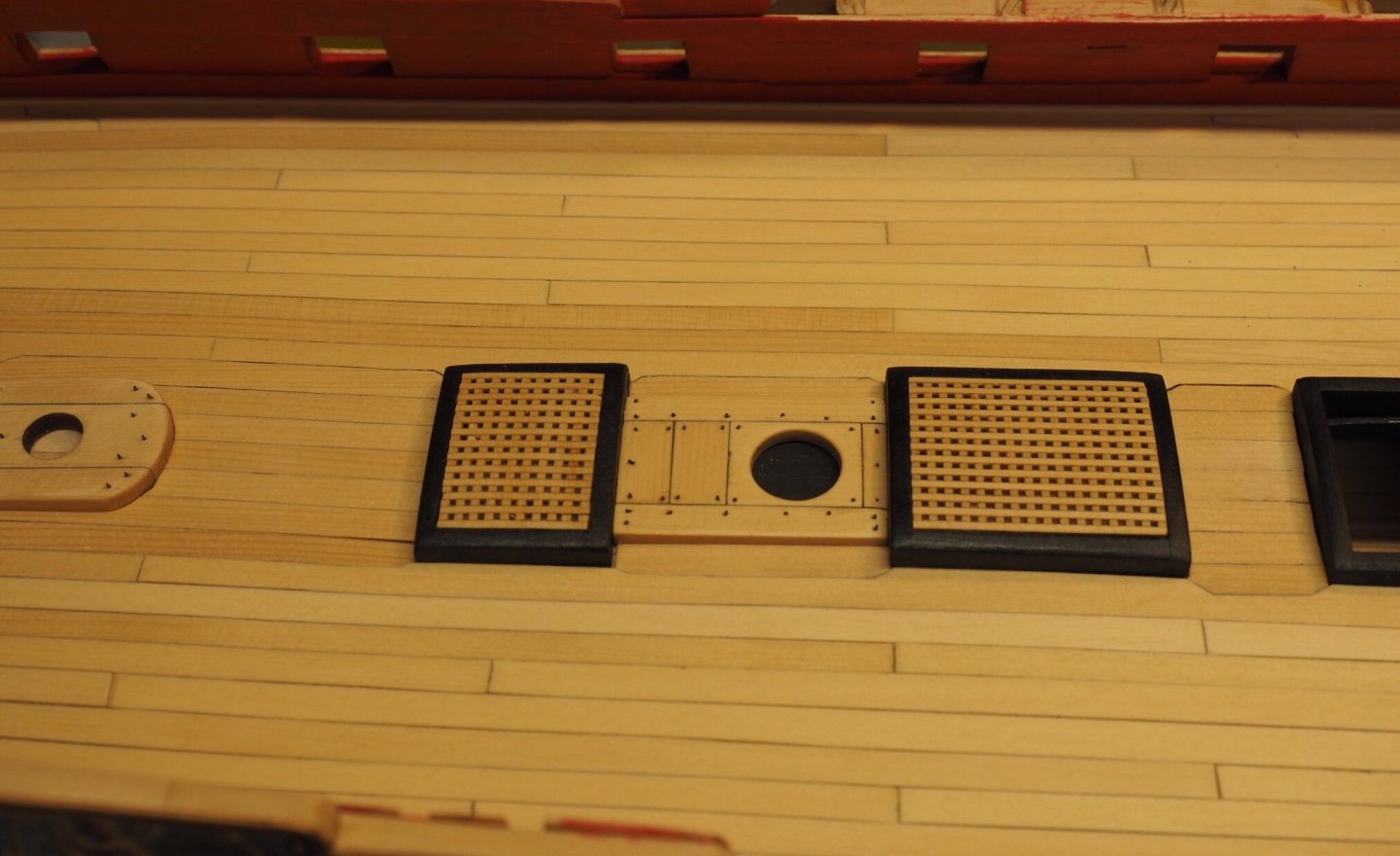

Thanks, Justin. There are a few areas that I'm completely thrilled with. Recently, that includes the gratings, cleats, mast partners, and ladders. Chuck's design work is amazing and it really makes this project a lot of fun. There are so many things coming up that I'm excited about.

-

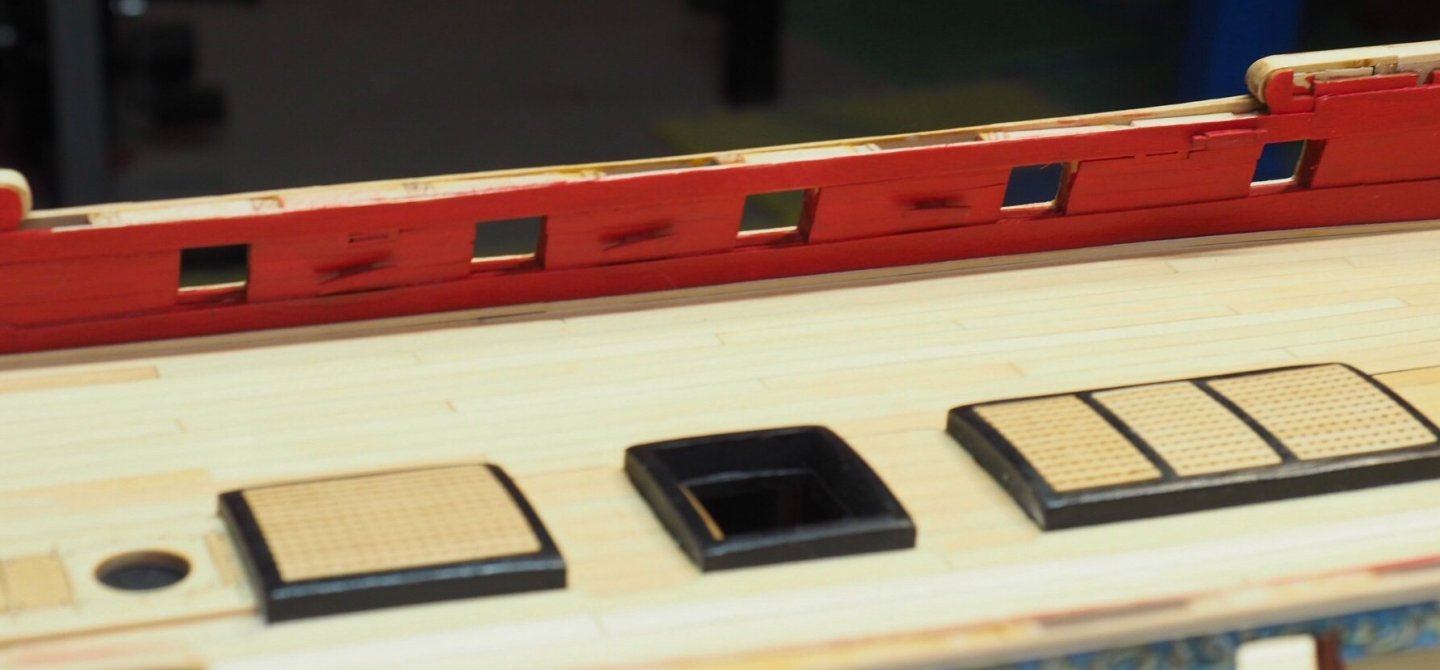

Thanks, Chuck! And thanks to the “likes”. The next thing I’m going to work on is the gun port lids.

- scrubbyj427 and FrankWouts

-

2

2

-

I’ve made some progress on chapter 5, starting with the rudder. It’s a beautiful set, but I broke several parts in the pintle and grudgeon sheet. Fortunately, they were easy to glue back together while I was gluing them on. My mistake was that I painted them before removing them from the sheet. This made them hard to cut free and i made a mess of it. But you can’t tell now because they went back together seamlessly.

the ladders went together so nicely. I really enjoyed the process. The double ladder rungs fit perfectly. It was really nice to work on.

I used annealed steal wire to pin the staghorn and cleats. This made it easy to paint them. I used the magnet of my torpedo level to hold them while the paint dried. Pinning them also let me test fit them to make sure I was happy with it before gluing.

- Jorge Diaz O, WalrusGuy, Rustyj and 11 others

-

14

14

-

Chris, maybe I’ve not paid attention to this forum closely enough. Are these Erycina and Nisha new Vanguard kits, or are they someone else’s that you will be selling? Do you have more details about these two ships and the kits?

- mtaylor, Canute and thibaultron

-

3

3

-

That stop cut on the tops looks like a really nice feature to help with the shaping. I’m looking forward to building these. They look great!

- Jorge Diaz O and FrankWouts

-

2

2

-

46 minutes ago, Chuck said:

This was hand carved by a human being with hands made of flesh and bones! It's astonishing. I can't even begin to grasp how and when I try, the questions I have are really perplexing: How did he know when he was done? 100 cuts before this point? 50? It had to look amazing 10 cuts before this point. But I'm sure one more cut would have been too much. Look at the scales on the snake and the feathers on the bird. The details are all so beautiful.

Sorry I got off track, Chuck. The carving porn overwhelmed me and I overlooked the headrail porn.

- FrankWouts, KentM, EricWilliamMarshall and 4 others

-

6

6

-

1

1

-

Chuck, I think we (the Winnie Group) are all here for the extraordinary. Please keep giving us the amazing detail you've given us all along. Most of us are two years into this project and expecting to be on it quite a while longer. Time is not a problem here (speaking for myself at least). And you've been working on her for at least four years! My vote is for doing it the best way possible and I trust you to make it something we can all succeed at. Your path is different from those other frigate kit manufacturers. Just as an anecdote - I have a kit I wanted to do for years sitting on a shelf in my workshop. Now that I've seen your kits and upcoming projects, I'm thinking about throwing that kit in the garbage or giving it away to someone I don't like.

-

Amazing work, Matthias. Those are hard to build in full scale. I have no idea how you did it in 1/4” scale!

- Edwardkenway and FrankWouts

-

2

2

-

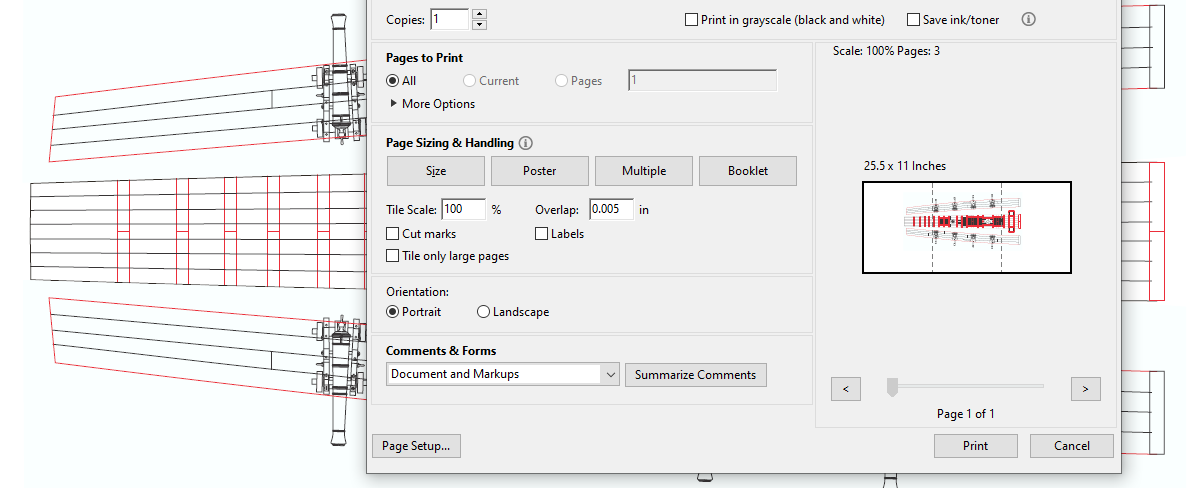

Don, when you print this, you will need to tile it. In your print configuration, you should have a button for "Poster" that will create the tiling over three sheets. There is an overlap at the mating of each sheet, but it should be pretty easy to figure out.

- scrubbyj427 and Jorge Diaz O

-

2

2

-

-

3 hours ago, rafine said:

I’m afraid that I can’t afford to slow down.

This reminds me of a neighbor I had when I was a kid. He used to say "at my age, I don't buy green bananas".

I have an idea for you, Bob. If you look at Chuck's post 1151 and his new post today, you could start on the forecastle bulwark and deck planking. They require no laser cut parts and he has issued the deck planking plan sheets. Like Chuck said, you'll whip right through it, but it would be something you can work on now. I really enjoy all of your build logs and I'm glad to be building Winnie at the same time you are.

- FrankWouts, Chuck and Ryland Craze

-

3

3

-

-

-

Thanks, Vladimir. I can see that I forgot to set my custom white balance before taking these pictures. My soft white lighting is looking pretty yellow. I'll post some better ones over the weekend.

-

- Rustyj, scrubbyj427, Edwardkenway and 8 others

-

11

11

-

Kurt, I made a donation today. But beyond that, I want to say thank you to everyone who makes this site possible and keeps it up. You do an amazing job of maintaining and moderating it, making it easy to navigate and a positive environment. I'm just a person who likes to build models and this site has brought me fantastic instruction, new project ideas, and a community of wonderful people who like to build and share together. I come to this site nearly every day, have my own build logs, and follow several other build logs. It brings me great joy to have this in my life. Thank you.

-

Jorge, your hull planking looks wonderful! Your cats are very talented model makers. My own cats are useless in the shipyard.

- CiscoH, bdgiantman2, FrankWouts and 1 other

-

1

1

-

3

3

-

18 hours ago, Justin P. said:

I may have trouble getting mine to fit as nicely as yours

One of the wonderful parts of the Winnie project is that the coamings were designed to fit the gratings perfectly. Before I saw it, I was really worried about it. Speaking only for myself, I can't imagine making the gratings myself when Chuck makes such nice kits with options on camber or no camber in boxwood, cherry, or AYC. However, I've seen some amazing examples of scratch made gratings that are obviously worth the effort. If it were me, I'd start by trying the Syren gratings to see, first if you like them, and second, if they fit or if you can easily get them to fit. Who knows - you might just get lucky and find that your spacing is just right. But at least the Byrnes saw has you covered if you have to remake them.

I bought the Triton plans and took a stab at making frames before I started Winnie. That attempt was awful, but I still want to build one at some point. I'm really happy to follow yours and see your inspiring work.

-

Beautiful work, Justin! This is turning out terrific. Your "dummy" gallows looks pretty darn good! I'm curious to see what will be different when you put in the "smart" gallows. I know what you mean about work getting in the way. I'm in the same boat on my model. Congratulations on the new camper! I hope you had a lot of fun with it this summer.

-

- Ryland Craze, mtaylor and Malazan

-

3

3

.thumb.jpg.6d6ee4bdbfaac2c58ecc77e7b80ae374.jpg)

Erycina by James H - FINISHED - Vanguard Models - 1:64 - Plymouth Ketch-Rigged Trawler - protoype build

in - Kit build logs for subjects built from 1851 - 1900

Posted

Beautiful work, James. I'm impressed by how well your masking went. You must have had the 3mm tape absolutely perfect to avoid bleeding of the red paint at the top of the white. Good job!. How is the lettering done? Did it come with the kit or was it something you added?