-

Posts

7,328 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Mirabell61

-

-

-

Update

I`ve completed the boats so far.

Special thanks go to Andy who kindly helped me with the number of portholes, and where they should be on the hull. After "glassing" them I put them on the hull already today.

Nils

here is a 1:87 (H0) sailor figure for size comparison

the name and numbers on the boats are printed with incjet on transparent self adhesive foil

sorry for the rather bad pic quality. The portholes "glassing" is made from 3 mm round silicon bar and glued in place with a drop of CA. The portholes housing is a brass hollow rivet with flange

-

A beautiful build Roger,

congrats to your good work

Nils

- Roger Pellett, Cathead, Glen McGuire and 4 others

-

6

6

-

1

1

-

-

Yves,

I do`nt make my own decals, but use Excel i.e. for doing the depth markings and printing out on glossy photopaper and cutting out. The encl. pic is showing the bow depth-marking of my Pamir.

For the Ergenstrasse I did`nt find any decal for the plysmoll marking in scale 1:87, but in 1:100. which I used in this case. And this little decal sheet it was on, had also depth markings on it. The pics are in my post. I would have made them with Excel also but here I bought them. Maybe I`ll change them out if I find appropriate decals in 1:87 one day.

With Excel its possible to follow the bottom bow-rounding quite well and even to choose the right color on the red white black Hull

Nils

Pamir bow-markings

-

well done Harry,

I`m looking for some fabric cloth I can do the covers for my boats as well. Also I do`nt know yet how I`m going to fasten the tying ropes to the cover`s trangle latches

Nils

-

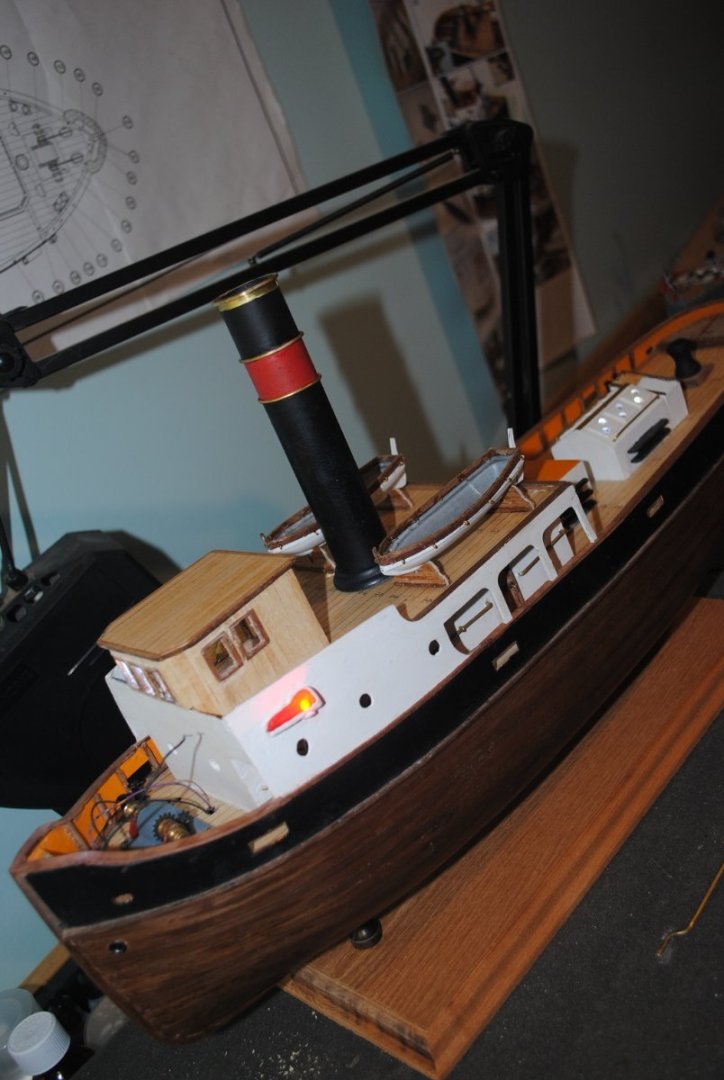

On 7/7/2023 at 7:01 AM, hof00 said:

Hi All,

Bit of an update:

I got my Plinth made today, NZ Native Timber, Rimu. (My favorite.)

Work on Lifeboats continues, Covers and Grab Ropes to complete I also Planked the Skids.

Funnel almost complete, need to add the Steam Whistle and Pipe, (Assembled). and Ringbolts for Rigging.

Davits completed.

Walnut Hull sealed.

Tug temporally mounted, I can soon assemble some Topside stuff.

Cheers....HOF.

Photos:

nice build Hof,

did you scratch build the boats, they also look good ?

Nils

-

-

-

- Retired guy, GrandpaPhil, _SalD_ and 9 others

-

10

10

-

2

2

-

-

intermediate session

after experiencing the make of the boats for 5 Elbe in scale 1:50, and for the liner Kaiser Wilhelm der Grosse in scale 1:160, I needed boats in scale ( H0 ) 1:87 for this project. I documented the building sequences for my own backup anyhow and thought it might be interesting for my fellow builders, whoever may require selfmade boats in special scales. So I`m sharing this intermediate session to whom it may concern. I still had some leftover two-component resin to allow the pruduction (material wise) of 3 identical double-ender lifeboats for Ergenstrasse. It would have been total 4 boats if I had not forgotten by mistake to mix enough hardener component there. Now my resin is used up and 3 boats will also do.

fake clinkering application of half plug (double-ender)

boxing for the silicon mold. Tapered filler logs to save quantity of silicon material used

setting of the halfplug into the mold and filling in silicon, use seperation wax spray for both plug and mold

silicon mold for casting the boats from

this is the second plug for the inner boat shapes, to be inserted into the silicon mold. Use temp. spacers for checking wallthicknesses and position of the plug. (fixing withe needles)

Two-compont resin into the mold with inserted plug. Use seperation spay wax for both plag and mold before casting

result after the resin is cured and the part removed from the mold ( inside view)

outside view

persons maximum capacity check when seated

preparing for cutting out the cockpit deck area

glueing 2 halves together

cut out cockpit cover. The boats length is 108 mm without the rudder

the open boat (without outer painting and rudder) is completed

there will also be some oars for the boat

-

very nice build Rick

Nils

-

Thank you very much Yves,

I`m still working on the plug for the clinkered lifeboats .For the lapstraking I`m using two-layer stripe foil before cutting them. Otherwise they would`nt show the lapstrake appeal after painting.

Boats in scale 1:87, taking up (in scale) 15 persons or so could not be found, so I`m doing them myself

Nils

some srap ply layers were glued to a block to shape the raw plug

- bruce d, GrandpaPhil, mtaylor and 12 others

-

15

15

-

-

Lovely gratings and stairs B.E

Nils

- Blue Ensign and mtaylor

-

1

1

-

1

1

-

Update

Started with the painting of the hull. The paint sticks on quite well together with the used promoting bounding primer for shiny aluminium. The lettering (names, homeport) is not yet attached but already printed in white letters on self adhesive black background foil (cut out patches).

I also started with the ships boats, because they are double-ender lifeboats, It will only require 1/2 a boat as a plug for doing the silicon mould. They will be cast in resin. Each two halves will be glued together, (total 8 halves), trimmed and 4 boats then brought to final shape.

I shall try to get some appropriate decals in transparent with white lettering for the front and aft depth markings, and for the Plymsoll mark midships

Nils

the sub-waterline is "African red" silk, acrylic paint, the upper hull is silk black, a silicone based black paint used for iron stoves and thear ductwork

the lettering printed on black foil (for cutting out patches)

preparing to make 1/2 a plug for the silicon mold for the ships boats that will be cast in resin afterwards

-

Right there Yves,

Thanks for your nice compliment

it is so long ago that the two kits you mentioned were available from Billing Boats. (thear great time) I see offers for these rare old kits now and then on Ebay.

It was also a time where there were no laser-cutten wood parts, and the good old jigsaw was used. I remember that for the Bohuslän I did`nt have the money for the seperate Billings fittings-kit, so all the

appropriate fittings were self made.

Nils

-

-

-

thanks for you comment Yves,

I`m using toothwheels of old mantel clocks for poncing (rivets). The handles are made from old paint brush handles.

Regards to your brother and I wish him much luck and fun with the Hjejlen build

Nils

if you look close, you`l notice different tooth sizes and by sloting the circumferal wheel I get even 2- and 3 fold "rivet rows. The 2-fold I used on the Ergenstrasse plating

-

13 hours ago, MAGIC's Craig said:

Fascinating work, Nils, and quite entertaining to follow along your construction sequence. I also will look forward to seeing how she comes together. 👏

Craig

many thanks for looking in Craig,

the superstructure details will have to be developed as I get to the appropriate sequences, I have an Idea though....

The masts will be tapered soldered and from brass tube material

Nils

- Canute, mtaylor, MAGIC's Craig and 1 other

-

4

4

-

13 hours ago, mikegr said:

Epoxy primers or etch primers for car industry may work good as well.

Thanks for that link with the etch primer Mike, I`ll keep an eye open on that

Nils

- mikegr, Keith Black, mtaylor and 1 other

-

4

4

-

many thanks Gary,

The plating is almost complete, I`m putting on the last few on the port side upper bulwark tomorrow and am pleased that my aluminium foil roll did last.

I have as an alternative tried out a special bonding primer spray for shiny aluminium surfaces and the results are quite satisfying so far. It usually would have been zinc-cromate primer like the aircraft industry had in use, but that is toxic and as far as I know its not being distributed any more. The next pics will be with the painted Hull in a few days

Nils

- mtaylor, Ras Ambrioso, FriedClams and 2 others

-

5

5

ERGENSTRASSE by Mirabell61 - FINISHED - 1:87 - steamship

in - Build logs for subjects built 1901 - Present Day

Posted

Update

I made the 2 masts and the 4 loading derricks.

For the frontmast I`m planing to fit the crows nest with an access ladder from deck to it

Nils

the 4 derricks with fastening pionts for the blocks and angle pivot, also the 2 "tapered" masts with fastening eyes for rigging- blocks and shrouds

the counter-points for the derrick pivot pins

"tapered" masts

the long aft derricks reach over the entire welldeck area with the 2 holds