-

Posts

5,946 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

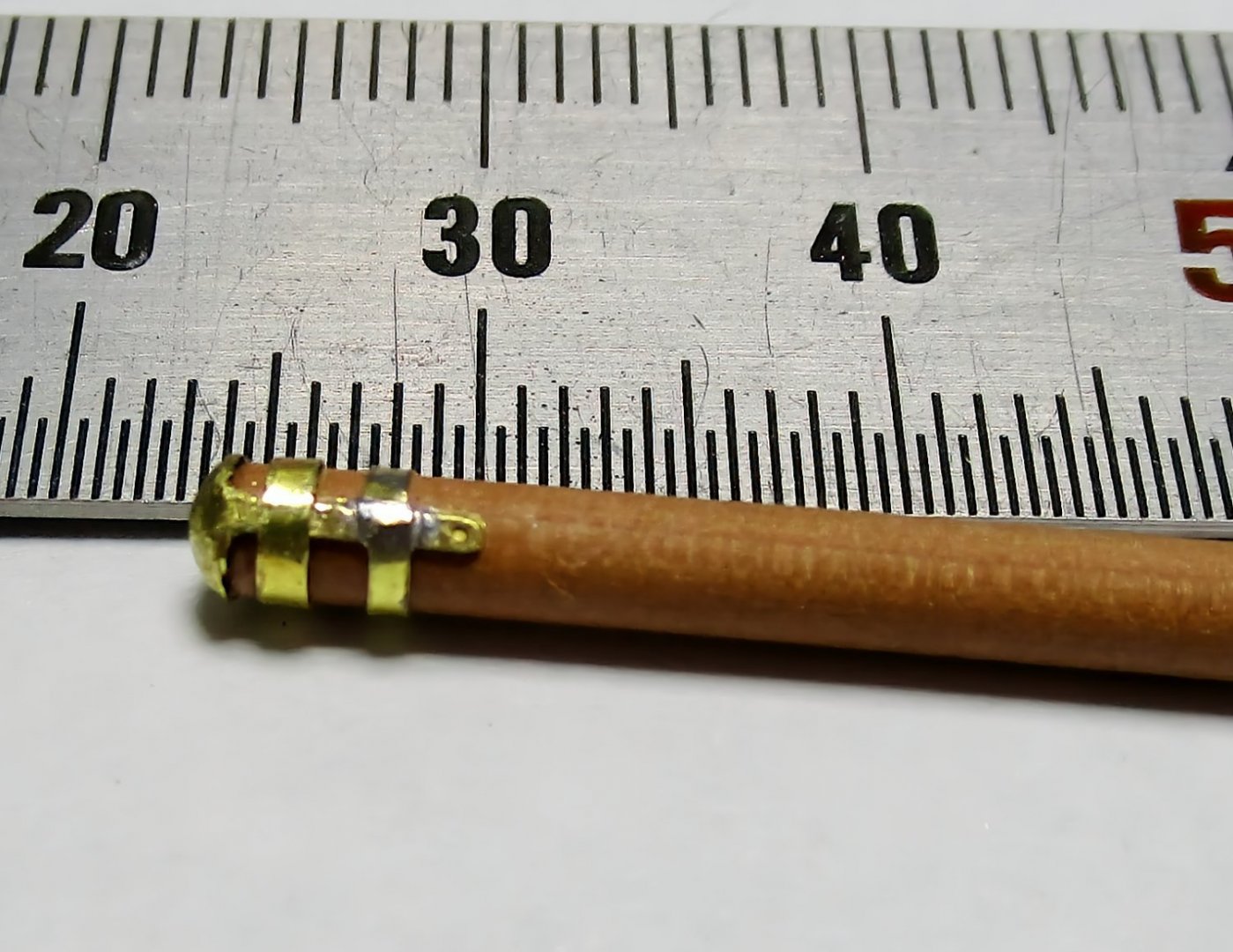

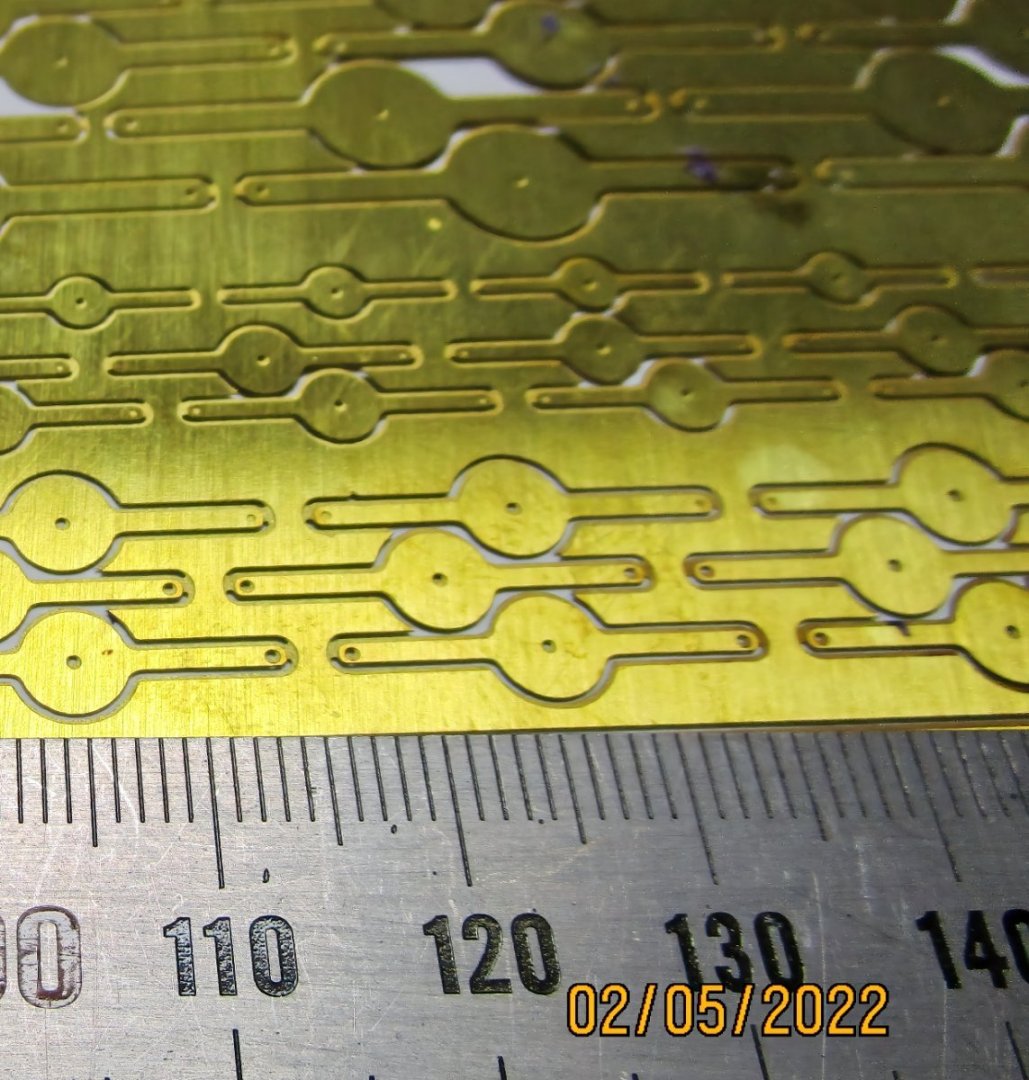

Well, I have finally got myself back into the workshop and started on some of the smaller fittings to be used in rigging the ship. The first are the fittings for the lower studdingsail/swing booms for which I need to make the ferule with gooseneck, and the spider bands. Noting the boom diameter is only a few millimetres in diameter, these are quite small. For the ferule I decided PE was the way to go, so drew up the basic stock parts. After experimenting I found I could not consistently 'round' a non-circular piece to form the concave end, so ended up going with a circular bit. I formed the concave shape by using a PE bending jig I have that has dimples inset for this purpose, then pressing the shape using a burnishing tool. I could not use tube for the bands as the diameters differ so I soldered a thin strip. The following are a couple of photos showing the end result of my first attempt where the alignment leaves a bit to desire, but overall, when viewed at eye distance, they look OK - not so great close up s they have not been cleaned up yet (the ruler is in mm). I will use some wire inserted in the end (through the preformed hole) as the start of the gooseneck. cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

What a beauty! Very nicely presented and a well constructed Model John. You should be proud of this one. cheers Pat

-

Simply wonderful work Eberhard; she/he is turning into a very eye-pleasing model. cheers Pat

-

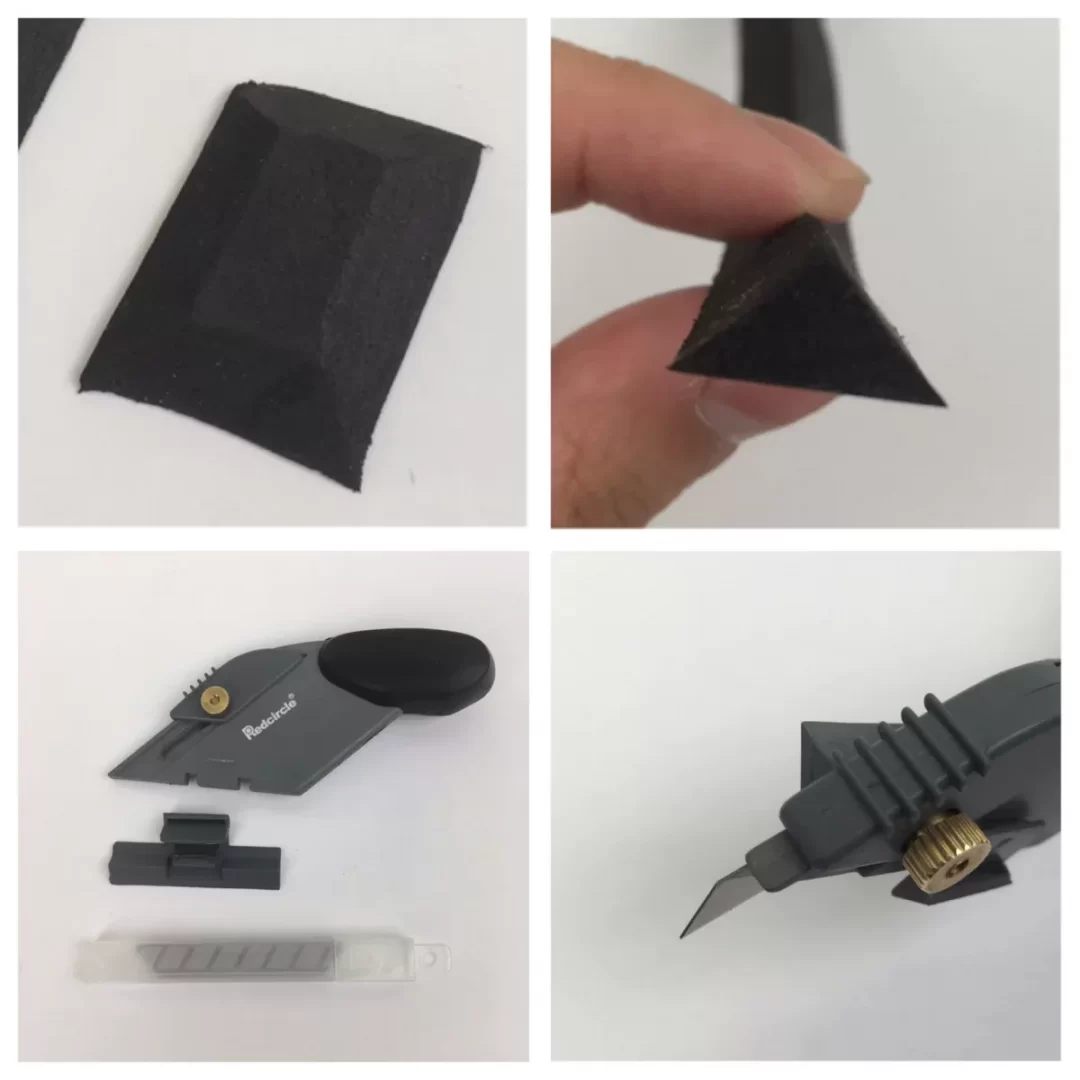

Allan, there are sure to be better solutions offered by the more experienced/talented builder but I used a 'splitter' tool generally employed by RC aircraft builders. I cut some very tight grained wood in thin strips to the required thickness to form the 'molded' dimension, then use this tool to take off thin strip to form the width of the stile etc. Below is a picture of the tool which I use with a jig clamped to a solid and straight edged cutting surface. I form a fence on the edge of the jig or table to guide the tool having clamped the strip to the surface (ensure it is square to cutting direction), and such that the cut strip between the tool and the stock ( I find that minimises the splitting sometimes experienced - a sharp blade is essential . Apart from the splitting, the other reason I have the cut piece restrained by the tool, is to stop it 'curling'. I hope that all makes some sense? There are various types out there, the first below is the style I used but I have also seriously thought of trying those card style cutters available from Office Supplies. The second image is a foam cutter that may also work? cheers Pat

-

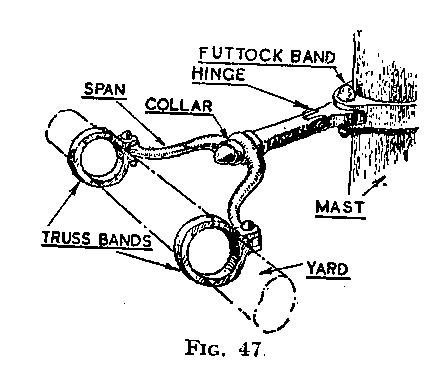

I think perhaps Barbara may be referring to the 'iron truss' that replaced parrels for the lower yards? Can you confirm please Barbara? See below which is an illustration by Harold Underhill in his Masting and Rigging Clippers and the Ocean Transport - Fig. 47. If so, there are some useful photos and illustrations available, but I have yet to find any useful guidance on the dimensions, especially the gap formed by the 'U' part - this gap allowed the upper masts to be struck through the resulting hole created when fitted to the yard. Some had a single joint/knuckle (hinge), others were double jointed to allow better clearance of the yard. when swung. As illustrated, they were usually incorporated as part of the lower futtock band. I do not know what type the 'Morgan' may have been fitted with? cheers Pat

-

NAIAD 1797 by Bitao - 1:60

BANYAN replied to Bitao's topic in - Build logs for subjects built 1751 - 1800

Very much up to your very high workmanship; a delight for the eyes. cheers Pat -

I think you may have started a new method for doing furled sails They look great, even up close. cheers Pat

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

I know that feeling only too well Keith. Very nice details to your launch, I particularly like that little engine/power derive. cheers Pat

-

Very nice work Brian; as Keith says, if you call this 'little progress' well .... Impressive detail. cheers Pat

-

hi John, ditto comments above - congrats to the team; the project is coming along very nicely and the additional detail in the photos is great to see. You have me somewhat confused though with the naming of the aux boiler. I am more familiar with that being the 'Donkey' boiler; not saying 'Doctor' is wrong, just wondering how you arrived at that name? Enquiring minds and all cheers Pat

-

Hi Peter, that's what I went with. Some ships crews may have painted the head part a little more ornately, but I just went for plain red ochre for the windlass stands and the heads. cheers Pat

- 79 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Agree with Mark, the idea and construction of that mannequin is a very clever idea. Robotic or not, it is a great way to visualise the ergonomics and rowing techniques. cheers Pat

-

The heads may have been painted anyway Peter, that was my choice anyway :). You're making good progress and I like that 'brown stuff' bottom.. cheers Pat

- 79 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

As with many 'exercises in frustration' Steven, persistence provides a great result. Slowly but surely the refit proceeds. You must be pretty happy with these results? cheers Pat

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

I love the simplicity of design for the display stand Greg; the stamp tops it off. cheers Pat

- 35 replies

-

Very nice Rob, that rigging is looking great. I particularly like the effect you have generated with the furled and weathered sails. I also work from aft-to-fwd; for me that allows me to bring the appropriate amount of tension on the backstays, stays etc as I progress forward - but more importantly, I found that if I rigged the bowsprit/jibboom first that I was constantly knocking it . As Druxey says; each to their own and whatever works for you. cheers Pat

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

NAIAD 1797 by Bitao - 1:60

BANYAN replied to Bitao's topic in - Build logs for subjects built 1751 - 1800

Those blocks look great Bitao, very nice work. Love that ropewalk. cheers Pat -

Nice work Steven, those new deadeyes look good, and as you stated, the whole arrangement looks a lot neater. cheers Pat

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

NAIAD 1797 by Bitao - 1:60

BANYAN replied to Bitao's topic in - Build logs for subjects built 1751 - 1800

You never fail to impress with your skills Bitao; lovely work as usual. cheers Pat

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.