-

Posts

5,946 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

Agree with Trevor. The contract for Victoria called for mats as well as baggywrinkles. The best I have been able to determine so far,. is that the mats were usually laid across yards whereas the baggywrinkles were applied to lines (both at any point of contact or potential contact with sails). cheers Pat

- 15 replies

-

- baggy winkle

- service

-

(and 2 more)

Tagged with:

-

That looks so good Ilhan. I now have to go back and possibly adjust the funnel on my Victoria as I didn't even think on hand rungs to climb the funnel. Great seeing more of your quality work. cheers Pat

-

Be over in a jiffy mate - just have to save my pennies for a while. Seriously though, your rigging is looking great, clean and proportionate in scale - well worth celebrating. cheers Pat

- 301 replies

-

- Constitution

- Bluejacket Shipcrafters

-

(and 1 more)

Tagged with:

-

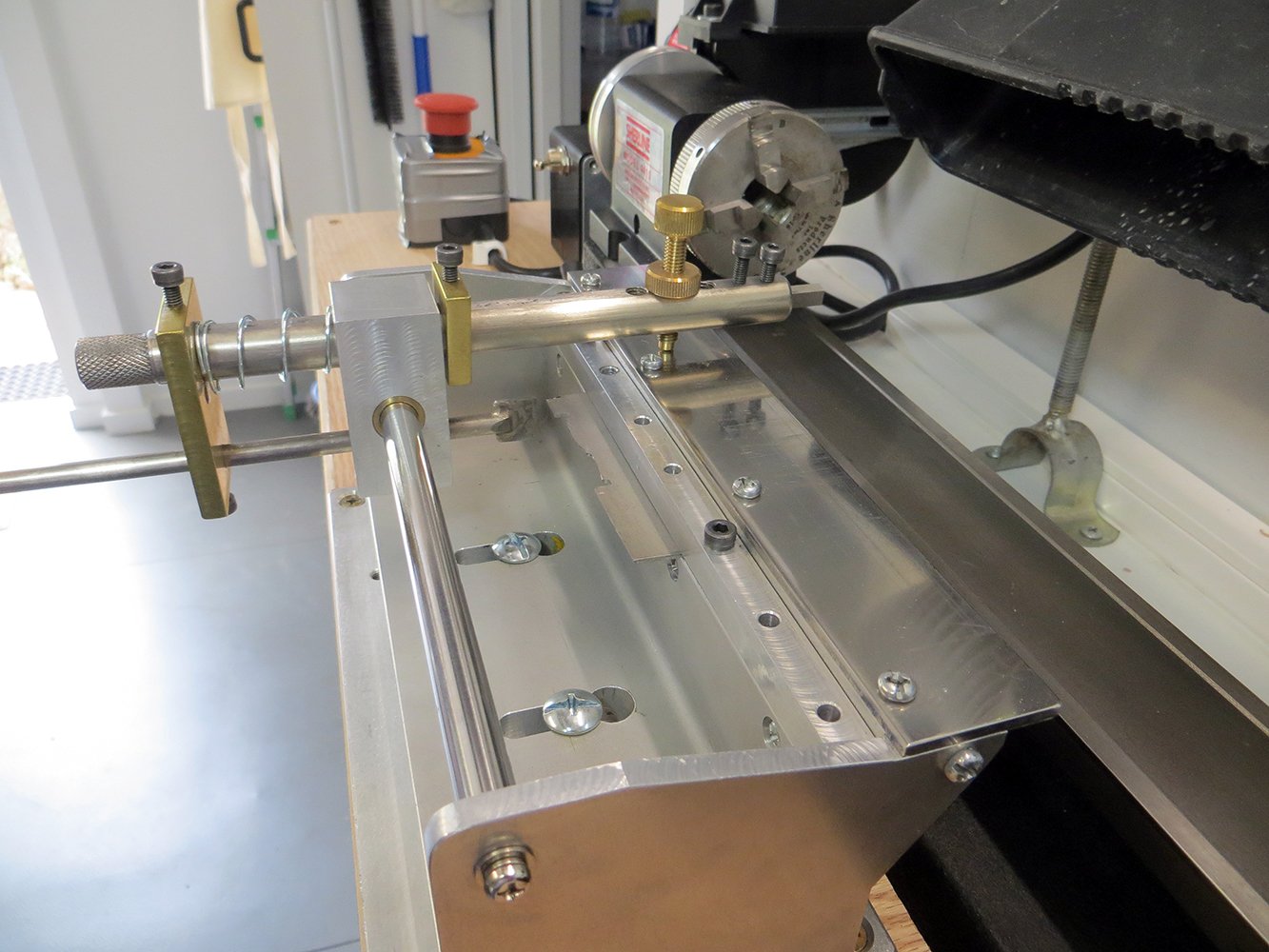

Hi Richard, I actually do all my spars on my Sherline (long bed) lathe. I first cut the required square and hex shapes slightly oversize, the (very roughly) shape them to a hex taper using a plane and then set it up in the lathe and use small machinist jacks and a follower rest to shape the final profiles. I use a combo of rasps, files and sandpaper for that process constantly checking the profile with calipers etc. For shorter sections I sometimes use the duplicator, especially about the hounds and masthead doubling. I then refine the squared and flat surface manually using a file rest and fine needle files to get them to the final dimensions. You can see some of my earlier dings (collision scars) between the Y cross-slide and the chucks before I made a stop for it Well, one has to learn some lessons the hard way; I put it down to the experience of learning. PS: Sorry, I should mention that I mainly work at 1:72 so, at your scale you might have some difficulty setting up spars etc. cheers Pat

-

A great diorama Greg, looks good and nicely detailed. I wonder though how they drink those beers on the Quarterdeck table with all that protective gear on I have enjoyed following this build. cheers Pat

-

Sorry to hear the news of the delayed recovery mate; best wishes for a better progress. cheers Pat

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Good to hear you are on the recovery path Mark, I hope all continues to go well for you. Look forward to seeing the up[dates... and, I know whay you mean by the scales for older ewyes. 1:72 is straqting to do my head in also cheers Pat

- 11 replies

-

- half hull

- half hull planking project

-

(and 1 more)

Tagged with:

-

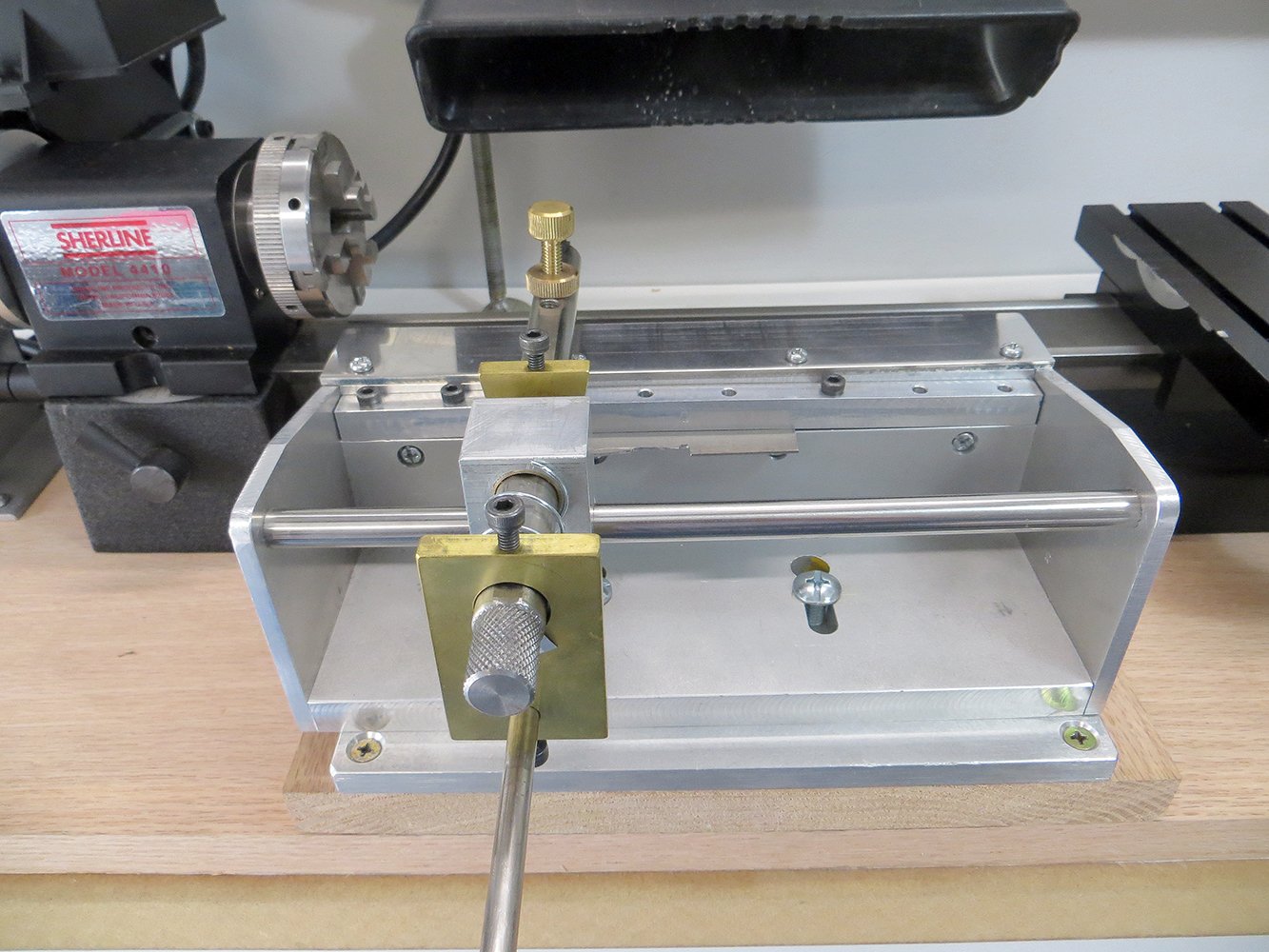

Hi Richard. This is one (home-made) that I use with my Sherline. The idea is to cut a profile (template) in metal that is used as the master profile for as many duplicates as you need - works best with more complicated shapes but will work with a simple flat/tapered profile also. However, I usually use a compound slide to cut tapers on the Sherline, but that only works well over shorter distances. Hopefully the photos are self explanatory, but essentially, the cutter (top) will only cut as deep as the profile follower (bottom bar) and the template will allow. cheers Pat

-

You are being too kind to the crew Keith - a good flogging to drive them up steeper ladders/stairs should be the order of the day Seriously though, Lula is coming along nicely, great work. cheers Pat

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

Interesting but very effective approach to cutting the tapers Richard. Appears this approach may be easier than setting up a shape follower (duplicator) arrangement. cheers Pat

-

OK, I'll continue the thread - fourth! Seriously, nice work Glen, looks really good, especially the proportions. cheers Pat

- 301 replies

-

- Constitution

- Bluejacket Shipcrafters

-

(and 1 more)

Tagged with:

-

John I would ignore the lot of them! You are the one doing the work and you govern the pace; not like you are under a Contract. So if you want to take your time you should; but, as you have indicated your intention to complete ASAP, that is your call and they should respect that. It is really a bit cheeky of them pushing you if you are doing this on a voluntary basis; they should be grateful and encouraging. She is looking great BTW, very nice work. cheers Pat

-

Tom, probably by voice pipe and possibly also bells. cheers Pat

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

Welcome back, great to see the build progressing. cheers Pat

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

It takes a brave man to admit defeat, but you gave it a really good effort mate. Look forward to seeing that addition. cheers Pat

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

This is building into an exceptional diorama Greg. The figurine painting skills you show are top-notch. cheers Pat

-

Great milestone Glen, one which I thinks not only deserves that drink BUT also an extra Rum Issue (break out the Bundy). All looks great, nice job! cheers Pat

- 301 replies

-

- Constitution

- Bluejacket Shipcrafters

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.