-

Posts

2,703 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Gregory

-

-

40 minutes ago, grsjax said:

Should be ok for light work

It's not really intended for anything but light work.

The head moves up and down as smooth as can be. The spindle and motor are very quiet. I believe the spindle uses some type of roller or ball bearings.

Is their any way to tell without taking it apart?

- mtaylor, Chuck Seiler and Canute

-

3

3

-

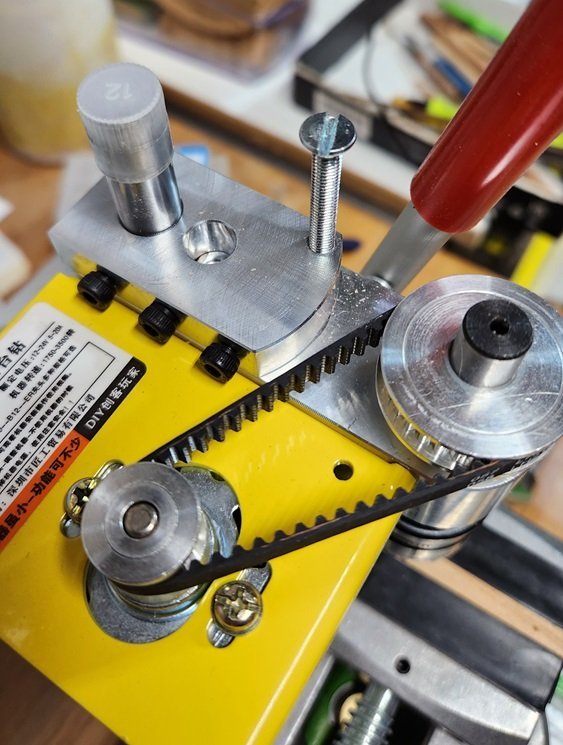

Well, the mini drill press is a little more of a beast now.

I used some scrap melamine to elevate the drill and the X-Y table a net of a little over 2 inches.

The little X-Y table is surprisingly well made considering the price. It seems very stable but doesn't have the precision that serious milling would require.

I could have done without the rotary table, but it will add a little more versatility should the need arise.

They do have a similar table on amazon without the rotary function at essentially the same price..

I discovered that the fixed part of the head has a threaded hole with which you can use a screw to fix the Z depth for milling.

I don't really have any jobs to do right now, but I feel like I have my micro drilling needs well covered as they come up.

I will do my best to answer any questions or try your suggestions.

It wouldn't surprise me if some of you could come up with a little more sophisticated configuration than I have managed.

- JpR62, wefalck, Thukydides and 2 others

-

5

5

-

1 hour ago, Snug Harbor Johnny said:

Looking at this rig, what the problem might be is that the planetary gears that turn the spools don't twist enough in relation to the revolutions of the large disc laying the strands on the other side (not quite sure what the exact ratio needs to be).

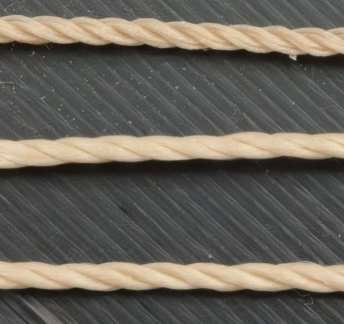

I mentioned earlier that there is apparently something lacking in the tightness of the lay .

The Rope Rocket and the Frolic style rope makers twist the strands hundreds if not thousands of times to create the tension that causes the rope to form.

The Domanoff machine doesn't appear to be twisting the strands more than a few tens of revolutions. Perhaps someone with more knowledge could give a more precise number.

- mtaylor and modeller_masa

-

2

2

-

I Have a full sized house brand drill press outside in my workshop where my other full sized tools are.

I don't want to take my model work outside, bring my full sized tools into my relatively small modeling area, nor re-configure my full sized tools to work on a one-off modeling project.

Still, I guess it remains an option.

- mtaylor, Thukydides, oakheart and 1 other

-

4

4

-

9 minutes ago, Twokidsnosleep said:

Or a stand for my Dremels

I had one of these..

I even had a dedicated tool for it, so I didn't have to change it out.. I got by with it for many years but I decided I needed more precision. It had to much play in it for the scales we are working at.

It would never have been suitable for any detail milling work.

- Twokidsnosleep, mtaylor and Canute

-

3

3

-

30 minutes ago, Chuck Seiler said:

What is the diameter of the post?

12mm

I think extending it with a dowel or metal rod using a good coupling would be relatively simple, but I am going to start with rotating the head and elevating the table.

I am waiting for delivery of my rotary table today. Hope to have update today or tomorrow.

- mtaylor, Chuck Seiler and Canute

-

2

2

-

1

1

-

-

10 hours ago, modeller_masa said:

It is a good subject for thought. - Is realistic thread better for a scaled model?

I know you are still in the experimental stage, and not concerned with color right now. but so far, your rope lacks something, and I wonder if it is a shortcoming of the Domanoff design.

The layup is not very tight, and lacks the look of rope.

Actual rope.

Compare :

To:

This from Ropes of Scale. Notice how you can see the individual threads and strands. I believe they use the Rope-Rocket.

Here is some of the smallest rope I have made. The individual threads are not as obvious.

I believe it is 3 strands of two threads, Gutermann polyester MARA 120. I use a simplified Frolic style mechanism ..

I could share more details if you are interested.

I'm curious as to your goal in your " studies on rope making " ?

- mtaylor, modeller_masa and Ryland Craze

-

2

2

-

1

1

-

12 hours ago, Bob Cleek said:

I'm curious as to whether this central core strand really makes a big difference.

I make up to four strands, with the option for a central core that I never use.

I don't have a problem with my rope not being round.

I have heard of, but not tried so far, the idea of using small wire as a core to make rope that could hold it's shape, like for better looking foot ropes.

-

Which one is the best ropewalk machine?

The one that makes miniature rope that looks like a scaled down version of the real thing.

Some rope I made.

Here are the components of my first rope maker. What I am using now is not very different in form or function.

Some results..

I don't make anything longer than 4 - 5 feet , but it suits my needs.

Edit:

My ropewalk uses the principles of the one described by Phil Krol found here.. Mine is not quite as elaborate.

https://modelshipworld.com/applications/core/interface/file/attachment.php?id=537569

- BenD, Ryland Craze, modeller_masa and 1 other

-

3

3

-

1

1

-

2 hours ago, kgstakes said:

Question would a little machine shop or other small x-y table work?

It should. See my last reply to Chuck.. If it wasn't made clear earlier, the drill head can be positioned away from the provided table, or removed from it all together.

- mtaylor, Canute and Chuck Seiler

-

3

3

-

17 minutes ago, Chuck Seiler said:

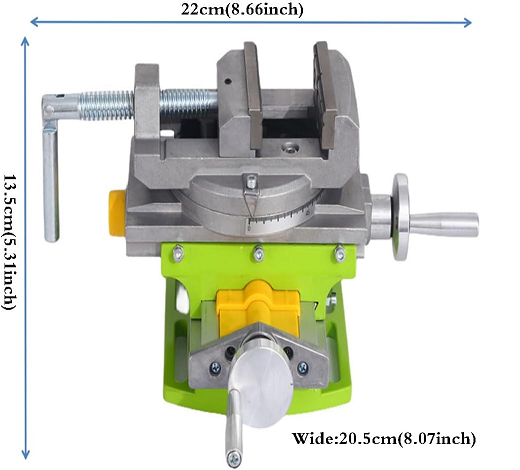

The vertical shaft (?) on the original press is only 8.66 inches. At 5.31 inches in height, will this rotary table fit?

I will be making a platform to raise the drill press to a working height for the table..

Stay tuned..

- mtaylor, Canute and Chuck Seiler

-

3

3

-

O.K., Call me indecisive.

When I was clicking through small vises at amazon, I was presented with this.

BACHIN Rotary Table $57.59

Check out the video for an idea of the working parameters.

Decent ( cheap ) mini-vises + an X-Y table were pushing if not exceeding that price point.

I feel this will give better control than moving a vise around on an X-Y table, and the movement range should be adequate for my needs.

I won't have it until Saturday, so won't have an update until then.

- Chuck Seiler, mtaylor and Canute

-

3

3

-

-

Have not used it a lot, but have not uncovered any concerns. I feel it is well made, and have not detected any play in the mechanism.

I don't foresee doing any work with it that would tax it to any extent.

If you have any specific task you would like for me to attempt, I would give it a shot if I have the materials available. I think I might be limited by the quality of my bits.

I have no reservations about recommending it to anyone who could see this fitting into their work environment.

- Canute, mtaylor, Chuck Seiler and 1 other

-

4

4

-

22 minutes ago, cdrusn89 said:

....my first model of a three masted ship.

Not counting Winchelsea! 😁

- cdrusn89, mtaylor and scrubbyj427

-

3

3

-

-

21 hours ago, Bob Cleek said:

Everything you need to know is to be found in this MSW forum sub-topic.

Another thing to keep in mind, when you spin your own rope, differences in machinery, set-up and conditions ( humidity, temperature ) an cause subtle differences, not necessarily negligible at scale.

-

-

Hold them with some small needle nose plyers and tap them with a small hammer to get them started. The I would use a small nail setting tool and the hammer to seat them.

- JFMJr and Knocklouder

-

2

2

-

-

-

-

5 hours ago, Giorgik63 said:

can the bridges in my plan be taken from the one I put on the Golden Hind (with the necessary modifications) ?

I suppose you can, but you are moving out of my area of expertise when you start drawing your own plans. Perhaps someone else can help.

It sounds like you may need some good drafting software to do this.

Mini Bench Drill Press

in Modeling tools and Workshop Equipment

Posted · Edited by Gregory

Definitely, now that you asked.

Want to kick me now, or later?

I could have got almost 2" of elevation by removing that plastic cap and moving the head up on the post.

There are scads of 12mm chrome rods at Amazon.

Here is a 23" for $18.99. A 12" would do it for my purposes..

Edit: Now I see you can choose from 200 to 1000mm.

Standby for super mini drill V2.0

Forget you saw that melamine crap, and thanks for the wake-up call.