-

Posts

2,694 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Gregory

-

-

1 hour ago, Mark P said:

Below is a picture of a model made with boxwood planking, which is very yellow; presumably sealed with something, but the colour looks lovely.

….

Just wait a couple of hundred years and all your boxwood will look that good…😁

- thibaultron, Canute, chris watton and 3 others

-

4

4

-

2

2

-

-

On 3/24/2024 at 7:56 AM, S.Coleman said:

CA glue will just get crystallised after awhile and break apart.

If it crystallizes, then there is something wrong with the formula, or the way it was used. Properly cured CA is just plastic, with fibers penetrating the wood, creating a mesh that is stronger than wood in some regards.

The bond can break under shear stress, but this is unlikely to happen with planking, and not any more so than PVA.The times I have seen a CA joint come apart there was always shared wood on the two pieces, which means the wood broke before the glue did.

- Canute, mtaylor, Scottish Guy and 2 others

-

5

5

-

With checkers up forward, surely you must have chess in the Captains cabin. 😁

- Thukydides, FrankWouts, Jack12477 and 2 others

-

5

5

-

43 minutes ago, Sceatha said:

One question that came up (sorry if I missed it in your log) is how you treated the bowsprit length.

I can't say that I used any verifiable reference.. I'm sort of a " if it looks good ( to me ) it is good " modeler. I think I more or less settled on the length shown in the kit plans.

The kit shows a jib boom as well as a bowsprit and I feel it has a balanced look, that I decided to go with.

-

-

4 hours ago, Lost and Confused said:

Im using Amati rigging line from HIS model. Is that cotton, polyester, or what?

Take a match to it ( not too close ). If it's poly it will melt, if it's natural fiber it will burn.

- mtaylor and Keith Black

-

2

2

-

If you look at my Resolution build you will see that the Corel kit is based on the lines of Ferret.

Corel forgoes the gammoning and rigs the bowsprit much like what is found on the later cutters.I have yet to see any ship similar to this. The Corel kit has many features that deviate from actual practice, so there is no good reason to assume their treatment of the bowsprit is based on good evidence.

While the contemporary lines of Ferret says the ship is a cutter rigged sloop, I believe this relates more to the mast placement and sail arrangement and doesn’t account for a moveable bowsprit like found on cutters.

PS

FWIW The gammoning you see in the Chapelle drawing is based on educated conjecture and not the drawings he references.

-

As I said above, just the process of making a cable out of several ropes would have resulted in the opposite twist.

I answered my own question in that regard.

I suppose the choice of one over the other, would be size..

- mtaylor, thibaultron and allanyed

-

3

3

-

With some thought, because a cable would have been laid up from ropes, it would have had the opposite twist of the ropes.

- thibaultron and mtaylor

-

2

2

-

56 minutes ago, allanyed said:

FWIW, confirming Greg's observation, all the breech rope in the drawings in Caruana's The History of English Sea Ordnance are right hand twist rather than cable laid.

Allan

Any idea how the lay of the rope affects the use/handling of the rope?

- mtaylor and thibaultron

-

2

2

-

On 3/13/2024 at 7:57 AM, mediocremodeler said:

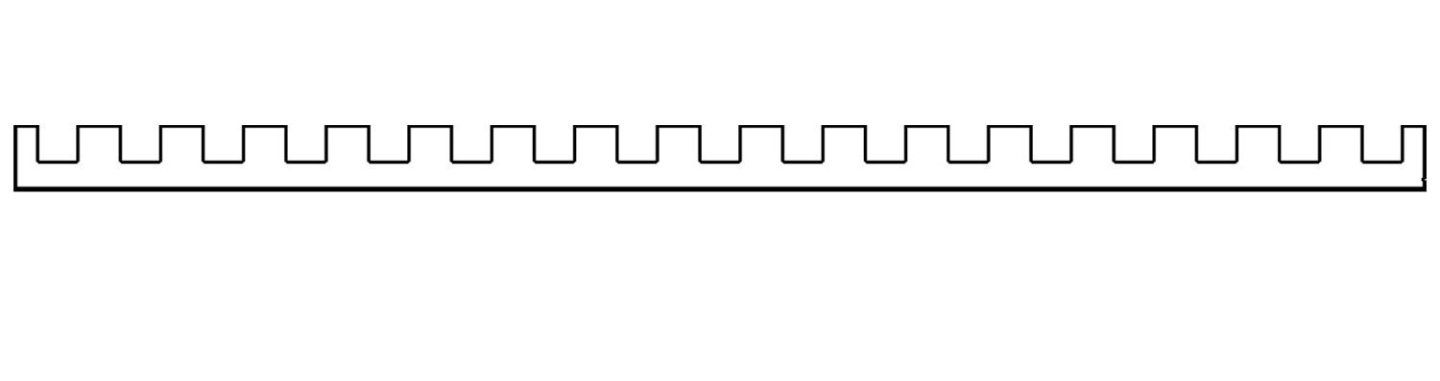

The “basketweave” can be delineated with a knife and ruler in a minute or two.

Since you have a laser, have you considered making pieces like these:

... and laying battens in the slots?

Your laser cut gratings do look good as they are. Nice square holes. Some lasers don't do that very well at these small sizes.

- mtaylor and thibaultron

-

2

2

-

Autodesk Fusion 360 is free for hobbyists, non-commercial use.

It's a little hard to find where they say it is free, but it is still there.

- modeller_masa and mtaylor

-

2

2

-

Have you tried Fusion 360 free version for your curve problem?

- modeller_masa and mtaylor

-

2

2

-

Have you looked at DrPR’s stuff? Could there be cleats in the shrouds?

-

-

Sort of interesting news story. Wreck was found in 1993 but archeologists are now taking a closer look.

Now, get this quote from the article:

QuoteArcheologists in 2021 surveyed the site and found five cannons, weighing between 6 and 9 pounds, about a quarter mile from the main wreck site.

Really.

-

-

1 hour ago, allanyed said:

Are you asking about the drawing Craig posted or ?? 😀

Thanks

Allan

It took me a while to determine that the drawings you posted are of St. Albans, 1687, a 50 gun fourth rate.

Interesting drawings but doesn't seem to have much in common with Rattlesnake. I appreciate the effort.

-

-

On 3/11/2024 at 1:47 PM, Bob Cleek said:

…..

There are relatively few knots that are requred. Once you've mastered a simple reef or square knot, a half hitch, and a clove hitch, and how to secure a line to a horned cleat you should pretty much have all you need. None are complex knots. You can find all of them demonstrated on YouTube.

Well said.. The biggest challenge is deciding which knot to use in order to “model” the look of actual practice.

- Knocklouder, Bob Cleek and mtaylor

-

3

3

-

Great idea but challenging at our level. Think “curling iron “ with a .5mm tip.

Polyester melts at about 250c. Perhaps some shaped tweezer-like tools with insulated handles that you keep in a small heated cauldron, then you use the tools and return to the heat source as needed.

-

Chuck if I may offer another suggestion for coppering the cupola.

I used copper leaf and put the part in a bag with some boiled egg to get the patina. I don't doubt that you would get a finer finish than I did with this approach should you try it.

My patina is probably a bit harsh.

-

Sorry Dave, I got sidetracked and forgot about getting you some info on what I use.

I use this soldering iron from Amazon.

..and a tip like this. It has a little dial for adjusting the temp fromm 200 to 450 C.. I use about 350 on the polyester thread/rope. A little lower might work. I would set it as low as you can and still have it melt. Too hot and it really discolors the rope.

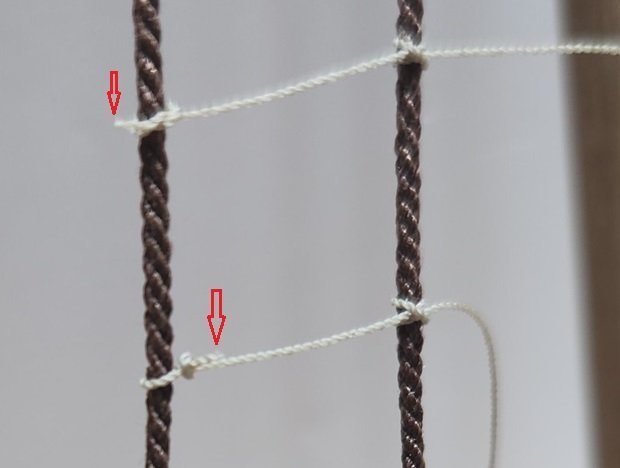

Here are a couple of different knots I made on my ratline practice jig.

The excess snipped off with a little nib left behind. that bottom knot is not as small as I would like, but I was just putting together a quick demo.

Here is after I melted the nib with my iron. There can be some dark discoloration, but you can minimize that by setting the iron as low as you can while still getting melt.

Also, cut the nib as close as you can while leaving something to melt. If the nib is too big you end up with a blob that detracts from the knot.

Needless to say, you have to be really careful not to melt any other rigging. Don't ask how I know this..

This method is good for almost any place where you want to minimize a loose end sticking out if you haven't managed to hide it in some other way.

Ship Ribbing with CAD?

in CAD and 3D Modelling/Drafting Plans with Software

Posted

Not necessarily nicer, but plywood will give you more strength for your framing. Very little, if any will be visible in the end.