-

Posts

3,076 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Gregory

-

-

Wipe on Poly works best for me by brushing then wiping with soft cloth after a few minutes. I may make any number of coats till I get the finnish I want .

FWIW, Wipe on Poly is just Poly varnish that has been thinned with mineral spirits. Maybe 75/25 varnish/thinner.

I make my own, about 50/50.

- Canute, Ryland Craze, bridgman and 1 other

-

4

4

-

-

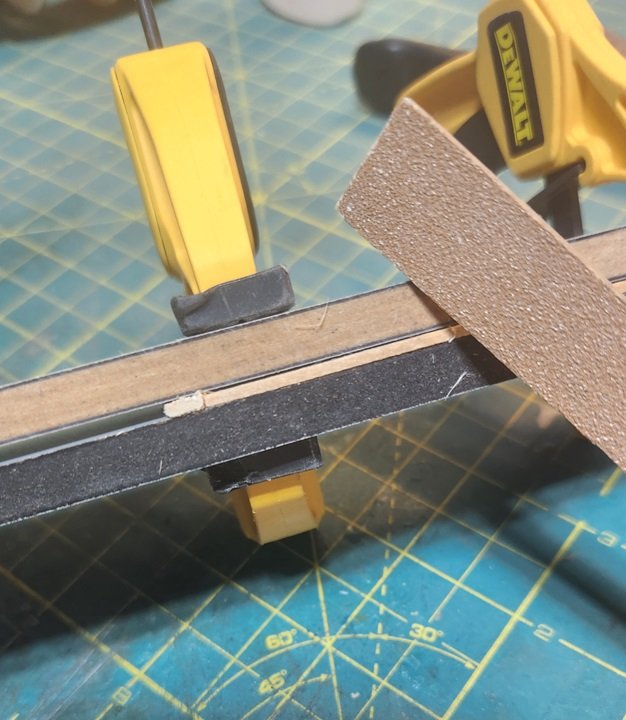

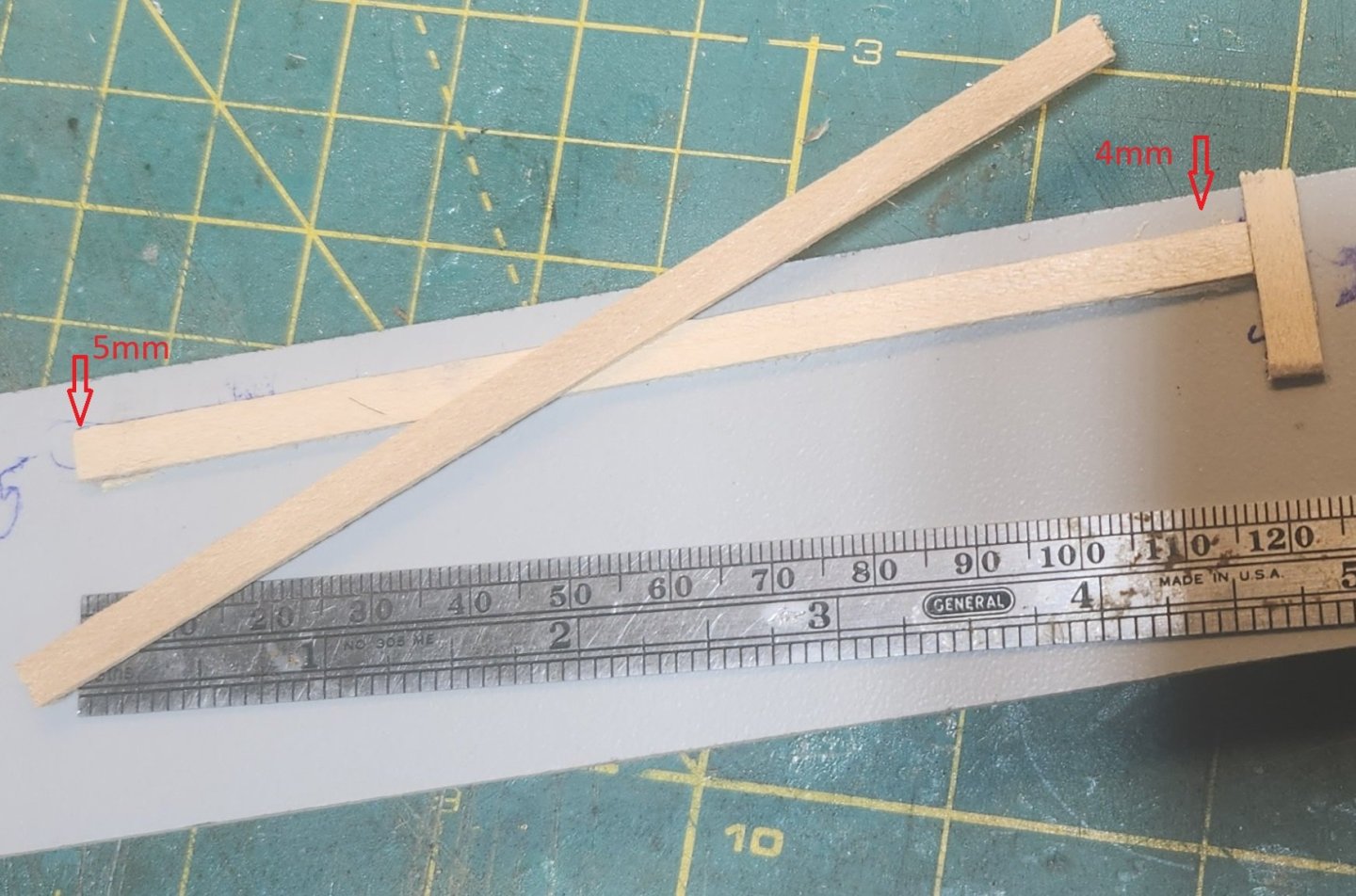

This is something I put together quickly to demonstrate, so it could be refined somewhat.

I have this real hard melame/mdf stuff, but I'm thinking aluminum might be better.

I glued ( just tacked at each end with CA, so it could be easily removed later ) a strip the same thickness and length as my target, to the MDF. The little vertical piece acts as a stopper.

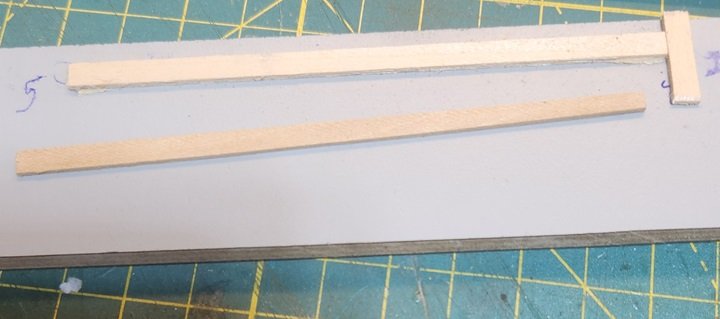

Note one end is 5mm from the edge of the MDF. The other end is 4mm. At this point you could probably just lay your strip to be tapered against the template above and trim with Xacto blade or scalpel and follow with a little sanding .

I took another option and clamped the smaller piece of MDF onto the template and trimmed from there. The target still has a tendency to move around, so you have to make sure it stays flat against the jig.

Make sure the business side of the two MDF pieces are flush.

I also thought I might screw the jig together for a tighter fit.

After the blade, I did a little sanding.

4mm On one end.

5 On the other.

Let me know if I can explain any better.

- Chuck Seiler, mtaylor, jloppermann and 1 other

-

3

3

-

1

1

-

-

-

-

-

-

Very nice.

What sizes will you be offering?

- thibaultron, Canute, Jack12477 and 1 other

-

4

4

-

Interesting subject.

The sails on the museum model look really good.

- mbp521, mtaylor and Keith Black

-

3

3

-

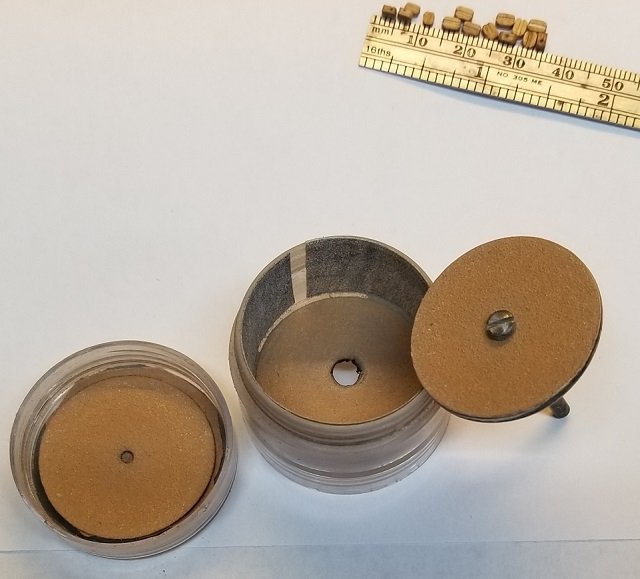

And... The results are?😁

FWIW, Here's my version.

-

If y

27 minutes ago, Dziadeczek said:Neither one, in my opinion.

Why don't you try to use a fruitwood, like cherry, apple or pear. Much better...

If you had a choice between mahogany or walnut, which is what michael101 asked about, which would you choose?

- michael101 and mtaylor

-

2

2

-

My experience is that mahogany tends to be less brittle than walnut.

- michael101 and mtaylor

-

2

2

-

We have a forum where members have discussed their CAD, 3D printing and similar endeavors.

CAD and 3D Modelling/Drafting Plans with Software - Model Ship World™

There are a lot of resources out there for getting custom work done. Just Google " 3d printing services " and " photo etching services " .

There are probably other online groups dedicated to those endeavors also.

11 hours ago, poleprince said:I am not able to create the CAD drawings that would be needed for these parts.

It may not be too late. Check out Fusion 360 .. It's free for hobbyist.

This guy has some really great tutorials for beginners. Product Design Online

If you use a 3rd party 3D printing service you can probably save a lot by having 3D drawings ready to go.

For photo etching, 2D should be all you need.

-

-

-

What is your method for annealing the brass?

If you are heating it with a torch, you might consider treating it with Birchwood Casey Plum Brown. It gives a nice dark finish that doesn't come off easily.

- mtaylor, Canute and SiriusVoyager

-

3

3

-

On 8/2/2024 at 2:32 AM, amateur said:

at smaller scales ratlines are almost always over scale

Good point.

This can be distracting on an otherwise excellent model when the knots scale to something about tennis ball size or bigger.

Ratlines on Victory.

Lees says ratlines are 1.75" circumference. About .5" diameter.

This scales to .01" at 1:48. At 1:64 its close to .008"

The smallest rope at Ropes of Scale is .009, so this would be a good match at 1:48. Syren has .008 and .012. At smaller scales you are looking at single strand thread to get a reasonable scale match.

On 8/2/2024 at 2:32 AM, amateur said:....at smaller scales a half hitch, or even no hitch at all (ratline through the shroud using a needle) can be visually better.

This is a good option. One might also consider just glueing the ratline to the shroud. A little blob of glue will look like a knot.

- Ronald-V, dafi, BLACK VIKING and 1 other

-

4

4

-

-

On 7/25/2024 at 4:40 PM, GGibson said:

I have to admit I'm clueless on what era/type of ship utilized the fiddle blocks and if they were used for a specific purpose.

They show up on rigs from the 17th century to present.

It is my understanding they do the same work as a double, but their shape is better suited for some applications.

They are often used in the vangs for gaff rigs.

Here is one in a back stay for Cheerful.

- Archi, Jay 1, chris watton and 9 others

-

12

12

-

Good answers from Johnny and Dziadeczek.

Just to clarify, here is a contemporary ' expansion drawing. This is Podargus (1808)

This shows the actual shape of the planks laid out flat. This illustrates why Chuck's bending method results in the planks laying flat against the bulkheads

-

-

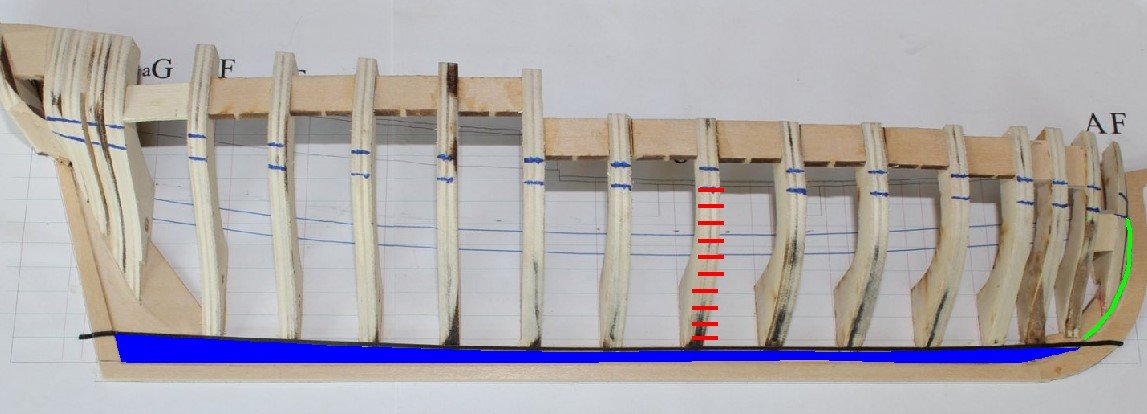

A good start might be to read about setting up the garboard.

The half hull planking project is a good reference for establishing the garboard and planking in general.

I borrowed this image from the Half Hull Project. The blue area is the garboard. The red tick marks show the width and number of planks at a mid-ship bulkhead. In this case there are ten. Which may or may not be the actual number of planks. I am just trying to illustrate.

You then have to measure the distance indicated by the green line. This is the space available for the same ten planks at the bow/stem.

Lets say that the planks are 4mm wide, so the area at the red tick marks would be 40mm. Lets say the green line measures 30mm. Divide 30 by 10 and you have 3mm.

So, your planks need to taper from 4mm at mid ship to 3mm at the bow.

Chances are you won't have the same easy measurements, but I hope the illustration helps.

- mtaylor, Paul Le Wol, tmj and 2 others

-

5

5

-

The iridescence is probably due to the oil content, which is common in tropical hardwoods. You might try rubbing with mineral spirits to help reduce the shine.

- SiriusVoyager, mtaylor, tmj and 1 other

-

4

4

OcCre Bounty Launch – frames perpendicular to false keel & glue?

in Building, Framing, Planking and plating a ships hull and deck

Posted

A common tool for squaring bulkheads to false keel are small leggo blocks. Clamp them in place till the glue sets.

Here is an example from another members build. Your model might require a different arrangement, but the principle would be the same.