-

Posts

372 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by PRS

-

-

-

- Gregory, niwotwill, GrandpaPhil and 8 others

-

11

11

-

So I ordered the saw Monday night and received it Friday from Home Depot.

I also ordered the other two different blades for it. The Super Cut and the Fine Cut blade.

This saw works pretty good and using the fine tooth blade is will be able to cut planks. The super cut is a weird blade and not sure what to use it for.

Now I did use the fine toothed blade to cut some MDF and completely ruined the blade. Lesson learned on my part.

I did make a crosscut sled and it works well. Having a table saw will be a game changer for me now as I can cut what I need and also cut many pieces to the exact same length when I need it.

-

Ontario checking in. Welcome!

- Keith Black and mtaylor

-

2

2

-

- Matt D, Nunnehi (Don), GrandpaPhil and 6 others

-

9

9

-

-

-

Thanks for the opinions everyone.

Yes I would get the more expensive Brynes saw but look at it this way.

$450 plus 30% exchange and then 15% duty and then shipping puts it out of my price range. Sorry I didn't specify that at the start of the question.

12 hours ago, tkay11 said:I love my FET. I have had it for 9 years and it's still going strong. It is very much used by other European modellers too, including the prize winners and the most accomplished, and you'll regularly see superb builds on this site where the FET has been used.

You can get lots of blades for it, especially if you buy the MicroMark saw blade adapter (item #83515) for the size of the bush. And the accuracy is very high once you have learned all the quirks of its main parts which are best done in a sequence. I can easily get mine to a tolerance of 0.1mm.

Of course, that alone doesn't make you a great modeller, and I am still learning. But it won't be because the saw doesn't work properly. Proxxon's backup service is also great.

Tony

I really appreciate that and you helped me make up my mind. Wanted to make sure it was decent and not a pile of junk.

Everyone here has been really helpful.

-

Before everyone tells me to buy a Brynes saw it is far too much for me to spend in Canada.

Home Depot sells the FET for $398 and would like input from people that have one and how it works out for them.

Since this has 4 inch blades it will work for what I want to do which is ripping planks and such. I did look at the cheaper Proxxon and also the Micromark saws but then cheap Proxxon has a 2 inch blade and doesn't have a full fence.

-

-

On 9/9/2021 at 7:16 PM, Nunnehi (Don) said:

That’s just beautifully done!

Don

Thank you very much Don.

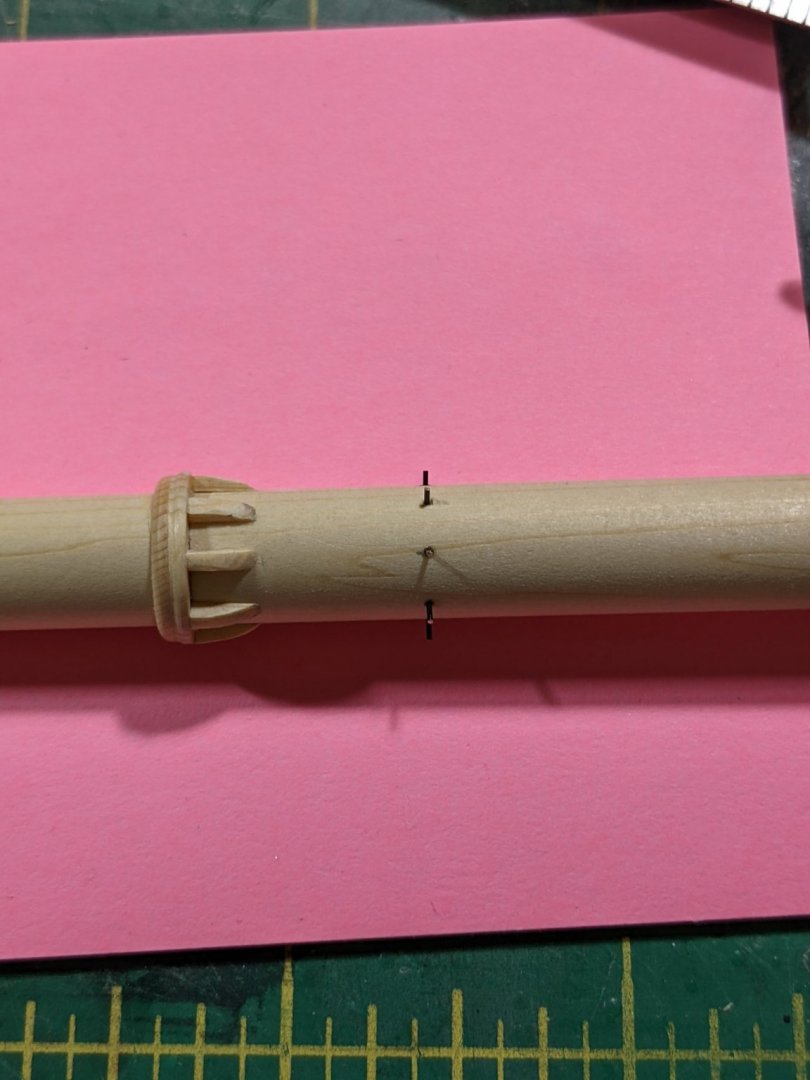

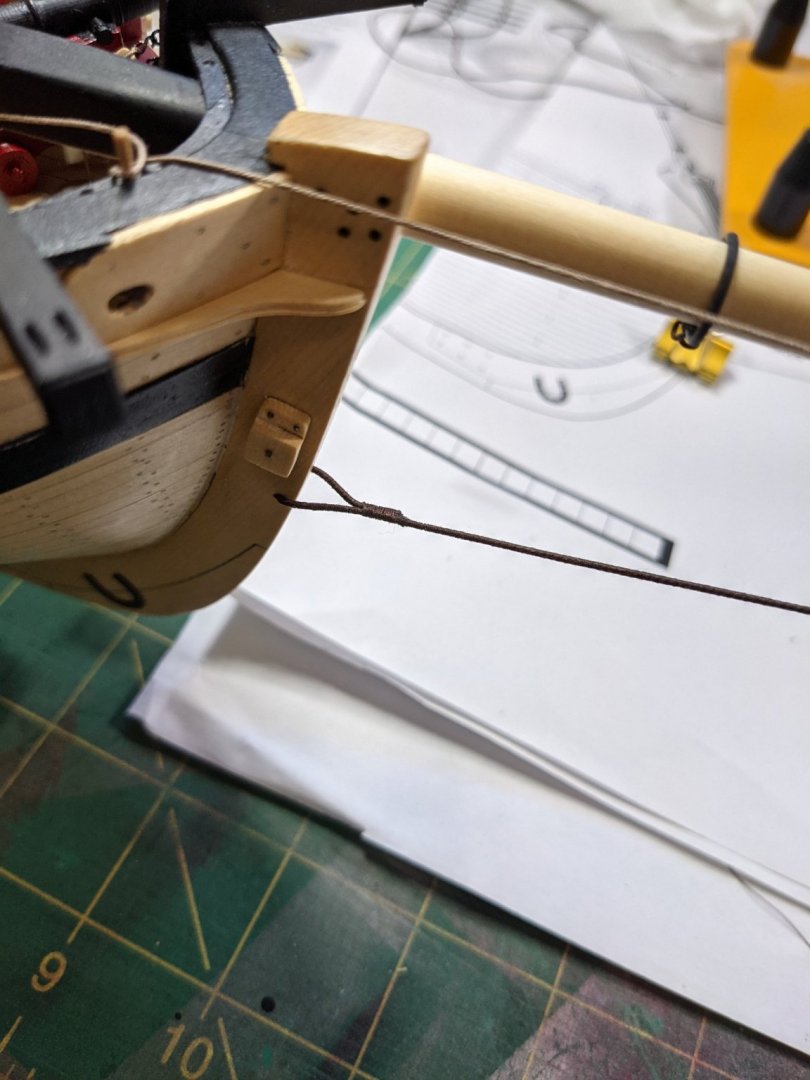

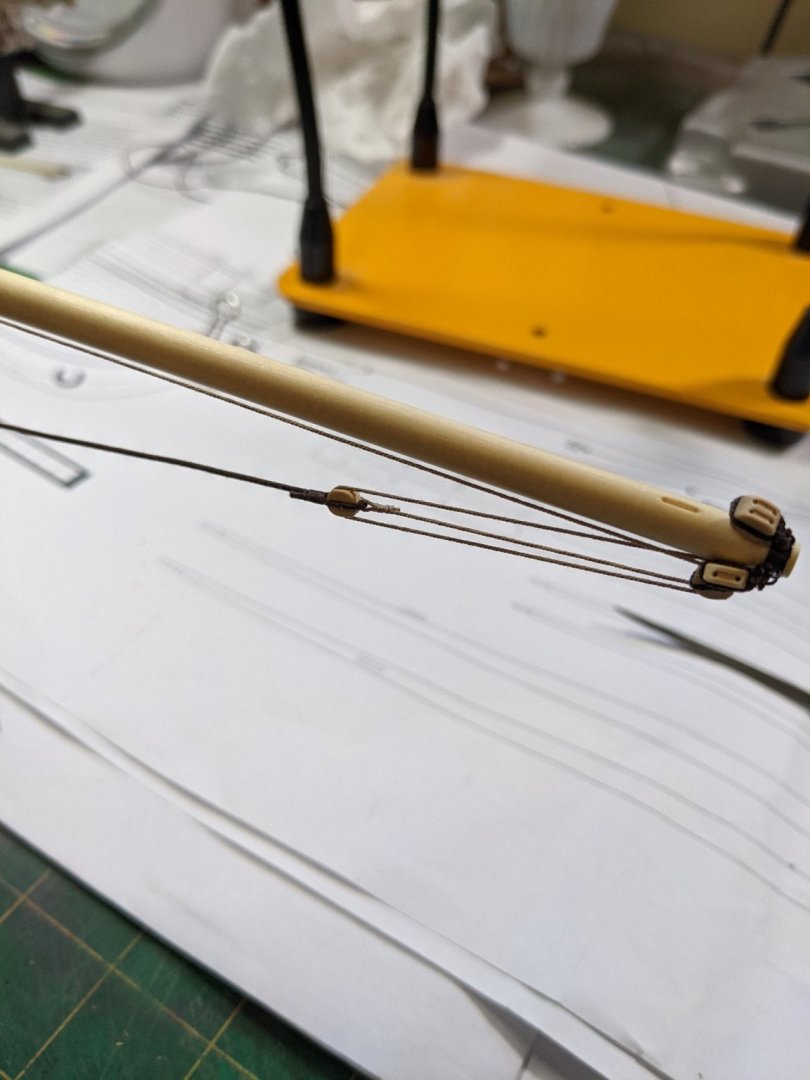

On 9/10/2021 at 1:06 AM, glbarlow said:I believe the shoulders on the mast should be thinner and flatter per the plans, but it's your model.

Nice work on the stop and chocks - it's hard getting all that stuff to line up right, well done.

Yes it was easier using the tic strip though and using the wires.

On 9/10/2021 at 12:24 PM, Chuck said:Beautiful progress!!!

Than you Chuck.

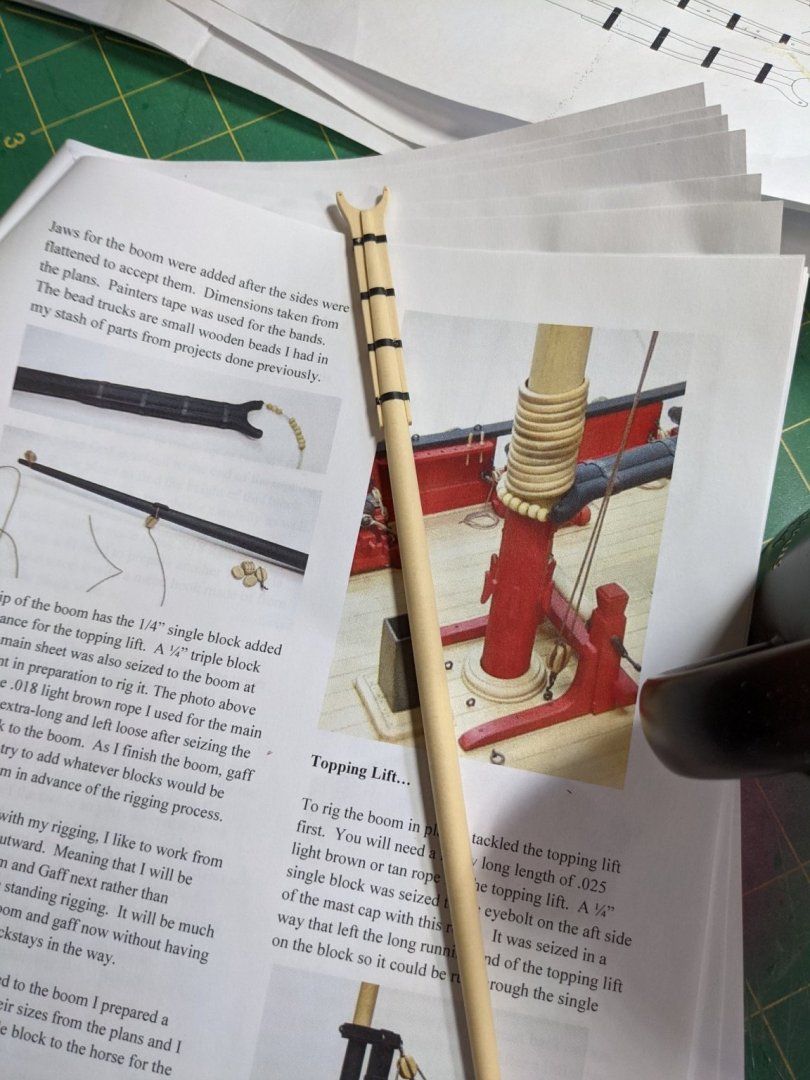

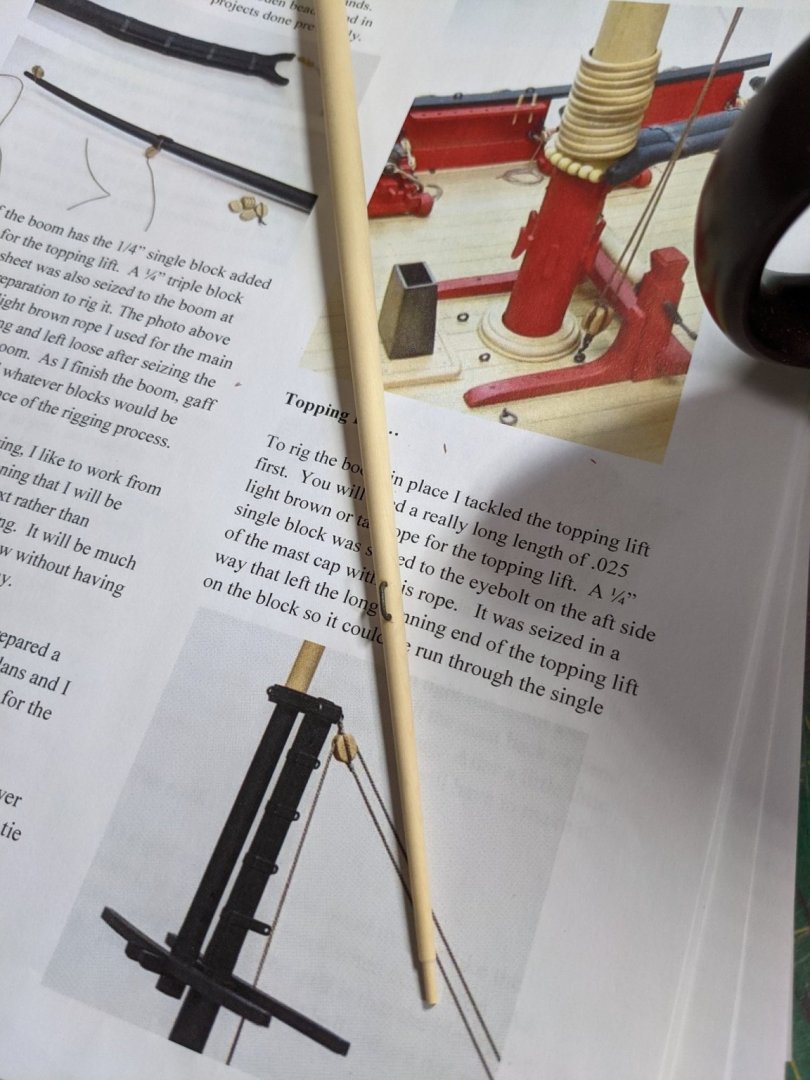

Making the boom. I love the smell of cedar shavings.

- BobG, GrandpaPhil, muratx and 2 others

-

5

5

-

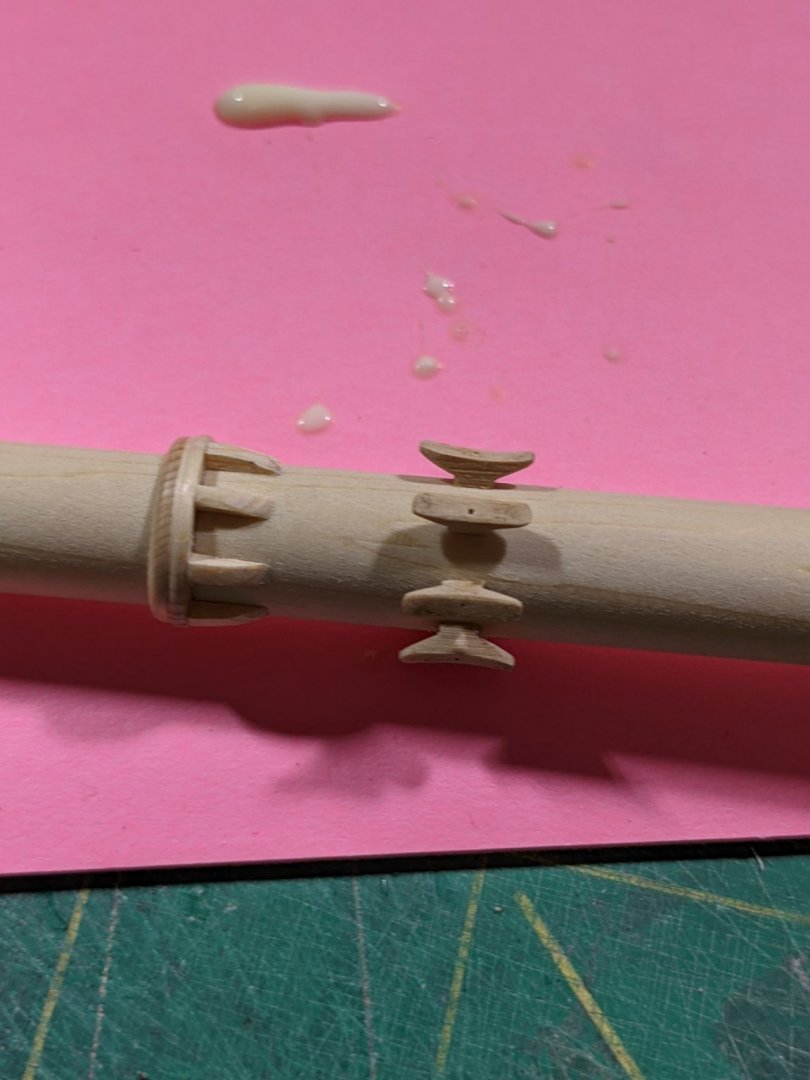

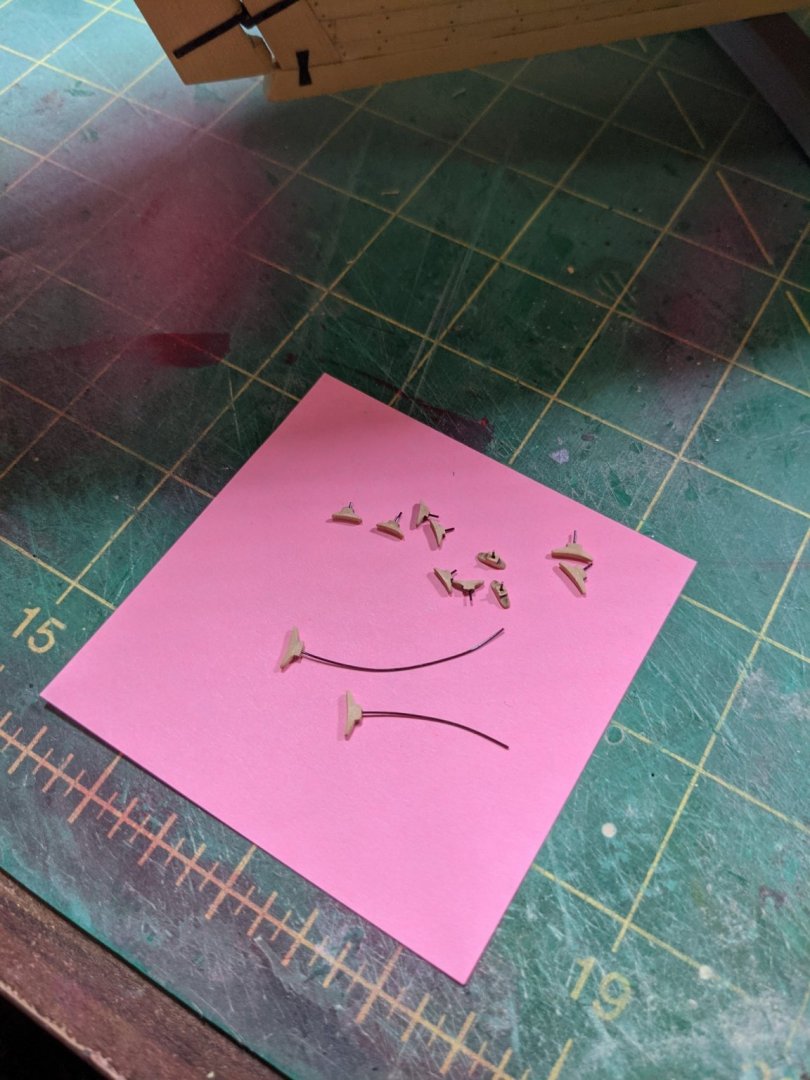

Working on the mast I made the stop for the rings. This is the second one I made as the first one broke too easy. This time I made a boxwood sandwich with the grain 90 degrees and it held up better.

Also used a tick strip to mark the locating holes for the cleats.

In these hole I glued a small piece of wire and also drilled locating holes in each cleat in the center.

Once the cleats were shaped a bit they were glued on trying to get them square.

Getting back to my question I had I decided that the pieces at the top of the mast should be beveled to form with the mast.

I think this looks better.

So the lower mast is done except for painting and some finish sanding and yes the rings still slide down over the top pieces.

-

One thing to keep in mind when airbrushing is the quality of the paint has a lot to do with how small the pigments are ground.

I have found that Vallejo has finer pigments than Tamiya paints but they are harder to clean out of the airbrush.

Tamiya Acrylics are very forgiving when airbrushing as they lay down nice and smooth and you can just about use anything as a thinner for them where the Vallejo cover real well and you have to use their thinner or the Tamiya Acrylic thinner. (don't skimp on thinner by trying to use water or windshield washer fluid as some suggest).

If you decide to up your airbrush game get a compressor with a tank. There are a lot of them on Amazon or since you are in the states TCP Global is a good source.

A dual action airbrush will be up to you what you want to spend but stay away from chinese brands. (I am looking at you Iwata NEO with your expensive replacement parts). The rest of the Iwata line are good airbrushes but pricy. Currently I am using a Badger Patriot and it is a great quality airbrush that comes standard with a .5 tip but they also have a fine needle kit for it also.

-

- JpR62, Ryland Craze and GrandpaPhil

-

3

3

-

-

- GrandpaPhil, muratx, niwotwill and 8 others

-

11

11

-

- CiscoH, JpR62, Ryland Craze and 4 others

-

7

7

-

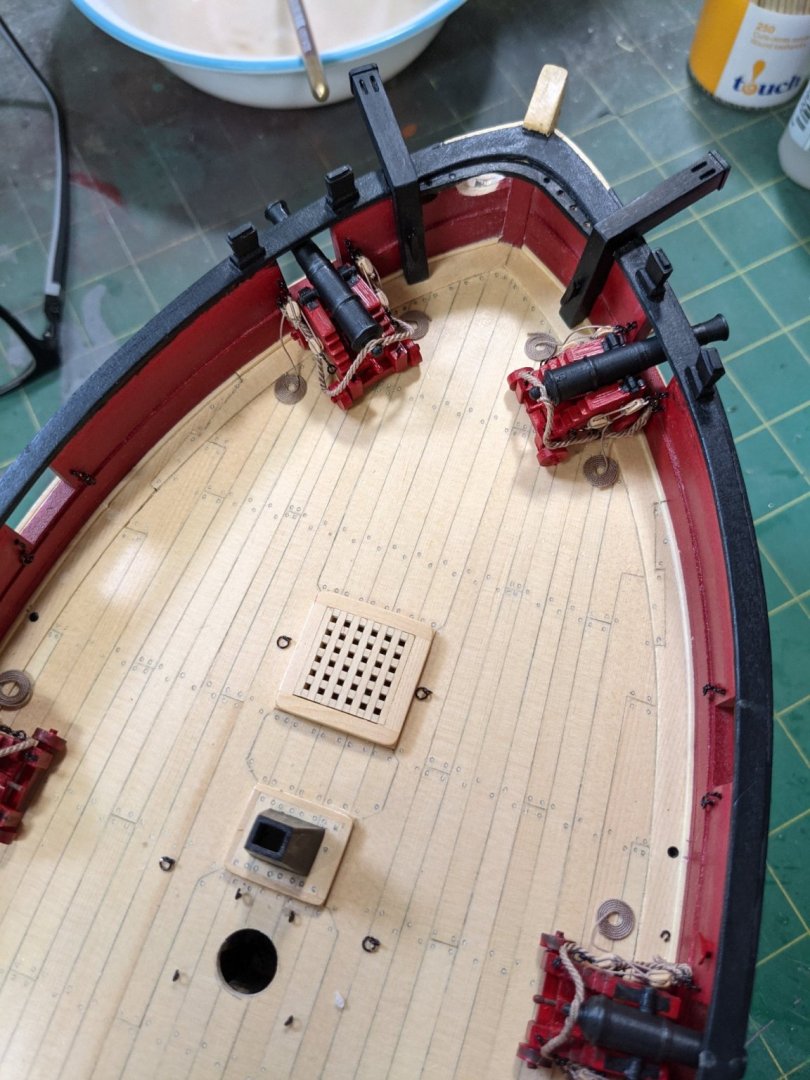

So I redid the deadeye stropping as I didn't like the way it was.

First used a 1/4 inch drill bit and wound some coils with 22 gauge wire.

The cut out the coils with flush cutters.

The soldered the ends together and with pliers made up the hook on the bottom. You will need a lot of these as they do pop with pressure.

Here are the eight I redid. It took about 3 times as many coils until I got the eight done.

Once they were installed I touched up the black paint.

- GrandpaPhil, Ryland Craze, muratx and 2 others

-

5

5

-

Thanks everyone for the comments and likes.

I have the chainplates done and the deadeyes stropped.

One issue I am having is the end of the 22 guage wire for the stropping is inside the chainplates and it is springing back and doesn't want to stay tight and the deadeyes come out easy.

Not sure how to remedy this or have the "seam" at a different spot instead of the bottom.

These deadeyes are Chuck's new ones that you don't have to make and they really look good though.

- BobG, Ryland Craze and GrandpaPhil

-

3

3

-

10 minutes ago, niwotwill said:

I haven't read this far in the monograph so I can look forward to the fun. Very nice process and the results look good. Soldering is the way to go and how will you blacken them?

She's coming along nicely and looking good.

I agree with soldering.

I will paint them black after using automotive grey primer. Just not sure how to hold them for painting yet.

- Ryland Craze, glbarlow and BobG

-

3

3

-

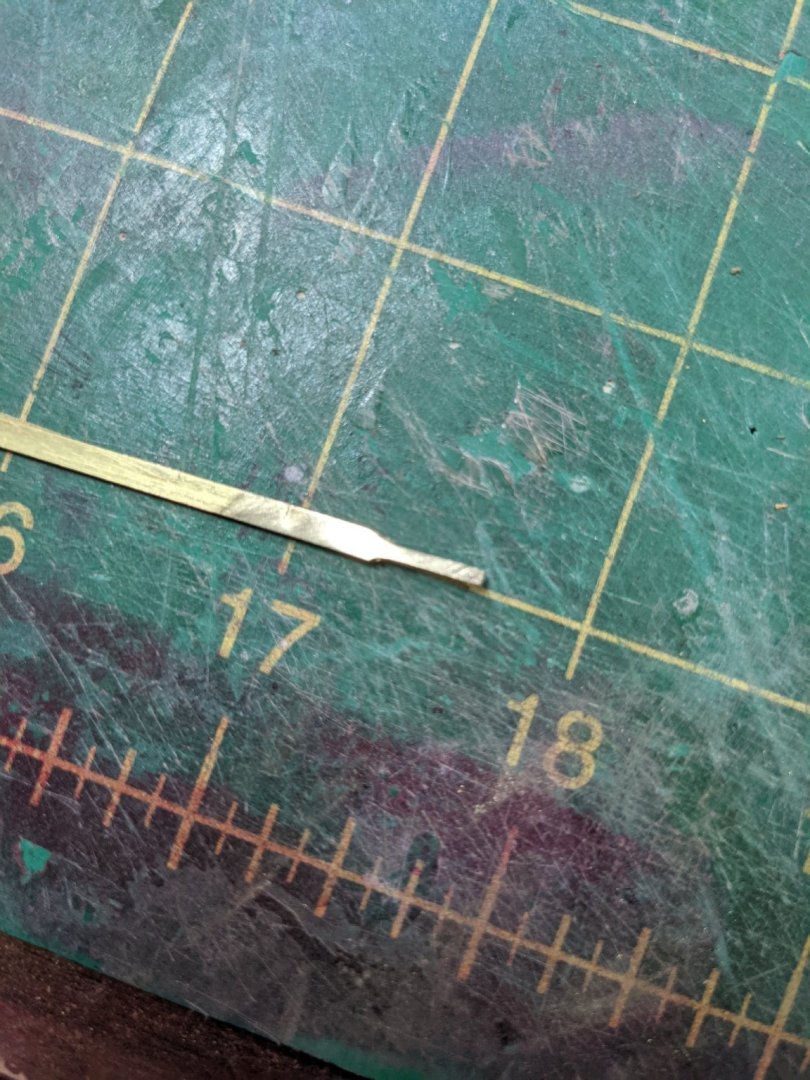

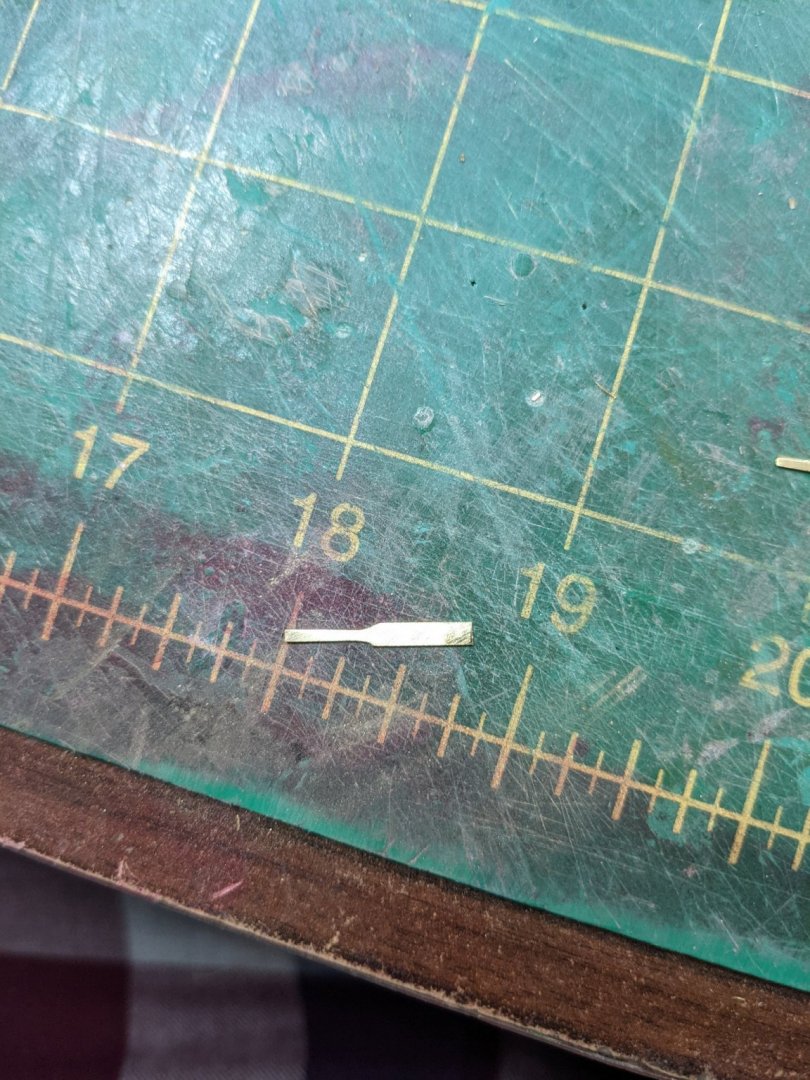

Started making the chainplates.

How I did it is a little backwards that what Chuck says to do but I found it easier.

First I ground down the part that will be bent with the dremel holding the piece with pliers as they will get hot.

Then finish filing the end to make it even and mark the length.

Then cut to length.

Round off the bottom and drill the holes.

And before bending the end I want to heat it up until it changes color. This way it softens the metal so it bends easier.

Then bend it around a round wire. You can see the color difference from the heat treating.

I haven't decided if I am going to solder the end or glue it. Once I finish all of them I will probably solder them.

- GrandpaPhil, Ryland Craze, muratx and 3 others

-

6

6

-

- GrandpaPhil, BobG and Ryland Craze

-

3

3

-

- niwotwill, GrandpaPhil, BobG and 6 others

-

9

9

-

(1)(1)(1)(2).thumb.jpg.792ad774561d3d4f35888704cde27a8e.jpg)

Proxxon FET Inquiry

in Modeling tools and Workshop Equipment

Posted

Thanks. Good information to have.