-

Posts

1,280 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Dave_E

-

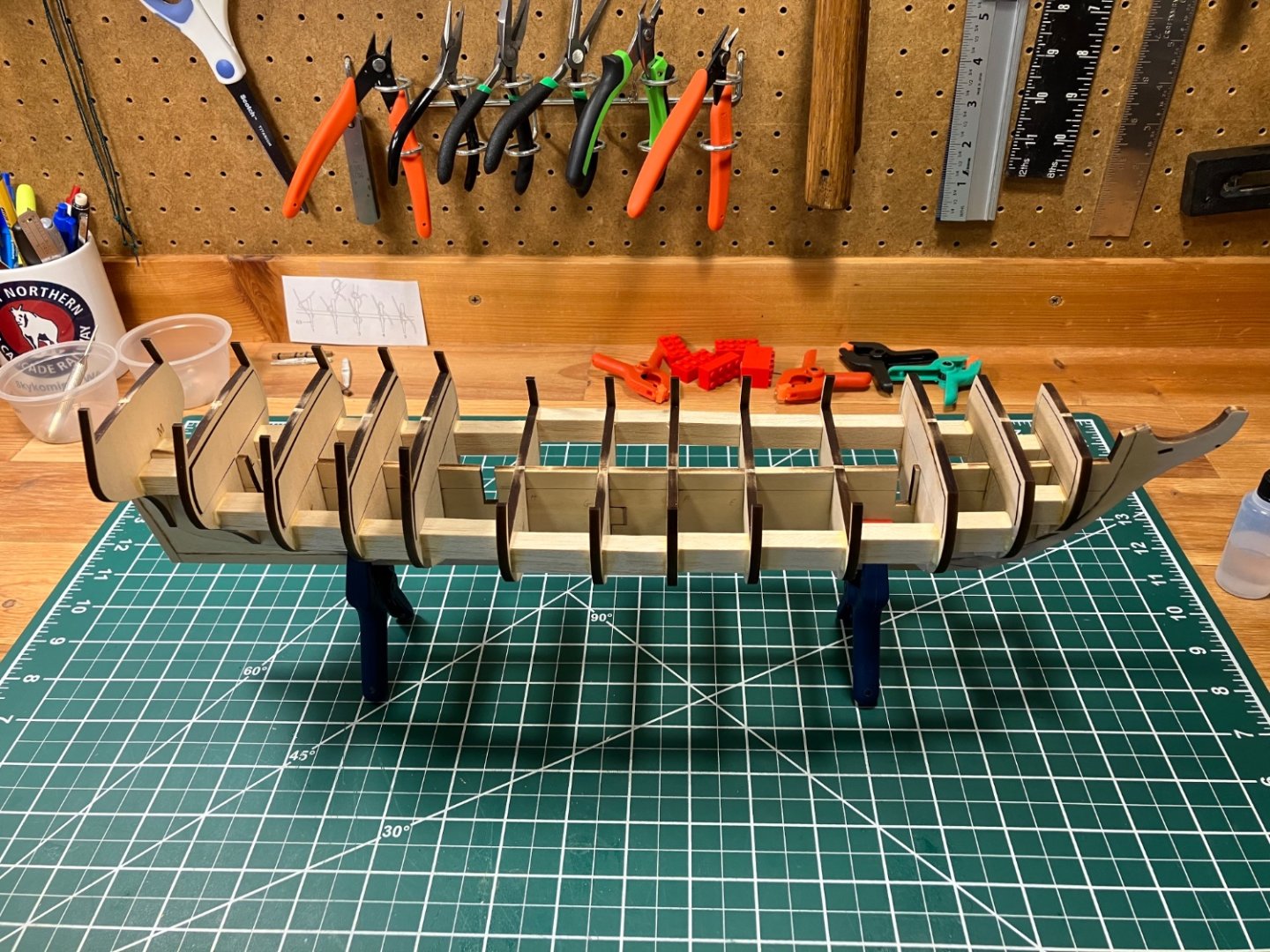

Hi All, I think I can call the skeleton complete. I have to agree with the other comments about the bulkheads being flimsy (bass wood), so I did what others have done and stiffened them up making sure the keel was straight. I’m also glad I did not precut or shape any of the bulkheads for planking. You can really tell the difference just handling it.

-

Hi Ken, how’s the build coming along?

- 152 replies

-

- rattlesnake

- Model Shipways

-

(and 1 more)

Tagged with:

-

Superior attitude to have before you even get the next kit for sure! On top of all the advice on what to build next… browse through the build logs, something may just jump out at you. That’s how I ended up with the Rattlesnake for my second build. What’s you name?

- 89 replies

-

- Enterprise

- first build

-

(and 2 more)

Tagged with:

-

Welcome aboard Fox. Feel free to look at my Lady Nelson build and ask all the questions you want. I did, that’s how you learn and grow in the hobby. 👍😀

-

Congratulations Sir! Outstanding! Now… what’s next? 😁

- 89 replies

-

- Enterprise

- first build

-

(and 2 more)

Tagged with:

-

Hi Jason, welcome to the forum. 👍😀

-

Thanks John, Just my .02, but I thought the same of my planking on the Lady Nelson and afterwords thought “show me a perfectly planked ship (in real life) and I’ll show you a museum piece”. After all the wooden recreational and fishing boats I’ve seen (even the Lady Washington), planking imperfection seems to be part of the game, especially over time. Your bulwarks look fine! 👍😀

-

Hi John, welcome to the forum! 👍😀

-

Hi Kale, welcome! 😀

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.