-

Posts

8,061 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by allanyed

-

-

5 hours ago, DaveBaxt said:

My primary reason for buying , was for the construction of the Frigate Minerva and learning something about plank on frame and scratch building.

HI David

I have 17 photos that I took of the model of Minerva (38) 1780 at Preble Hall in Annapolis and would be happy to send them your way if you wish. The description card they had for her in 2011 follows as well as a closeup of her planking at the bow.

- mtaylor, GrandpaPhil, davec and 1 other

-

4

4

-

-

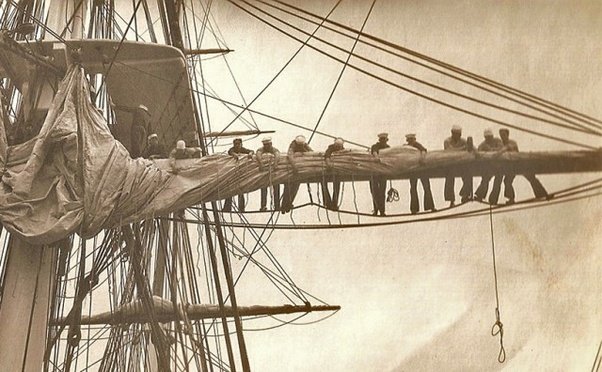

Very interesting point and your test group is a great idea. To add to any confusion that there may be James Lees mentions that the footropes or horses were 2 feet under the yard on page 69 of The Masting and Rigging of English Ships of War, but then on page 70 goes on to say that the stirrups should allow the footropes to hang 3 feet below the yard. Looking at the photos below, this makes some sort of sense. Where as the stirrups were probably pretty much the same on a given ship, not all seamen were the same height so maybe topmen assignments were partially based on their height just as strength was a consideration in assignments. The below are photos thus obviously more modern times, but may fit the discussion. Hopefully the sailors between the stirrups were the taller ones. 😀

Allan

- dafi, paul ron, Keith Black and 2 others

-

5

5

-

Overall really nice model and your metal work is some of the best we have seen. For the future, in the past couple years, thanks to builder/author Ed Tosti, for some parts I have found copper to be better suited than brass. It solders very nicely and can be blackened instantaneously after being fixed in place on the model with diluted liver of sulfur then rinsed without staining the wood.

Allan

- Scottish Guy, John Ruy and GGibson

-

2

2

-

1

1

-

On 4/7/2024 at 4:16 AM, Firs49 said:

Looks like lots of sanding and filler ahead.

Post #31 from Ross is spot on. If you take his advice you will be happy with the result. The main thing is to be sure you do not get the lifting from excessive edge bending so there is not excessive sanding needed.

Allan

-

On 4/6/2024 at 7:28 AM, DaveBaxt said:

There is also an additional 2 holes for the outer eybolts for swinging the cannon fore and aft.

This is really interesting and great that you included it as it is not often seen. Lavery discusses it briefly in the Arming and Fitting of English Ships of War on page 143. He states that by an order of 1779 additional eyebolts were to be fitted between the ports to give extra leverage to the side tackles, when the gun was being trained. It is not clear to what extent this order applied, or how long it lasted.

Allan

-

Sorry to ask, and I really am not trying to be obtuse, but what is this shaft? Your topic is laser cut cannon brackets so I'm totally confused.😕

Thanks😀

Allan

- thibaultron and mtaylor

-

2

2

-

Bonjour Alain

WELCOME TO MSW!!! It would be nice if you posted a little intro in the new member forum here at MSW. I don't think you are supposed to post your email address. I am sure a moderator will remove it as you may get spammed if it is left there. If it is in your profile, members can find it or PM you.

Regarding your question, what era, what type of vessel, which mast, what nationality? Are you talking about the hoops on the top and bottom of the wooldings or the hoops to which sails are attached on a schooner for example?

Again, welcome to MSW

Allan -

On 4/6/2024 at 10:55 PM, hamilton said:

I didn't use any of the kit-supplied planking except below the wales and I also didn't use those metal gunport frames, but framed out the gunports with scrapwood..

Hamilton, Kudos for going the extra mile/km.

Tennfox, many are happy with what the kit provides, which is great, but some are interested in going a bit more in depth. The dimensions of virtually every piece of your ship is in the 1719 Establishment. Many of these are inconsequential when viewing the finished model, but some are quite noticeable. These can be found at RMG and in several books if you are interested in this kind of information for now and in the future.

Allan

-

9 hours ago, druxey said:

For the main part of the process I will loop the end of the shroud up (once it is in place over the masthead)

I will definitely try this Druxey. Am I correct to assume you do something similar with a swifter as you do for a paired shroud. With the pairs, reinstalling evenly seems like it would be pretty easy, but for a swifter is the loop at the mast head done first so it can be removed like the pairs? Or, do you find it easier to just secure it at the mast head after the deadeye is seized so it is line with the other deadeyes? (I am on the road so could not check if this addressed in TFFM IV.😀)

Allan

- Keith Black and mtaylor

-

2

2

-

BE

The Construction and Fitting of English Ships of War, pages 108-110 go into this is some detail. There were either two or four transom knees depending on the size of the ship. (He also mentions there were exceptions with some ships having an odd number of knees based on contemporary models.) In short the transom knees (standards) were to add strength to the transom as well as give support to the tabernacle for the flag staff as you show on your model. The fore and aft arm was sufficient to span 3 deck beams and the vertical arms terminated just below the taffrail.

Allan

- brunnels, Blue Ensign and jpalmer1970

-

3

3

-

Found this on line.

Creating an Original Plug

When beginning the process of creating an original plug, you must first determine the type of material that will be used. Plugs can be created from a variety of materials, as long as they are dimensionally stable. These materials commonly include wood, MDF, clay, SMC, foam and balsa. If the plug is to be made from a porous material such as wood or foam, the surface must be sealed with a resin or primer. #1041 Duratec Gray Surfacing Primer is ideal for this application and will be discussed later in this article. Plugs need to have a slight taper so that the mold can be easily removed. Typically, a larger plug will require more rigid and reinforced materials. From https://www.fibreglast.com/product/Plug-Construction-Guide

-

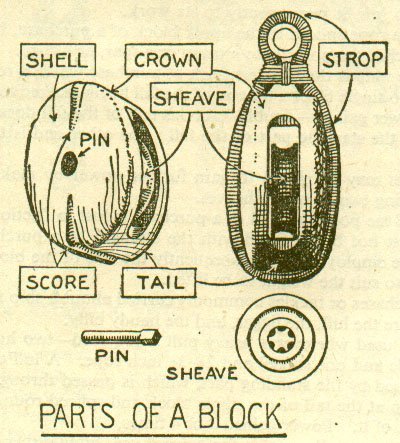

Nice work, it looks close to the below, a common single block. How did you round the edges? A block/rock tumbler is a huge time saver and does a great job if you are doing this by hand.

Allan

- mtaylor and thibaultron

-

2

2

-

53 minutes ago, druxey said:

I find black a little too visually contrasty, but that's a personal preference

I agree, burnt umber is a better choice.

Allan

- jpalmer1970, Pirate adam and mtaylor

-

2

2

-

1

1

-

On 3/31/2024 at 2:53 PM, Pirate adam said:

I used black tissue paper

I have used black tissue on deck planking with good success. For other joints such as scarfs an alternative that I have found to work very nicely is to add a drop of black acrylic paint to a puddle of PVA glue, mix and apply. These joints have held up for many years so I am confident the little bit of paint has not weakened the joint.

Allan

-

Looks like really nice miniature rope and EXCELLENT workmanship on your part.

Allan

- Keith Black, mtaylor and Freebird

-

3

3

-

1 hour ago, wefalck said:

anyone with a good tool-grinder could make such tools from round HSS-blanks.

I usually agree with you Eberhard, but on this one, not so much. 😀 The smallest U chisels would be a challenge for 99.5% of anyone trying make these. These are exquisite chisels that would take someone with lots of experience and time to make a set as well made as Mihail's. Maybe some member could take up the challenge which would be fantastic.😁

Allan

- mtaylor, druxey and thibaultron

-

3

3

-

There are several brands, Avery being the best, but maybe not worth double the price or more than others. $13.60 for 100 sheets for Betckey brand

Allan

- davec, JpR62, jpalmer1970 and 2 others

-

5

5

-

Thanks for sharing this Phil. Great model and great photos!!! I did a quick search and $75 seems to be spot on. Includes shipping with Amazon Prime so I may take the plunge. https://www.amazon.com/Speedlite-Adapter-Pentax-Olympus-Cameras/dp/B09685NGWJ

Allan

-

7 hours ago, Stuntflyer said:

with acid free rubber cement or even Elmer's School glue.

This is a great way to go. An alternative that I switched to some years ago is to print on full size sheets of label paper. Cut out the drawing of the part somewhere near the lines, peel off the backing and stick on the wood. Once the wood part is cut and sanded to the lines I find it easier to remove the paper and clean up compared to rubber cement or other glues. I do try to print as many parts as possible on a standard 8.5"X11" page to save on paper.

Allan

- jpalmer1970, davec, druxey and 2 others

-

5

5

-

I contacted Model Expo and asked what kind of wood this is. Caveat emptor

I wrote:

Is this boxwood buxus sempervirens (English boxwood) or calycophyllum multiflorum (Castello)? If not, can you please let me know what species it is? Thank you kindly for your help.Their reply is below:MessageIt is yellow in color. Other than that, I do not know. -

Good question Alan and there may be no conclusive answer. The set up appears to be a workable substitution for using a fiddle block. Based on Lees The Masting and Rigging of English Ships of War), Page 54 from about 1680 until bees were introduced on the sprit, fiddle blocks were used on the fore topmast stay with the stay tackle fall. Lees goes on to write on page 56 that the main top mast stay also had a fiddle block and the stay tackle fall. Then again, ships often had their own rendition in accomplishing a given task. By about 1745, the stay ran through sheaves under the bees sheaves to a heart of thimble. There are detailed drawings of the set up of the fore topmast stays on page 53. (see below)

Allan

-

Your build brings back fond memories of Daryl Greenamyer flying his P51D at Tonopah and then his F104 for the low altitude speed record over Mud Lake. Also enjoyed the scene at the end the movie Top Gun-Maverick with Tom Cruise flying his P51. Had the great fortune to meet and interview Daryl as I had worked for PPG at the time and we had supplied to paint for the F104 from the Ditzler division of PPG.

Allan

-

Breechings seized or tied to a ring bolt

in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Posted

Caruana gives the following description on page 384 of The History of English Sea Ordnance Volume 2.

Allan