-

Posts

8,149 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by allanyed

-

Spell Check

allanyed replied to allanyed's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

Thenk yu everryone I wonder why all three words are underlined in red on my screen😀 -

Hi John, Bluenose II carried two Caterpillar 250HP Diesels and props for propulsion. (See BNII photo below) Interestingly these gave her a top speed of 8 knots under this auxiliary power, half of what she could achieve in a strong wind with only sails. I am not sure what engines and prop sizes are on Bluenose IV. If your model has no props, it would make sense that she is the Bluenose I so the only chain would be the rode shackled to the hemp line. These would probably be no more than about 10 to 15 feet. As an aside, the following article on the transition from hemp to iron is very detailed and interesting. https://www.tandfonline.com/doi/full/10.1080/00253359.2013.767000 Allan

-

Arnold, Is your model the Bluenose 1921, Bluenose II 1963 or Bluenose IV 2007? There are many differences between them including twin 250 HP Diesel engines on the Bluenose 2 that were not found on the Bluenose. Other differences such as anchor lines, fittings, electrical apparatus and more might be considerations for your model depending on which version you are building. Allan

-

Hi Chapel, What size launch is this? I notice you have the tholes set up with two for each of three thwarts, but no tholes for two of the thwarts so no possibility of rowers to use these thwarts which would likely never be the case. Is this a kit instruction? If it is single banked they would be alternating and more likely having six thwarts, but if double banked every thwart would have a pair, not just some of them. Maybe consider scratch building a launch or other types of boats on your next adventure, it is not a difficult project. There are several current launch builds in the scratch build forum (1751-1800) as well as a dozens of contemporary drawings on the RMG Collections site and the Wiki Commons site that should help. There are scantlings available for everything from frames to risings as well, in a number of publications. I realize this is only your second build, so baby steps. 😀 It is never easy but should always be fun! Thank you for sharing your build with us! Allan

-

Spell Check

allanyed replied to allanyed's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

Test - Yep it wrked Thanks Baker Allan -

Arnold Welcome to MSW!!!! According to Howard Chappelle, Banks Schooners used hemp cable, not chain. Chain cable was used for harbor service. When chain was carried for harbor service it was stud link chain with 5 inch X 3inch links on boats more than 75 feet long so would be appropriate for Bluenose. He does not mention how long the rode is nor if it was hemp or chain. If you need to make a rode of chain, at your scale, links would be 12 links per inch. Keep in mind the links are stud links, not open links but at your scale may not be noticeable to most folks. Allan

-

Making brass parts chrome

allanyed replied to John Ruy's topic in Painting, finishing and weathering products and techniques

If you want chrome rather than paint you can chrome plate parts yourself. Might not be worth the effort compared to painting but it is an alternative. https://caswellplating.com/electroplating-anodizing/chrome-plating-kits.html Allan -

2nd rate London 1656 – the art of the shipwright

allanyed replied to Waldemar's topic in Nautical/Naval History

https://www.rmg.co.uk/collections/objects/rmgc-object-136130 for a VDV portrait. Don't know that the following will help but if her keel length was 123' 6": For the R&S, one could use the information in Goodwin's The Construction and Fitting of the English Man of War for a second rate ship. Per Deane, the moulded beam is the length of keel X 3/10 123'6" X 0.3 = 37.05 feet Depth of keel = 1/2" for each foot of moulded beam X 37.05 = 18.5" Siding of frame = 5/7 X depth of keel = 12.86" Assumimg an average space between frames of about 2" the R&S is 12.86+2+12.86+2 = 29 3/4" Someone might want to check my math just in case🤔 Allan -

Yes, making the framing for the lights is a challenge at any scale from about 1:48 and smaller. I have even used wire for an experiment at 1:196. At 1:98 the frame parts would be something like 0.01X0.015 so can be done with a good hard wood like box or someother tight grained hard wood. For the future, maybe consider plastic frames. There are styrene strips available at 0.010" X 0.02" that might work for you. It can be mortised with out breaking for a good fit of the parts. I like to make a template for each light then make and assemble the muntons and stiles on the template. Once the framework is complete you can glue a clear plastic piece to the inboard side of the finished unit then glue the entire assembly in place. Just be sure to have a ledge of some sort in the light opening to support the assembly when it is placed and glued in place. It is a challenge to be sure, but they are a very visible and noticeable part of any model so worth the time and effort to make them as neatly as possible for many folks. Allan

-

Hi Kostas Thank you for sharing your build, it is a pleasure to follow your nice work. Are the stern and gallery lights (windows) from the kit? The reason I ask is that the stern lights have nine panes in each light rather than the six shown in post #17 and I believe the gallery lights have two rows with six panes and the lower row with nine panes. I realize this may be a kit design error. Allan

-

Hi Rob Just tuned in and congratulate you on your points in post #2. You have spotted a lot of things that could use some improvements. There are a couple build logs on building ships' boats in the scratch build forum that you may find helpful. These center around a 23 foot launch but the methods can be applied to any type and size boat and as you have a thicknesser set up you will have an easy time of it. Treenails at your scale may be a challenge for the deck planking. They would be about 0.015" or less in diameter. For the hull they would be closer to 0.03" so doable but as this is POF, you will need to account for the 70 or so missing frames. For trennals, when in doubt, leave them out. Looking forward to your progress!! Allan

-

A warm welcome to you. Our youngest son and daughter-in-law ran a 200+ mile foot race in Wales last September and raved about the beauty of Wales. Hope the admiral and I get to visit there one day. Allan

-

Your photo appears to be a replica ship or modern rebuild and may not be representative of a ship that is a contemporary of the Bellona,1760. The decks were trennaled at that point in time and often sunk sufficiently to be able to be covered with a wooden piece so the trennals would not be very noticeable at full size and all but invisible at 1:48 and smaller. The trennals on the deck were typically 3/4" to 1" diameter, so at 1:48 a diameter of about 0.015. Making trennals at this diameter is a daunting task even with bamboo. I like to use trennals on the hull planking at 1:48 or larger (1.5" to 2" diameter) but very careful about what wood to use, so as to yield a subtle appearance. Too many models have trennals that are out of scale and/or have a stark contrast with the planking like in your photo so it looks like a very bad case of the measles on a model. I agree with the idea of not showing the trennals, but your not knowing where the deck frames are and with the extremely high quality of your work that would really surprise me ...... 😀 . https://www.rmg.co.uk/collections/objects/rmgc-object-81150 Oh, and lazy??? NO way a lazy builder will achieve the quality you have reached. Love your log Yves, it is fun to follow! Allan

-

Everything takes time in this hobby of ours, and I am talking years, but as you try new methods that have worked for hundreds of years, it does get easier. Not easy, but easier. Allan

- 21 replies

-

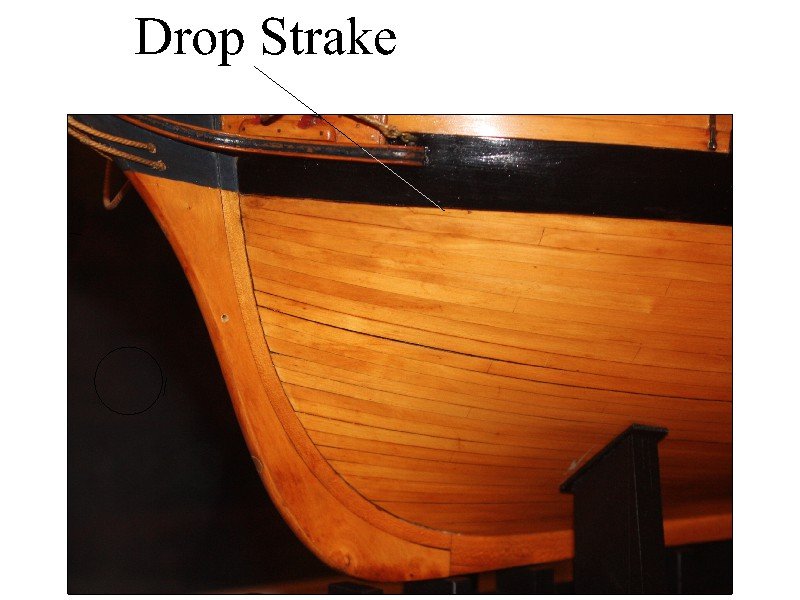

I understand that with the kits they provide pre-made strips of wood so spiling is not possible. A great alternative is to use the method in the videos by Chuck Passaro. You can use the strips they provide in the kit and still taper them as would be normal on a ship and preshape the edge bend with heat or water and heat. The method works beautifully for most species of wood. Look at the below and you will see what a properly planked hull looks like with the tapering as well a drop strake at the bow and a stealer at the stern. Also, note that the garboard strake next to the keel does not ride up the stem, but rather, it ends at the boxing joint. It may seem like a lot to digest, but one step at a time will work for you. Once you have done this it will make a lot of sense and it will be easier on following projects. Allan

- 21 replies

-

If you study the tutorials mentioned above and some of the many build logs here at MSW you will see there is no need for nails and all the problems that come with using them. Allan

- 21 replies

-

PCA Belated welcome to MSW!!! Have you studied the tutorials here on proper planking techniques? If you take some time to study the article by David Antscherl in the articles data base here at MSW and the Youtube videos on the internet on planking by Chuck Passaro, both of whom are expert model builders and members here, you will learn a lot that will carry forward. You mention white glue. Maybe consider yellow PVA (carpenter's glue) White glue may not be the best choice. Allan

- 21 replies

-

Success (of sorts)!! The following contemporary photo of a 38 gun frigate of 1805 and the second photo of the Lowenstat (32) 1761 show no signs of blocks or deadeyes. I agree, deadeyes seem like overkill. There are probably more on the RMG site but using it is not as user friendly as in the old days, at least not for some of us.😕

-

Nice work all around Dave. You model brings up a question that I don't think has been answered before, based on contemporary information. You show 8 deadeyes to secure the lines holding the upper tier of ship's boats in place as well as a simple tie down for the lowest. Were deadeyes, blocks, or just ropes and eyes with a simple tie down normally used? I have seen a number of photos of contemporary models showing boats but only one so far that has ropes holding the boats in place and that is a simple tie down much like what you used for the lowest boat. I have no idea what the usual method was, but would like to know for future use. Thanks for sharing your build! Regarding Diana, all those different types and sizes of boats will be fun projects in themselves!! Allan

-

Amongst the nicest gratings ever posted at MSW. Very well done!! I am not familiar with Pegasus, but do the corners of the coamings and head ledges get rounded above the top of the deck line? Enjoying following your build, thanks for sharing. Allan

- 889 replies

-

Sergal HMS Bounty.

allanyed replied to mark j's topic in Building, Framing, Planking and plating a ships hull and deck

As this is your first build, maybe consider setting it aside for the time being and start with something that will teach you the basics that will carry forward with more complex projects. There is a lot of agreement here at MSW that one of the very best starter series is the three boat set designed by David Antscherl available at Model Shipways. Your choice of course, but something you may want to consider. Too many folks new to the hobby start with a kit that is too complex for their experience and they sometimes give up the model and hobby as a result. Fear not, we have all failed at times in this hobby of ours. Learning from our own mistakes is a huge part of the hobby. And don't be afraid to spend as much time researching your ship as you do making sawdust, including reading the many fine pieces in the Articles Database here at MSW. Allan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.