-

Posts

6,664 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by wefalck

-

Ketih, I am using a really cheapo laser-cutter. The input are b/w JPEGs, which are converted to pixels and when it finds a black pixel - zap! This conversion and perhaps the mechanical resolution of the stepper-motors limit the efective resolution to 0.1 mm. This means that the 'planks' are only about 7 pixels wide at their widest part, tapering down to about 3 pixels at the ends over a distance of 200 pixels - so steps are programmed in

-

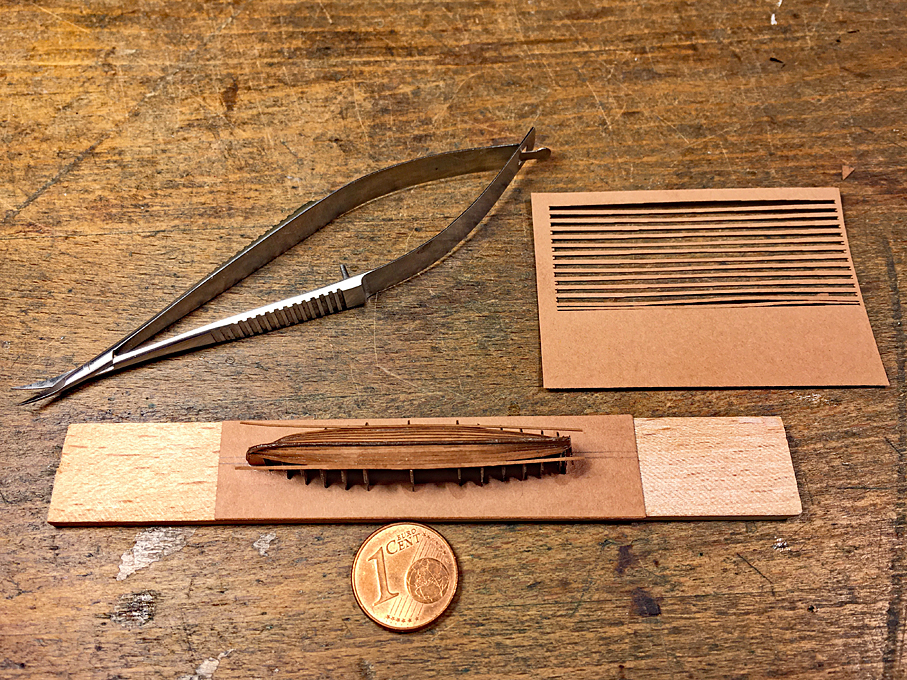

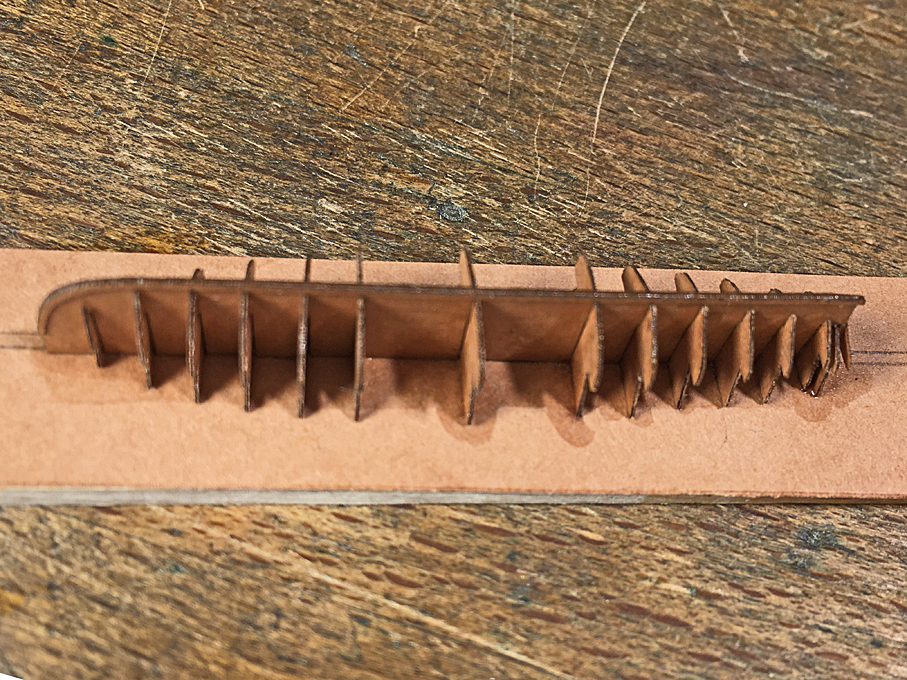

Thanks, gentlemen, for the encouragement - much needed Pat, the gig will be represented cover, so no need to worry about the internal structure. There will be only one small boat shown uncovered and I have to think about that construction. I first have to check, whether for this bent or sawn frames were used. ***************** Planking the Gig Just a little update on my efforts to plank the gig. The framework was fixed to a piece of wood to keep in shape and for ease of handling. The ‘planks’ were laser-cut from Canson-paper as indicated earlier. Unfortunately, I do not have a software (yet) to develop a planking layout, so the planks were tapered, but straight and all of the same size. However, when wetted with varnish, the paper, unlike wood, can be relatively easily bent and shaped across the wide side of the plank. Planking in progress When laser-cutting the planks, I ran into a small glitch, that is the outside of the planks have such a shallow curve, that the ‘stepping’ due to the 0.1 mm resolution of the cutter becomes quite pronounced. I hope I can remove this later by sanding. When fitting the planks, I found the best way was to fix them in the middle first and then work towards the ends. This is not ideal at the bows, where the plank has to run against the rabbet. Paper as such cannot be sanded for a close fit. I cut them as best as I could with my micro-scissors. When soaked in varnish, the paper can be moulded and squeezed, so that I did not need to thin the overlapping part of the lower plank, which would have been quite impossible in paper. Planking progresses from the middle to the ends Finally, the hull will probably require some touching up here and there with putty. Let’s see how it looks in the end with some paint on. To be continued ....

-

HMCSS Victoria 1855 by BANYAN - 1:72

wefalck replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Pat, it is difficult these days to name suppliers. In watchmaking, the spade drills are also called pivot-drills and they are in principle available down to 0.1 mm. Some 30 years ago I bought a few in a local (Nottingham) watchmaking supply shop. The straight fluted ones are also called EUREKA-drills after one brand. Not sure that they are still made. The Internet does not turn up much useful. I think they were available down to 0.3 mm diameter. I can post a question re. suppliers Down-Under on a watchmaking (tool) forum, where I am also a member.- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

wefalck replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks for the link to the pics, Pat. I didn't realise, that you were talking about those lugs, I thought it was the spider-band for belaying pins. As someone suggested above, spade drills would be a good option to drill thin brass. Not sure, where you would find them Down-Under. There are also straight-fluted drills for watchmakers, but they tend to be expensive and even more difficult to find.- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Pre-confectioned paint did not come onto the market until about 1860 and then it was originally mainly anti-fouling paints. For everything else, the components, that is pigment, medium (mainly lineseed oil), and thinners where supplied separately. Paints were mixed adhoc according to either prescribed recipies or whatever the bo'sun saw fit. RN ships were supplied with an annual dotation of material and were expected to make due with them. If the captain was prepared to pay for the materials, there was a certain leeway for colour-schemes. On the merchant ships the colour-schemes were pretty much determined by the local fashion of the period. Overall, it appears that around the middle of the 18th century ship became more colourful, with wales painted in different colours, coloured bulwarks inside, coloured spars and or spar-tips while masts and parts that may have seen chafing were only oiled. After the middle of the 19th century paint-schemes became more sombre, with black and white dominating. It seems that black hulls became more prevalent due to the increasing contamination of harbour waters by oil and soot from steam-ships. Around European waters in the first half of the 19th century, it seems to have been common to have had inside bulwarks, deckhouses, spars or their tips and doublings painted in either pale green, pale blue or light ochre to match. Painted or scraped wales seem to replaced by all-black hulls from the later 1840s on, but these were retained by certain local ship-types much longer.

-

HMCSS Victoria 1855 by BANYAN - 1:72

wefalck replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Ah, you use low-melt solder, not silver-soldering with a torch ... Do you a picture of the item ?- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

There were at that time so-called field-forges, used by the military. They are essentially a cast-iron basin on legs with a hand-driven ventilator underneath to supply the draught. They have a half-hood in sheet over it to arrest sparks.

-

HMCSS Victoria 1855 by BANYAN - 1:72

wefalck replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

If parts heat up to the point of melting a silver-solder joint (+600 °C ...), that sounds, as if the drill-bit is dull ...- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Also being a geologist, I would concour, even though 'boat on the rocks' is not necessarily something you wish to a boating party

-

On the use of steel parts in modelmaking

wefalck replied to starlight's topic in Metal Work, Soldering and Metal Fittings

The problem with the mixture steel/wood is actually the wood that contains various organic (humic) acids that corrode the steel. The ferric-humic acids compounds that form are black, hence the blackening of wood around iron fasteners or other parts. I never combine steel and wood, so this problem does not arise. Nickel silver is not available in too many different shapes. Another possibility for obtaining bright silver parts in brass is to chemically tin them. Salts or solutions for that purpose are available from electronics suppliers and certain modelling shops. -

On the use of steel parts in modelmaking

wefalck replied to starlight's topic in Metal Work, Soldering and Metal Fittings

I am guilty of using steel in my models for the very simple reason that there no real alternatives to it for turning long slender parts. There are some hard brass variants that may work in certain instances, but such brass is extremely difficult to buy. I making miniature models and need e.g. belaying pins of 0.2 or 0.3 mm diamater - this simply does not work in brass, even with my watchmaking lathe. On a real ship, there would be very few parts with bare ferrous metal visible. I can think of the meshing surfaces of gear-wheels for instance. Also, if you have a steam-engine visible, various parts would/could not be painted, even on a steam-engine that is exposed to the elements (such as those for windlasses or winches) at least the piston rods would be bare steel. So my choice would be to make them from steel, as nothing looks more lile metal - than the metal. Some 30+ years ago I build a small plouging engine model with various exposed real steel parts. They have been varnished with something that is called zapon-varnished, which is used to prevent tarnishing of silver- and brass-wares. As of today no signs of corrosion, but the model has been stored in a glass-case in a dry environment all the time. A few months ago I had the occasion to visit the workshops of the Musée de la Marine in Paris and talke to the chief-restorer and used the opportunity to ask her, what they use to keep the rust away from those splendid models of iron-clad battle-ships of the 1860s to 1880s, where the armour is bare steel. She told me that they use solutions of 'micro-crystalline' wax (check Google for it). So the answer is, I am using steel, when it is needed fro structural reasons and to represent the look of real steel, but otherwise I would not use it. Particularly, shy away from the combination of 'acid' woods (such as oak or beech) and steel, where the wood itself can corrode the steel. -

The 'stoic monochrome' appearance indeed largely is an inadvertent invention of the (art) historians of the 18th century, when interest in the aesthetics of artefacts of past generations awoke. Not only ancient sculpture and buildings were garishly painted, but also the churches of the romanesque and gothic period that today we value for their architectural structure as such. Also, in many protestant areas chruches were white-washed, as the painted decoration was considered distracting and that is how we are used to see them today still. The 'Royal Sun' is coming on nicely and it is good to see the research going into the project. Not that necessarily the colour rendering pleases me aesthetically (I am also more educated in the 'stoic monochrome' tradition), but if it is historically correct, so be it.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

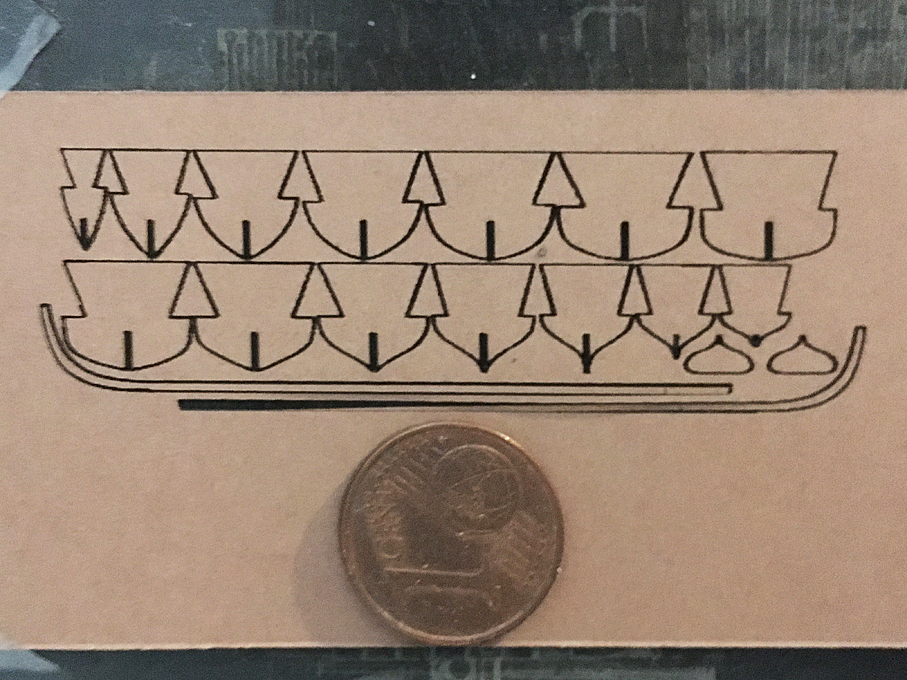

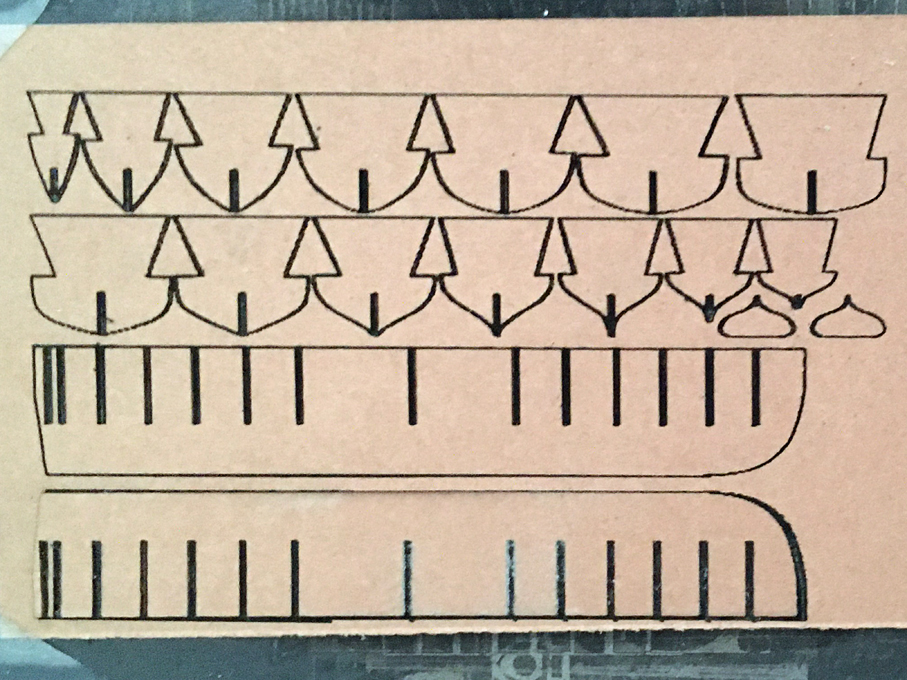

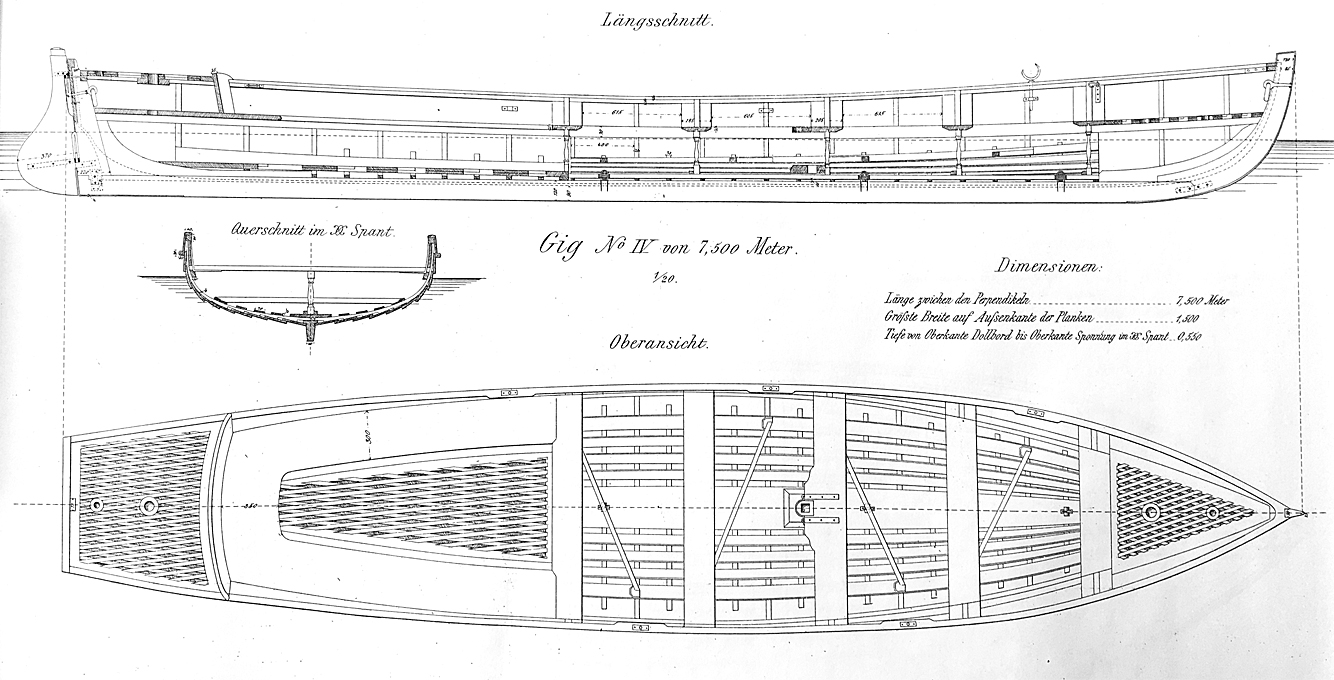

Ship’s Boats While I was waiting for the wire for the chain-rails to arrive, I turned my attention to the ship’s boats. At that time there were four, two class IV cutters, a gig, and a joll-boat. In 1:160 they are all less than 50 mm long and 10 mm wide. Thanks to some research of various colleagues in Germany, we have reasonably good information on these boats, including lines and their constructional arrangement. In addition, there has been a text-book on boat construction, published since 1878 with updates every few years until 1929, which gives quite a few details on the naval boats. I don’t quite feel like building four boats with all their internal constructional and fitting-out details, so I decided to show three of them covered, ready for the sea, while the small joll-boat will be shown ready for launching in an emergency, as it was custom. I don’t actually know, whether this boat or one of the cutters was used for the purpose, but assumed that the smaller boat would be easier to get into the water in a hurry, say in case of man-over-board. An additional challenge is that these boats were clinker-built. I once built a clinker-dinghy in 1:60, which was only 50 mm long, but it was much wider and deeper and with wider strakes. These boats typically have ten strakes on each side. I picked the long, but narrow and shallow gig first. I had a body plan available, drawn by a colleague some years ago. In addition, the text-book (BRIX, 1883) provides constructional details. The text indicates the dimension of the various parts. Drawing of gig from Brix (1883) I decided on an overhead plank-on-bulkhead (POB) construction, which in a way seemed easier than trying to carve the hull with its hollow lines aft from a solid piece of wood using templates. The individual framing stations were taken from the body plan and drawn with additional material on the top in order to arrive at a common reference plane for overhead construction. The bulkhead were laid out for laser-cutting from Canson-paper. Laser-cut bulkheads and keel-pieces A second drawing for laser-cutting contains another set of bulkhead and doubling pieces for the keel and stem, so that a rabbet for planking can be created. All pieces are doubled up after soaking in varnish to stiffen them. 2nd set of laser-cut bulkheads and doubling pieces for the keel and stem The pieces then were assembled as is tradition for POB-construction and mounted onto a piece of Canson-paper for extra stiffness. The whole assembly will then mounted in turn on a piece of wood to ease handling. So far so good, but planking will be challenge, as the individual planks will be less than a millimetre wide overall. In theory, they should be only 0.06 mm thick in 1:160 scale, but I will give it a try with the 0.15 mm thick Canson-paper and see what it will look like. If the planking looks to coarse, I will have to start all-over again … The assembled parts for the POB-construction Tapering such planks by hand would be too much of a challenge an not quite feasible in paper I think. However, my 2D-CAD program gives the length of the Bezier-curves used to draw the outline of the frames. So, I simply took this length, divided it by 10, divided the result by 4 and then multiplied it by 5, which gives the plank width at each station line assuming that they overlap by about a quarter of their width (according to the drawing in BRIX, 1883). The contours of the planks were drawn for laser-cutting with this information. A first run, was not so successful – I will have to optimise the cutting parameters. BRIX, A. (1883): Praktischer Schiffbau – Bootsbau.- 38 p. + 15 pl., Berlin (Hütte). To be continued ....

-

Man-made fibres tend to be water-repellent or at least their wetting behaviour is not as good as natural fibres. That's why a solvent-based lacquer/varnish (including shellac) is a better option. Personally, I prefer what is zapon-varnish as used on silver- or brass-ware to prevent tarnishing. It is colourless and remains somewhat flexible (in comparison to shellac). Every varnish that really soaks in and does not stay on the surface as a coating will deepen the colour of materials ('ropes' and wood). This is normal and a physical effect of light guided (like and optical fibre) into the pores, rather than being reflected.

-

I may repeat myself, but I would rather use some fast-drying solvent-based varnish. I soaks in better and can be easily loosened with a drop of acetone or the respective solvent, if it needs to be adjusted.

-

Somehow I missed this project so far, although I am quite interested in these rowing rescue boats. It is interesting that whe was clinker built in wood. The German, Dutch, and Danish society rescue boats of the time were mostly constructed after Francis' patent from corrugated steel plating that was hammered to or hydraulically shaped over wooden formers. They were unsinkable and self-draining boats and much lighter than a wooden boat. They had to be much lighter, as they had to be transported on special horse-drawn carriage over the wide tidal beaches and mud-flats of the North Sea coast.

- 30 replies

-

- small

- clinker built

-

(and 2 more)

Tagged with:

-

Do you have a concrete link to the item on Amazon ?

-

Dear Keith, Condolescences also from me. What a terrible loss ... our thoughts are with you and your families ! Eberhard

-

Matching Deck Colors

wefalck replied to hof00's topic in Painting, finishing and weathering products and techniques

We are not in house painting, we are in artistry What you were talking about is 'ragging', technique used to create a spotty and distressed looking surface in house painting. Of course this technique could be used also in modelling, but people then tend to use small pieces of sponge. No, washes are applied with soft brushes. The nicety about acrylics is that you can work fast, as fast as the paint/water dries. So you can apply very dilute washes, wait a few minutes and then apply the next wash, and so on. This makes the process very controllable. If you applied too much, you can also soak it up again with a dry brush or a piece of tissue (use a folded edge in order to not leave loose fibres on the surface). As always, don't ask too many questions in advance - just try on a sample or two. -

Matching Deck Colors

wefalck replied to hof00's topic in Painting, finishing and weathering products and techniques

Exactly ! There are also various 'tutorials' around on YouTube etc. for both small-scale shipmodelling and railway modelling on how to represent wood in that way. -

Matching Deck Colors

wefalck replied to hof00's topic in Painting, finishing and weathering products and techniques

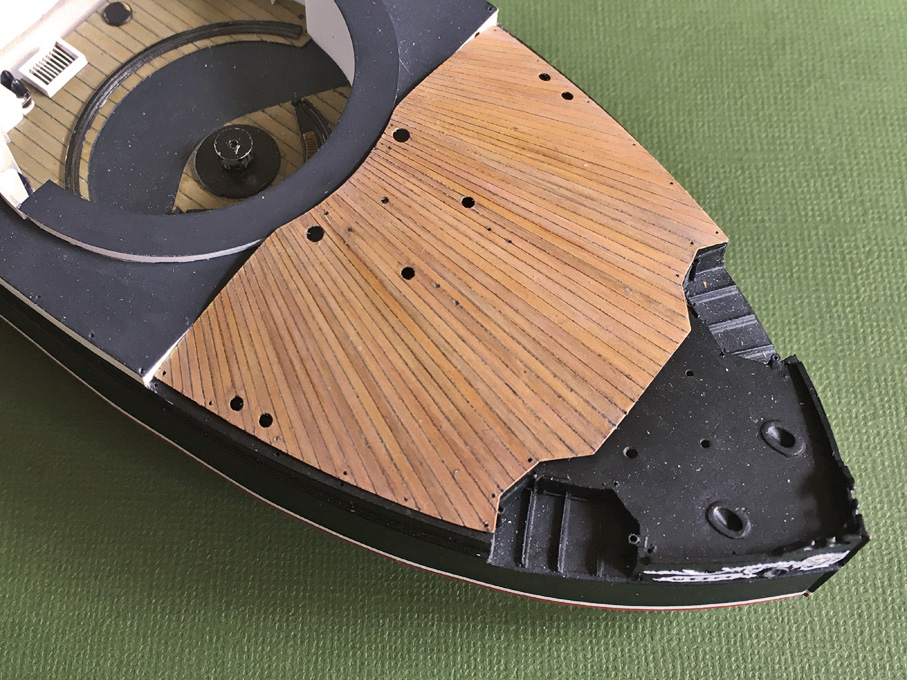

A couple of additional observations: - I try to avoid mixed paints - you will hever hit the right shade again, particularly, when you work with small quantities only; in the case of decks this is also not necessary, as one can very well work with washes to arrive at a convincing colour. - I don't know what your kit designers did, but one would normally design the parts (including PE parts) in a way that allows pre-painting parts to achieve a clean colour separation; I designed my decks so that they can be pre-painted and then installed; this means one has to think carefully about the sequence of assembly and not put everything together and then wonder, how to paint it. - It is a lot easier to brush-paint in particular PE-parts, when there is already a sprayed coat of paint on them. - If it was me, I would not bother with colour-matching the painted decks to the wood veneer; this is an opportunity to make the decks look more realistic: lightly sand the wood, apply a thin coat of sanding sealer and then lightly sand again; this gets rid of the far too coarse wood texture and surface structure; then paint in the same base colour as the PE-decks; pick out different planks in different shades etc.; apply a coat of satin varnish to seal; with a black pigmented 0.05 mm 'fine-liner' follow the laser-engraved/etched plank seams, wiping off the excess immediately; apply a light wash of a cream paint; seal with two coats of satin varnish and then with a light coat of matt varnish. It will look a lot more realistic than these awful 'real wood' decks. BTW, the example above is in 1:160 scale, so not too far off from your 1:200 scale. -

Matching Deck Colors

wefalck replied to hof00's topic in Painting, finishing and weathering products and techniques

I don't think that you can achieve the look of wood with a single colour of paint. I start with a suitable base-colour and then apply washes of burnt umber, other beiges/yellows and/or white; finally a couple of coats of satin varnish and for a deck final-final coat of matt varnish sprayed on (otherwise it does not become really matt). Judging colours from pictures (on the Internet) or even what is printed onto the lables is notoriously misleading. The only way to find out is to paint a sample. Here is a recent example from my own production: The following procedure was used: The piece of decking was given a base-coat of Vallejo Model Air 71075 ‘sand (ivory)’ using the airbrush. In a next step single planks were randomly given a light wash with Prince August 834 ‘natural wood transparent’ or Vallejo Model Air 71023 ‘hemp’ (which turned out to be a bit too dark actually). In a next step randomly selected planks, particularly those ‘hemp’ ones were given a very light wash with Vallejo Model Air 71288 ‘Portland stone’. Another very light wash with Vallejo Model Air 71041 ‘armour brown’, toned down with yet another very light wash using Vallejo Model Air 71132 ‘aged white’, pulled everything together. -

Much of the armour thickness would have been made up of the hardwood-backing of the steel armour.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.