-

Posts

6,415 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by wefalck

-

I remember reading the research thread, but somehow missed until now the building log. I am interested in everything that happened on the Seine, after all it flows past in sight from where I live. However, judging from the background on the photographs, I think Santos Dumont must have run his trials on the Bassin d'Argenteuil, a quiet lake-like stretch of the river between two barrages a few kilometres downstream from me. Coming back to the construction material: I also would think that steel-tubes as in bicycles were used. Aluminium tubes would have been extremely expensive at that time, if at all available. There was no welding technique at that time that would have not drawn the temper from the steel-tubes. So, I think they were silver-soldered, as is the practice for steel bicycle frames.

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

My comments about coiling were actually not 'assumptions', but that is what happens to me, when I coil rope. Of course, it is also a question of the thickness of the rope relative to your arm movements when coiling. I regularly use this lacquer/varnish and acetone method on models spray-painted with acrylics and did not experience any problems. Of course, when you create puddles of acetone and let it standing there, that may soften the paint. The point is to just brush enough onto the rope to soften it. It will evaporate in a few moments afterwards.

- 2,623 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Not sure, why people continue using diluted white glue to stiffen ropes, perhaps because it is handy on most workdesks ... If you use a fast-drying organic-solvent based lacquer (zapon lacquer or old-fashioned nail-varnish, not the modern acrylic ones), you can soften the lacquer easily with a drop of acetone. That also takes care of any flash produced during the original stiffening. And, why did you make the coils elongated, any particular reason? Naturally, as the rope has the same stiffness all along its length, it would coil up in more or less round coils. Of course, one can pull the coils long afterwards, but this would be extra work. Otherwise, I would echo the comments of the others, that it continues to be an impressively well-done project 👍🏻

- 2,623 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Actually, you did a pretty realistic painting and weathering job, I think 👍🏻 I discovered 'dry-brushing' (as it is called now) for myself some 50+ years ago in my teenage plastic-model building days and it is a very useful technique. Also, using lead- or coloured (mainly white) pencils are very useful to put highlights onto edges or raised parts, enhancing their three-dimensionality.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

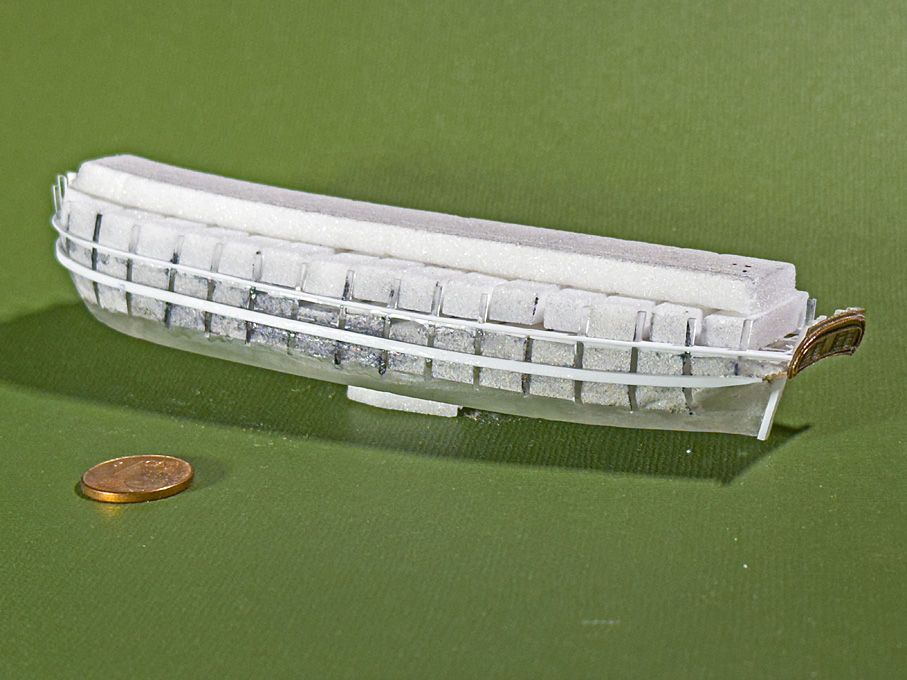

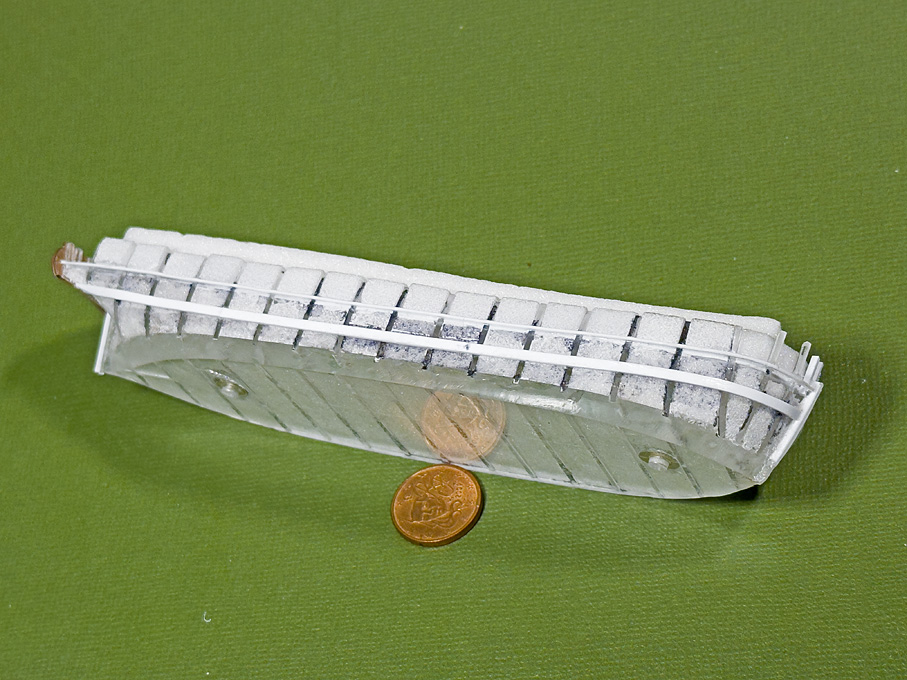

Thanks for the 'thumbs up' ! ***************************** Installing the wales It was fortunate that the upper edge of the wale was marked in the original drawings. I had transferred this to the bulkheads and cut appropriate notches. Somehow, however, these notches turned out to be not very useful as I would have to score the whole core of the hull accordingly, which would have been messy. In the end, I ignored them, though used their upper edge as guidance for placing the wales. I have no information on their dimension, but thought that a width of 240 mm = 1.5 mm looked about right on the hull. They would have been probably composed of two thick planks. For the thickness I choose 0.75 mm, as the hull-planking will be 0.5 mm thick. Contemporary pictures and naval construction books show both options, smooth hulls, where the thicker wales are not visible and step-changes in thickness. I think smooth hulls became fashionable around the middle of the 19th century, but in the Baltic they were always lagging a bit behind, so I went for the stepped design. Perhaps this is a problem of building up the planking around a solid core, but the way how the wales run against the gilling at the stern caused me some head-scratching. The point where the upper edge of the wale touches the gilling is marked in the original drawings, but it is not clear, where the lower edge touches it. While the wales have an easy run all along the ship, at this point some twisting is needed. I had not done any planking with styrene before. It turned out to be quite simple: unlike wood, it does not have grain of course and strips can be easily bent and twisted even across the long sides. Pulling the strips around a round piece of e.g. steel causes the strips to curl and one can thus achieve a nice pre-bending without the need of much clamping force, when cementing them on. Nevertheless, the wales were attached with the recently discovered artificial nail cement, that is a mixture of light-curing acrylic cement and cyanoacrylate. It sets fast, but not so fast that no adjustment would be possible. I let it seep under the wales attached to the hull with Sellotape. Hereby I worked from the more complicated stern forward in more or less long sections, depending on the curvature. Final clean-up will be done, once the rest of the planking has gone onto the full, with the view to blend everything nicely together. To be continued ...

-

I thought this was a fairly common tactic at the time (and probably still is, using modern boat-types and propulstion systems) to attack anchored ships off-shore. Such small boats at that time wouldn't have been able to keep up with moving warships. With today's speedboats the situation is different, as the pirate-attacks in various waters show.

-

So no condenser fitted? Or a boiler feedwater pre-heater? Do the steam-pipes get some insulation? I could imagine, that in winter one would get a lot of loss of pressure and condensation.

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

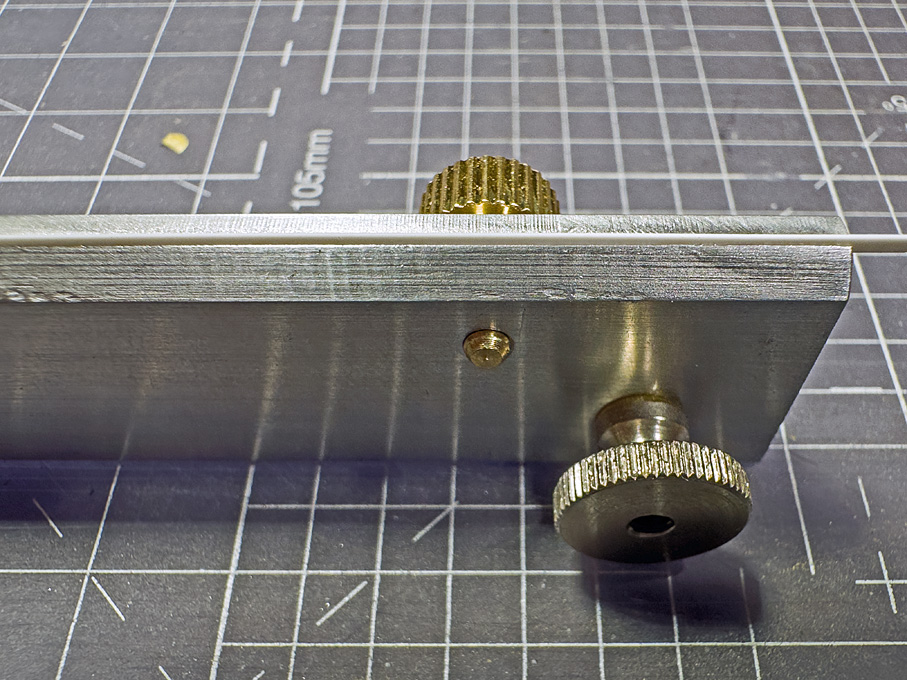

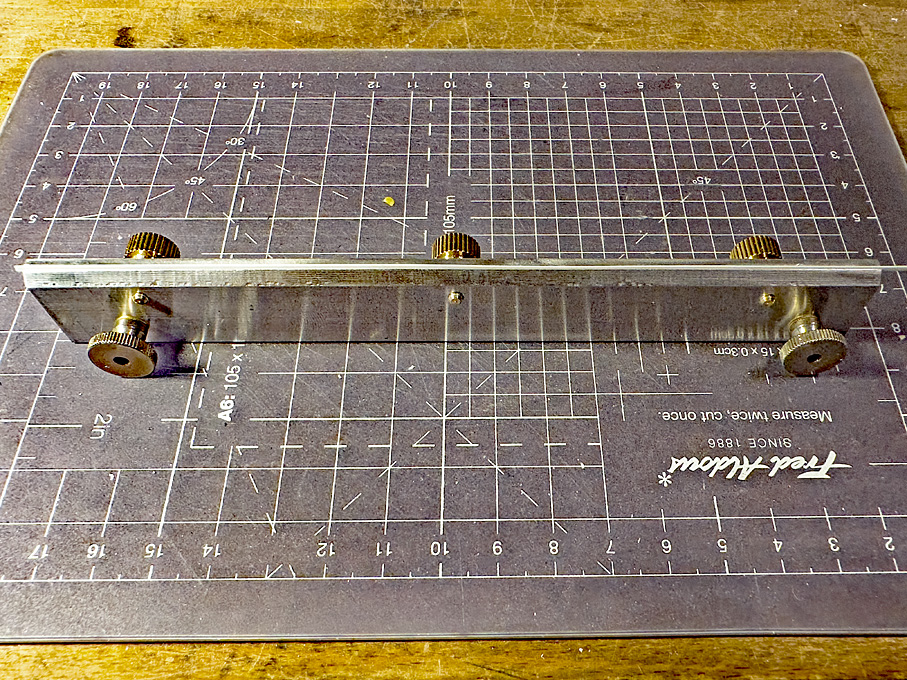

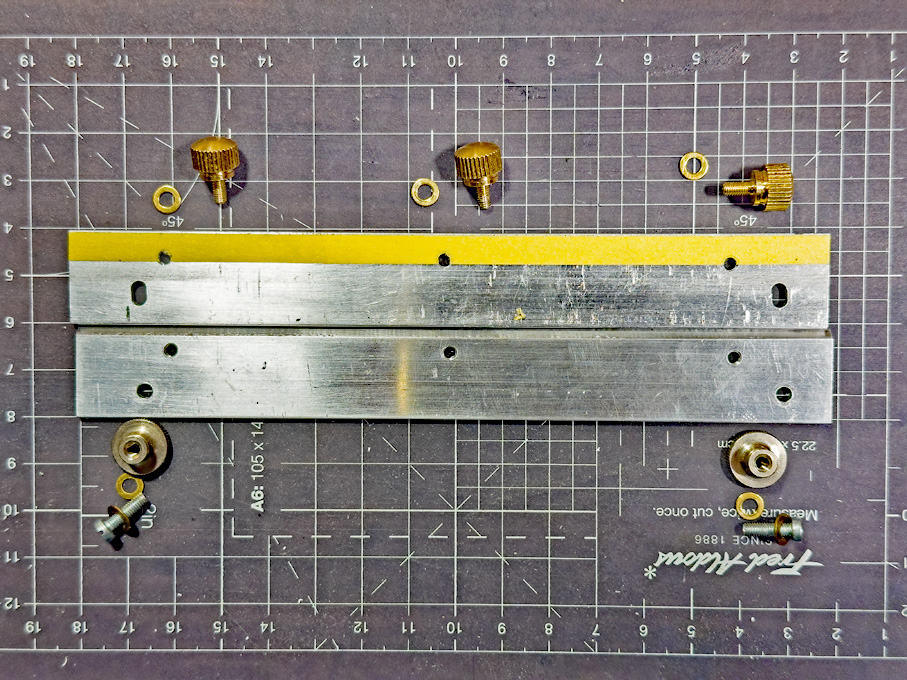

Thank you very much for the kind comments and the 'likes' ! ************************************************************* Digression 3 As the start of the planking is imminent, I had to think about a way to shape thin, narrow and long strips of styrene. A clamp is needed that can hold strips down to 1 mm width, 0.25 mm thickness and 150 mm length securely. In addition, the strips have to be held in a way that allows to slightly bevel the edges, if needed. The idea was to clamp the material between to flat metal bars of sufficient stiffness. I happened to have to matching aluminium bars of 20 mm width and 3 mm thickness that once formed part of a jig and could be repurposed. The two bars were tightly clamped together and milled flat on the top so that they abut with sharp edges. Then, one edge was bevelled to 45° to give clearance for bevelling the styrene (or wood for that matter) strips. Unfortunately, the table travel of my mill is not long enough to do the milling in one set-up and I could not clamp the whole length of the bars in the vice, which resulted in some chatter marks. Not beautiful, but still functional. The clamping action is exerted by three thumb-screws for which holes were drilled and tapped. I stuck a strip of Tamiya masking-tape at about 0.5 mm distance from the top edge in order provide a stop for very thin and narrow material. Now the clamp has to be tested in anger, to see, whether it really proves useful – not all of my home-made tools that felt like a good idea, really turned out to be that practical 🫢 Building log to be resumed soon …

-

... it also a good idea to draw onto the template the shrouds as they should be. This shows you immediately, whether you are pulling them together by accident. Leave securing the knots until you are sure that everything is adjusted to be 'ship-shape, Bristol-fashion', unless you use some organic-solvent based varnish or shellac, which can be re-dissolved, should further adjustment be needed.

-

Absolutely ! This is what the engineer would call cumulative errors. For the outhermost shrouds, I would use a 'cow-hitch' (https://en.wikipedia.org/wiki/Cow_hitch), where the loose end returns on itself. This is the same amount of work as a clove-hitch, but looks more like 'real' thing.

-

Nice clean work! How did you do the profiling of the roof, with a router, or by scraping with drawplate?

-

BR-18 Locomotive by Greg Davis - OcCre - 1/32

wefalck replied to Greg Davis's topic in Non-ship/categorised builds

Actually, nothing was welded at that time. Welding in sheet-metal construction was not common until after WW2. Contrary to what I said earlier, I think the boiler-cladding was probably screwed on in some way. It had to be removed without becoming damaged during the in-depth boiler revisions that had to take place every few years. -

BR-18 Locomotive by Greg Davis - OcCre - 1/32

wefalck replied to Greg Davis's topic in Non-ship/categorised builds

I did not examine the photographs of the original, but wondered whether they actually used such prominent 'rivets' on the boiler-cladding (this is thin layer of sheet metal over an insulating layer, but I don't know what was used on these locomotives, perhaps asbestos sheet). They took great pride in their appearance then. I seem to vaguely remember from the catalogue description when Arnold Rapido produced a N-scale model back in the early 1970s that the painted surfaces where puttied and sanded down several times, then several coats of paint with sanding in between, and finally several coats of gloss varnish. That applies to the green livery, not the later black livery. So they probably would also have used sunk rivets and puttied over them. Hence, the rivets would not interfer with any 'coach-lining'. -

You could make yourself a little jig for making the shackles: just to pins in a piece of wood around which you wind the wire for the shackels. Make sure that you pinch the eyes in a way the connection between them is right in the middle, i.e. are symmetrical to the loop of the shackle. Another method that works for really small shackles is to flatten the wire at both ends a bit with a punch or flat pliers, then drill the holes for the bolt and finally file the ends round. These guys most probably did not have much access to sophisticated hardware, but then as they found turnbuckles, they may have also found shackles. The turnbuckles, however, do not seem to the marine version.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Pin vise recommendations

wefalck replied to kgstakes's topic in Modeling tools and Workshop Equipment

On the original question: the question is always what one wants to do with a tool. One may need different sizes and different types for different jobs. I have a whole range of sizes and types. There is also a short version used by tool-makers to hold small files or reamers, which I find quite useful for certain applications. I got them in a second-hand lot by chance, but one could also shorten commercial ones, of course. For drilling, there are also miniature archimedean drills. I got one from a watchmaking supplier nearly 40 years ago that virtually clamps down to zero. The advantage is that they have free-spinning head, which allows you to put pressure on the drill, while moving the dolly up and down. There are also spring-loaded 'single-action' models. Don't go for the cheap small archimedean drills that have appeared on ebay & Co. a few years ago, buy quality. -

Possible Planking Clamp?

wefalck replied to Thunder's topic in Modeling tools and Workshop Equipment

The idea is to pull up the edges of grown-in toe-nails. Bought one of thosen years ago to be used indeed as gear-puller and for similar tasks. -

I must admit that I don't know next to nothing about the shipping around the Pacific coast of the USA. I am always amazed that at the beginning of the 20th wood was still used as constructional material for quite substantial steam-ships, but then wood must have been a comparatively abundant resource in that part of the world. Why did you settle on the odd scale of 1/71 (if I understood correctly) and did not go for the common scale of 1/72 ?

-

A marine dictionary, such as Paasch's 'From Keel to Truck', that in it's 4th edition of 1908 not only covered English, French and German, but also Spanish and Italian, might help sorting out questionable machine translations. I think it is available as PDF.

- 75 replies

-

- ancre

- Bateau de Lanveoc

-

(and 2 more)

Tagged with:

-

BR-18 Locomotive by Greg Davis - OcCre - 1/32

wefalck replied to Greg Davis's topic in Non-ship/categorised builds

Yep, but Bavarian locomotives were not painted in 'any' colour. The standard livery was green before the state railways were unified into a national railway in 1925. The 'livery' of the 'Reichsbahn' was black with red frames, wheels and inlays in works. At some stage the S2/6 also was painted in yellow-ochre for an exhibition or something. I think the lining then was red, but one would need to check. -

Same for me ... posted too early or too late. I think there is a lot of tradition involved in Europe. You N-Americans seem to have been much less inhibited by traditions. Push-barges didn't came into use on European rivers (mainly the Rhine) until the 1970s or so. Before it was side-wheel or propeller tugs with a tow of a maximum of four to six dumb barges. On Eastern European rivers, that were less well-regulated, wheels seem to have persisted longer, though quite a bit of research had been going on to improve screw populsion in shallow waters through putting the screws into tunnels. One river on which sternwheels have been used for quite some time was the Rhone, but not for tugs, but for fast packets. No idea what reasons where, why they kept for so much longer 'towing' than pushing.

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

I was thinking of parallel towing in harbours etc. However, it seems that in N-America the rivers tend to be more violent than even the unregulated rivers here in Europe.

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.