-

Posts

4,126 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by glbarlow

-

Keeping in mind the wind and weather was always coming from aft quarters my best guess is to keep some of that from hitting food being prepared or fueling the fires on the stove, nothing more than a wind break. I’m with BE though, while I appreciate Chris being true to the design I’ll leave it off because it obscures a view below the forecastle I’d have spent time building. No one is cooking anything on my models.

-

I really wish Chris had those boats when I built four of them the old hard way for Vanguard, Chris is making it easy for us. I agree that setting up right is a much better look and no problem fitting out for someone with your skills. The masts look nice, making them from anything other than kit walnut dowels is a big step up. I plan to do the same again with Flirt in boxwood when I get back to her. Meanwhile it’s one plank at a time for me.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Great choice, I’m a fan of Admiralty Paints version, I prefer it over gold (and white), seems more realistic, to me anyway. Your stern is looking great, creative and just bold enough.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Left the black card behind a long time ago. The shrink wrap tubing works well, I have a selection of sizes but it can be challenging to heat it just the right amount, clearly BE has that down. These days I prefer black masking tape, more of an iron look that artist tape and easy to fit and then paint to complete the look.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Well done, I’m always impressed with your creativity. And I agree, attention to small things as you do sum together into a great model.

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Congratulations on finishing your Cheerful. It looks great.

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I believe the boats are always sitting up to make them faster and easier to launch, but i could be wrong. The leather dye is an interesting choice, but I recall from using it back in my time the army as being a total mess to work with. No matter how careful I was it wound up in places I didn’t want it and near impossible to remove. Still a nice effects, you seem to have kept it in control.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Thanks for defining “huge,” I knew we could count on you😂🤣

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

A really good point to remember for some that want to point to a book and deem themselves as purveyors of truth and historical accuracy. My answer is more simple, the dark brown looks better on the model than black, and is my personal preference. On another note, the guy that climbs that rope ladder along the mast is braver than me, and just how huge are those deadeyes and the rope making up the shrouds. 😳

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

How did you attach the graphics to the wood? Nice that you have the Winchelsea set modifies for use on Sphinx. I matched my to Winsor & Newsome cerulean blue with maybe a touch of Mars Black. Yourclor match looks great.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I wonder how many broken ankles came from nighttime strolls on the quarterdeck.😊

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Quality work, bothe the beams and ring bolts. It’s the small things that make for a great model like yours.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you all for the likes and comments!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

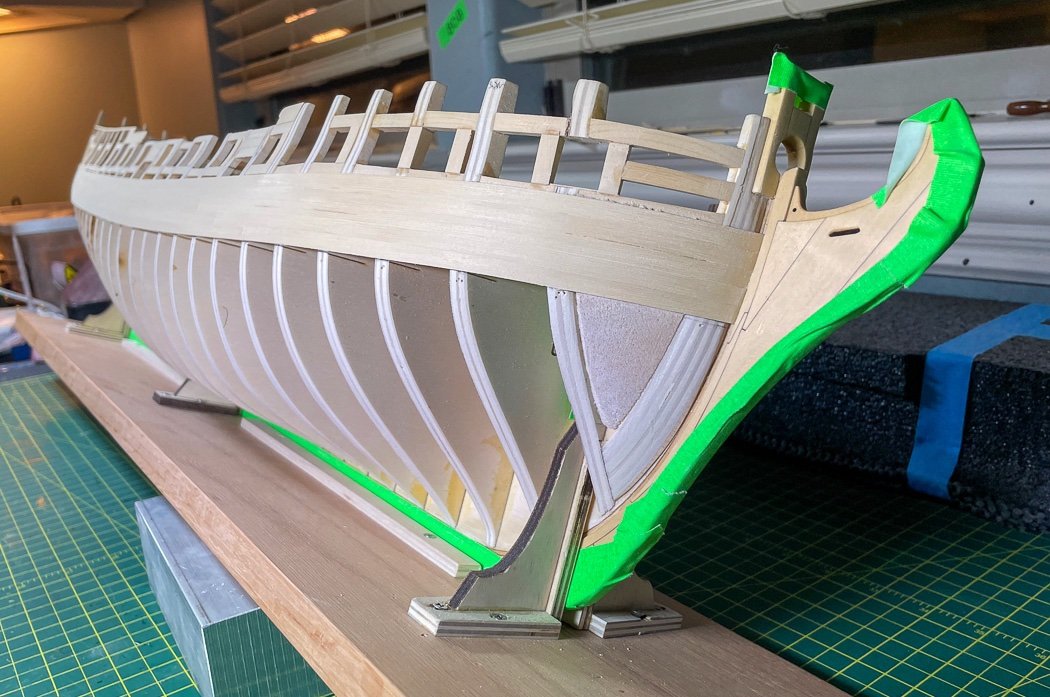

Thank you, the time spent on fairing paid off.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

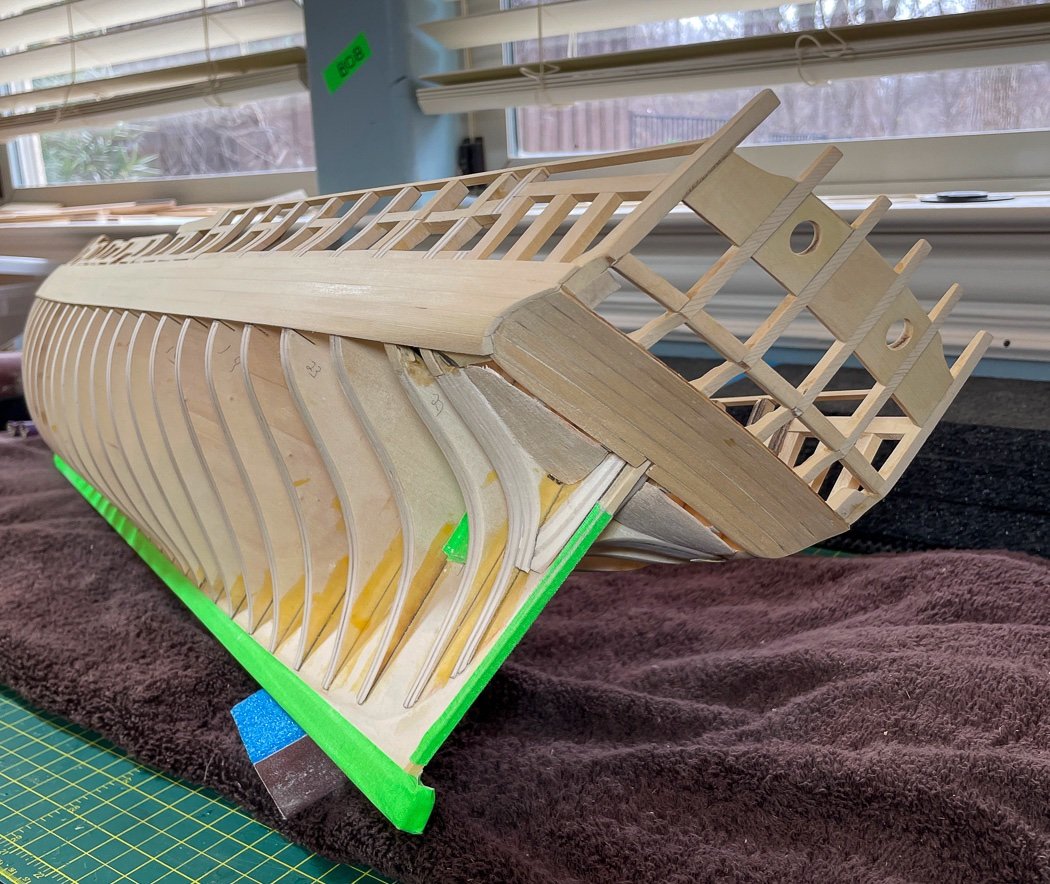

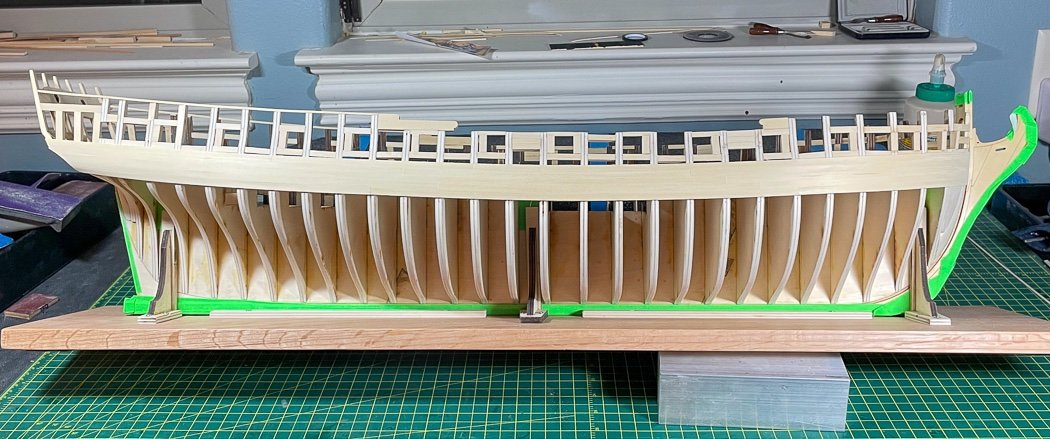

Wales, First Layer I completed the first layer of the wales. I usually try to make my logs either entertaining or informative, this time here’s a few photos for reporting purposes. I’ve only done rough sanding, I’ll wait until I complete more planking above and below to do more, I’ll also even up the sides as visible from the stern then. I did not follow a butt shift plan for this under-layer except to not to place them at the same place for the plan’s pattern I’ll use on the top layer. Obviously no reason to pencil between planks either.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I make my own rope. I just fill out this form, supply some money and my rope arrives made. I appreciate the talent, but there are just some things I have no interest doing. No rope rocket for me.

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.