-

Posts

13,302 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Good question, Dirk. The English also made repairs and replacements easier by through-bolts that were forelocked. How early this practice began, I'm not sure.

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

I use the MicroMark lead-free pewter. As for all casting metals, you ned to skim off the dross before pouring. I can see that the urn-shaped opening might create a bottleneck/backup, allowing cooling to occur before complete filling of your mold. If low melting point is an issue, there is always Wood's Metal - it flows at below the boiling point of water! I've no idea what blackening agent might work on it, though. Cerrosafe is a non-toxic alternative.

-

Congratulations on a fine result, Thunder. I remember seeing advertisements in Model Shipwright back in the '80s and wondered if the kit was as good as the photo in their ad. It is.

- 102 replies

-

- speedy

- model shipwright

-

(and 1 more)

Tagged with:

-

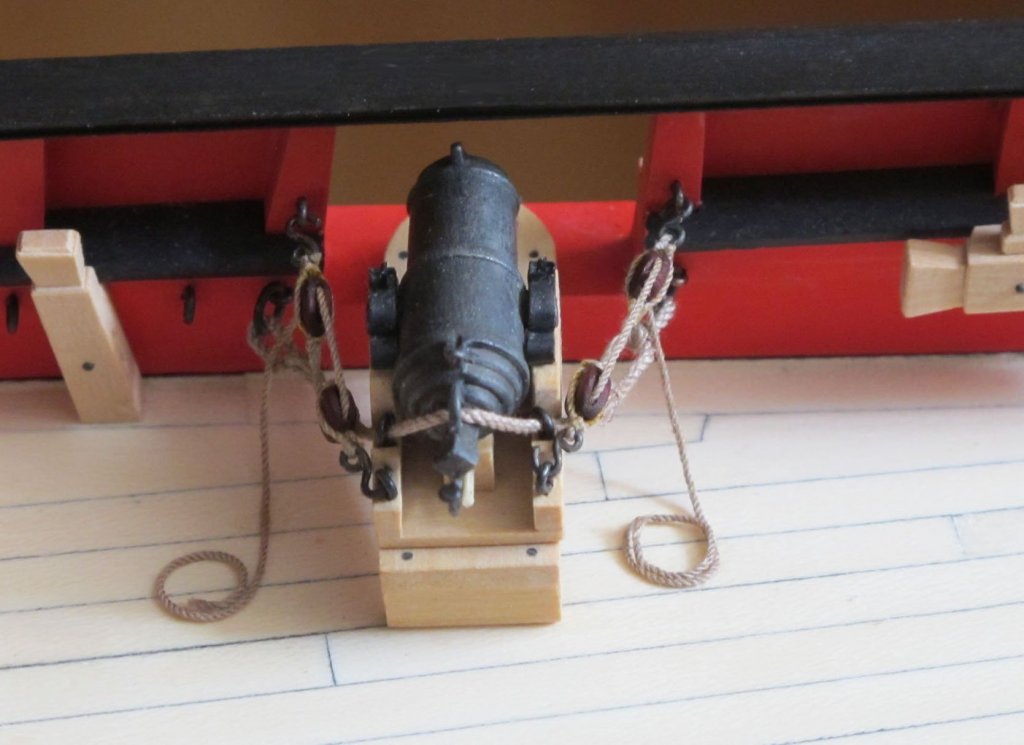

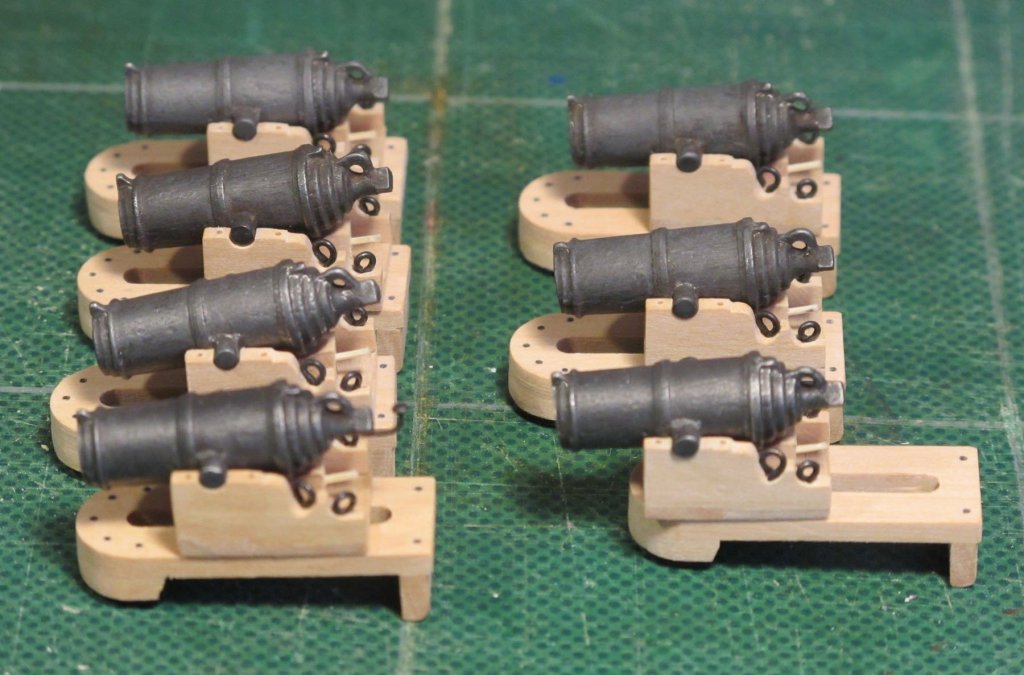

Depending on how nicely the RTV mold is 'clamped' by the outer plaster one, the seam should be minimal. The slight seam, if there is one, is easily filed off. The finish used was a chemical one: Jax Pewter Black. Incidentally, the carronade pattern shown was the earliest one of 1782 that lacked the muzzle cup or extension seen on later ones. Another consideration is providing air vent passages in the mold to allow a complete 'fill'. Did you have such channels when you attempted to cast?

-

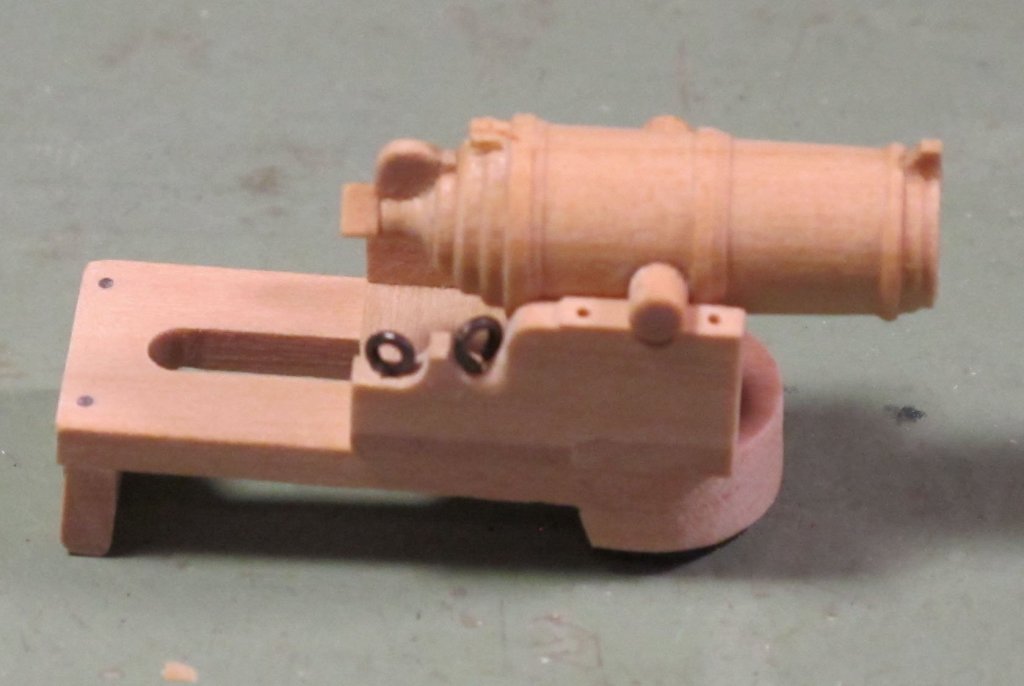

I used to pattern/duplicator turn my guns on a Unimat. The taper angle had to be a trial and error offset of the headstock. I found I needed a very fine-tip cutting bit for the reinforcing rings. Eventually I realized that it was not the best method of producing multiples, so made masters in wood. (By this time I also had a watchmaker's lathe, whose cross-slide could adjust for taper turning.) These masters were cast in clam-shell RTV molds supported by an outer dental plaster shells, then cast my cannon and carronades in lead-free pewter.

-

...and, order begins to emerge from chaos!

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Glad you didn't just take my word for it, Alan: verify, verify, verify!

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

What an intense collection of belayed lines! And trying to rattle down those shrouds at this stage of rigging must be a real endurance test. You continue to amaze us, Ed.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Michael! That isn't 0-gauge live steam, is it? It reminds me of Emett's Far Tottering and Oyster Creek Branch railway.

- 2,215 replies

-

That's a lot of machining for a single piece! Looks beautiful.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

Happy travels, Cathead! We look forward to your return.

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

-

Um, you could try to get another $10 off, Alan: decks had wood plugs over nails, not treenails!

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

Miniature wood plane

druxey replied to michael mott's topic in Modeling tools and Workshop Equipment

Plane sailing, perhaps? (Sorry, couldn't resist that.) -

Nice. I approve of your lining up the screw slots so nicely!

- 2,215 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.