-

Posts

13,362 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Things to bear in mind: 1) The roundup or spring of each transom and gallery increases as you go upward. This counteracts the illusion of sagging. 2) The apparent spring in photos can look exaggerated as the lower the viewpoint, the greater it appears to be. This illusion is because of the round aft of the various knuckles and rows of lights. 3) Any row of lights have the same height throughout, as you've noted, Mark. I thinks that exhausts the subject - for now, anyway!

-

Echo by Maury S - FINISHED - Cross-Section

druxey replied to Maury S's topic in - Build logs for subjects built 1751 - 1800

I agree with Greg. Your model is progressing very nicely, Maury.- 324 replies

-

Shaping stern fascia

druxey replied to pauls's topic in Building, Framing, Planking and plating a ships hull and deck

Walnut ply isn't the best material for this purpose. Soaking it well was a good move, but rather than bend it on the model, bend it and clamp it on a curved form that will support the whole fascia. Best is a two-piece curved form if you have the facility to cut it out. Leave the assembly overnight. Hopefully this will work for you. -

I'm personally not a great fan of contact cement. Volatile fumes require respiratory protection, no wiggle room in laying the wood down, and so on. Plain ole white glue does it for me. If the pieces to be joined are thin, water content can cause warping, so dampen the unglued sides of the wood to balance out this potential issue.

-

HMS Sussex by mij - Scale 1:48

druxey replied to mij's topic in - Build logs for subjects built 1501 - 1750

If wood glue ever freezes, that can compromise it, mij. Is that a possibility? -

'Spring' Ed, in the 18th century referred to the round-up of the stern transverse curves. Your quote, "The after beams of the quarterdeck must be gradually sprung to answer thereto." implies - to me, at least - that the beam round up increases, rather than is forced up by pillars. Thanks for coming across that one. I don't recall having read it. This should set Mark's mind at rest, as well as those of us that have participated in this thread!

-

One small addition to the good advice: never use power equipment if you are tired or in a hurry!

-

Michael: the OED cites 'rhoding' from naval architecture books, 1850,(which is very late) but, alas, gives no origin as to its meaning.

-

Sometimes headroom in the great cabin was improved by progressively raising the deck clamp aft, relative to the deck below. I suppose it might be possible that deck beams were of decreasing radius to achieve a similar result. However, that would be far more complex and time consuming. It seems unlikely, but one never knows….

-

So, the gauntlet has been picked up! I'll look forward to seeing the result. Good move, sir.

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

It's expensive, but front-silvered glass eliminates that 'gap' in a mirrored half model. A possible help for rigging of the earlier period might be to look at blocks recovered from Mary Rose. They are certainly different than 18th century or modern blocks. OK, they are not as early as your model, but might give some useful pointers anyway. Lovely work, Dick.

-

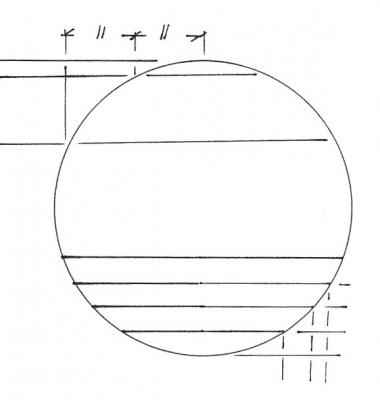

The fallacy in your argument, Mark, is assuming that the round up is directly proportional to the with of the beam. A moment's thought will tell you this is not so. As the beam narrows, the 'fall off' of the round up is quite small. The wider the chord of the circle (i.e the width of the beam), the more rapid the increase in round up. In the upper half of the illustration, twice the beam width is not twice the round up! The corollary of this idea is shown in the lower half. Hopefully this clears up your dilemma.

-

Not that I wish to influence you in any way, Remco, but a) a brick hearth would look really interesting and different and I'm sure you could make a superb one. (He walks away, whistling nonchalantly…)

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Mark: if you can find good linen line without slubs in it, either keep the source secret or just share it with me! Seriously, it's nearly impossible to find that quality any more.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Congratulations on your new project, Ben. You are off to a fine start.

- 889 replies

-

It looks as if the lower deck was lowered forward to accommodate the galley. The notation on the drawing suggests that draught is very close to the 'as built' for Swan and Kingfisher. Remember that these two ships were the leading ones of this class, so the earlier type of galley would make sense here. It's a nice variation on the Swan theme - or is that the swan-song?

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

It's a nice compliment to your research and drafting that you are getting these requests, E&T. Do I also sniff a book in the making?

- 346 replies

-

- terror

- polar exploration

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.