-

Posts

13,390 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

I anneal brass tube, cut off slices and put them in a thickness jig to file both cut edges flat. I then place the ring on a steel block and flare both sides using a centerpunch.

-

Congrats on a beautiful finish, and condolences on the result of the seventh....

- 167 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thank you, Bruce. With a little practice, one can get the consistency of paint right (rather like airbrushing!) and a ruling or bow pen will lay down a consistent line. I can see the advantage of the striping pen, except that you are limited to white and yellow.

-

Chuck; you make a very good point that has otherwise bothered me; the output looks too perfect! For figures such as the captain above, it's great, but for carved work on a ship, the surface lacks the markings of actual tools. Your concept of hand carving the output before hardening addresses this issue.

-

Loose Planks

druxey replied to Rich Sloop's topic in Building, Framing, Planking and plating a ships hull and deck

Is this water-based paint? Wait until the moisture has completely evaporated and see if the planks sit down again. Then reglue from the inside. (I assume this is still accessible.) -

A less expensive book is the facsimile reprint of Rees' Naval Architecture. While slightly later, the plates are copies of those in Steel. eg: https://www.abebooks.com/Reess-Naval-Architecture-Rees-Abraham-David/31527245291/bd Although the plates are half the scale of those in Steel, they are still too large for a home scanner.

-

question about waxing thread

druxey replied to ford34tom@comcast.net's topic in Masting, rigging and sails

Wax used to be recommended years ago to lay 'fuzz' on rigging line. Unless you are using really cheap and fuzzy stuff, forget about using wax. Also, beeswax is slightly acidic and will rot the line in time. (A lot of old timers' advice was not the best!) If you absolutely have to use wax, use conservator's pH neutral wax instead. Ideally, use good quality commercial line such as from Ropes of Scale. This has no fuzz and does not require 'treatment'. If you need to use adhesive, pH neutral white glue is best. Avoid CA (superglue) as it will eventually make the line brittle and break. Alternatively , spin your own rope! -

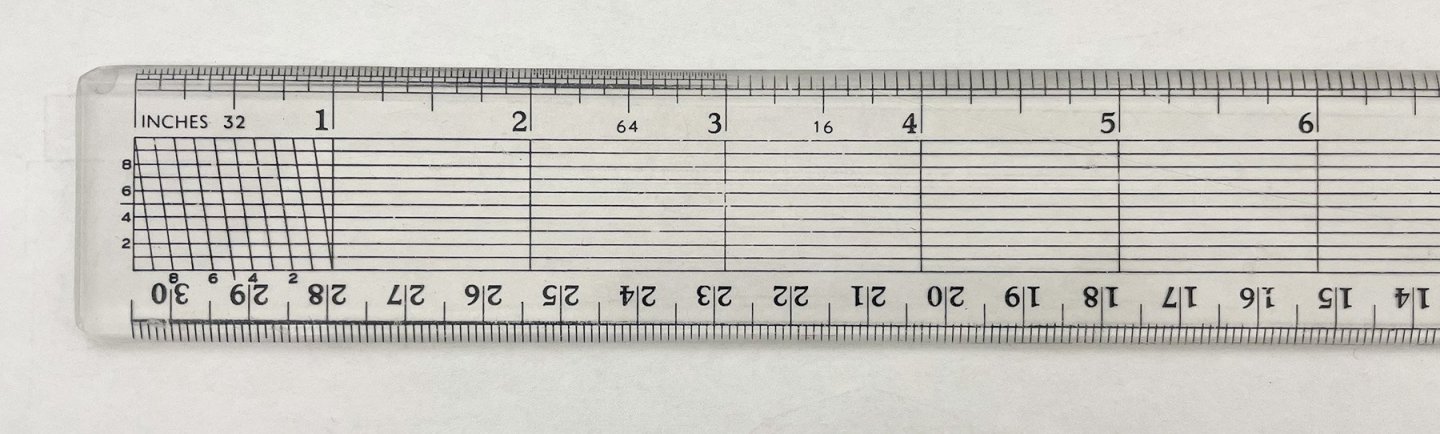

The y axis markings allow one to draw a series of closely spaced parallel lines. I have a rule that works on the same principal. Glad to oblige, Mike!

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Bowlines (literally 'bow lines') normally lead forward, at least in English practice. The line for the fore course leads forward to a block hooked to the aft side of the bowsprit cap, then aft to belay at the forecastle. The main course bowline also leads forward. The English belayed it at the fore topsail sheet bitts forward of the fore mast. In your diagram it appears to belay inside the bow bulwark, presumably on a pinrail. Hopefully this is of some help!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.