-

Posts

1,244 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by MrBlueJacket

-

-

Your progress makes me smile.

- mtaylor, Canute and thibaultron

-

3

3

-

-

- thibaultron, Ryland Craze, Canute and 2 others

-

5

5

-

- Canute, thibaultron, Jim Rogers and 2 others

-

5

5

-

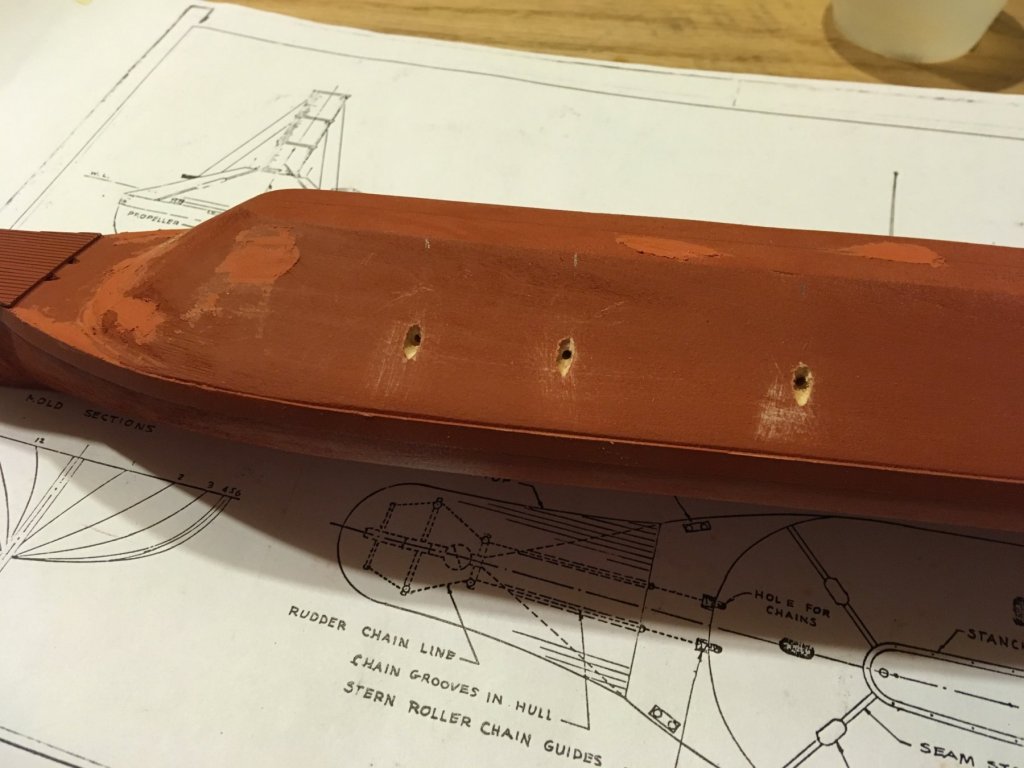

Haven't done much work in the last two weeks, but made a little progress this past weekend. The instructions show adding strips of heavy paper to various parts.

For the armour belting I used 1/32 x 3/16 basswood. Then I shot a quick coat of primer on the model to see how much more sanding I need to do. The even color makes it easier to see irregularities than the bare wood does. Time for a little auto body filler, I'm afraid......

- Tim Curtis, Tom E, mtaylor and 3 others

-

6

6

-

-

- thibaultron, Ryland Craze, mtaylor and 4 others

-

7

7

-

- thibaultron, Canute and hexnut

-

3

3

-

-

- John Allen, Elijah, Ryland Craze and 6 others

-

9

9

-

- Ryland Craze, Elijah, hexnut and 3 others

-

6

6

-

- kuya, Ryland Craze, Elijah and 3 others

-

6

6

-

- Duanelaker, yvesvidal, kuya and 9 others

-

12

12

-

-

-

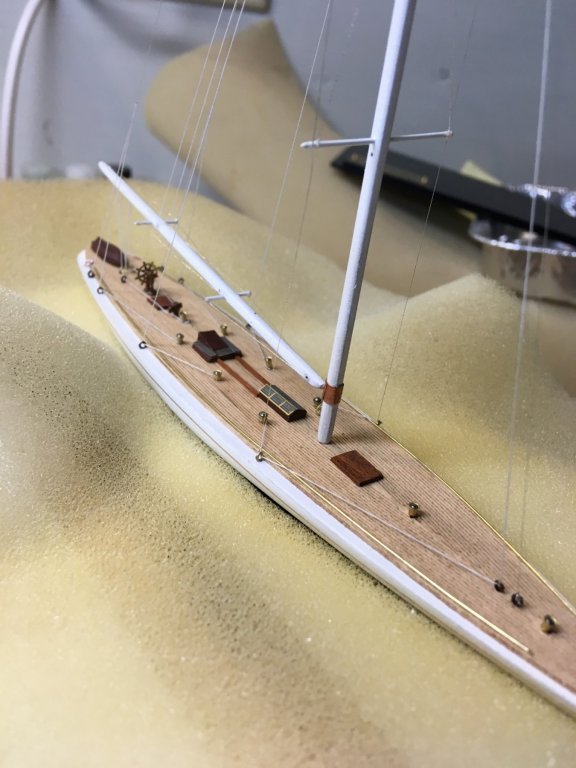

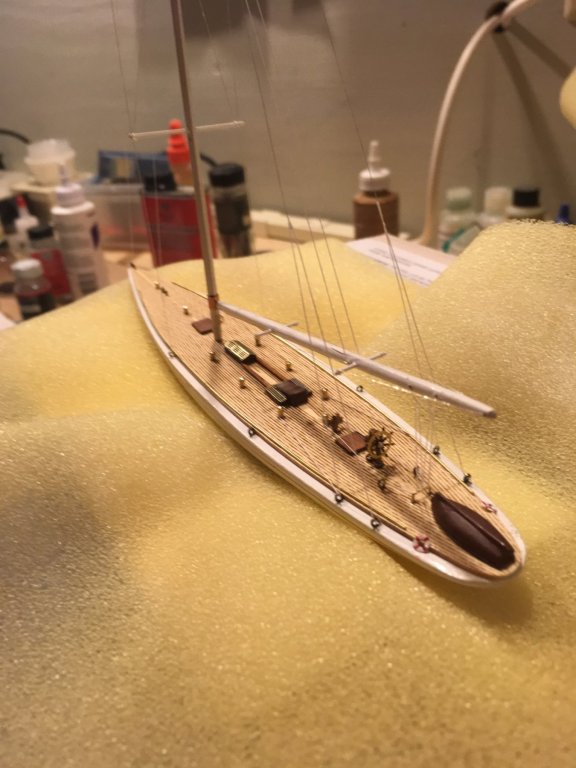

Over the weekend I had some time to do the rigging. I was able to do all the standing rigging with silver metallic thread, and some of the running rigging with .005 white thread. Only 3 lines left to go and it will be complete. Then comes the final mounting into the case, which is 11 x 4 x 14 acrylic.

- popeye the sailor, yvesvidal, Tom E and 3 others

-

6

6

-

Bluejacket Shipcrafters was the topic of "small businesses in Maine" on WAB I TV, which airs every Thursday during the 5:00 PM segment. Here's the link:

If that doesn't work, go to www.wabi.tv and search for bluejacket.

-

I really haven't done much over the holidays, just made the mast and started to finish the display base. Here's a shot of the incomplete pieces cobbled together so I can get an idea of the finished model. I think every modeler plays "put together" with the sub assemblies. I know I always have.......Notice the left plaque says "thank you" in the middle

-

- hexnut, popeye the sailor, Nirvana and 3 others

-

6

6

-

-

- hexnut, Nirvana, popeye the sailor and 1 other

-

4

4

-

-

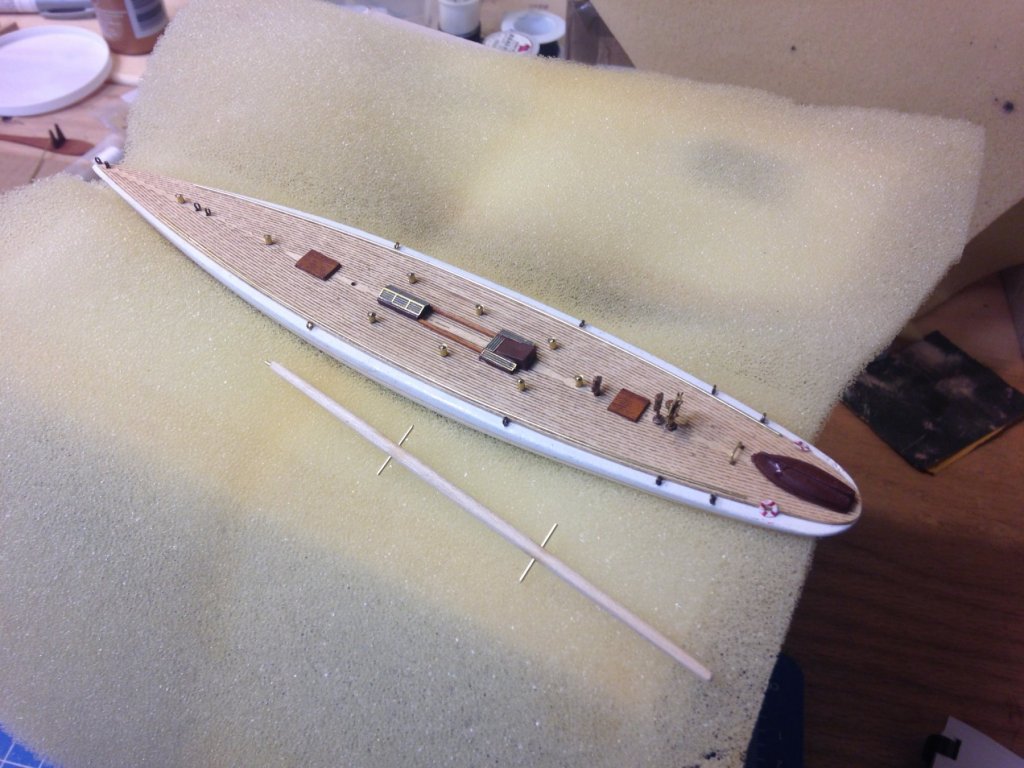

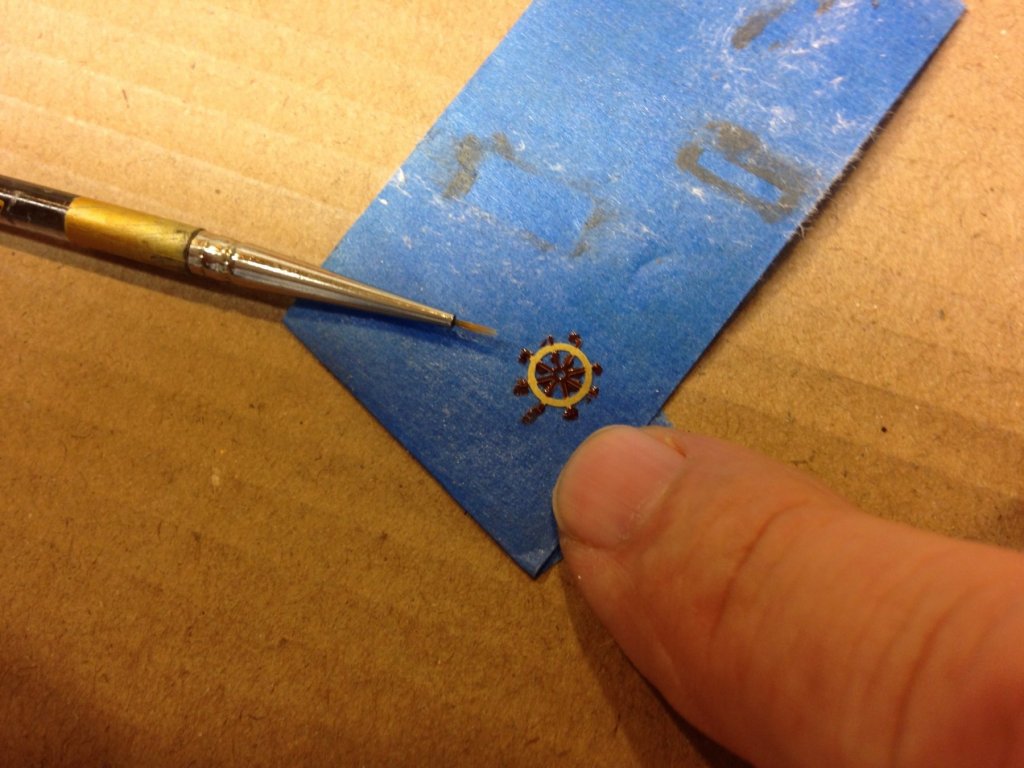

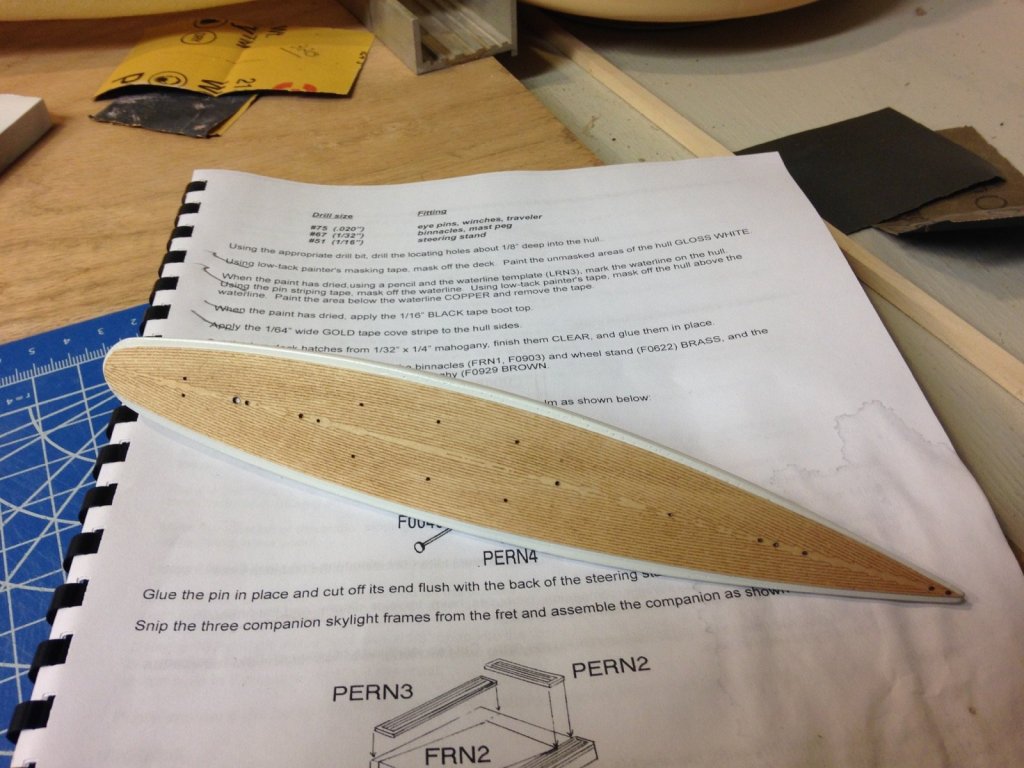

Last night I attached the laser-cut deck to the hull.Having the locations of the major components cut in is a big help, no need to measure where things go!

To make a work cradle, I cut an oval out of a cardboard box bottom and lined it with foam. I used the waterline template as my guide, cutting about 1/2" larger all around.

Now I can start to do some fun stuff, like populating the deck and getting to the rigging. I consider the hull work a necessary evil that has to be done so I can get to what I like to do.

(makes no difference if its' a solid or planked hull)

-

The trailboards are a pair of boards that may be found at the bow of certain sailing vessels, where they run from the figurehead or billethead back to or towards the hawsepipe. They are in the main decorative, though they often bear the name of the ship; they may be more or less elaborately carved and painted.

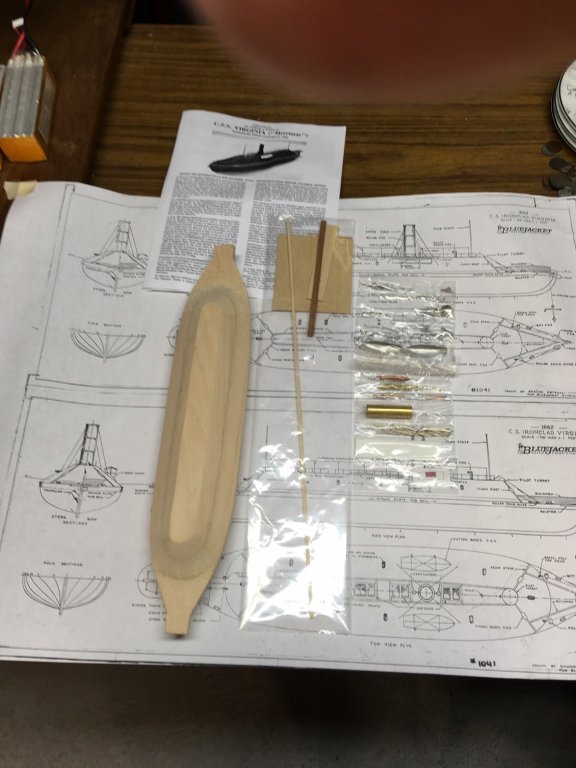

CSS Virginia by MrBlueJacket - FINISHED - BlueJacket Shipcrafters - scale 1:192 (1/16" = 1')

in - Kit build logs for subjects built from 1851 - 1900

Posted

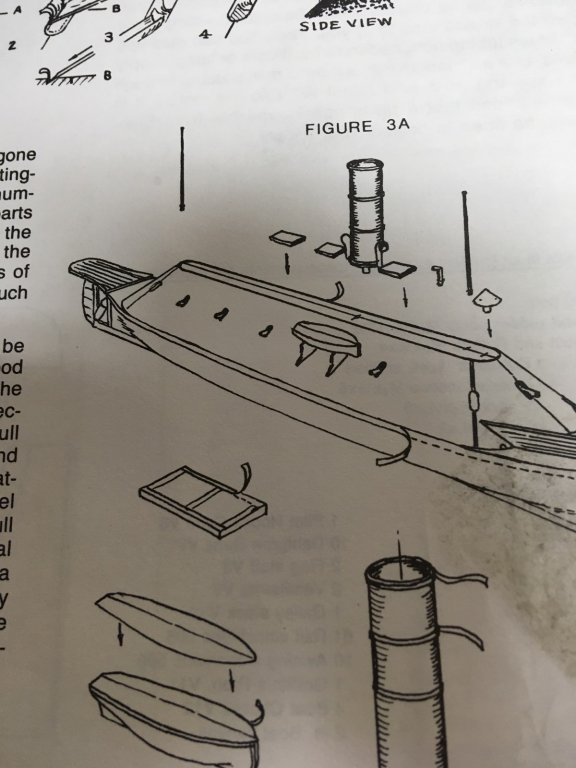

After several weeks of other things, I am back to the Virginia again. I decided to laser-cut the gunport lids, and a Google search showed them to be split vertically, with the hinges on the upper outer corner. Note they are only on the ends, not on the broadside.

These laser cut lids, and the top gratings, will be added to the kit.