-

Posts

406 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by hexnut

-

I always love your hyper-detail updates. I am making the same face as all those deadeyes! 😮

-

Joseph Conrad and the Otago, Allen Villiers and the Joseph Conrad?

-

Very nice work. vaddoc! Are you using Rhino? First of all, I understand the pushback from the "ship's curves and paper" fans, but at the same time, I think part of the frustration some experience is that CAD offers a LOT more precision, and old boats simply were not that precise. Go down to the drydock on a nice, salt-spray-blowing November day in Bristol, crawl around a large hull taking measurements, dodging teams of workers doing sheathing and caulk, go back to the office and calculate the offsets by candlelight--Or during the initial build, lay out the stations with splines, ducks and chalk on the lofting floor, then have wrights rough the sections out of wood with a pit saw and broadaxe.... It's enough to give a quality assurance/risk mitigation director nightmares... I think the historian in all of us can't help but have enormous respect for primary sources, or high-profile scholars working at an earlier time (Chapelle, Longridge, et al.), but the reality is that by CAD standards, the original plans often weren't all that accurate. One of the biggest problems in lofting a hull in 3D is getting the stations and WL's to line up and meet while being fair in both directions. I have yet to trace a vintage plan where that happens, because the original was never fully-resolved until wood started coming together. There is a bit of an 80/20 rule--what is good enough to start construction without wasting too much material? When doing it in CAD, every tiny surface imperfection is abundantly highlighted; where on the model, it's an issue that may be solved in 30 seconds with some 120 grit. vaddoc, the truly good news is that now that you've put the work in to make a faired hull, once you make it solid you can boolean ribs and even planking out of it, setting up shiplap profiles at a station and extruding single-rail surfaces using the planking curves projected onto the hull. You can also offset the polysurfs to accommodate whatever you choose for wood thicknesses... Great-looking hull!

-

They had rubber pads on the tracks... Graf Z looks amazing!

- 345 replies

-

- graf zeppelin

- trumpeter

-

(and 2 more)

Tagged with:

-

Ala-Kart by CDW - FINISHED - AMT - 1:25 Scale - PLASTIC

hexnut replied to CDW's topic in Non-ship/categorised builds

I tape a cut length of plastic straw to the nozzle to decant into the airbrush... -

Ala-Kart by CDW - FINISHED - AMT - 1:25 Scale - PLASTIC

hexnut replied to CDW's topic in Non-ship/categorised builds

Tamiya also makes a pearl clear (TS-65) that is pretty nice--helps even out coverage... https://www.amazon.com/Tamiya-85065-TS-65-Pearl-Clear/dp/B0006SG21C -

Great work! I've also had good luck with Vallejo paints, both w/ brush and airbrush. They go on thin enough to keep detail and permit layered glazes, but also cover well enough so that too many coats aren't needed... https://acrylicosvallejo.com/en/producto/hobby/sets/war-games-en/french-infantry-napoleonic-wars-en/

- 2,696 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Epoxy for structural patches, but good ol' Bondo automotive filler works great for cosmetic fill/surface coating, with Nitrostan/Red Lead as a final skim coat. Additionally, cabinet scrapers and box cutter blades work well over PLA for knocking down the FDM print lines...

- 133 replies

-

- alert class

- tugboat

-

(and 1 more)

Tagged with:

-

Brilliant work, as always! Reminding me a bit of some of Charles Sheeler's great artwork... 🙂

- 238 replies

-

- leviathan

- troop ship

-

(and 2 more)

Tagged with:

-

Completely concur w/ the advice to print the barrel vertically, redesign the assy. to be 3-4 parts w/ interior lap joints (YMMV, but .3mm clearance should yield a press fit after a quick clean-up), size the i.D. so you can press fit the parts over a dowel and chuck it into a rotary tool--spin on slow speed while gently scraping w/ a blade to knock down the steps. (I use a small Olfa blade in a pinvise) --don't worry about getting too undersized--a coat of filler, primer and paint will make up the difference. If the printer has a GUI like Ultimaker Cura, it's pretty straight-forward to change the settings to slower speed/max rez. I would also turn off the auto supports and build them into the model only under the trunnion section; use about a 5mm raft under the barrel sections so everything sticks to the platform. I would also do the logo as a couple-layer flat (make a few copies) sand it to thickness and mount it to the barrel w/ epoxy...

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

This was so much fun to watch, and the results are terrific. Thanks for sharing!

- 287 replies

-

- michelangelo

- ocean liner

-

(and 1 more)

Tagged with:

-

CA adhesive- spontaneous combustion?

hexnut replied to Srodbro's topic in Metal Work, Soldering and Metal Fittings

From Wikipedia: Reaction with cotton, wool, and other fibrous materials Applying cyanoacrylate to some natural materials such as cotton (jeans), leather or wool (cotton swabs, cotton balls, and certain yarns or fabrics) results in a powerful, rapid exothermic reaction. This reaction also occurs with fiberglass and carbon fiber. The heat released may cause serious burns,[26] ignite the cotton product, or release irritating white smoke. Material Safety Data Sheets for cyanoacrylate instruct users not to wear cotton (jeans) or wool clothing, especially cotton gloves, when applying or handling cyanoacrylates.[27] I also use it w/ baking soda quite a bit and I have to be really careful--I've burnt my hands before... -

Looking awesome! You may be already using something like this, but for mirror finishes, I find these things: https://www.micromark.com/Soft-Touch-Sanding-and-Polishing-Pad-Set-Set-of-6?gclid=EAIaIQobChMI7Lakytmr2AIV27rACh0Jpg2qEAQYASABEgLXkfD_BwE to be close to magic...

-

Billings 50ft. HMS Renown Steam Pinnace - Need some help

hexnut replied to grsjax's topic in Wood ship model kits

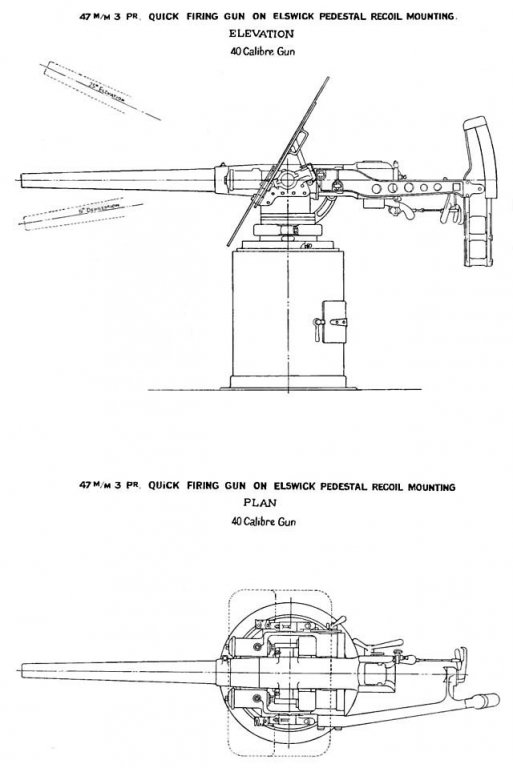

Don't know if you've already seen this, but nice image of the Hotchkiss gun: http://www.nmrn-portsmouth.org.uk/exhibits-and-collections/steam-pinnace -

Awesome work on Michelangelo-- golf is too frustrating for me, I stick to Highland Games...

- 287 replies

-

- michelangelo

- ocean liner

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.