-

Posts

5,452 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Nirvana

-

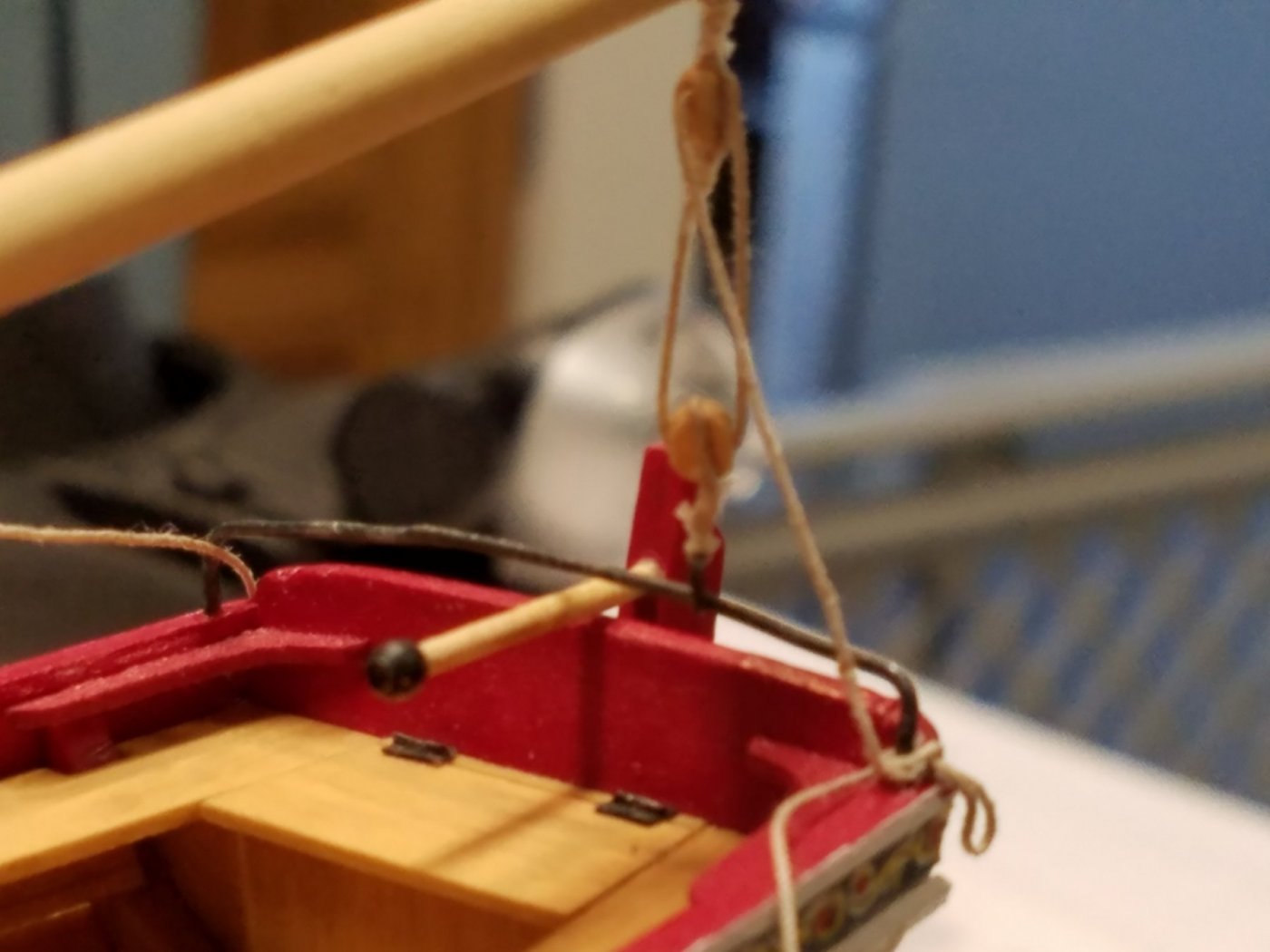

Getting there, Now it's time to get the bowsprit installed and doing the final part of rigging. Some paint touch up and then give it to my Admiral. It was her birthday last Friday. Couple of days late, but still.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Bug, I think Augie is smiling now and am very greatful letting you do the final job. My hat off to both of you.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Aah, a friendly face has appeared on MSW after some absence. Welcome back Floyd.

-

At one time sailing my T37 I lost rudder control, it was hard to her back just using the sails but I was able to do it. You were lucky!

- 96 replies

-

- tugboat

- Tippecanoe Boats

-

(and 2 more)

Tagged with:

-

In order to get the shrouds equally I used the deadeye claw while tying the opposite side. Think it worked out fairly nice. I am intending to work the shroud tying just like when doing tighten up nuts/bolts on the wheels of the car, crosswise. This way they will be equally taught.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

I am so glad having Lennart Petersson's book regarding rigging. I needed details of connecting the deadeyes. Perfect illustrated on page 2.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Bug, That is a very nice setup you have for photo sessions. Good use of a table tennis unit. Back in Sweden in my early days I had a Stiga too. Useful for many things.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Oh, I really like the possibility of uploading many pictures at one and the same time.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Well, I am into rigging and things are coming together. This is a lot of fun. I am enjoying it tremendously! Here are a few pictures I took with my phone. Not the best but showing what is going on.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Similar tape can be bought from car paint shops. They have a very nice flexible blue tape that does the trick. I don't know about the price difference, but would guess the tape from a car paint shop should be slightly cheaper. But when it comes to the pinnace I am surprised of the difficulties involved. I would have guessed the pinnace would have been little easier than the longboat. This due to it's size. But Mike, you have done a fantastic job and recovery of her.

- 129 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

-

Oh, and as for the divider, make sure the needles are replaceable. Now back to the build of the Gunboat - Mike take over.

-

Mark, It's worth to spend some extra money for a good quality. Don't settle for a divider under 60 dollars! I did and sent it back. Second one is made in England and I spend 90 dollars instead. Nice quality and nice protective box too.

-

Nice build, I love the lines of her.

- 70 replies

-

- pen duick

- artesania latina

-

(and 1 more)

Tagged with:

-

Model Shipway's Paints

Nirvana replied to Worldway's topic in Painting, finishing and weathering products and techniques

If not Google, Bing it! -

Mike, Thank you for that tutorial, you broke down the whole part perfectly to a basic. I have no questions at all and you were lucky with the numbers! This planking is going to go fast for you.

-

Model Shipway's Paints

Nirvana replied to Worldway's topic in Painting, finishing and weathering products and techniques

Check the ModelExpo website. -

SS Mariefred by captainbob - 1:96

Nirvana replied to captainbob's topic in - Build logs for subjects built 1901 - Present Day

There are several Swedes on this site, and I know if you have any question we are than happy to help out. I certainly looking forward to this project of yours. -

SS Mariefred by captainbob - 1:96

Nirvana replied to captainbob's topic in - Build logs for subjects built 1901 - Present Day

Roger, I am sorry if I mislead you but I was referring to the link about M/S Juno. Back to you CapnBob, sorry for the side step. -

Model Shipway's Paints

Nirvana replied to Worldway's topic in Painting, finishing and weathering products and techniques

As Mark mentioned, did you read the article about materials and tools? I also posted that article for you to read in Chuck's planking questions. I would sincerely recommend to read through many of the help and hint articles posted. Most of the questions will be answered there. -

Model Shipway's Paints

Nirvana replied to Worldway's topic in Painting, finishing and weathering products and techniques

Amazon has the paint too. I like Vallejo's paint. -

SS Mariefred by captainbob - 1:96

Nirvana replied to captainbob's topic in - Build logs for subjects built 1901 - Present Day

Here is the official link to SS Mariefred -

SS Mariefred by captainbob - 1:96

Nirvana replied to captainbob's topic in - Build logs for subjects built 1901 - Present Day

I lived in Sweden and was part of the Steam Boat Heritage Society for a long time before moving to the USA. SS Mariedfred's hull is made of steel, a major part of her superstructure as well. This is boat I worked on during the summer of 1983. She was also a steam boat but later converted to diesel. -

Steve, At JoAnns I had a great service experience with one of the ladies working there. I told her what I was up to, and showed a picture. That really made my day as she called on co-worker around her. Suddenly I had three ladies explaining differences and quality of threads. They all agreed that a combination called poly/cotton would be the best for me. Pure cotton is breaks easily under tension and has "hair", while the poly/cotton doesn't. Looking forward to see your rigging.

- 165 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.