-

Posts

5,512 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James H

-

ancre Coureur by cafmodel - 1/48

James H replied to cafmodel's topic in - Build logs for subjects built 1751 - 1800

I really cant wait to see this one! She's going to look very different to a regular POF -

I used aerosol paint for the underside and all the red areas (but you can use enamel/acrylic etc). Humbrol enamel for the blue and yellow areas, and Vallejo acrylics for the small details. Check the manual as I put the paint type and numbers in there. I wrote the manual and did the build, but forgot the blue paint code. That's Humbrol 25 Matt Blue. I also used 74 Linen for the Yellow.

- 164 replies

-

- vanguard models

- flirt

-

(and 1 more)

Tagged with:

-

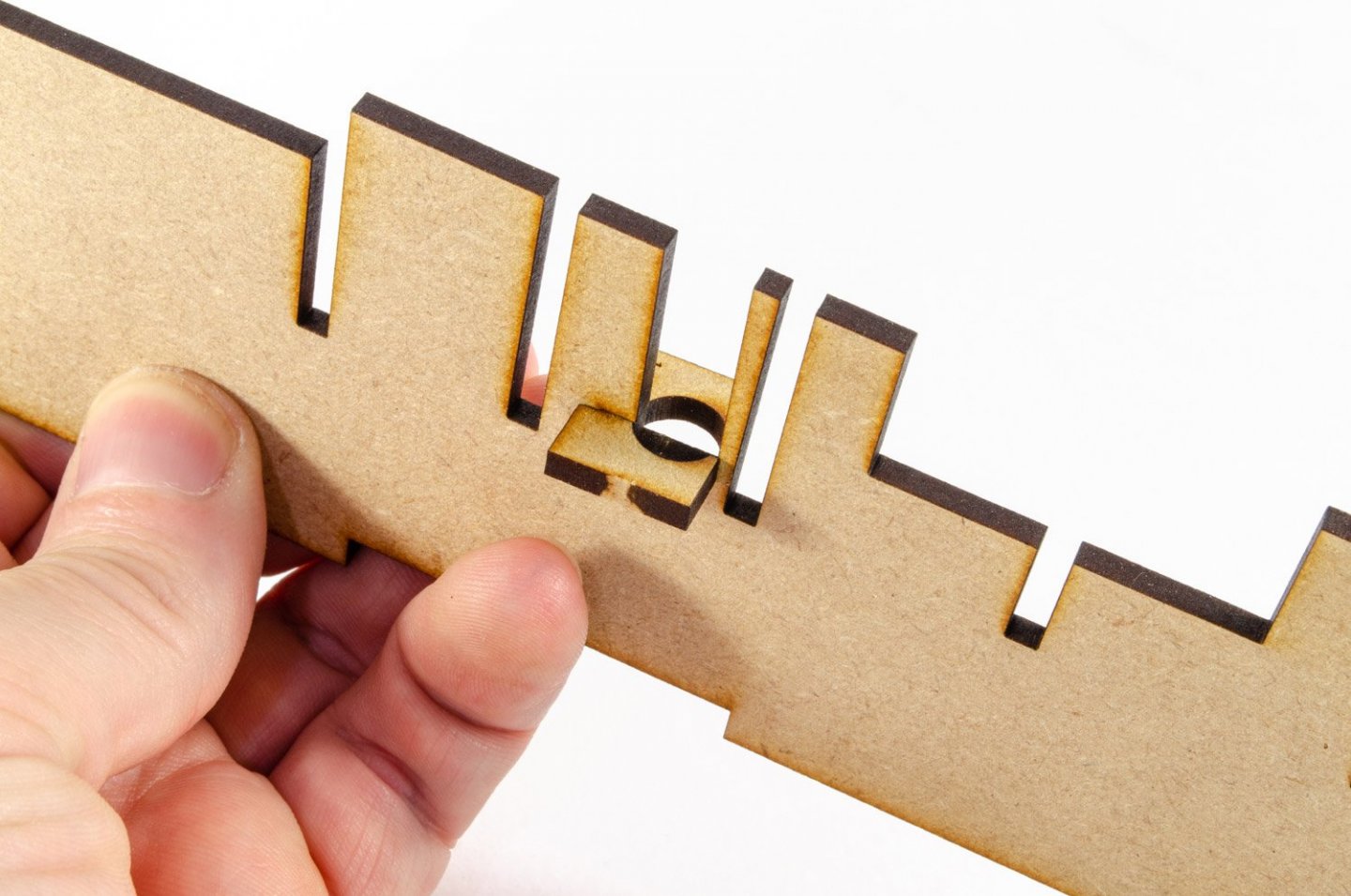

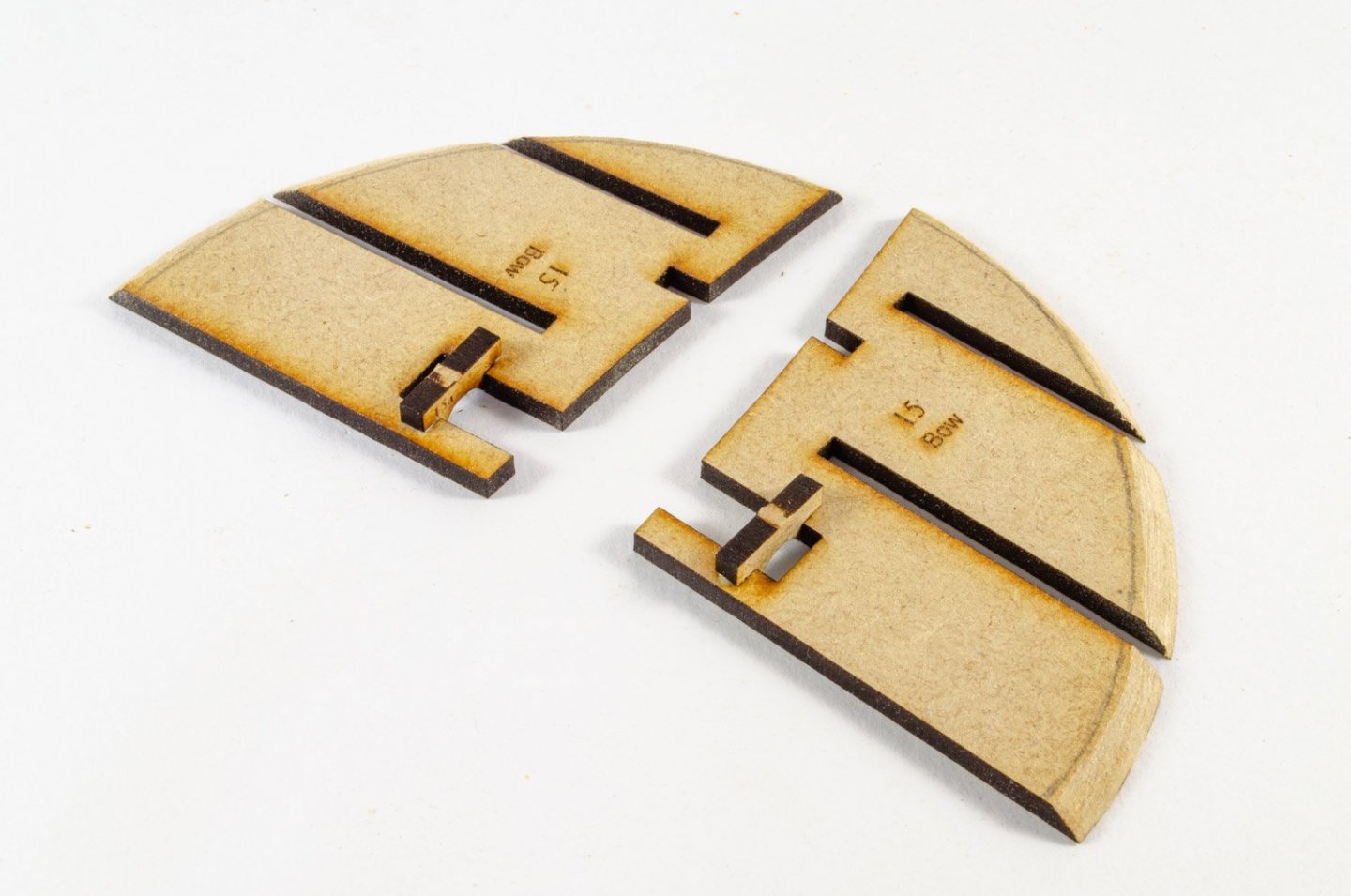

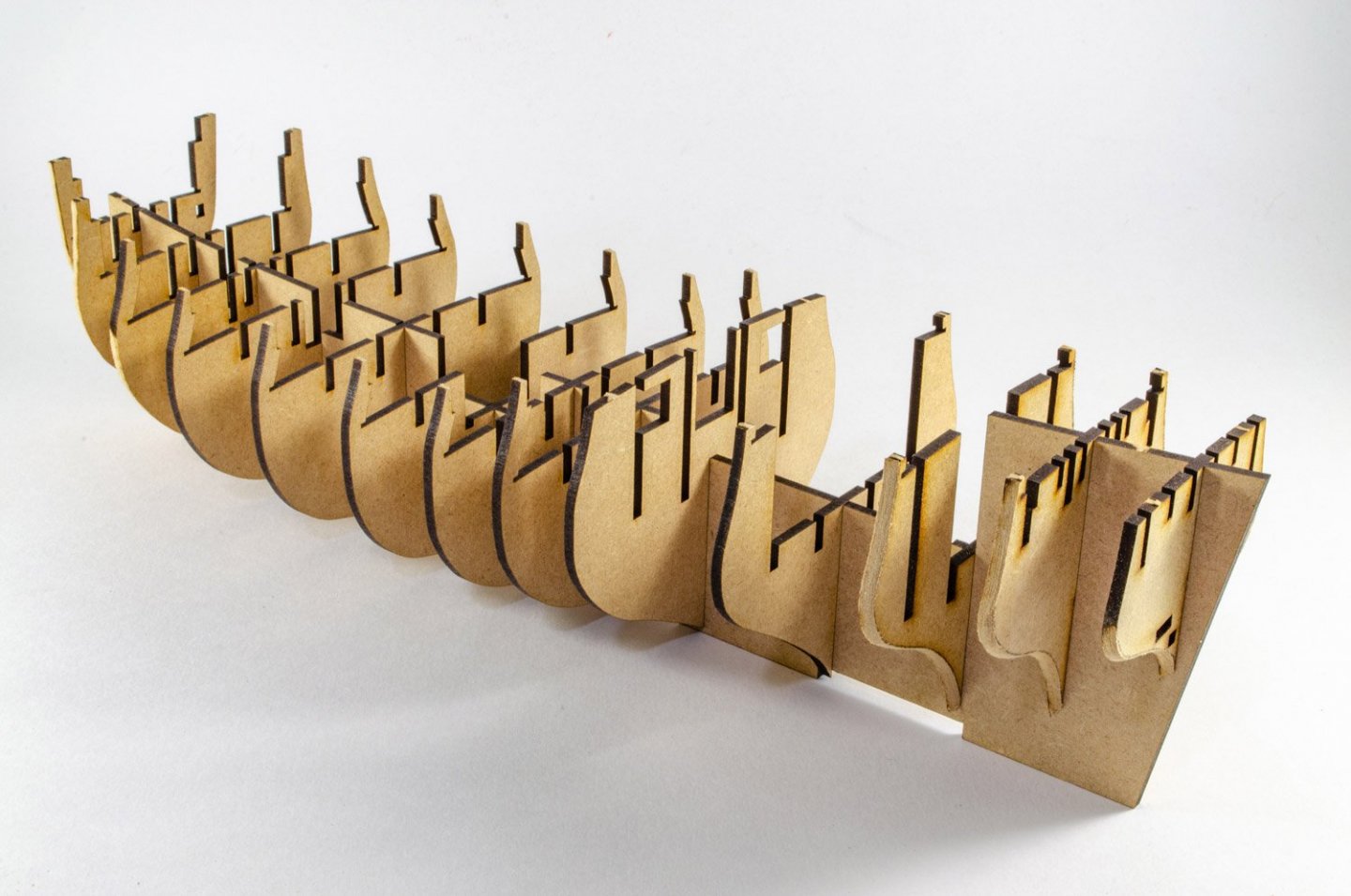

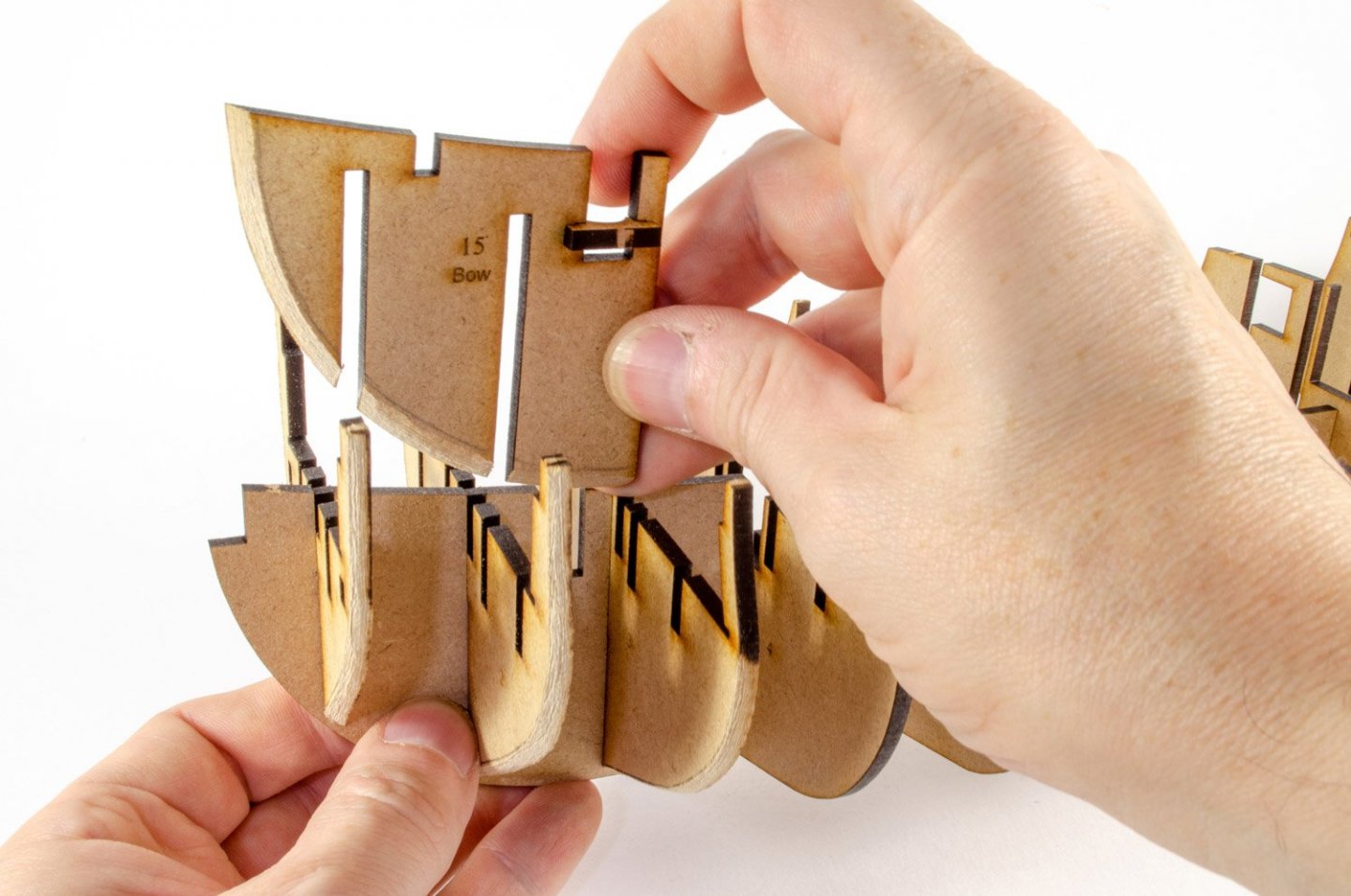

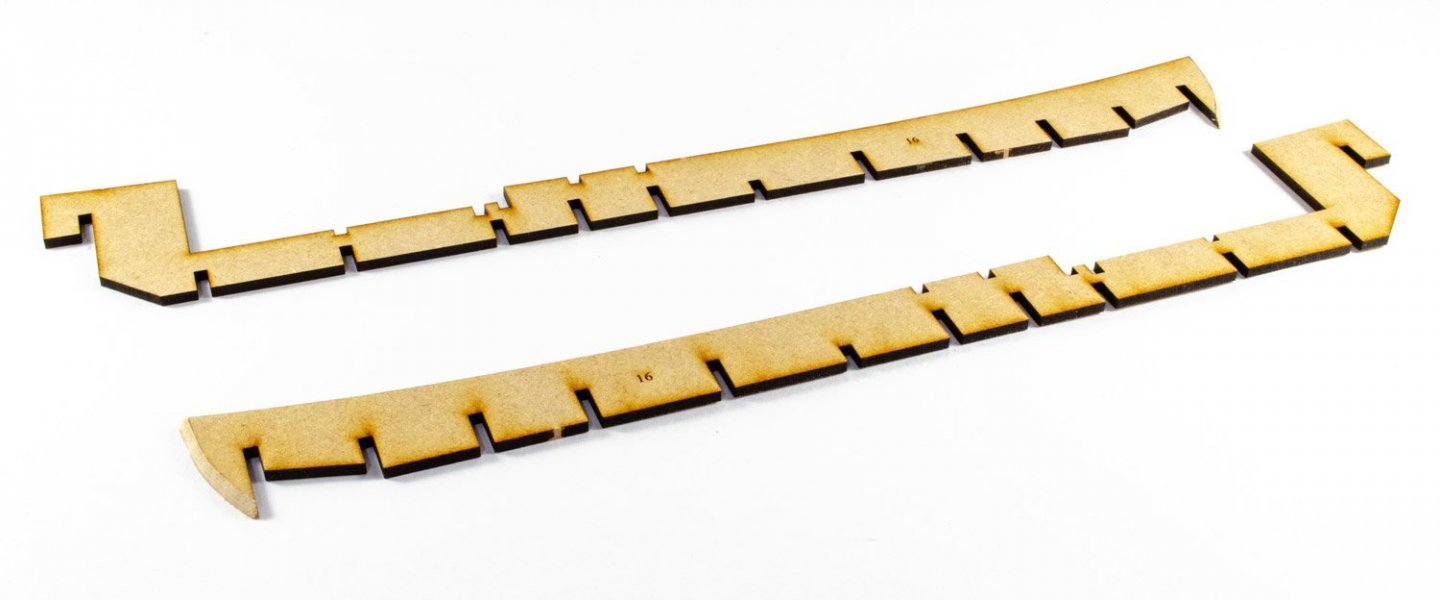

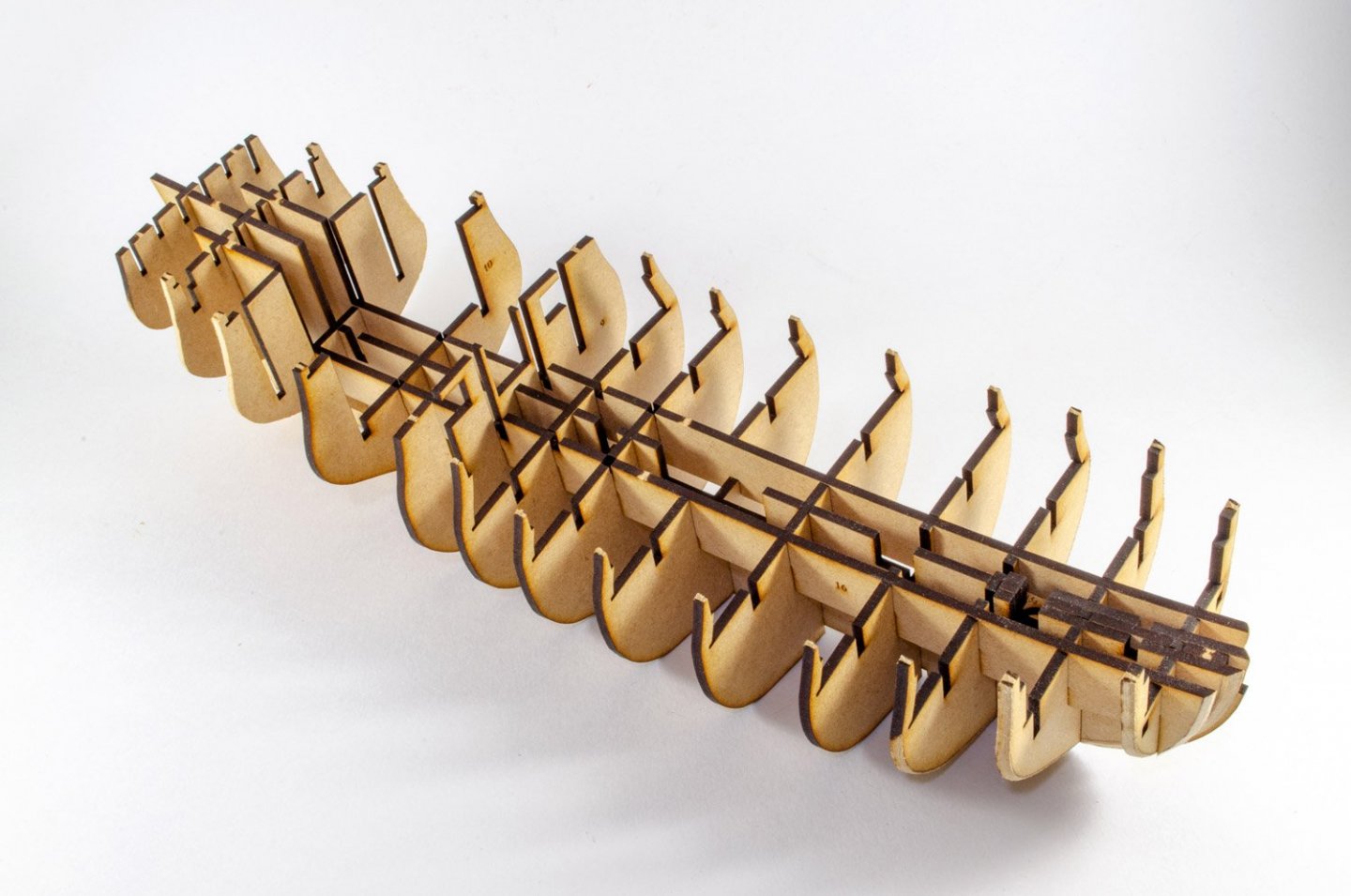

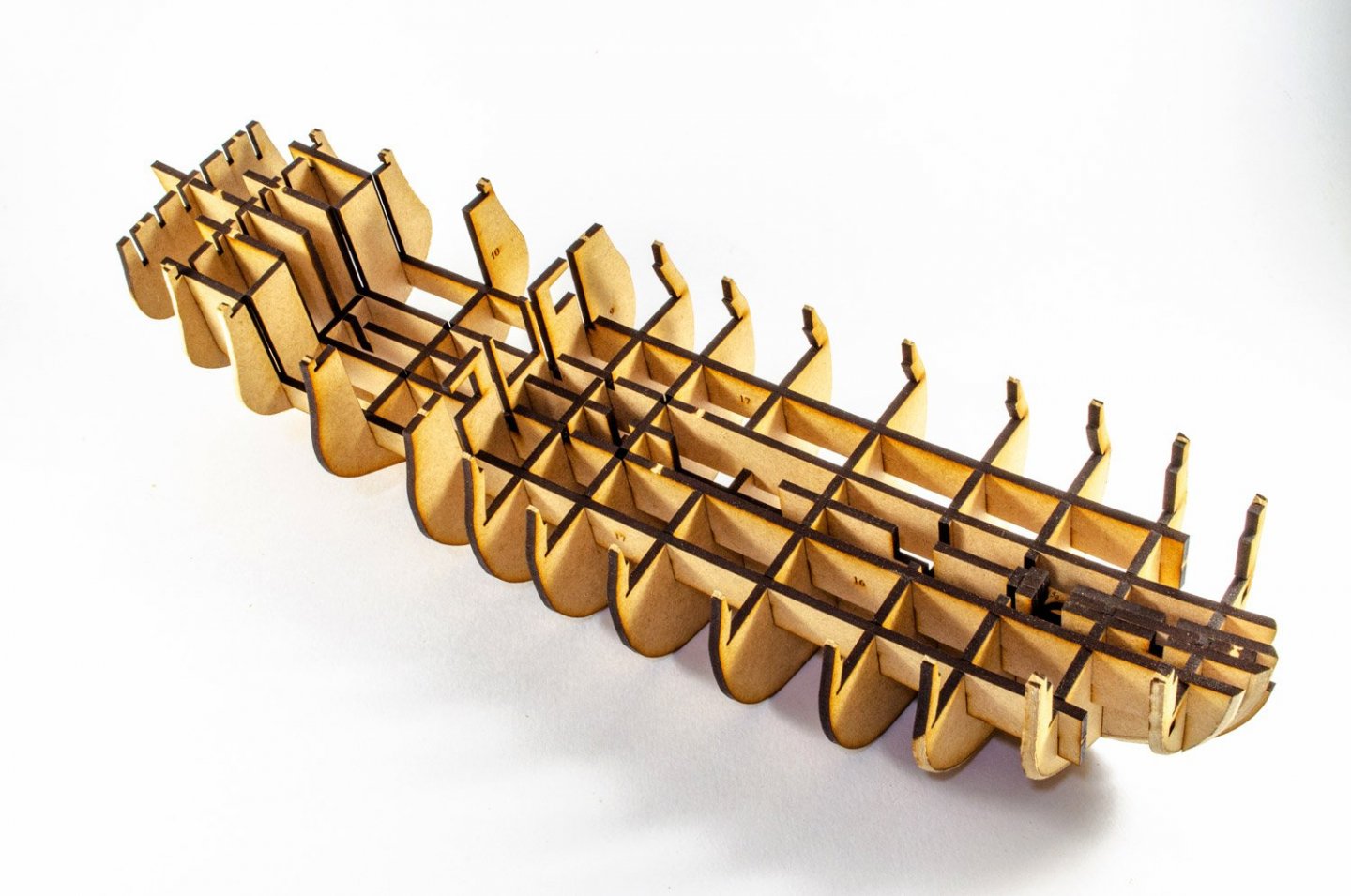

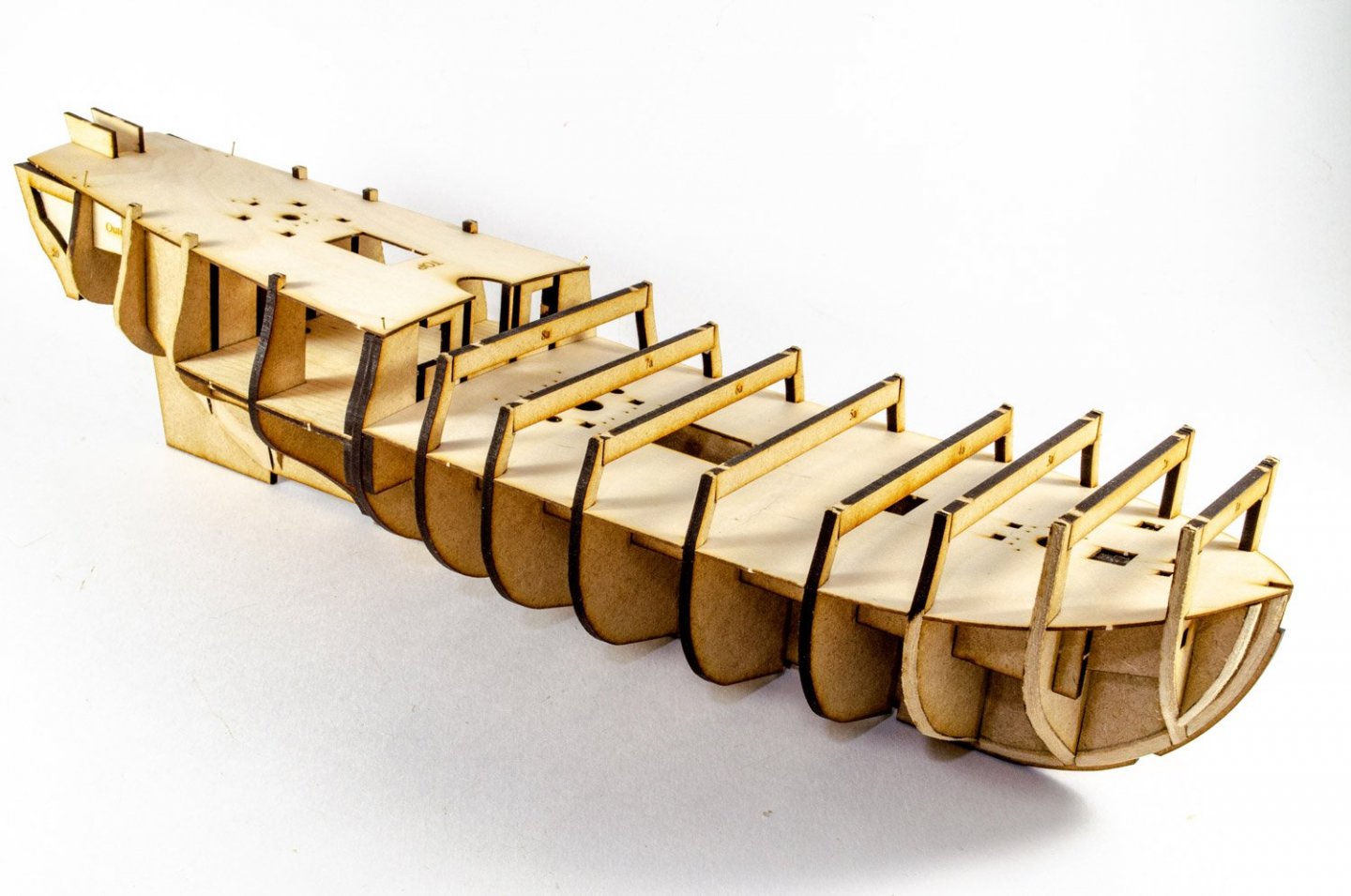

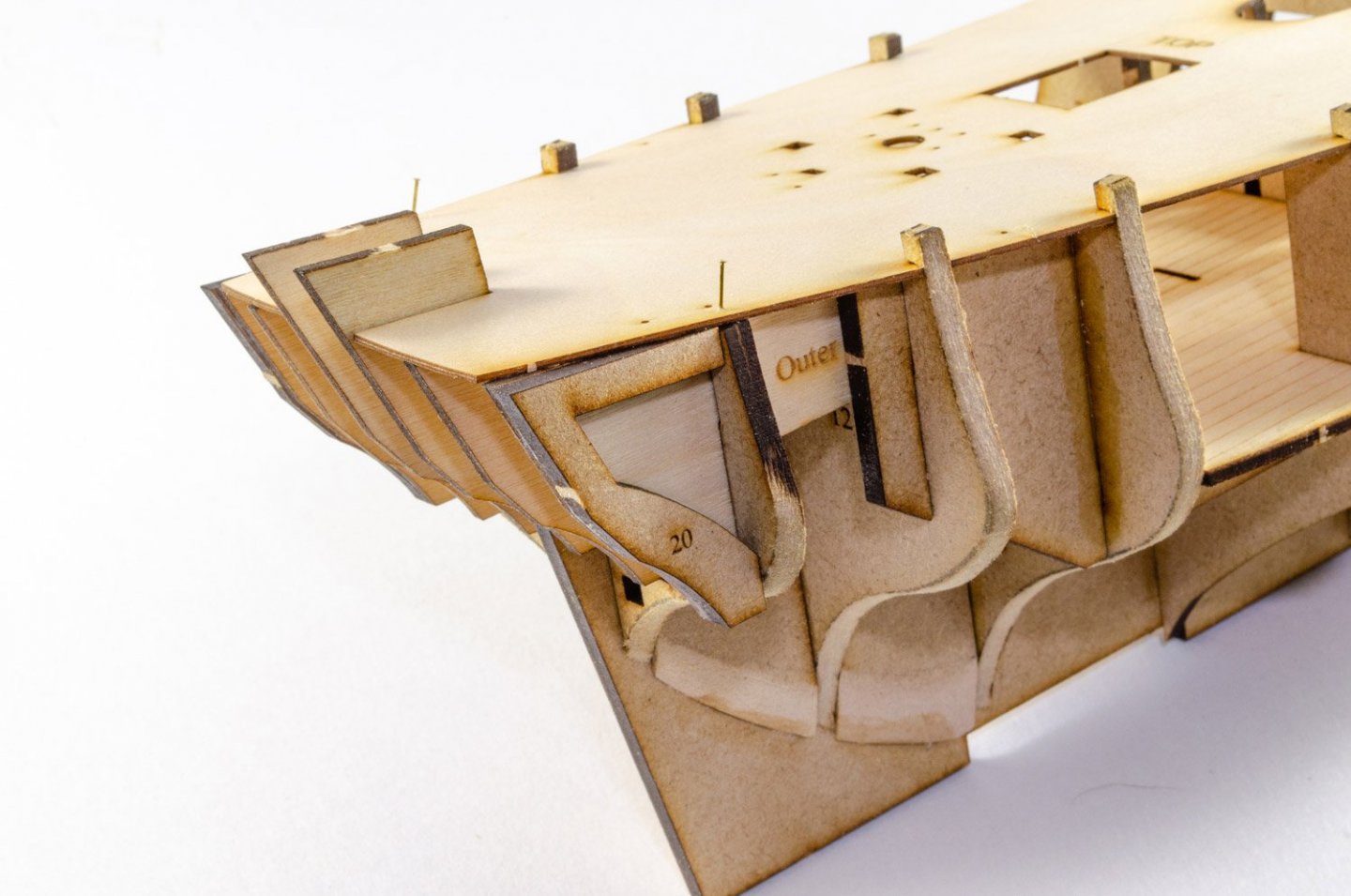

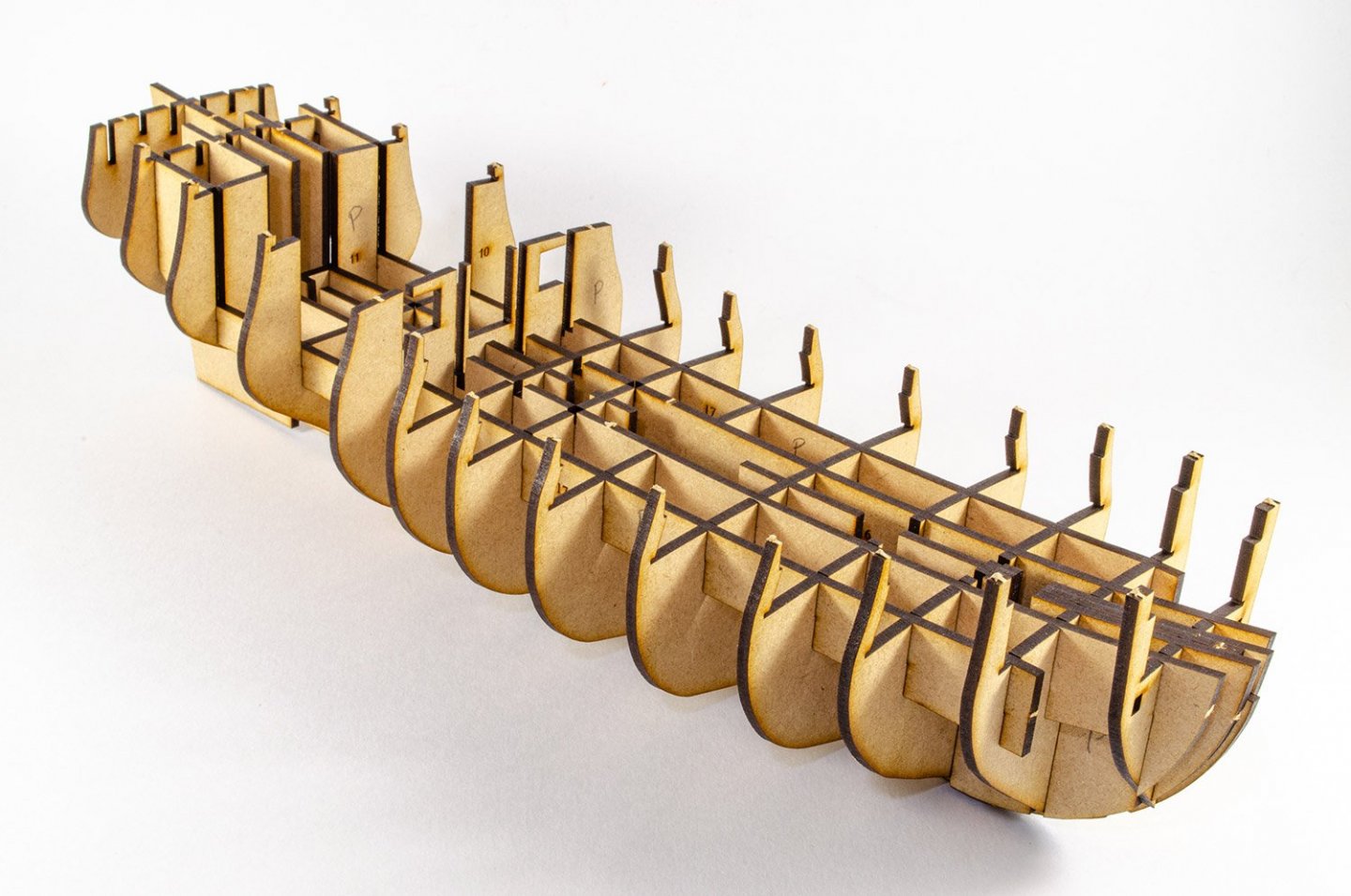

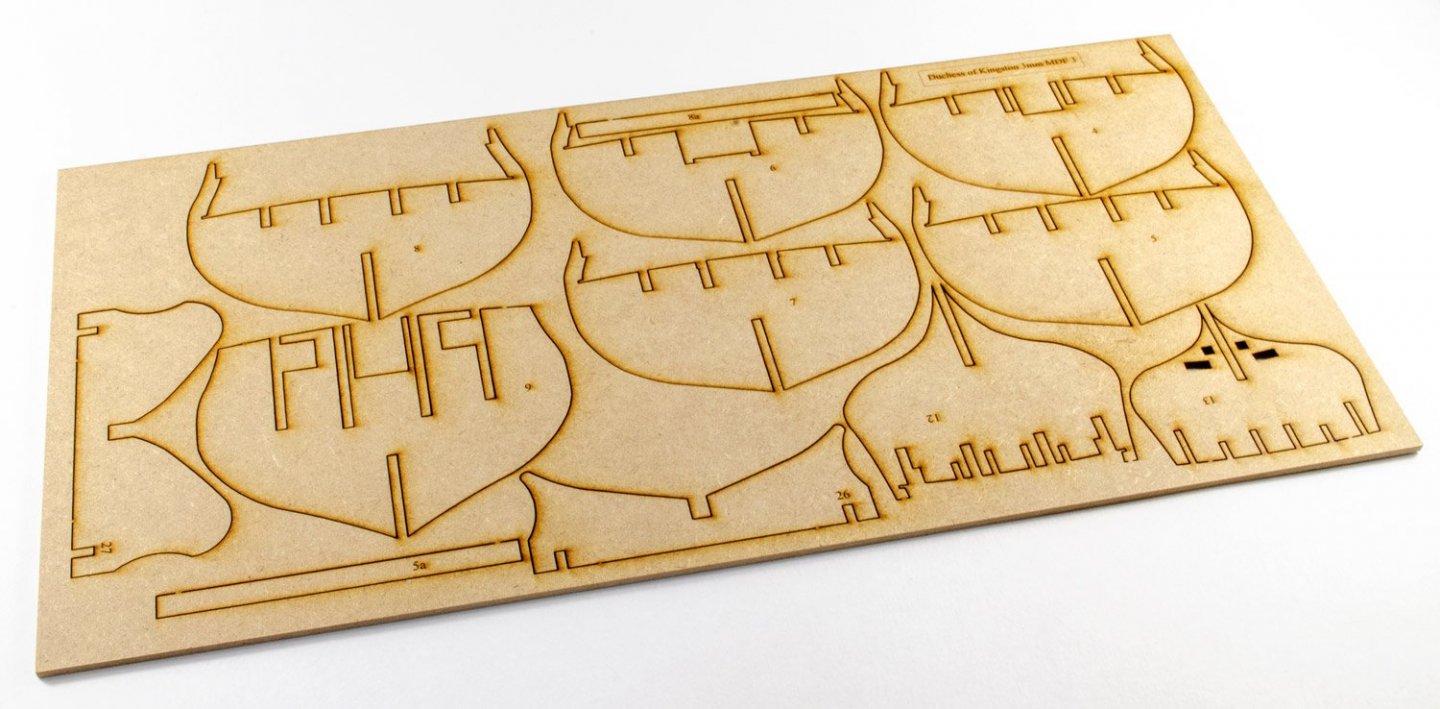

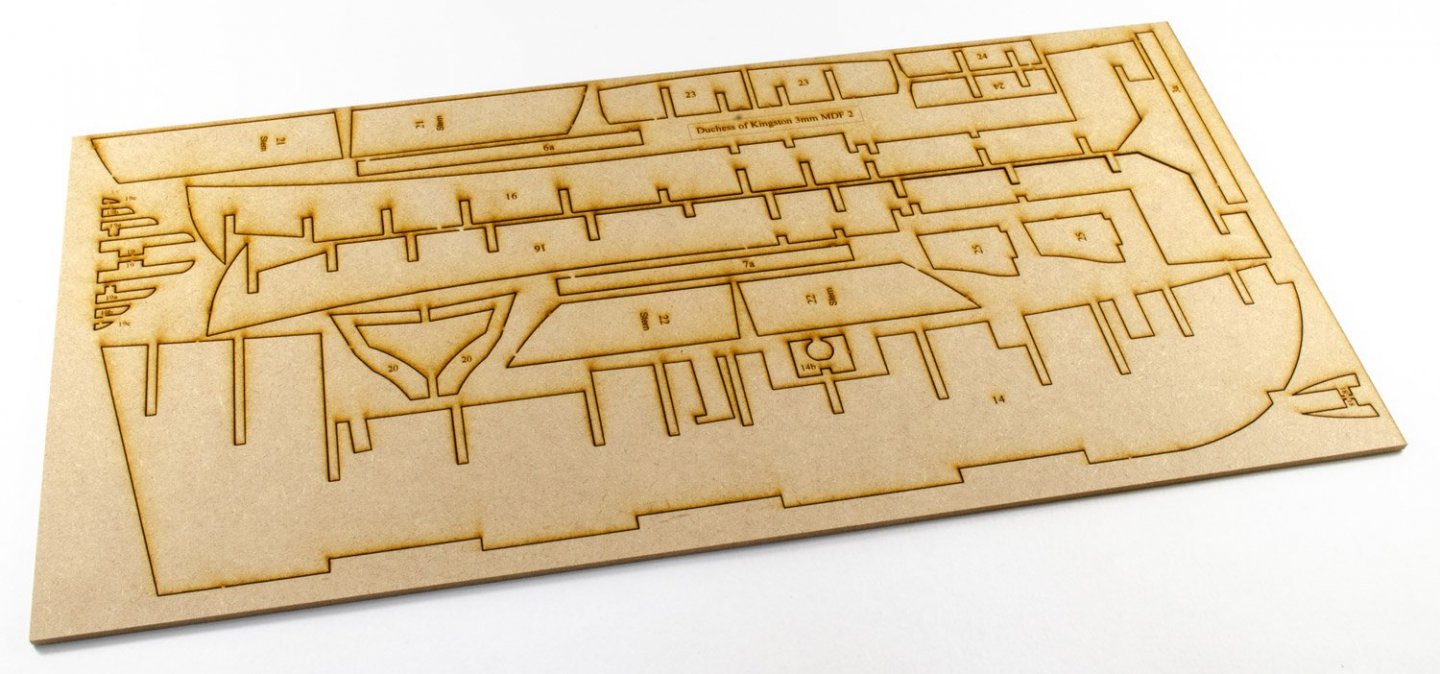

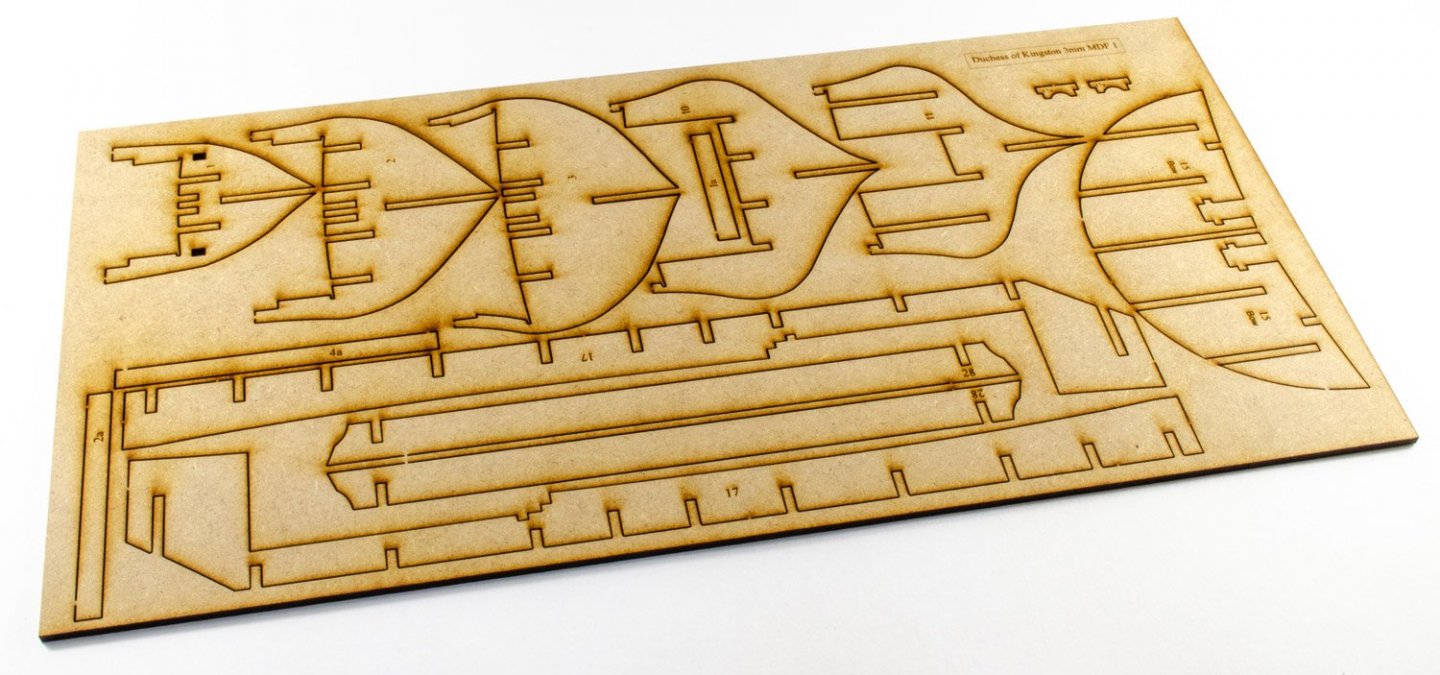

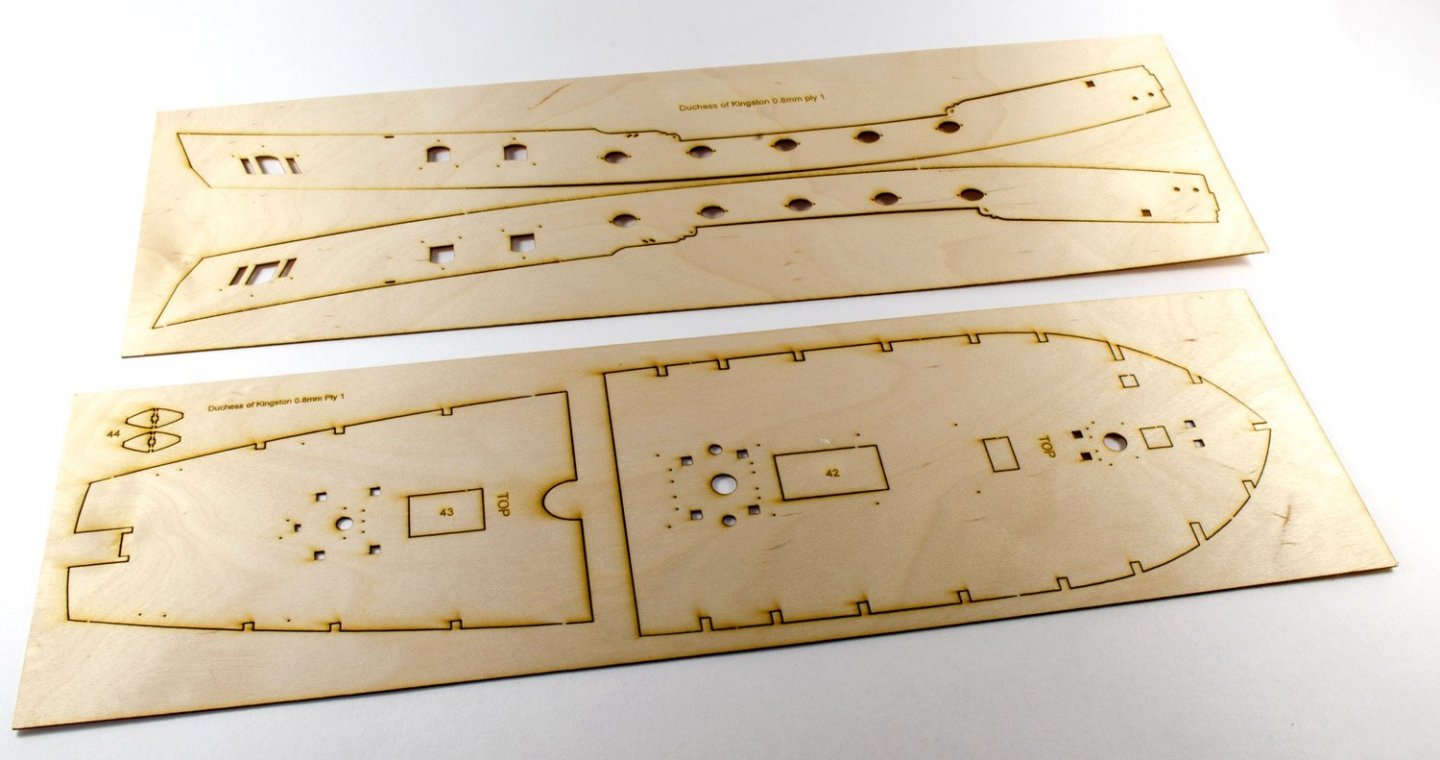

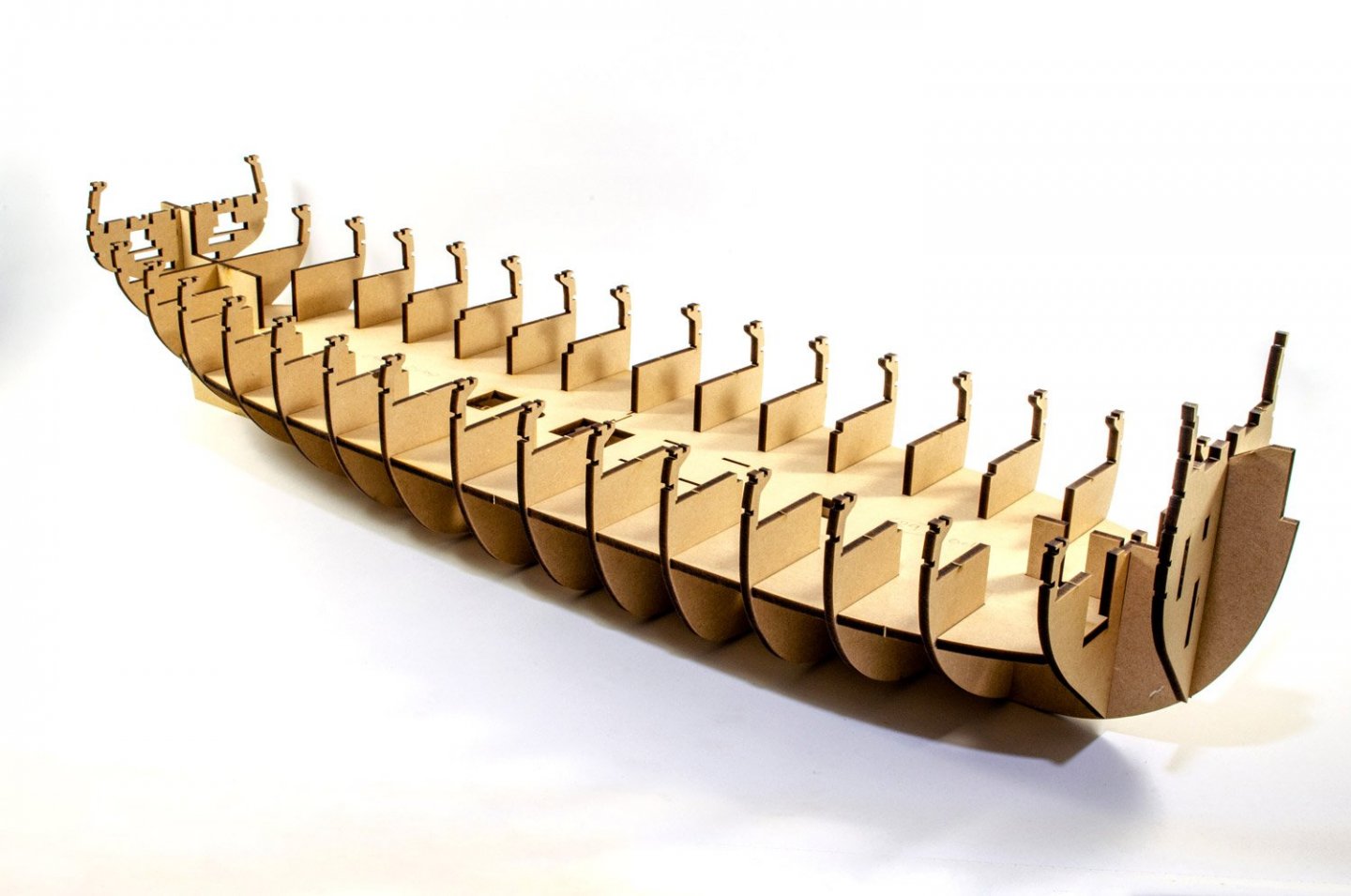

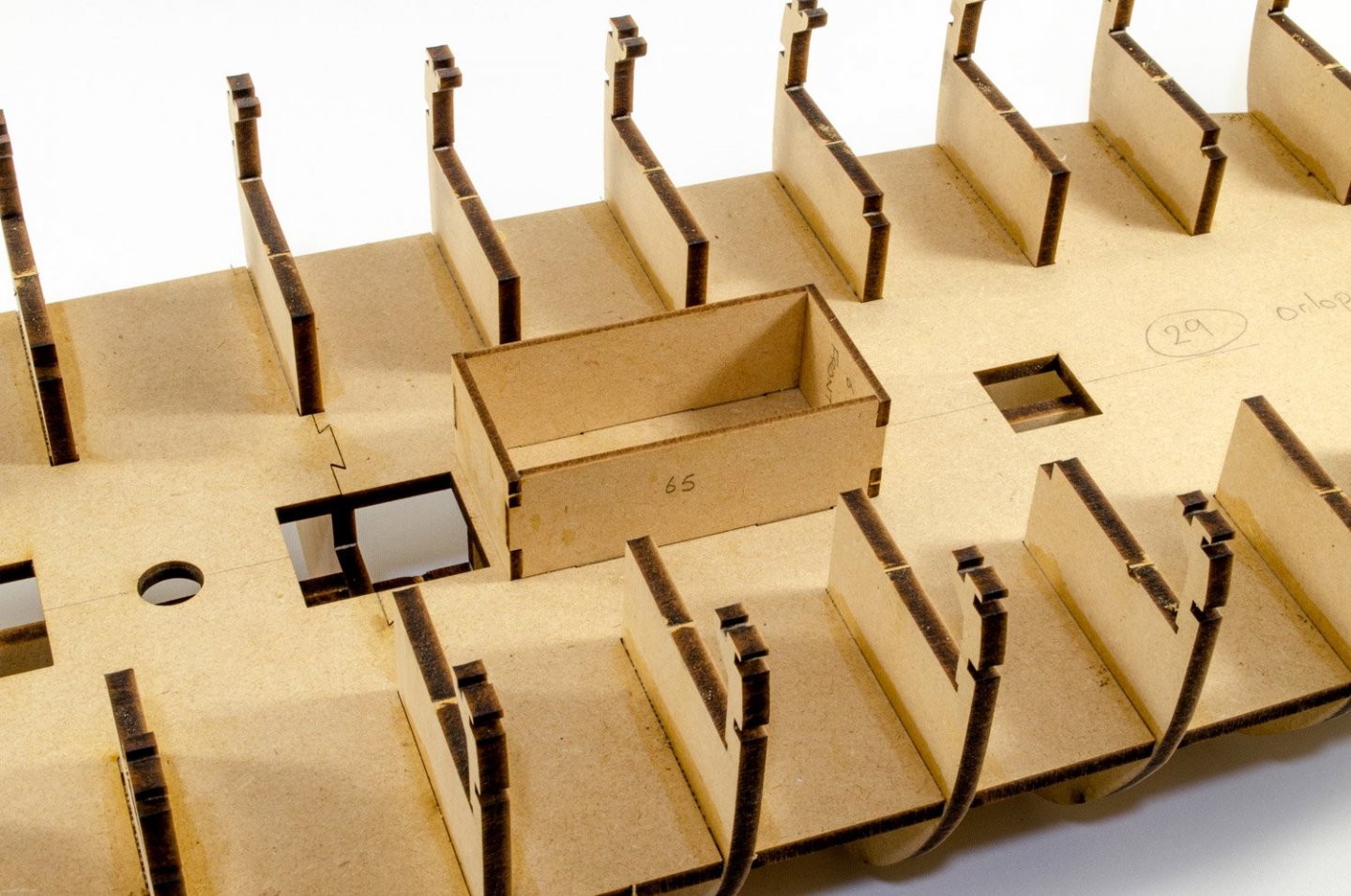

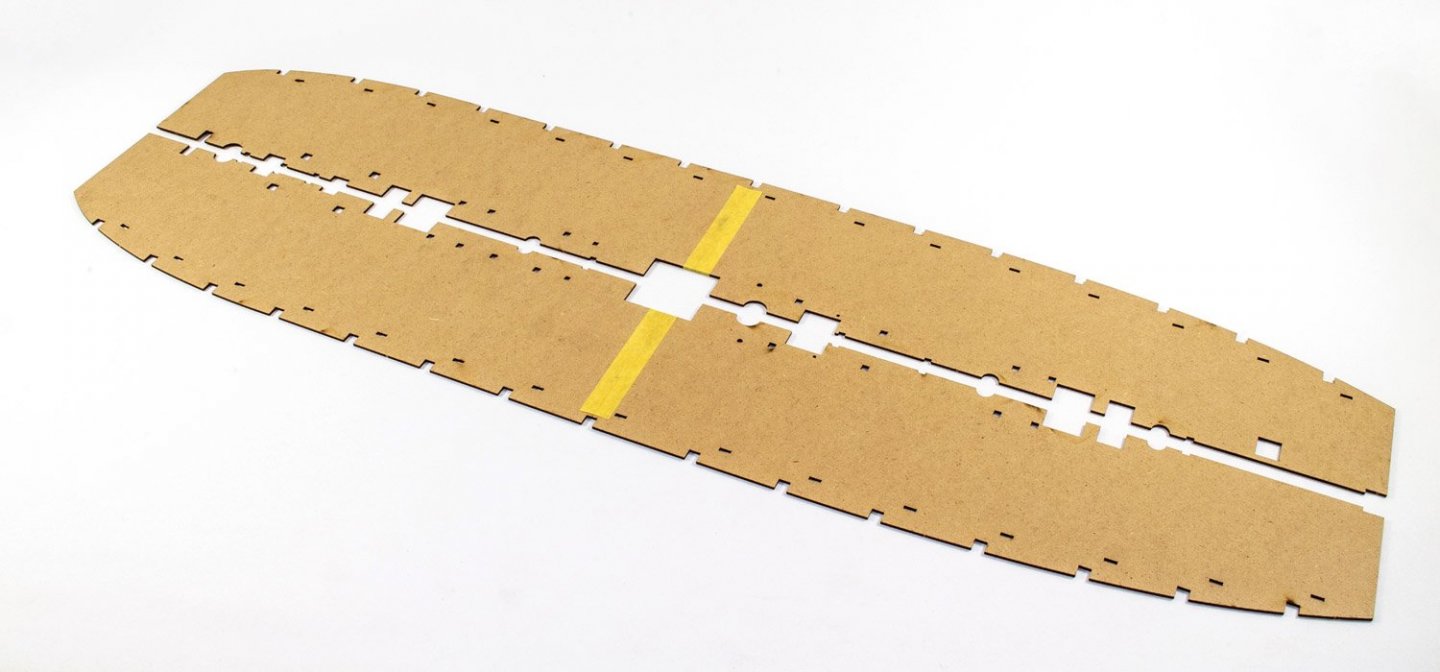

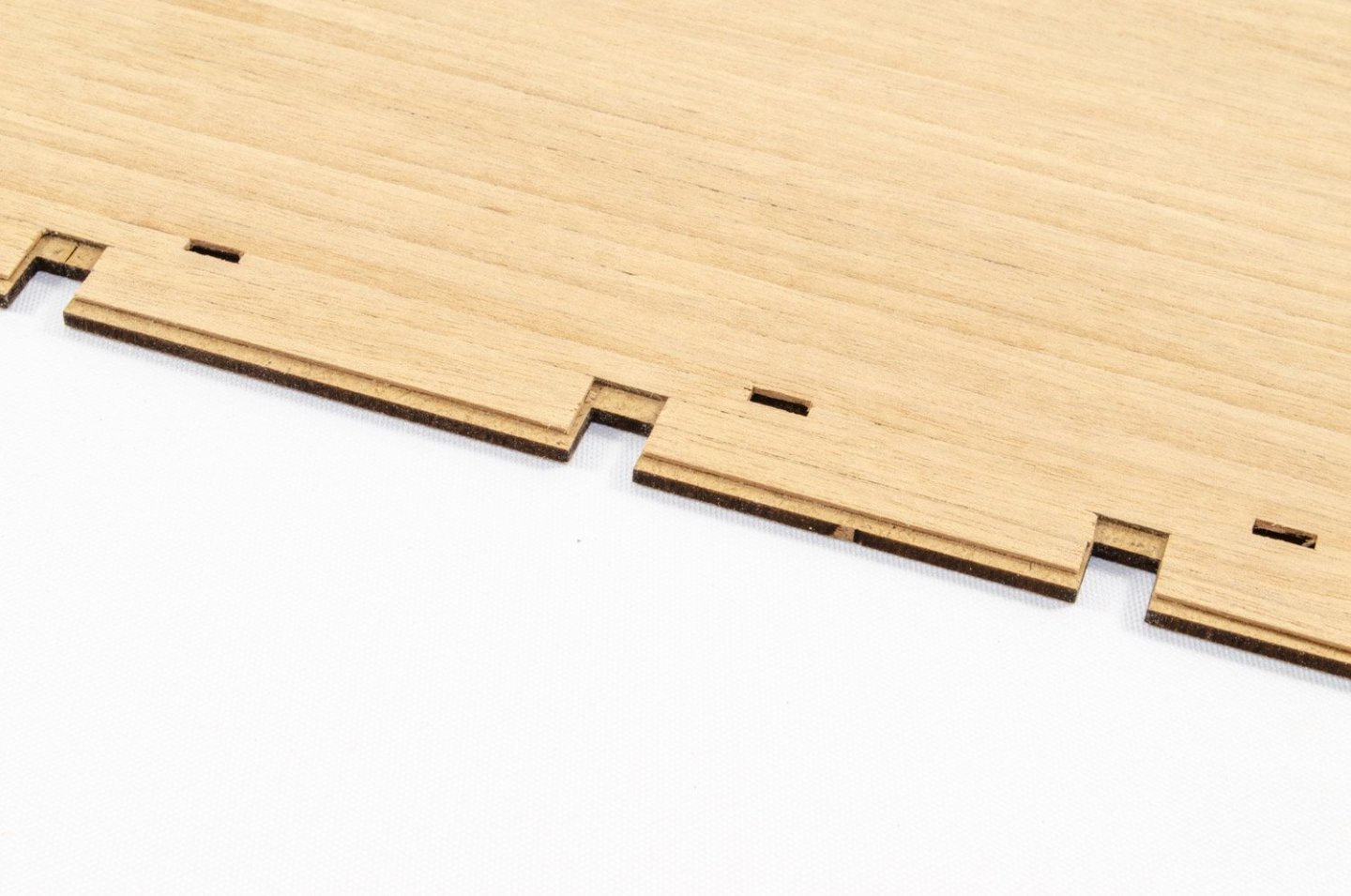

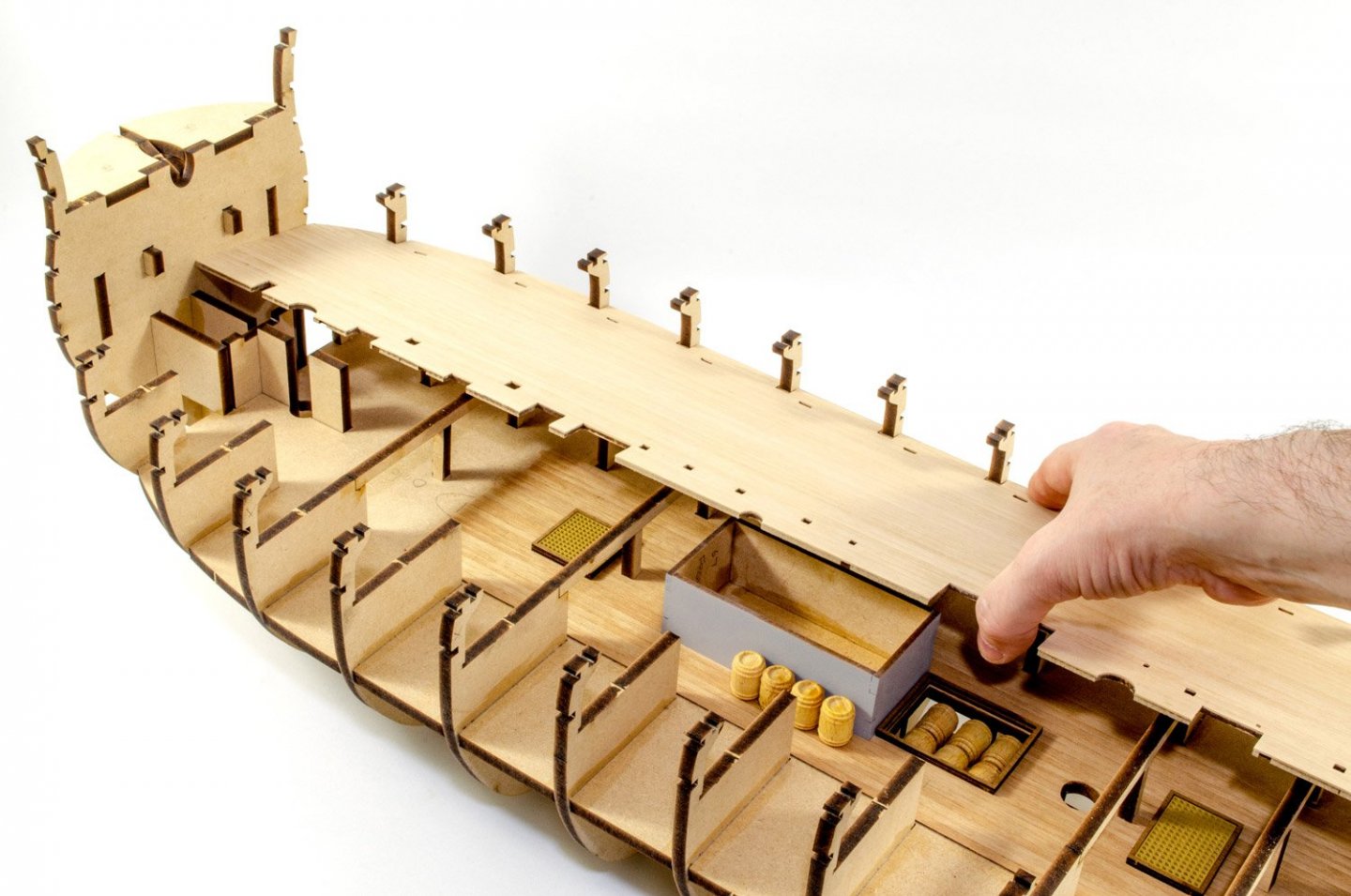

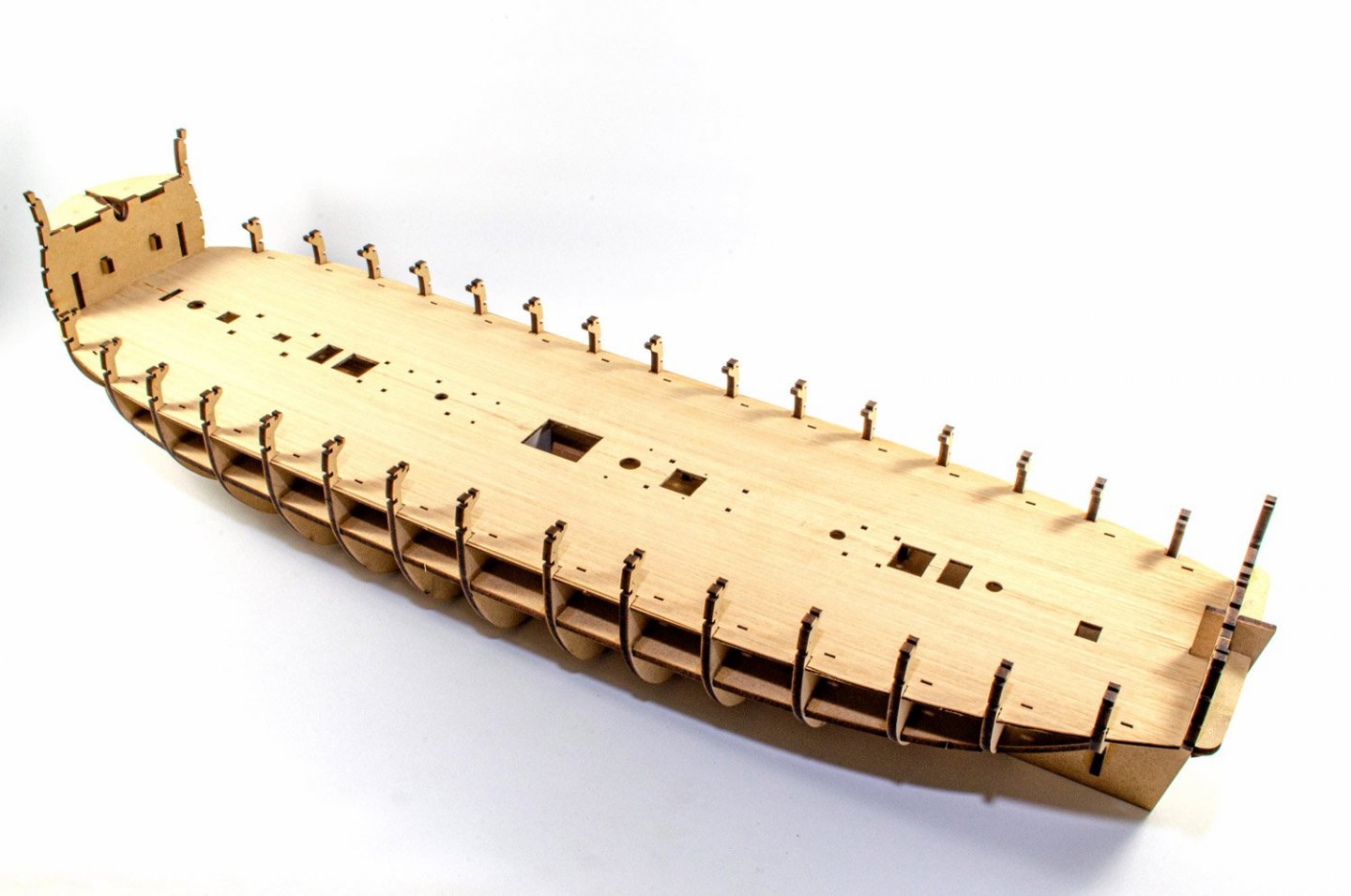

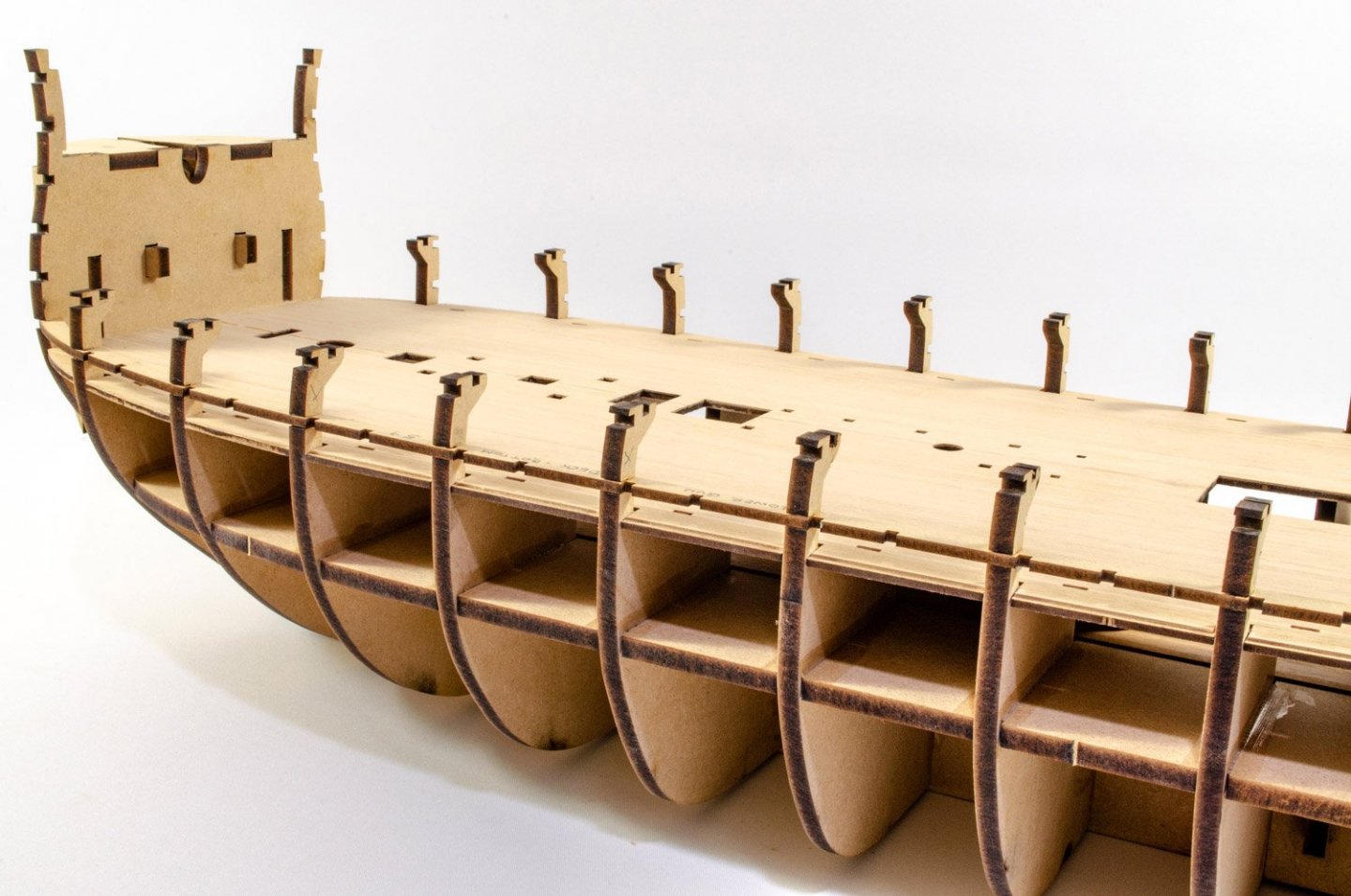

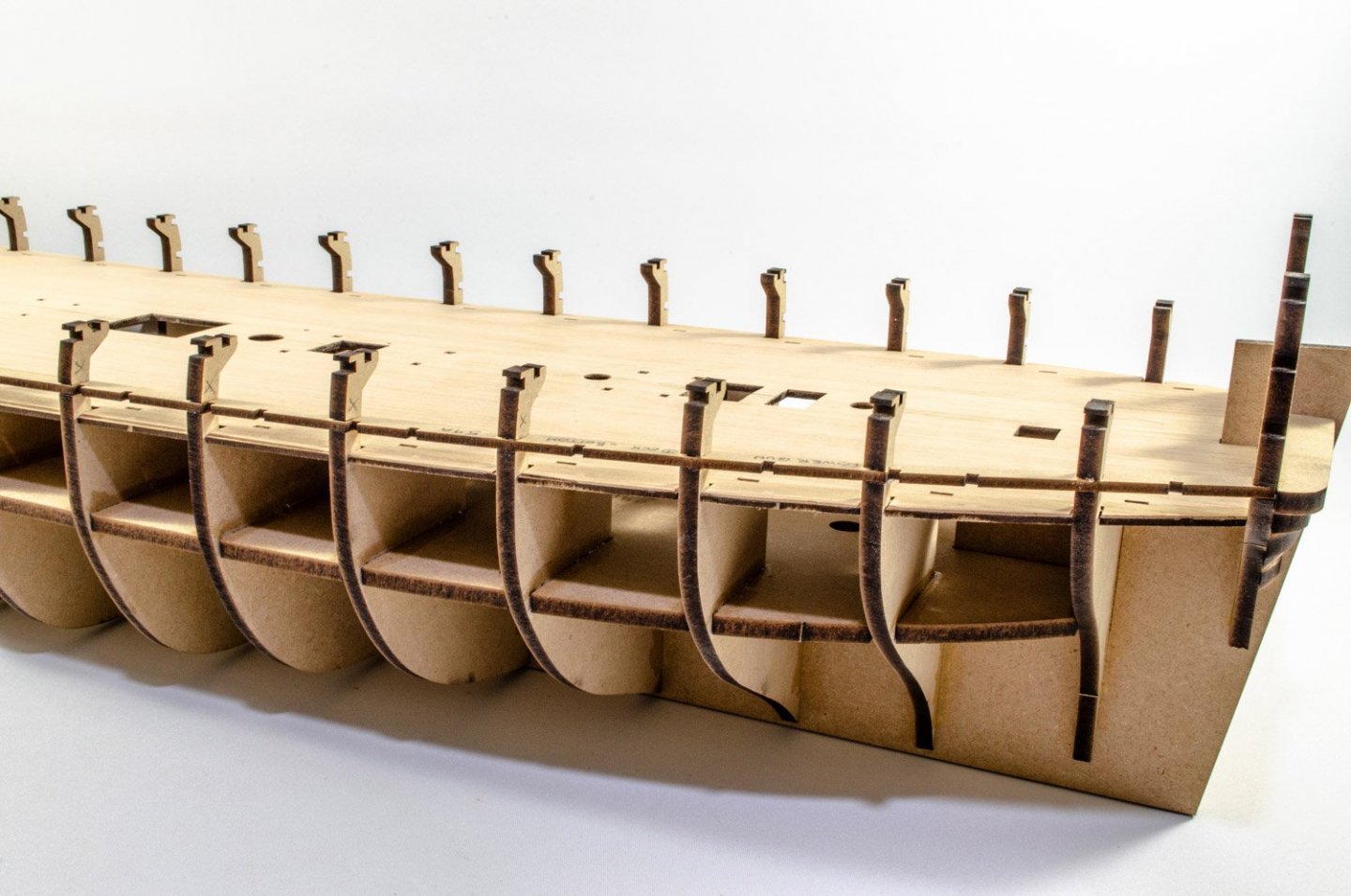

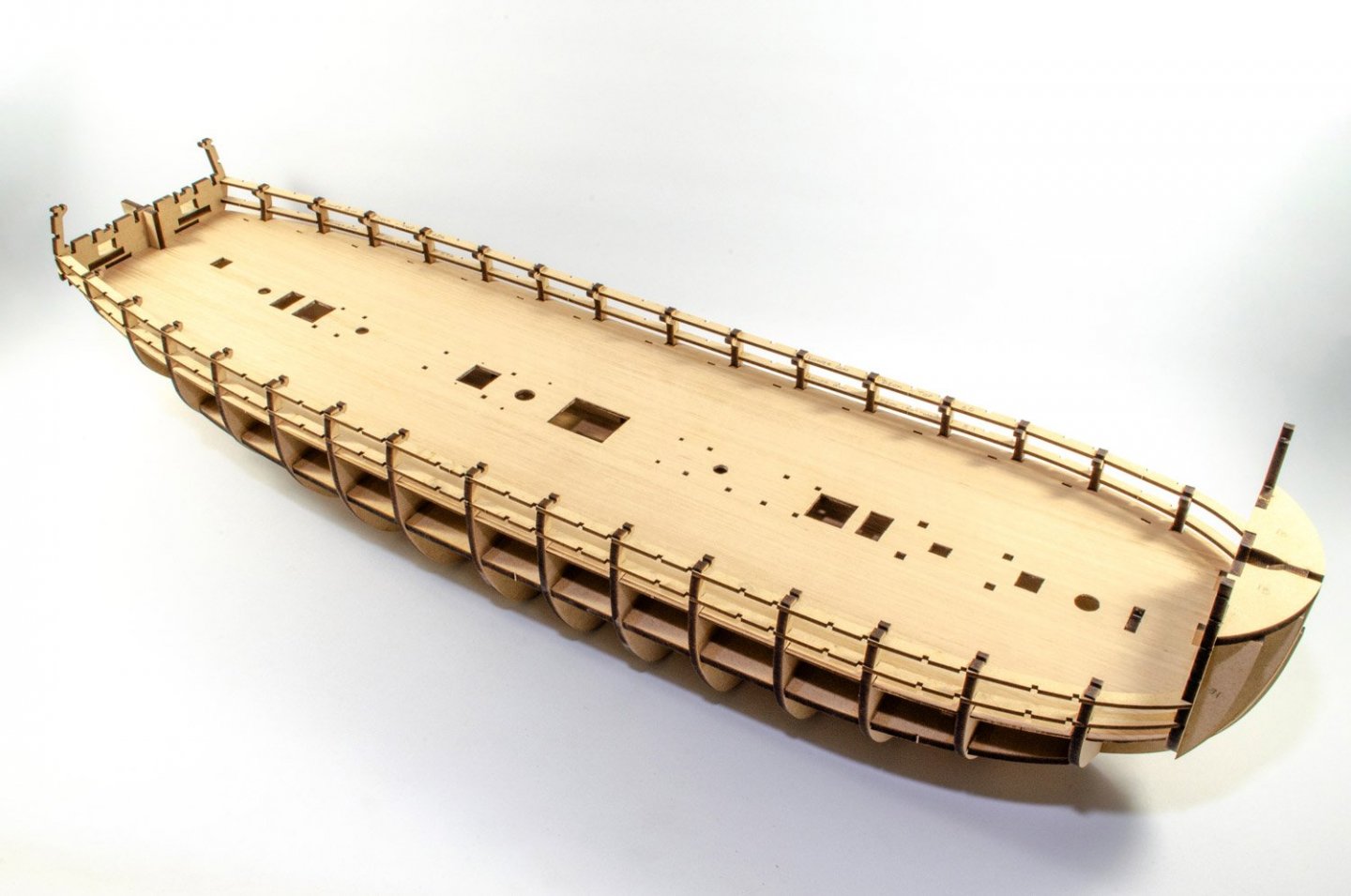

Time for an update. Of course, these photos are part of the instruction manual, so I've taken a selection to show where I'm currently up to with DoK. There are three 3mm MDF sheets, and I took my time to remove all of them and clean the tabs up with a knife and/or sanding stick. All parts are engraved with a number, and I knew all would be used in this quick bench session. First up, I built the temporary cradle. There's a gorgeous acrylic one for final use, complete with engraved nameplate, so this one is the scrapper that I'll throw away at the end. As the model is single deck and won't have the usefulness of another lower deck into which the masts can align, a simple part is slotted into the keel before any work starts. It's most accessible to add at this stage. The part is a nice, snug fit. This is the main mast position. Before any bulkheads are fitted, I first mark a rough bevel line on the first and last three bulkheads and then grind this away with my Dremel. A number of other parts are also bevelled at this stage too, such as the outer cheek parts and the front of the inner longitudinal beams. All bulkheads are now slotted into place. For the foremast, a couple of parts are added to the outer cheeks. These will create a round base into which the down will sit. These are then slotted into place. Now, those longitudinal beams are now added, starting with the inner two... ...and followed by the outer two: At this stage, I painted wood glue into the joints and left the whole lot for a few hours to cure. I prefer this method when there are so many slots and such perfect tolerances. Construction of the stern gallery areas starts with slotting in three frames, easily recognised with their engraved position ID. These just slot straight into position as shown, and are then glued. Four extra pieces are added just before and after the midships cabin area. These are to support the floor/deck at either side. The cabin floor is also fitted and clamped until set. Both the main and upper false decks are now glued into place. These are 0.8mm ply and you need to bend them and allow them to fit into the slots in the bulkhead tabs. This holds the deck parts remarkably flat across all bulkheads. As an insurance policy, I also add a couple of brass pins to the forward upper deck as there are no slots there to hold in position. One nice little touch are the temporary beams which now slot into the bulkhead tabs. These are to give everything some real rigidity whilst the hull is worked on from this point. Afterwards, the beams and tabs will be broken out and discarded. A few extra pieces at the stern, but not quite all. The model is now setting before I start to sand the hull to shape and add the ply bulwarks. More soon...

- 117 replies

-

- vanguard models

- yacht

-

(and 2 more)

Tagged with:

-

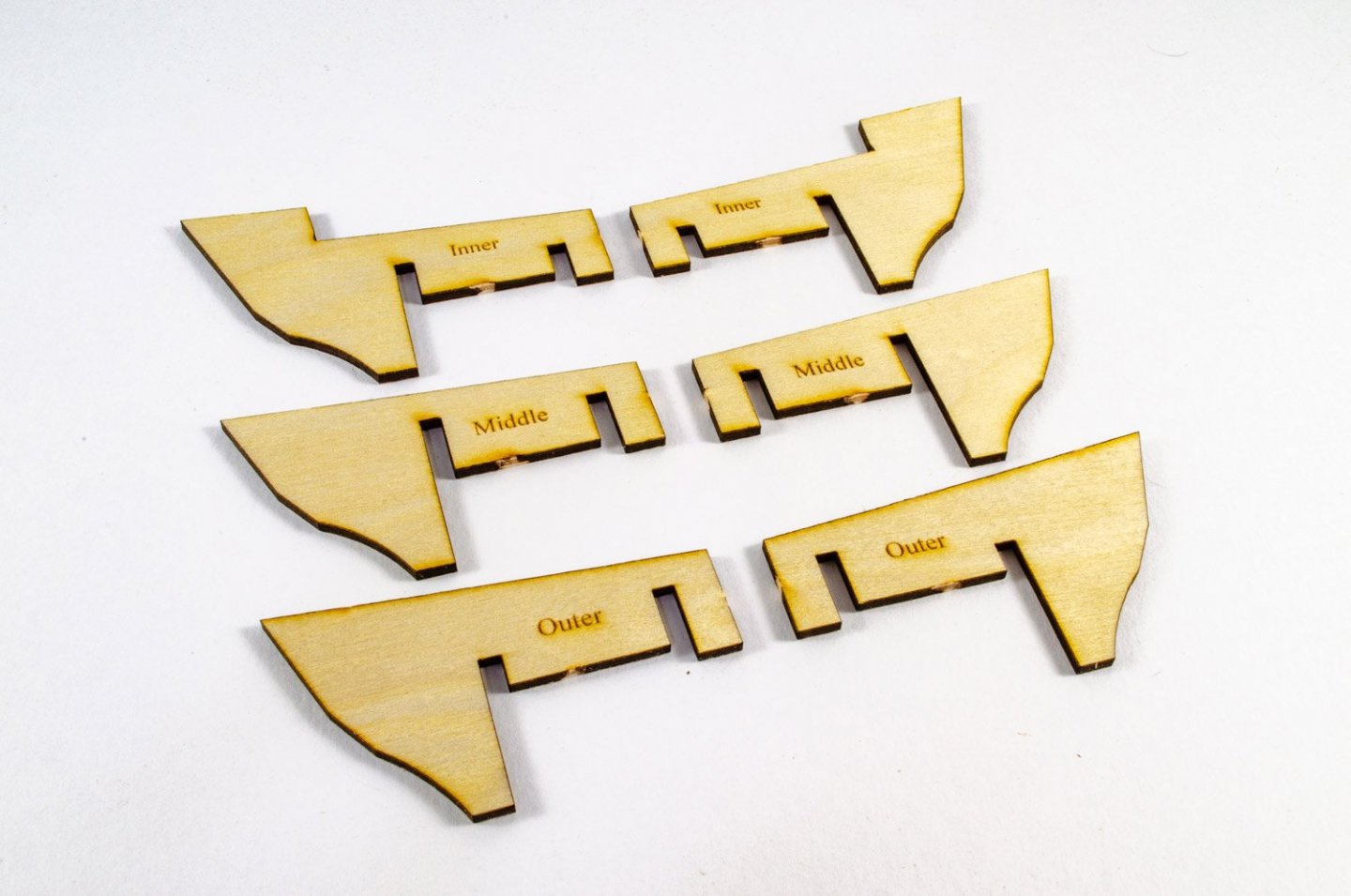

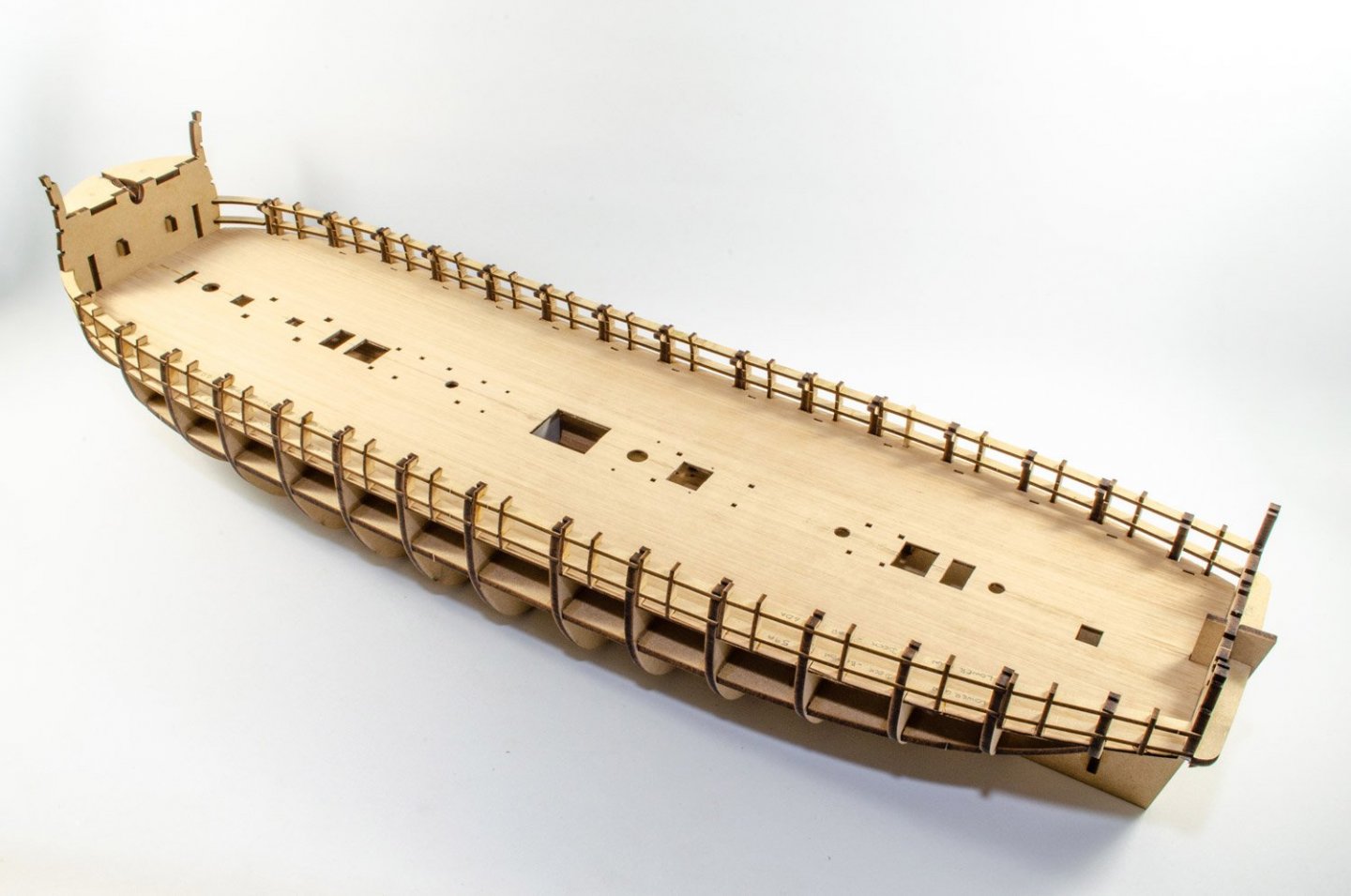

Here's a quick build up of the older parts. This won't be used in the build, but gives an idea of how she'll be built.

- 117 replies

-

- vanguard models

- yacht

-

(and 2 more)

Tagged with:

-

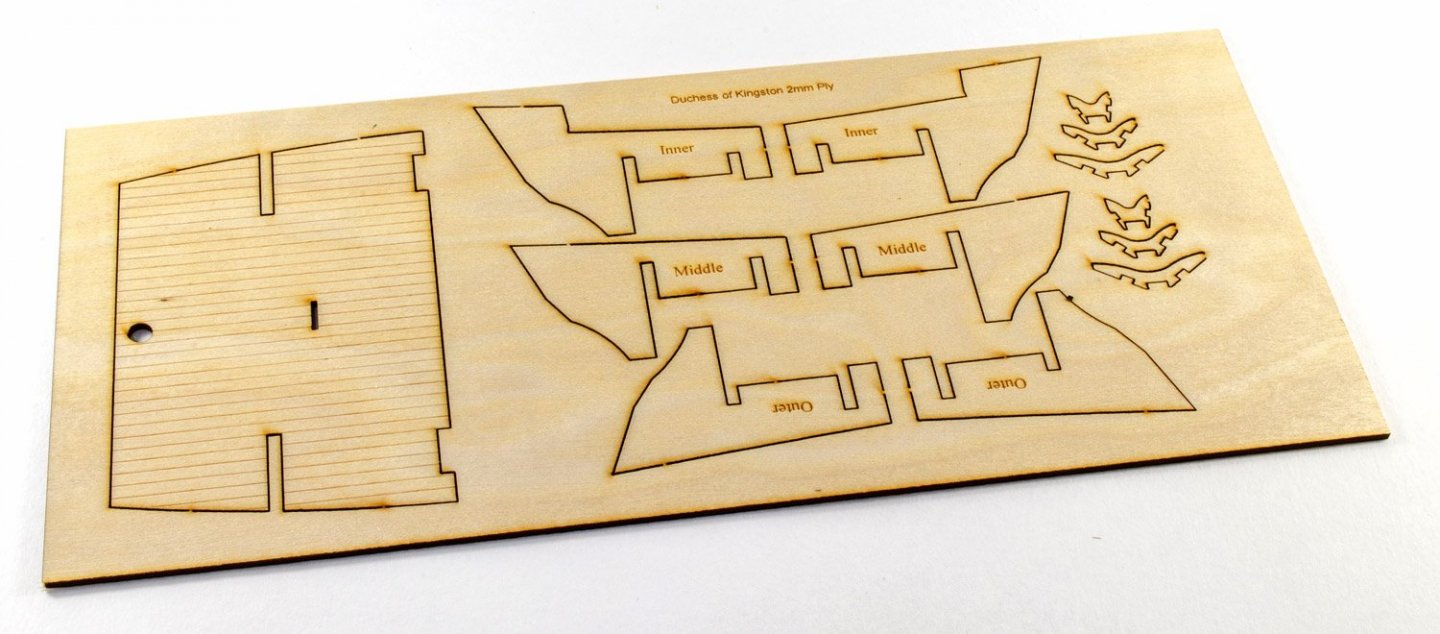

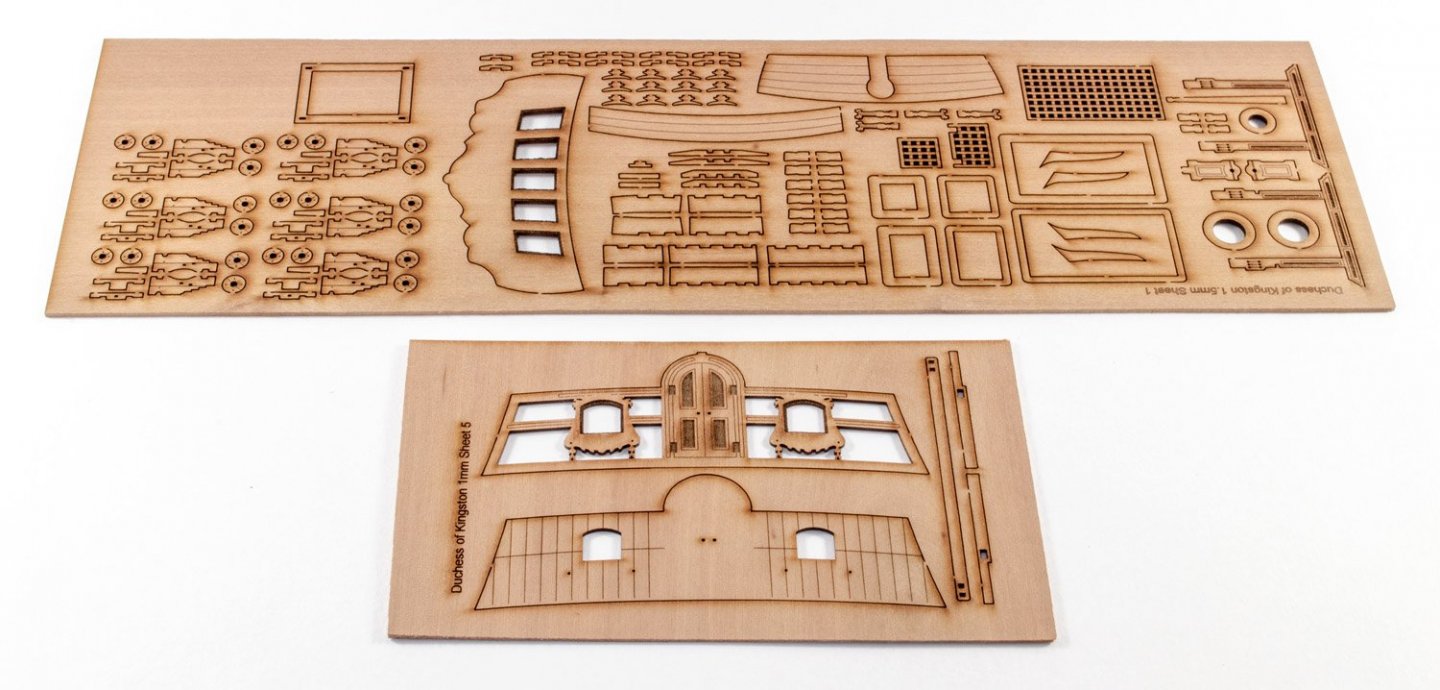

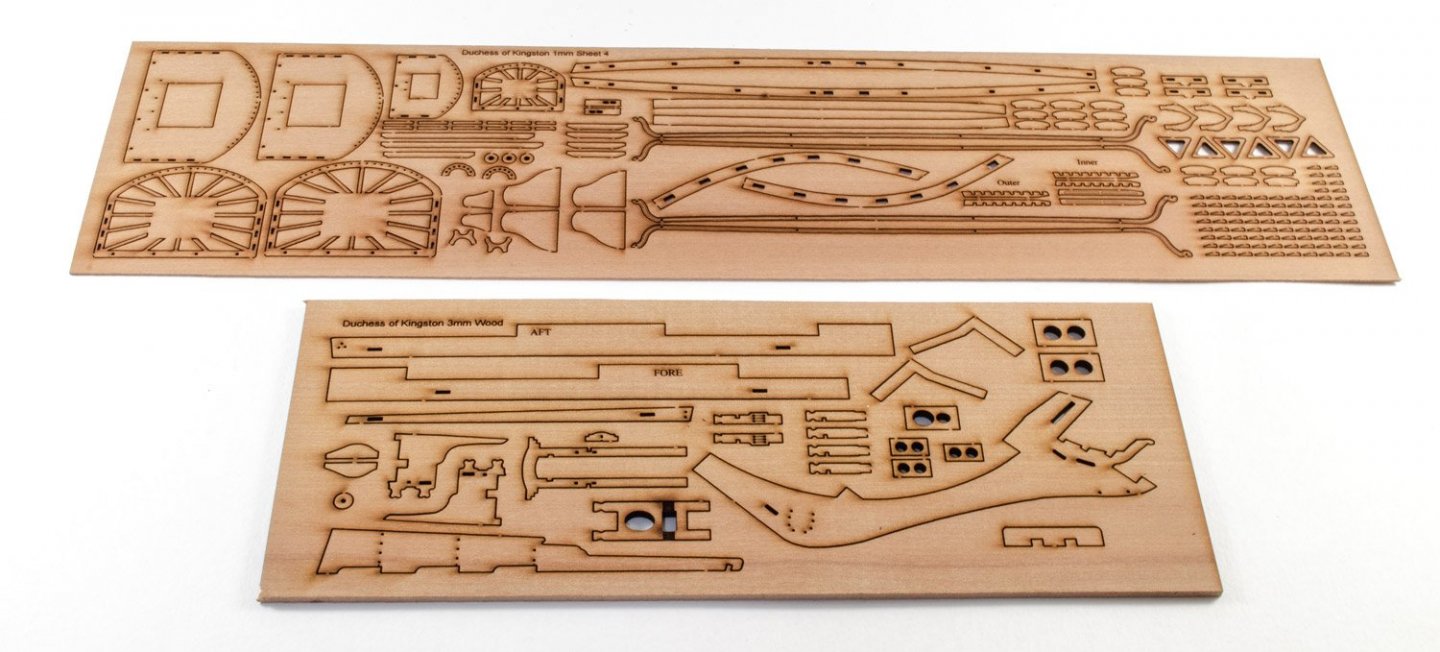

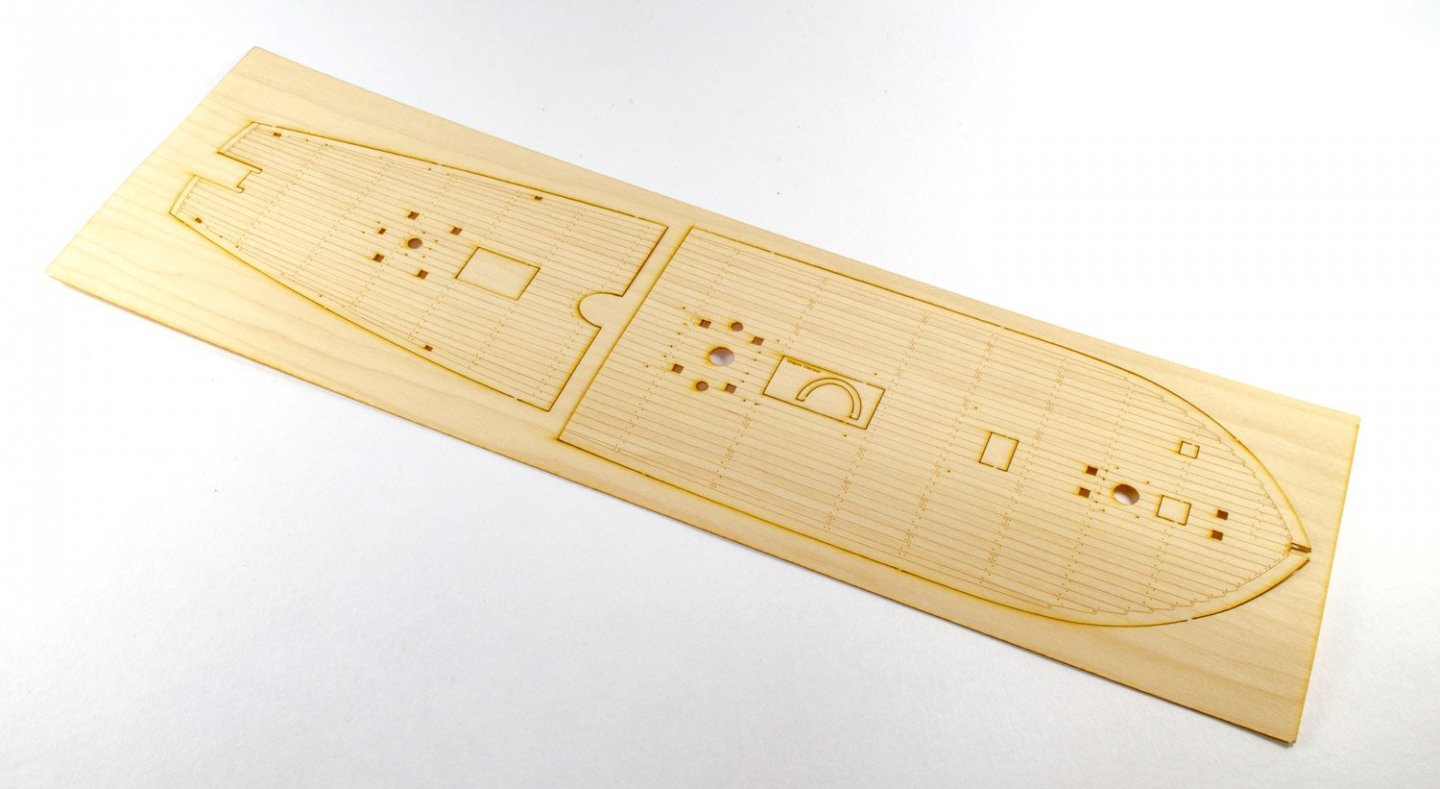

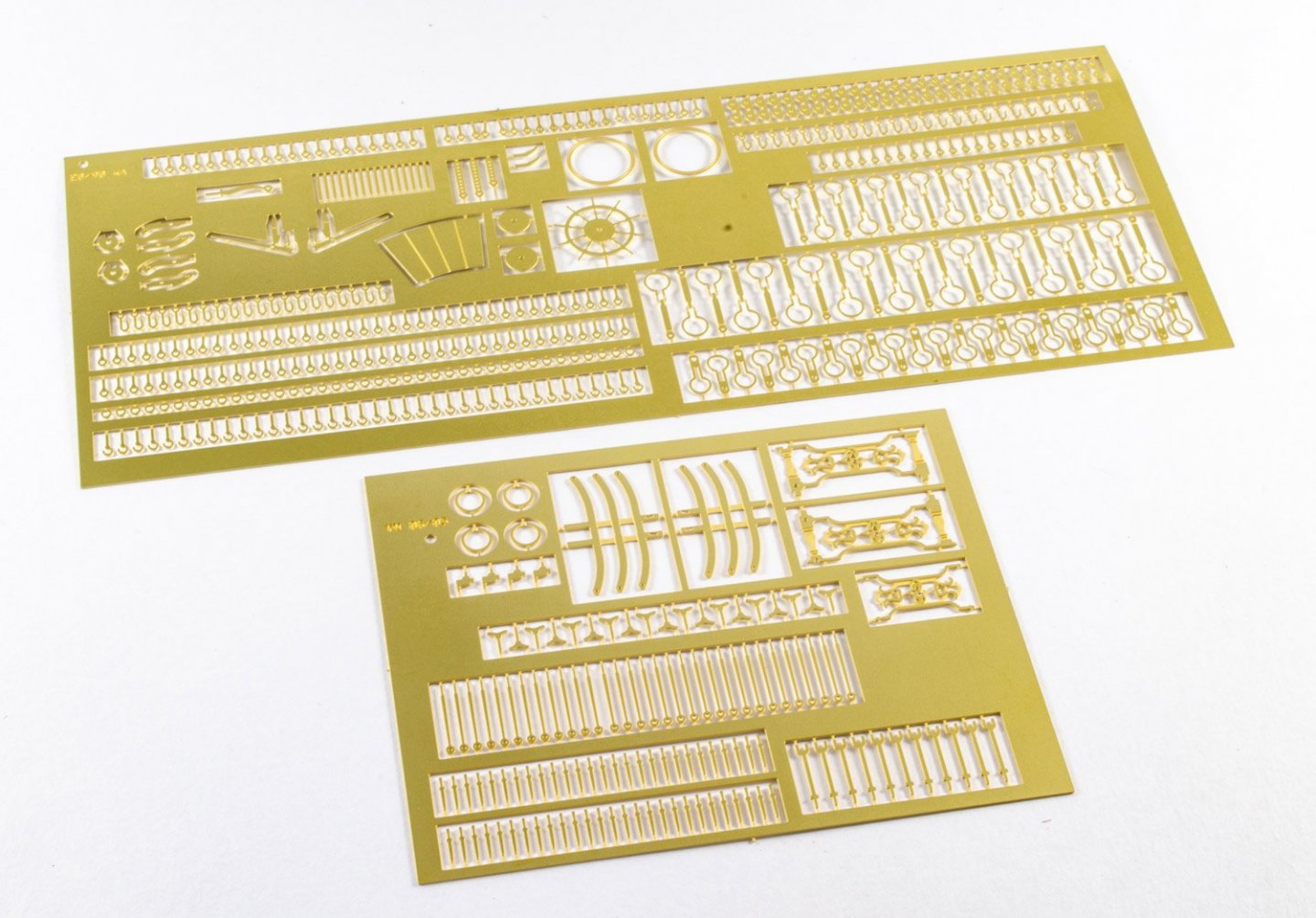

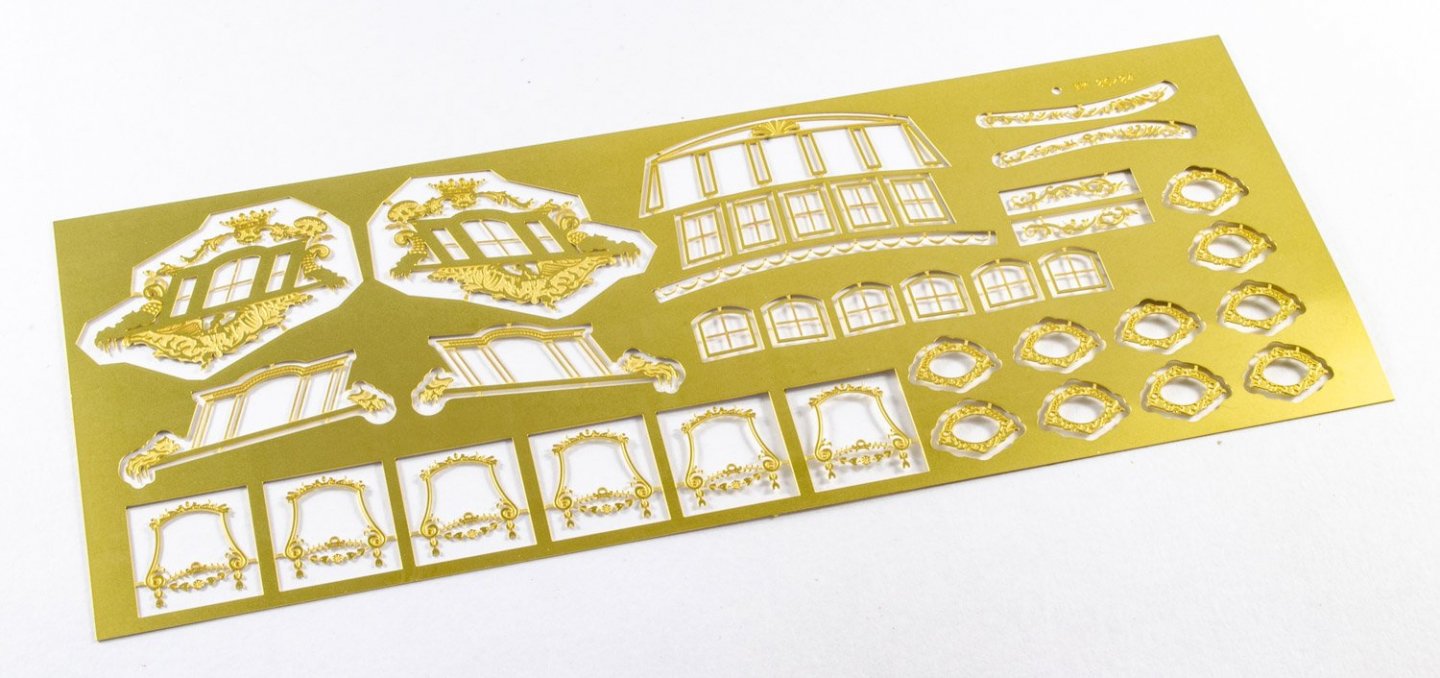

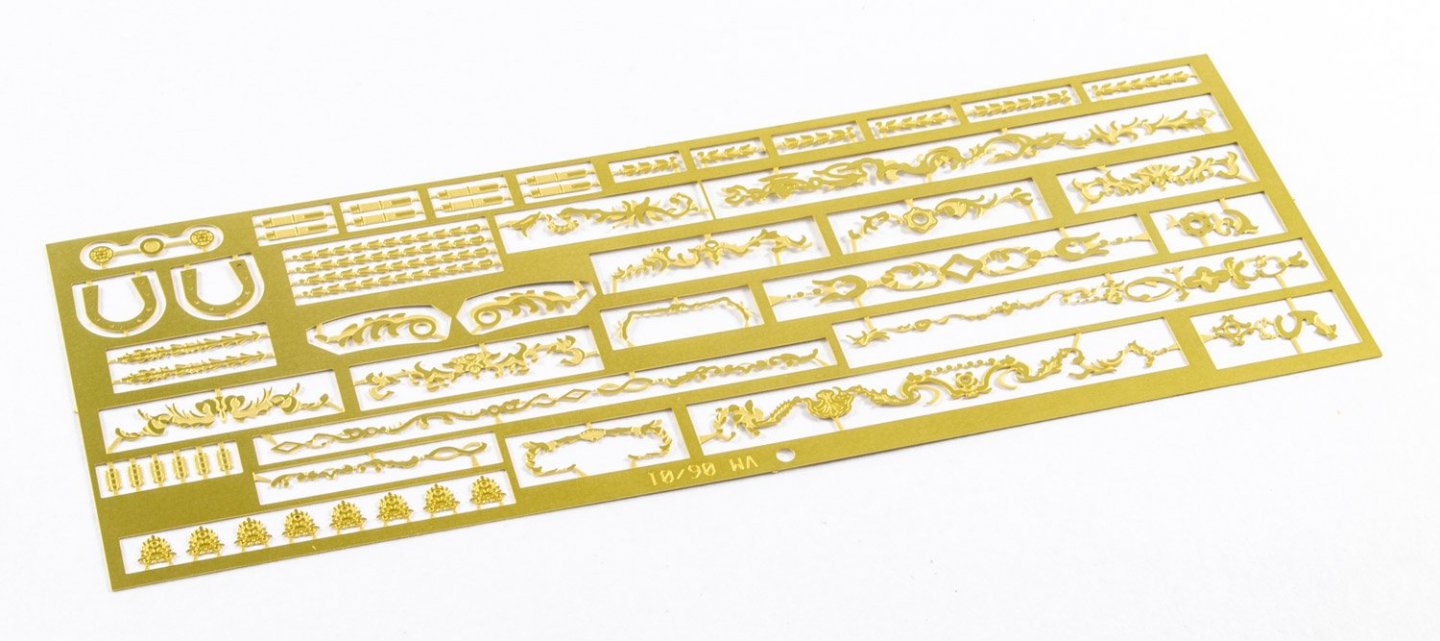

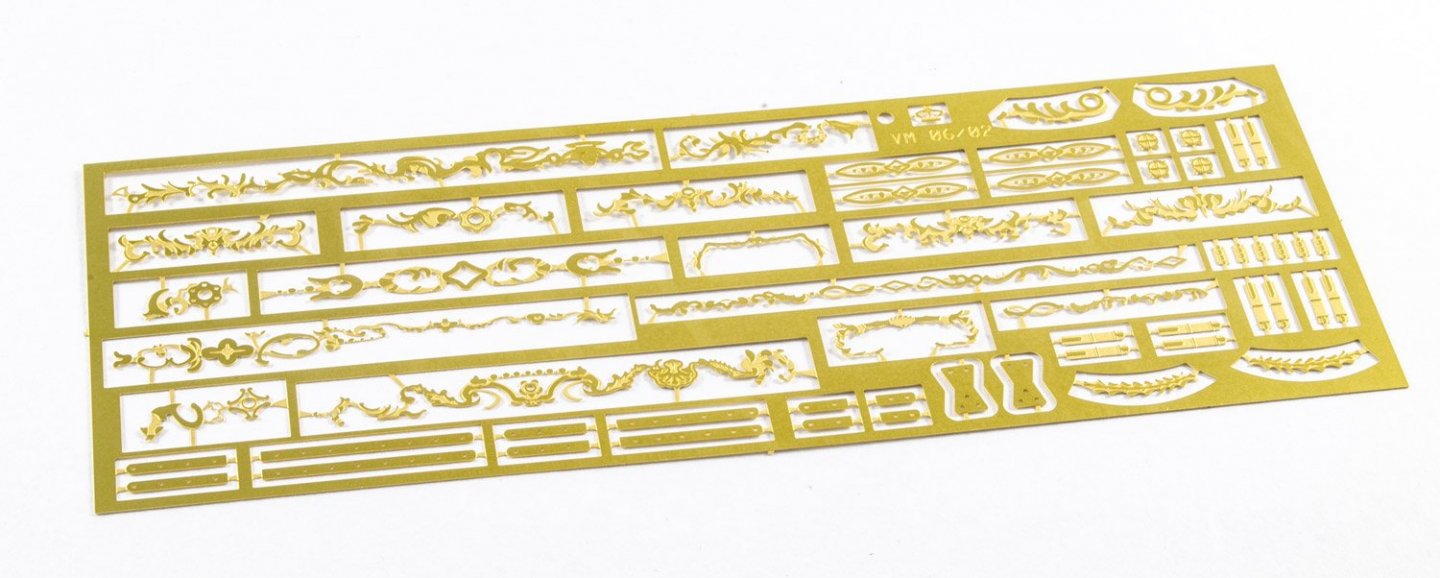

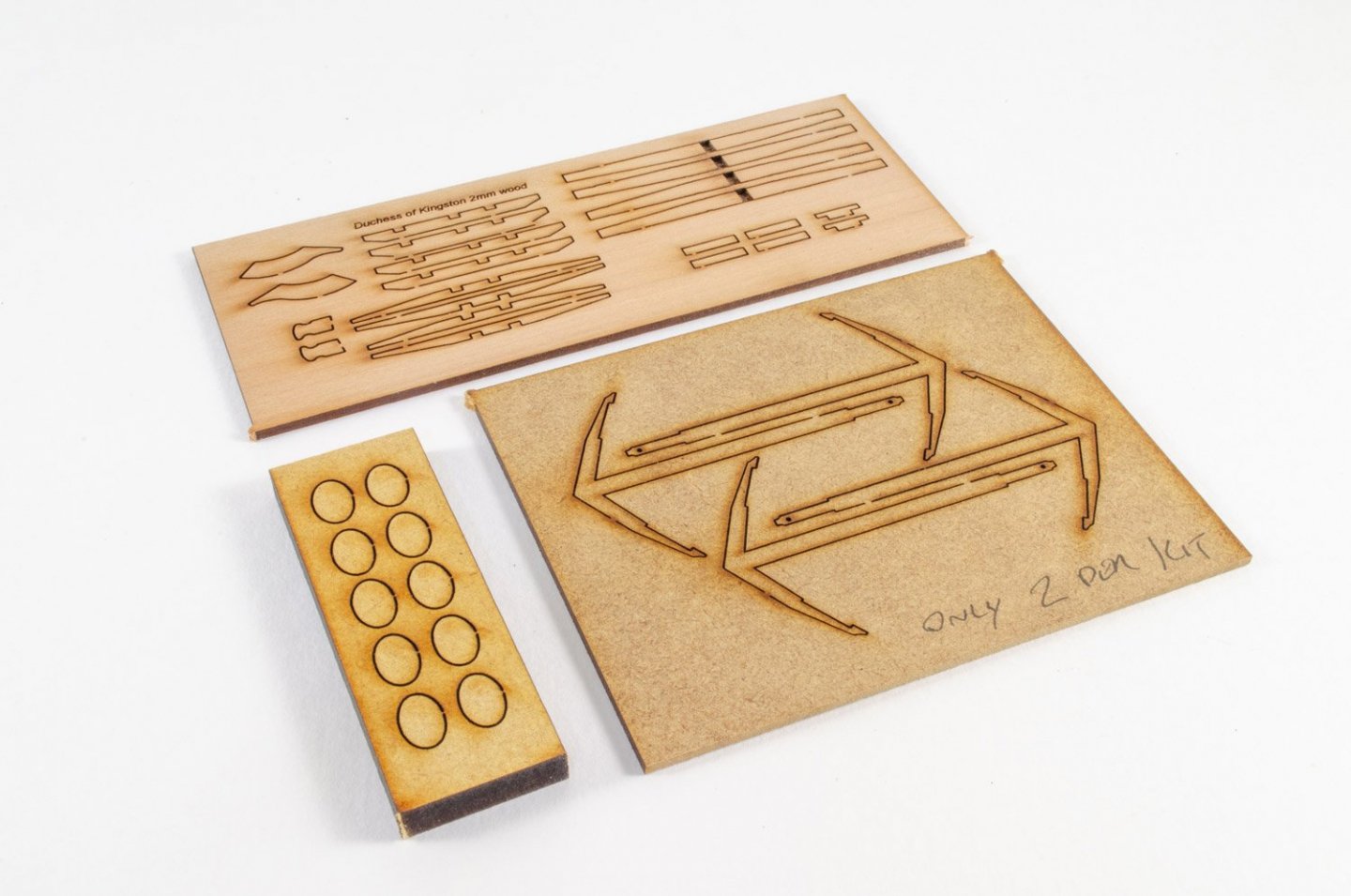

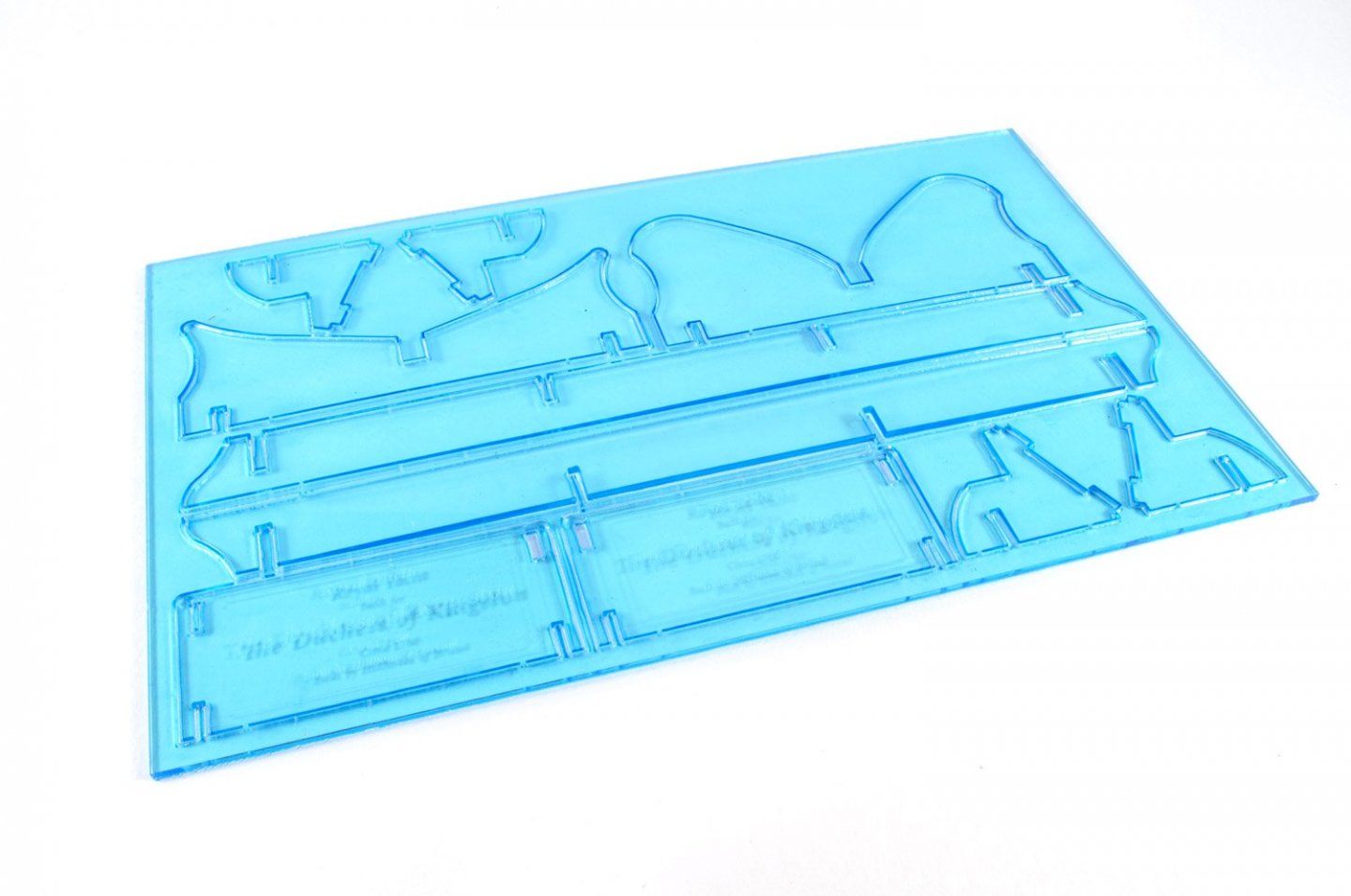

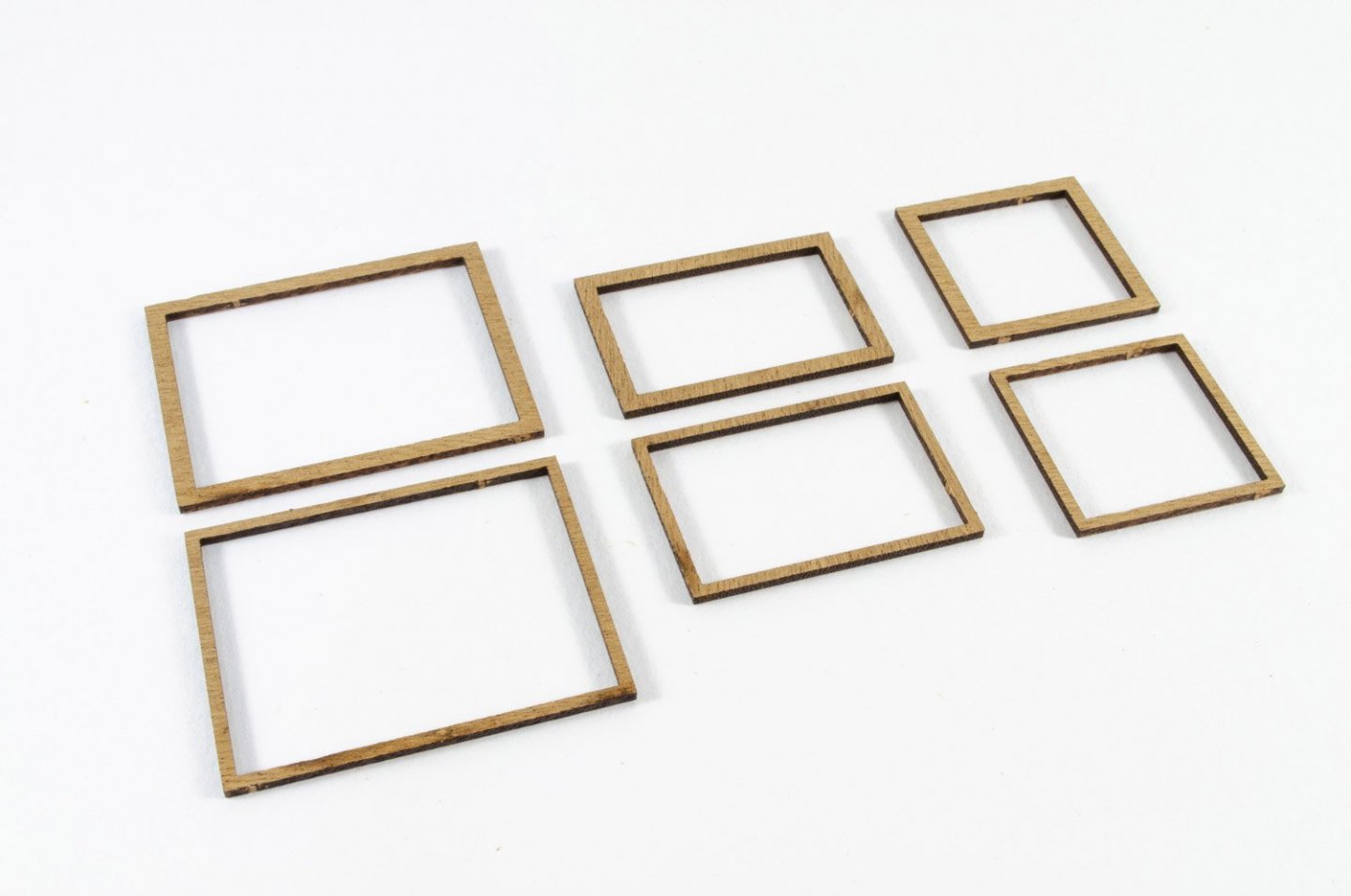

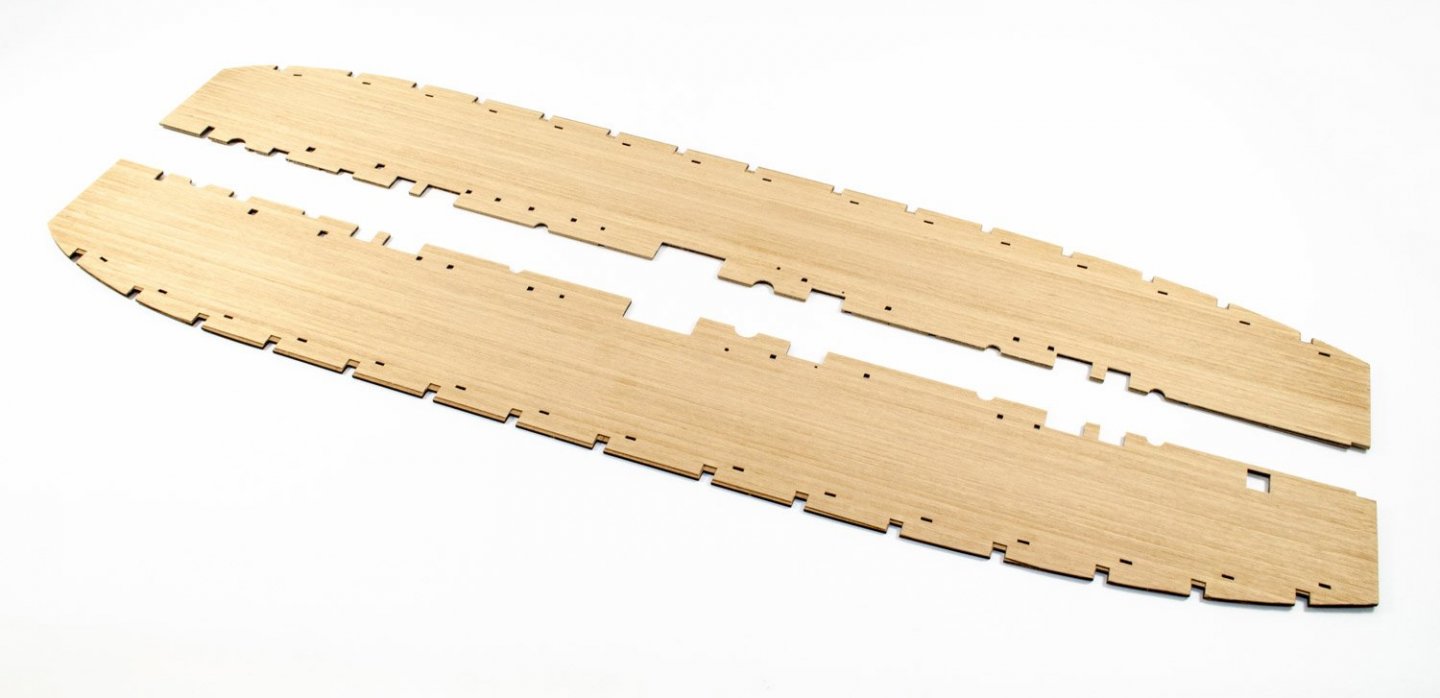

Good morning! As my Amati HMS Victory is currently on hiatus due to needing a good number of sheet replacements, I'll start work immediately on the future Vanguard Models release of the Royal Yacht, 'Duchess of Kingston'. As with my other VM stuff, this will be for the kit instruction manual. Chris conceded that (1) he hadn't taken enough photos of the original build, and (2) the design had changed significantly enough from his own build to merit a new build anyway, so the manual is representative of the final product. Yesterday, I received a large box with the final production parts, and also a second set of earlier parts, including PE sheets. The photos here are of the production parts, and I'll cobble together a dry fit of the bits later, to give you a very quick idea of how this goes together, before work starts proper. This kit must've taken an age to produce with all the sheets of pear, plus the pear overlays and beautiful engraving too. Here's what you can roughly expect to see in a final production kit: MDF Maple deck Ply parts Pear parts Other laser parts Strip wood Photo etch Resin parts Fittings etc. Rigging cord Acrylic display stand (with engraved name plates) It's interesting to see some of the design ideas, such as the stern/transom where the resin ornamentation sits atop the pear panel, and that panel has recesses engraved into it to allow the PE window frames to sit within! I'll post a dry fit image of the hull a little later on...

- 117 replies

-

- vanguard models

- yacht

-

(and 2 more)

Tagged with:

-

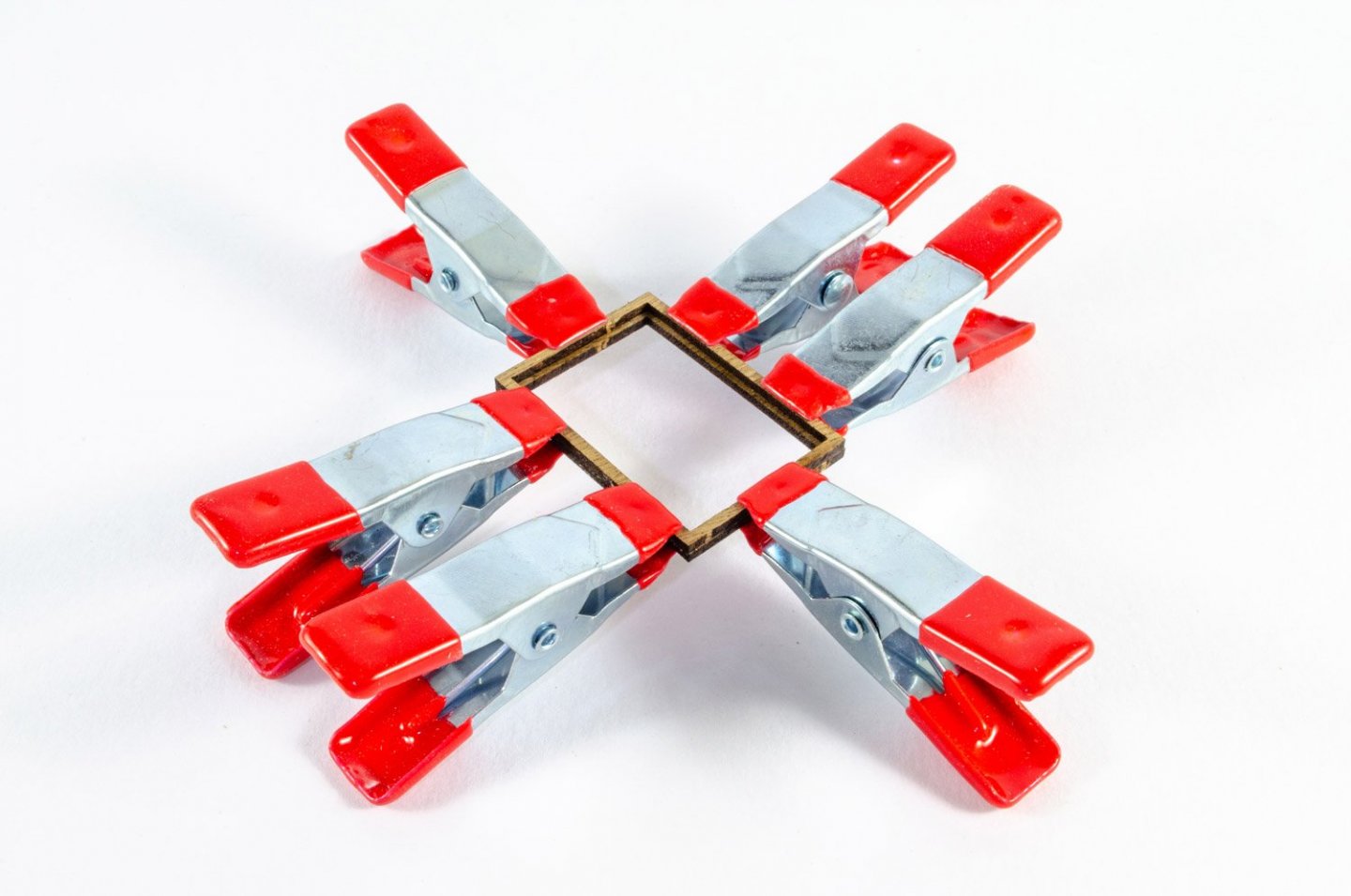

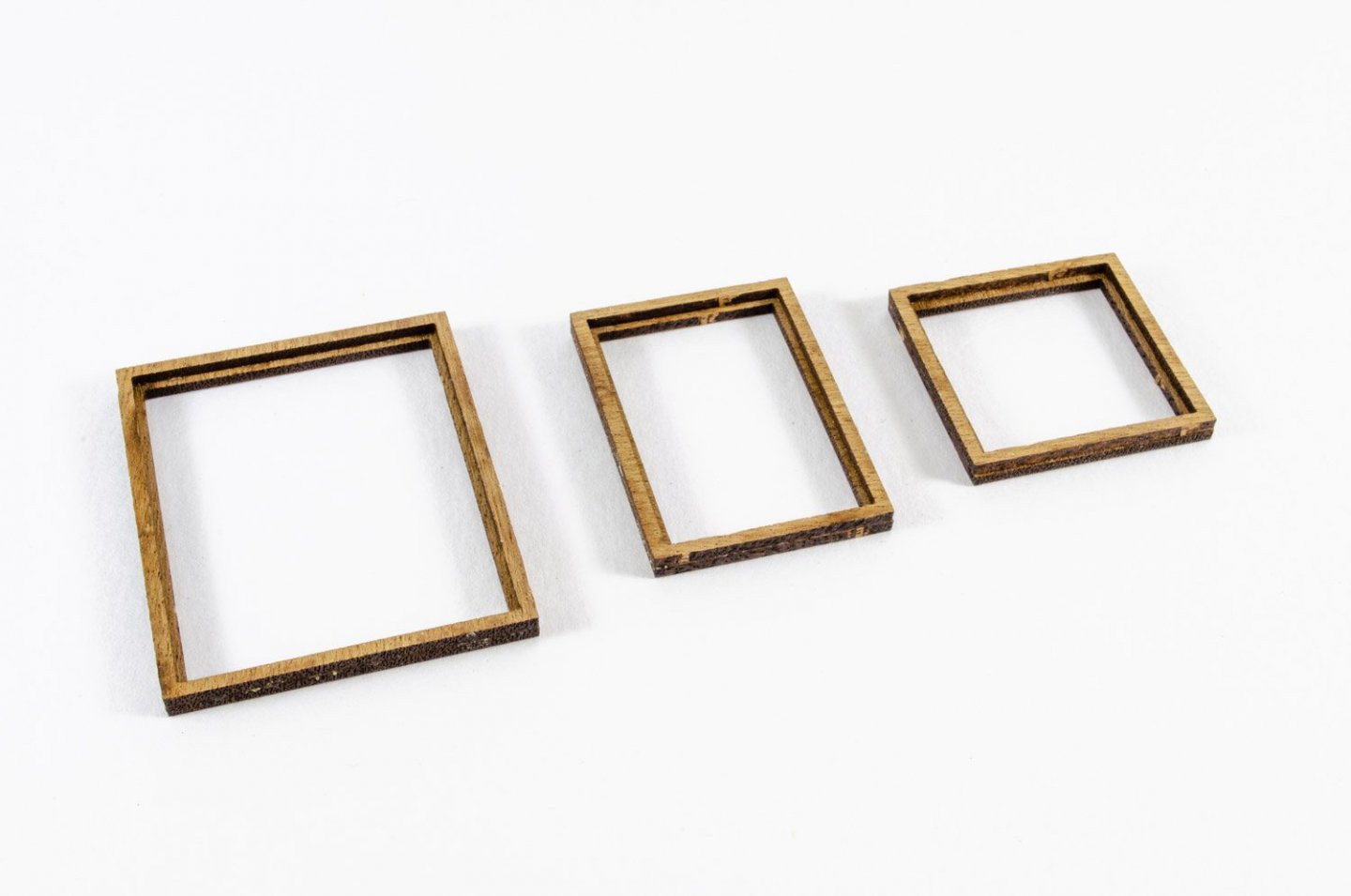

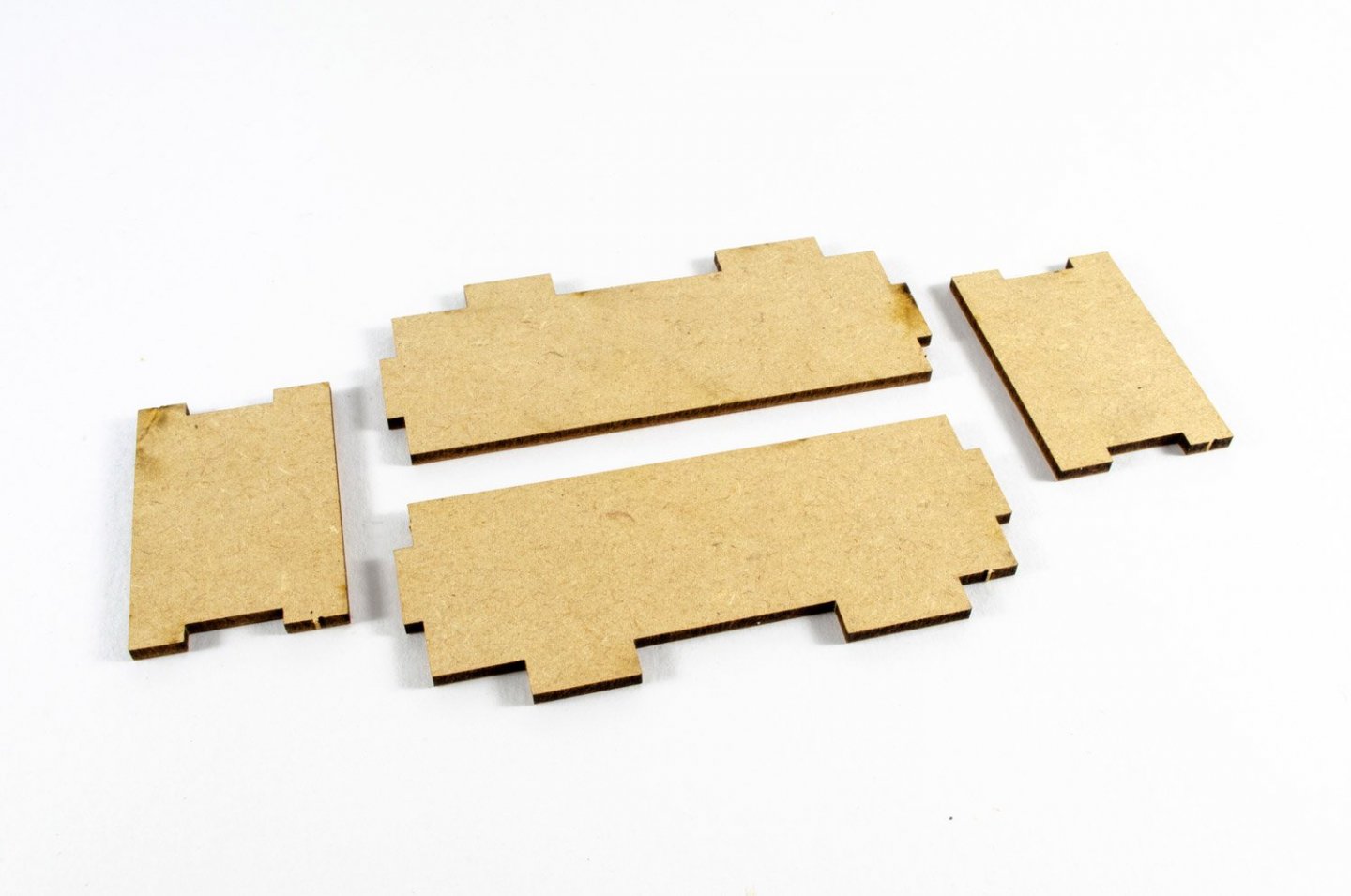

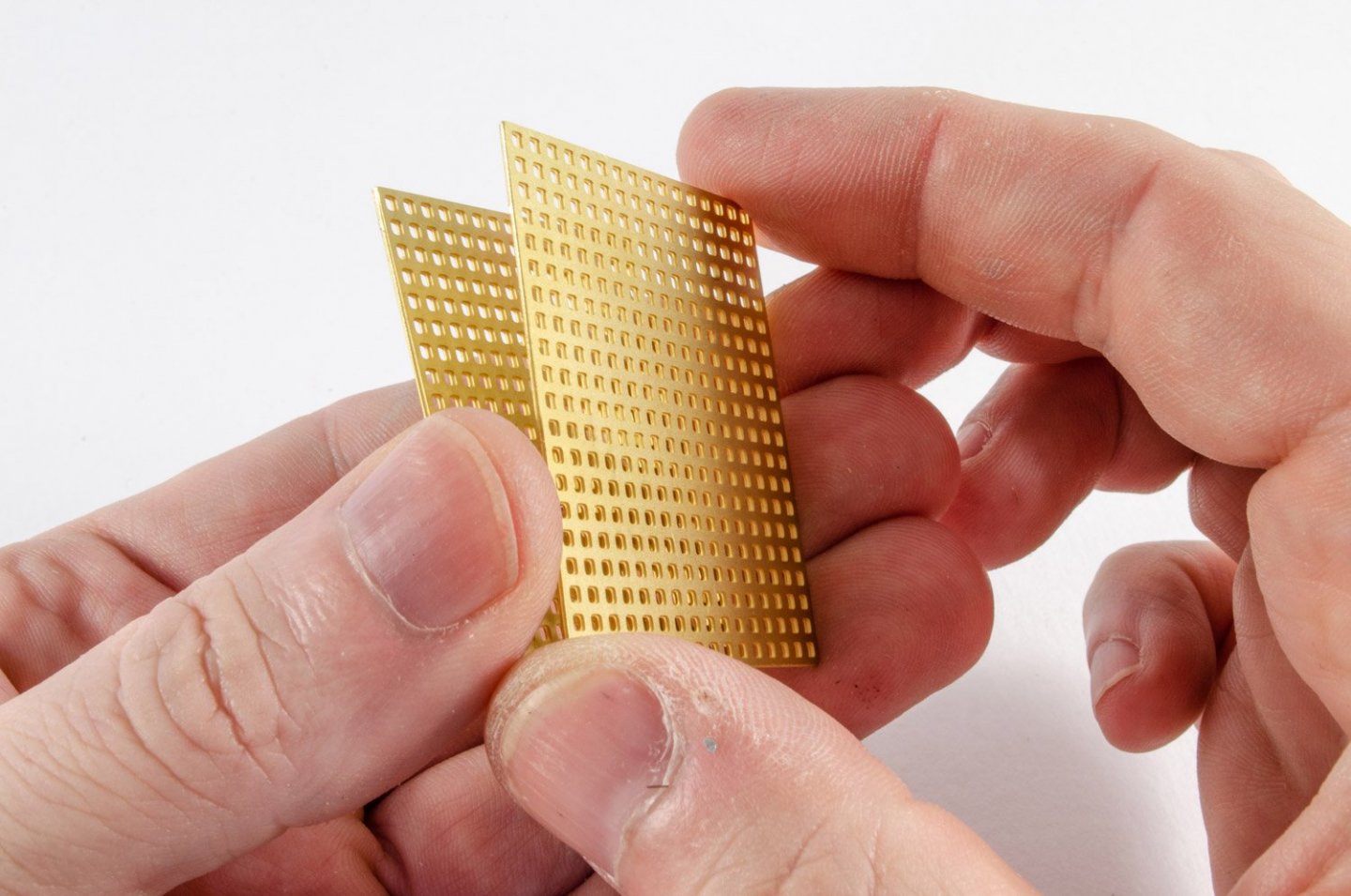

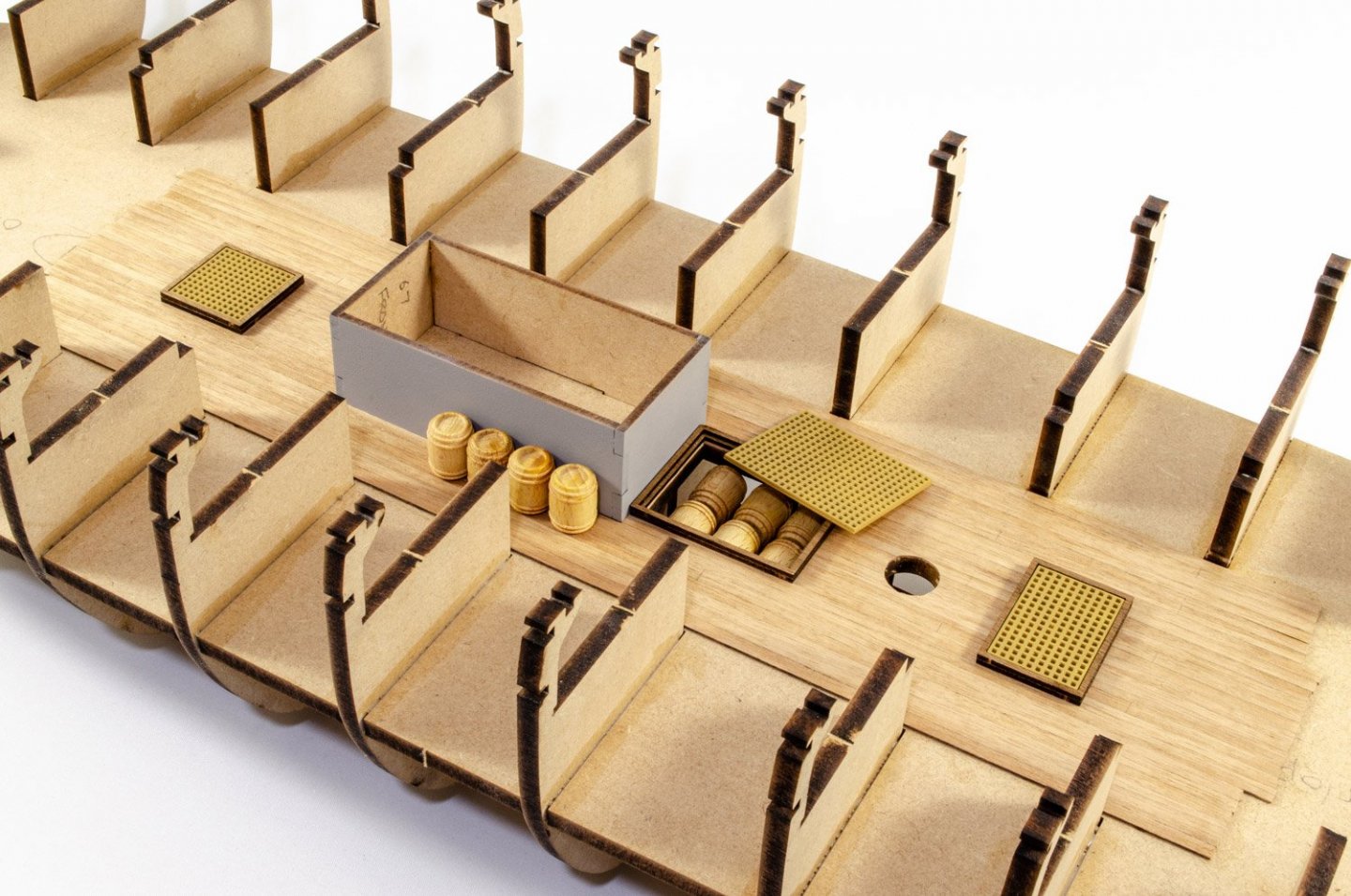

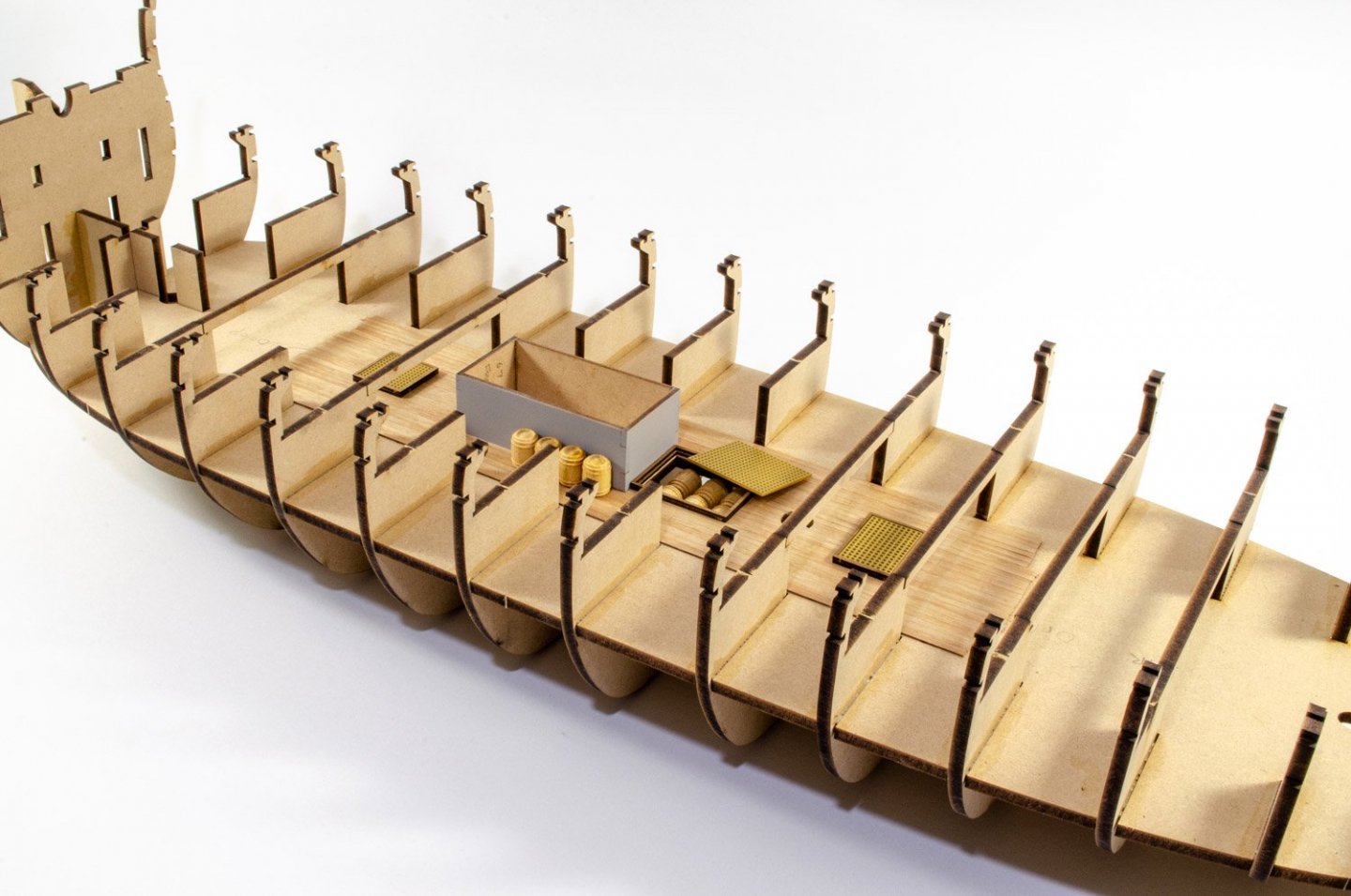

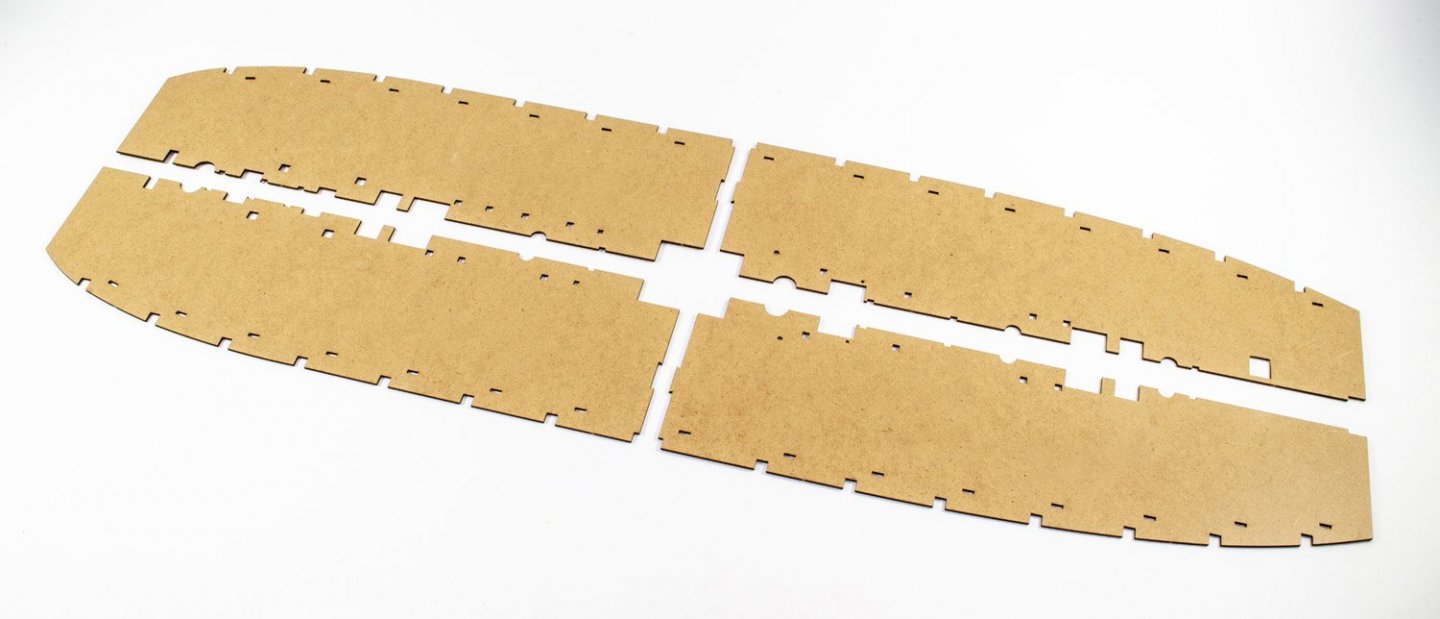

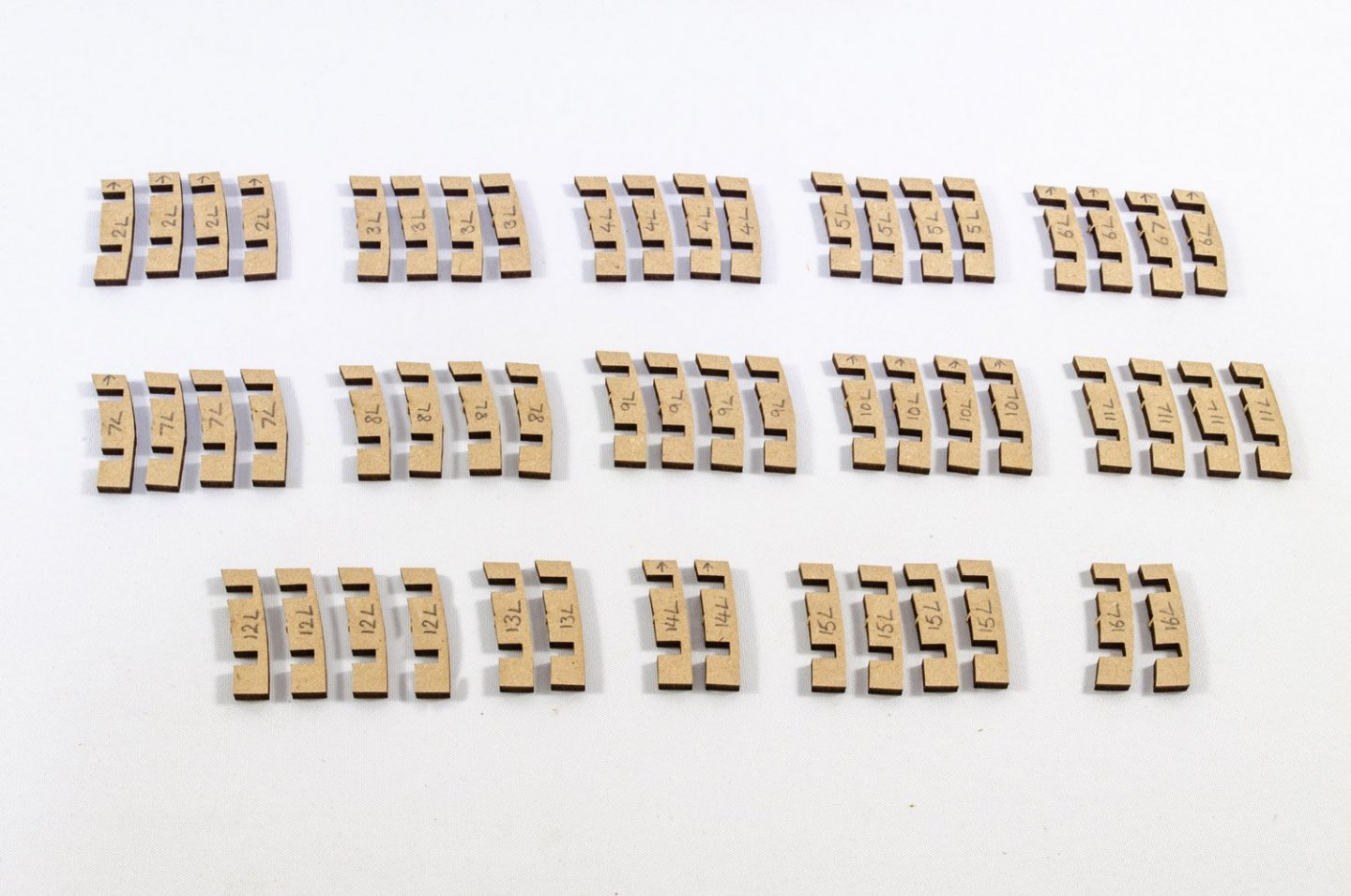

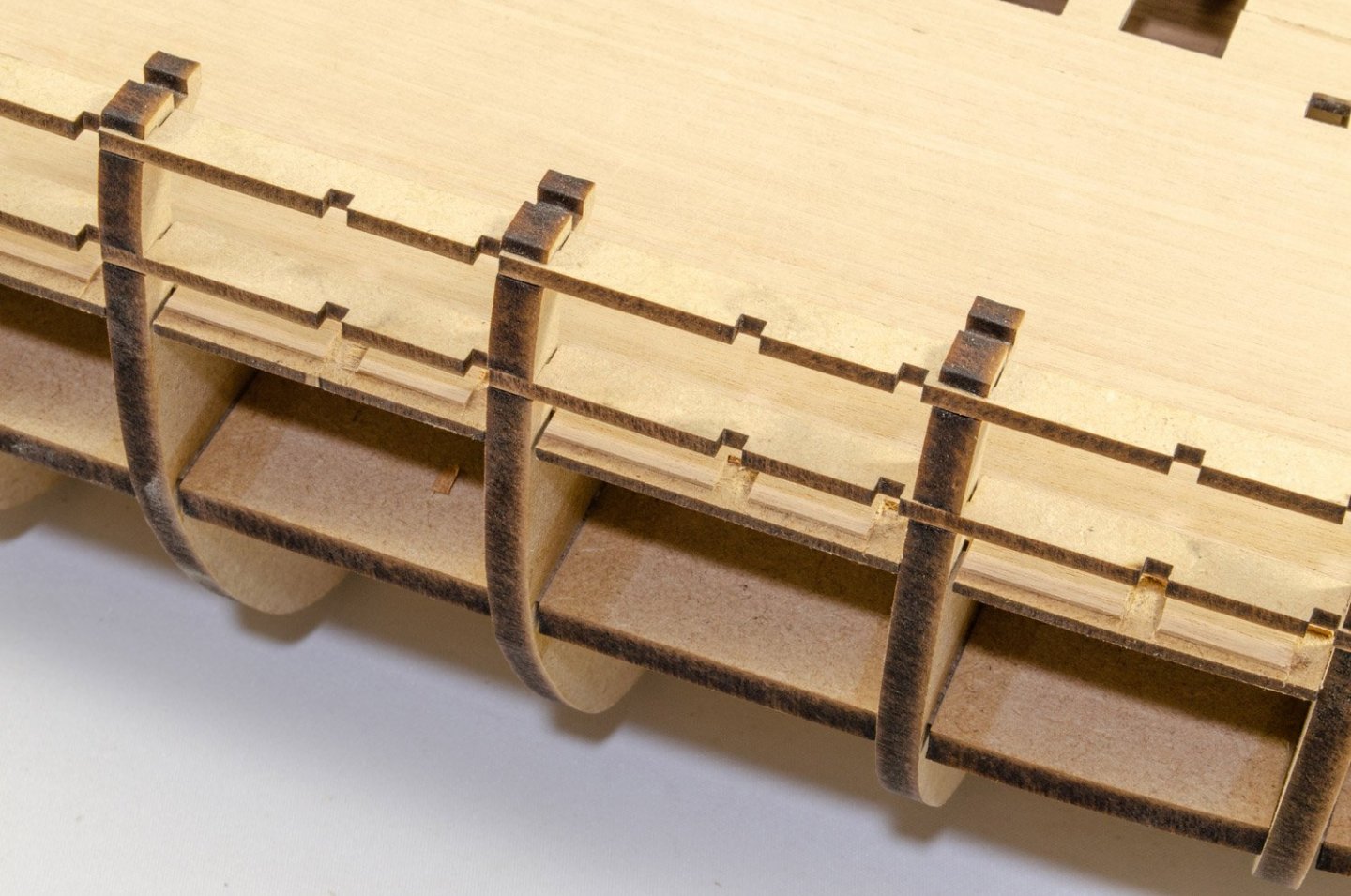

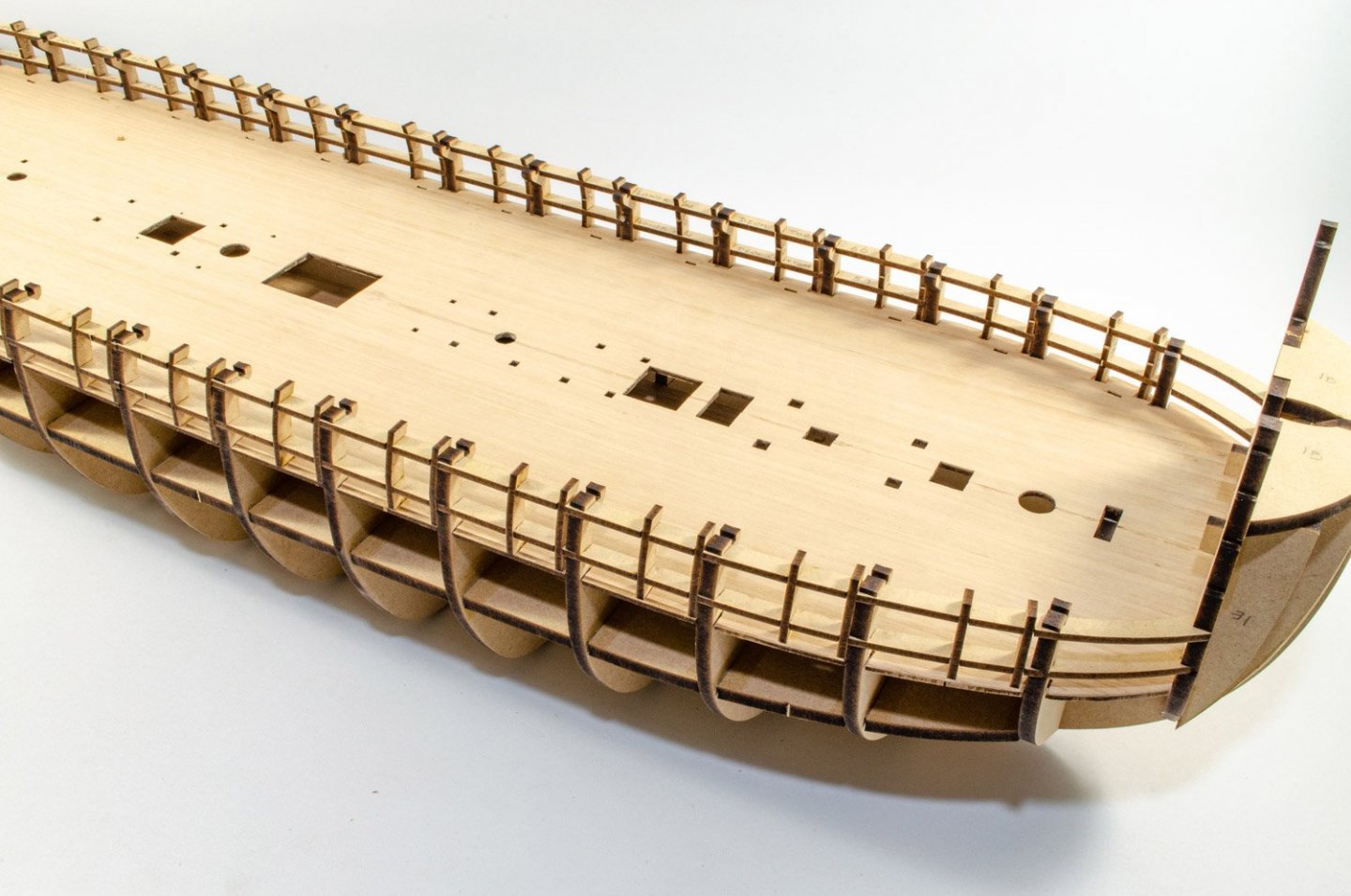

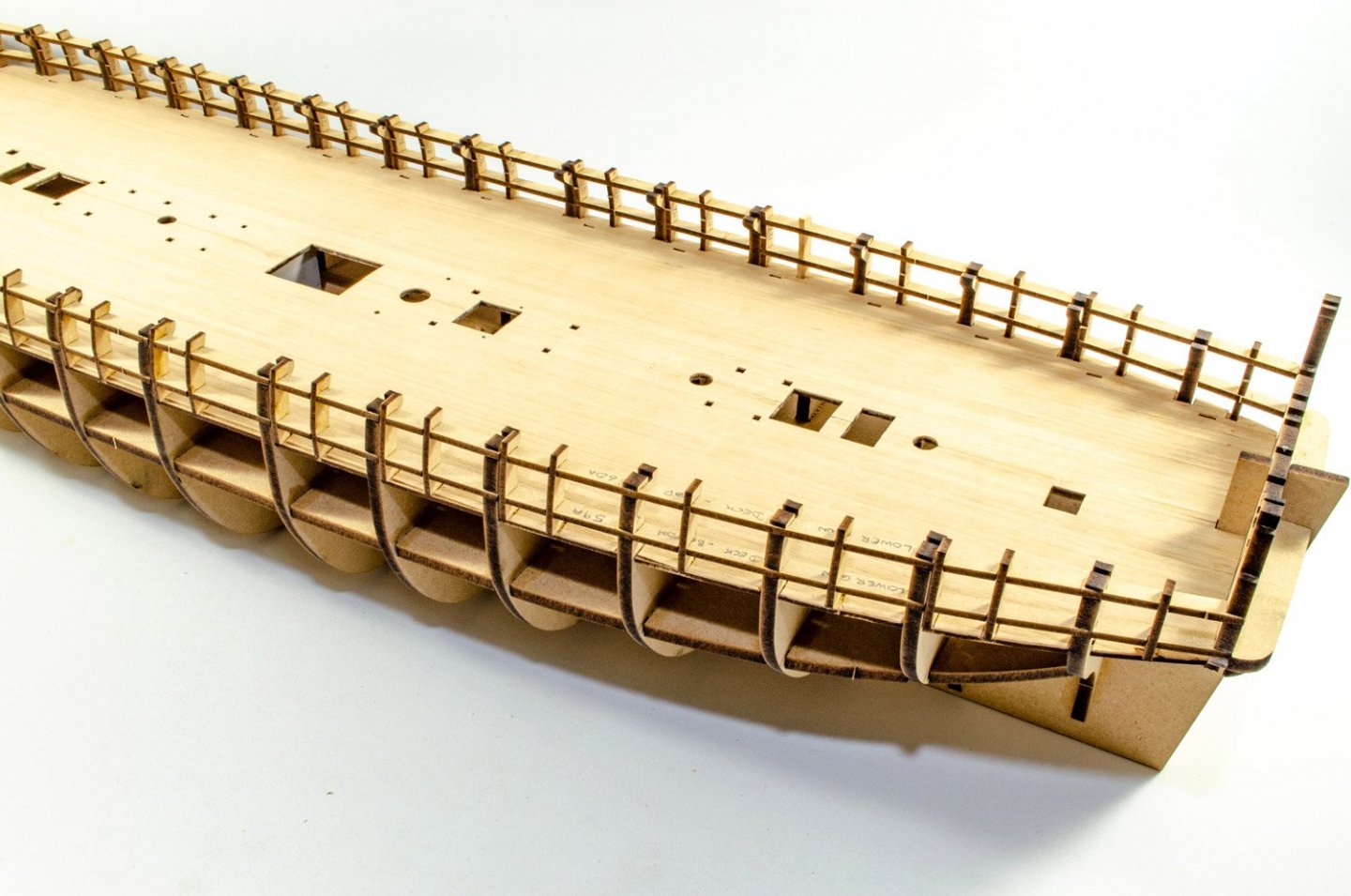

I thought it best to do another update on this one. Amati sent a lot of the wooden sheets made from the wrong material for the job, and the laser company is going to replace them all. As Italy is in holiday mode for August, I anticipate these will arrive in September. It didn't stop me working on and completing the orlop deck, and making a start on the lower gun deck too. Plus, I've just got back from a week away in Devon, otherwise this update would have been a little earlier. Orlop deck After fitting the 6mm MDF orlop floor sections, you will have an option to plank a section of it. You may not consider it worthwhile, and to be honest, you'd need an endoscope to see it when done, but for the purpose of the instructions, I've decided to do it. Before planking, I decided to assemble the hatch coamings. Three of these are required, build up from two parts. Always a good idea to clamp. You can never have enough clamps, especially with a model this size! The orlop also has a small superstructure within. As well as being sort of authentic, it also goes some way to supporting the centre of the lower gun deck. This structure is built over the slots in the orlop floor sections, and then dry fitted into place whilst I planked the orlop deck. A cut-off from the coamings was used to add a small floor to the central hatch area. This was also planked as per the deck. 4mm x 1mm tanganyika strip was now added to the section of the orlop deck which I thought was at least worthwhile planking. This could be seen if you left off all the gratings from the upper deck, right down to the orlop....but still only if you had specialist camera equipment! A 2B pencil was used to edge the planks for caulk, and CA gel was used to fasten them down. The coamings were then glued in place and the superstructure painted in a grey that looked close to the ones on the real ship. This structure was now glued into position. The grates are made from two layers of photo-etch. These are CA'd together and then painted in Tamiya Desert Yellow, before being glued in position on the orlop. A numbest of supplied barrels are also fitted into the hold area and alongside the structure. Some beams are now fitted across various bulkheads, but not all. This is so there is no fouling the open hatch areas. Bow/Stern parts Before the lower gun deck can be fitted, the bow and stern bulkheads need to be fitted, along with the various shape parts that will need to be sanded. No sanding will occur until the lower gun deck is due to be fitted out. Lower gun deck The L A R G E deck comes in four sections, primarily due to the size of the thing. These sections are fitted into the slots in the bulkhead ears, but upside down. Once they are in place and positioned correctly, tape is used to temporarily secure the port and starboard halves, before the sections are carefully removed from the hull. The sections are then slightly bent and white glue applied to the seam between them, and the upper side of the deck sections are planked in 4mm x 1mm x 1000mm tanganyika strip. After a sanding, the various slots, notches etc. are cut out from the halves. Note also that the deck planking doesn't quite run up to the edges of the slots for the bulkheads. This is because the deck slots into those bulkhead ears along the edges, and holds the deck edges down, in place, so no need to pin the edges of the decks. Those familiar with Chris Watton's work will be used to that concept. As the deck still needs to be held down along the centreline, some 6mm MDF props were temporarily pushed under the centre of the deck beams. To be honest, I don't think it needs this, but better being safe than sorry. Each bulkhead with a beam was also marked with and 'X' to help me identify them when it came to pinning down the decks at those points. The deck halves are now finally glued into place and pinned down along the centreline region. Once dry, the temporary MDF props were pushed away. Various grades of sandpaper were now used to give the deck it's final finish. For the finest grit, I used 320. Amati's Victory will not need any guesswork when it comes to the position of any of those gun ports. This is because they are designed into the frames of the ship.....no plywood sections to second-guess here! The thickness of Victory's bulwarks also allows this to be done. First of all, a 3mm strip is run along the bottom notches of the bulkheads, in two sections per side. Another set of strips is then run above these. Note how those strips have more slots. These are for the cannon port frames. Here you see them. Each port is numbered and I've added an arrow to them to show which way up them will point when fitted. These need to be pushed fully into those slots when you glue. The ports start at #2, thru to #16. I cut away a small section of the tanganyika deck where each gun port frame will fit. All gun port frames are now glued into position. This creates a surprisingly strong structure until which the mid and upper gun decks will eventually fit. The small slots in front of each gun port are where the cannon carriages will securely plug into. Remember, these are full carriages and guns. No dummy barrels here, and this whole deck will be fitted out with capstans, pumps, bitts, coamings etc. Ok, for the time being, that's it. Until I get the stuff from Amati, I will be working on another quick project for Vanguard Models. Victory is one very heavy model, even at this very early stage!

-

That's looking really good. Amati's Santa Maria is a model I built very early on, and I think you made a very good choice.

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

That turned out superb! Please feel free to add some completed photos of her to our Gallery 📷

- 38 replies

-

- vanguard models

- fifie

-

(and 2 more)

Tagged with:

-

Nice project, and there's some nice reference material out there too.

- 67 replies

-

- granado

- cross-section

-

(and 1 more)

Tagged with:

-

kit review 1:32 Fifie – The Scottish Motor Fishing Vessel by Amati

James H replied to James H's topic in REVIEWS: Model kits

Chris already stated his sources and they are robust. Roger, if you have a problem, please take it up with me via PM. The forum isn’t an area to argue. -

kit review 1:32 Fifie – The Scottish Motor Fishing Vessel by Amati

James H replied to James H's topic in REVIEWS: Model kits

If you can bring some information to the table that’s real and credible, then do so. It sounds like you have something important to share with us? -

kit review 1:32 Fifie – The Scottish Motor Fishing Vessel by Amati

James H replied to James H's topic in REVIEWS: Model kits

Following along too.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.