-

Posts

2,876 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by thibaultron

-

-

-

-

There are also the old Sterling plans. They are for the schooner rig.

-

-

Currently on Ebay, there is a seller who has just started listing accessories for the saw. He has several, including a better rip fence, miter gauge, and a back plate. I ordered the fence and the plate. I contacted him, and he plans to keep listing new items. He has been making them for several years. Presently he has the fence, plate and gauge at least available.

-

Will be restating soon. I just finished refurbishing my shop to the point I can start working in it, and found the wood I bought for the mast and boom, that had been packed away.

-

-

-

-

-

-

-

-

Part 14

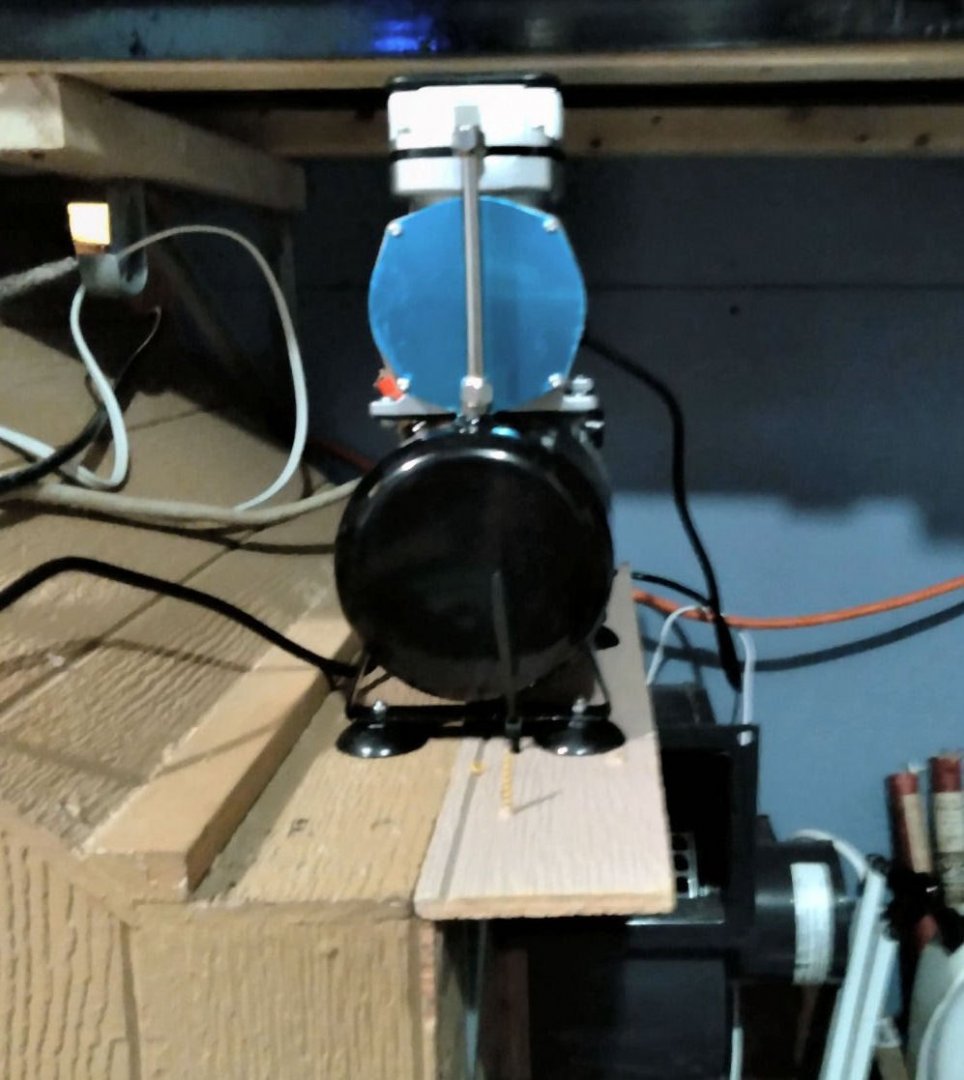

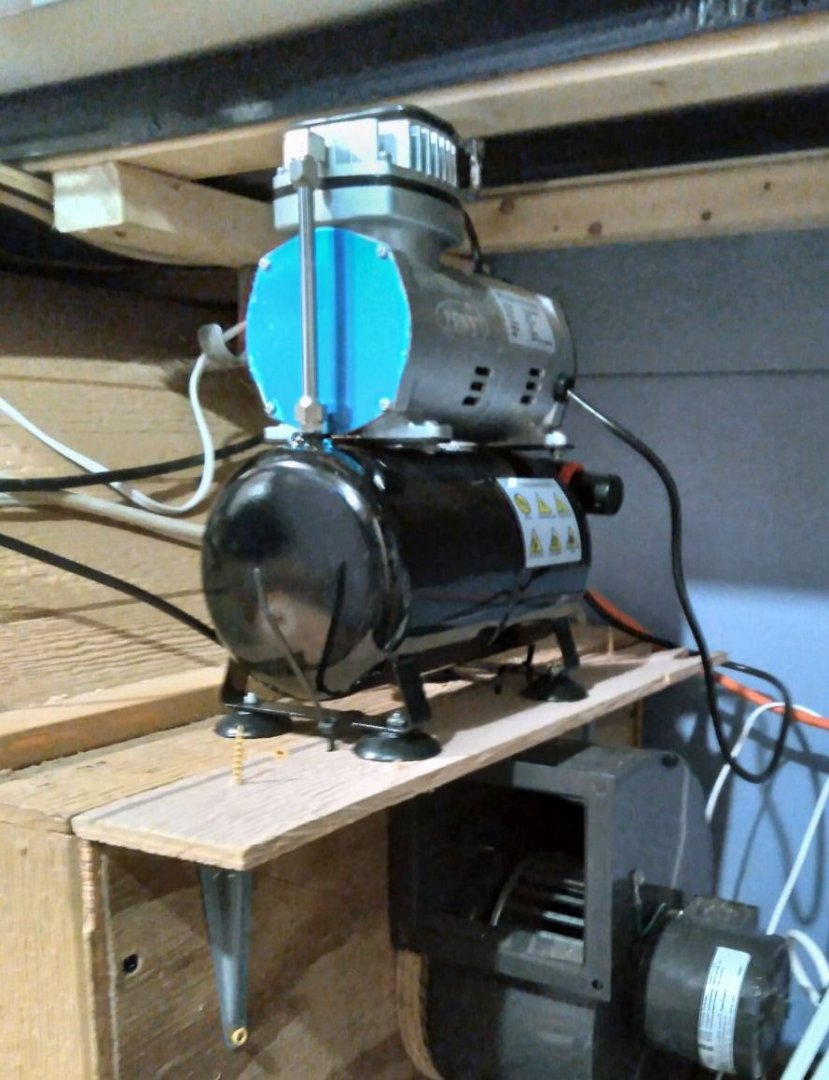

Today I installed a small shelf on the back of my spray booth, to mount my new dedicated airbrush compressor. I screwed a couple small shelf brackets to the back of the booth, and temporarily screwed on a small shelf on the brackets. Using this piece, also, means that I have completely used the entire 4X8 sheet of plywood I built the booth from, no waste!

I have to buy some small machine screws tomorrow, to finish bolting the shelf in place. I drilled holes in the shelf on either side of the compressor legs for wire ties to hold it in place, while still allowing the rubber feet to dampen vibration. When I install the machine screws, I'll add a couple of eyelets in the main spray booth housing for two additional wire ties at the "forward" edge of the legs. It "Just" slides under the shelf above it, but as I'm going to be moving the work bench and spray booth in the near future, this is not a problem.

Sorry the photos are a little out of focus, I didn't realize the flash was turned off on my phone.

- lmagna, Ryland Craze and Canute

-

3

3

-

-

Most of the cross section kits are highly inaccurate. These generally have the wrong number of decks depicted, for starters!

The only two accurate ones I know of, are the new Model Expo USS Constitution cross section, and CAFs HMS Granado cross section.

- bruce d, MEDDO, Ryland Craze and 3 others

-

6

6

-

Here is a video given at a virtual Model Railroad clinic recently, on using the Cricut machine.

- mtaylor and Captain Poison

-

2

2

-

-

-

-

-

The Cricut Explore can handle up to about 3/64ths basswood. It has trouble with interior cuts, like for a window opening. It has a pivoting blade so to insure the corner is cut "square" it cuts past the corner, then back at an angle to start on the other section. This leaves a small triangle extra cut out at the corner. Not bad if you will be adding a trim piece to frame the opening, but a pain if you want just the square opening.

The new Cricut maker can do at least 1/16th bass, and has a gear driven knife for square corner cuts.

I have had difficulty going from CAD to the machine, but have not had time lately to revisit it.

If you are trying to cut an existing card pattern (As in a cardstock building, or file download (ship card model, where you want to print out the file and cut to the printed patterns) you are limited to I think 6X8 inch maximum output size. This is because their proprietary software Design Space uses your browser software as a print engine, and you are limited (for unspecified reasons).

Clipart and Line drawings can use the full size sheet up to the largest cutting pad size. Remember though that the cutting pads are sticky to hold the material, so small delicate parts can break or rip when you go to remove them.

As I say I've not had time recently to play with my Explore machine more.

-

but I was able to hone the tube out enough to rune the wires up the tube.

Yes, a little magic always helps!😀

Sounds like one of the steps in Project Development. "Then a miracle occurs."

- popeye the sailor, mtaylor, Egilman and 1 other

-

4

4

-

Spilling (very long) planks

in Building, Framing, Planking and plating a ships hull and deck

Posted

Thanks, this will be a big help!