-

Posts

168 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by KennyH78

-

-

-

-

Chuck, the chairs, table and cushions are next level! Just when we think that you can't possibly outdo yourself; you yell out "Hold my beer!"

- jpalmer1970, KenW, mtaylor and 1 other

-

4

4

-

-

Such amazing work! If one did not know better, one might say that you are actually building a real ship and not a model.

- bdgiantman2, AJohnson, mtaylor and 2 others

-

5

5

-

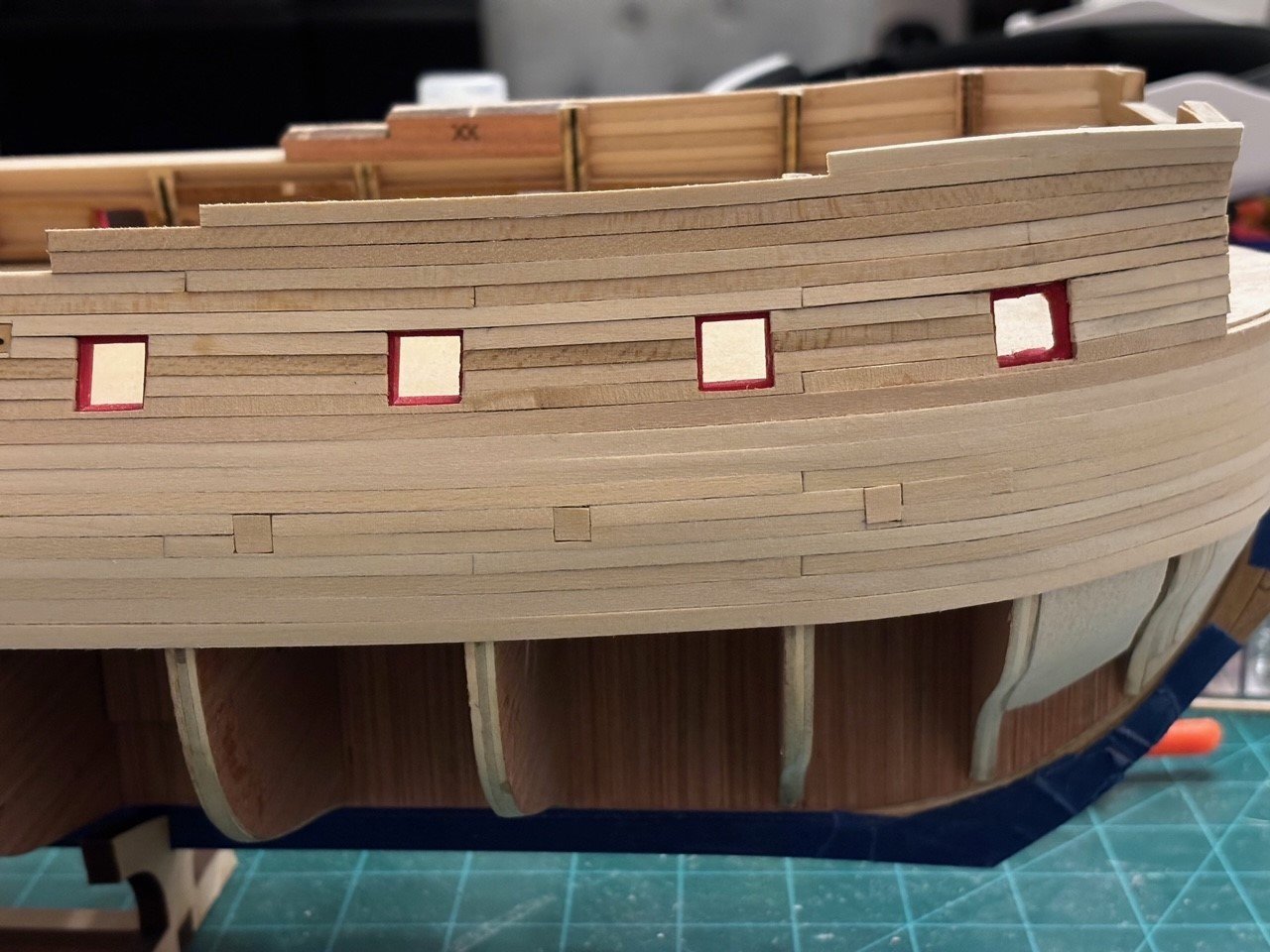

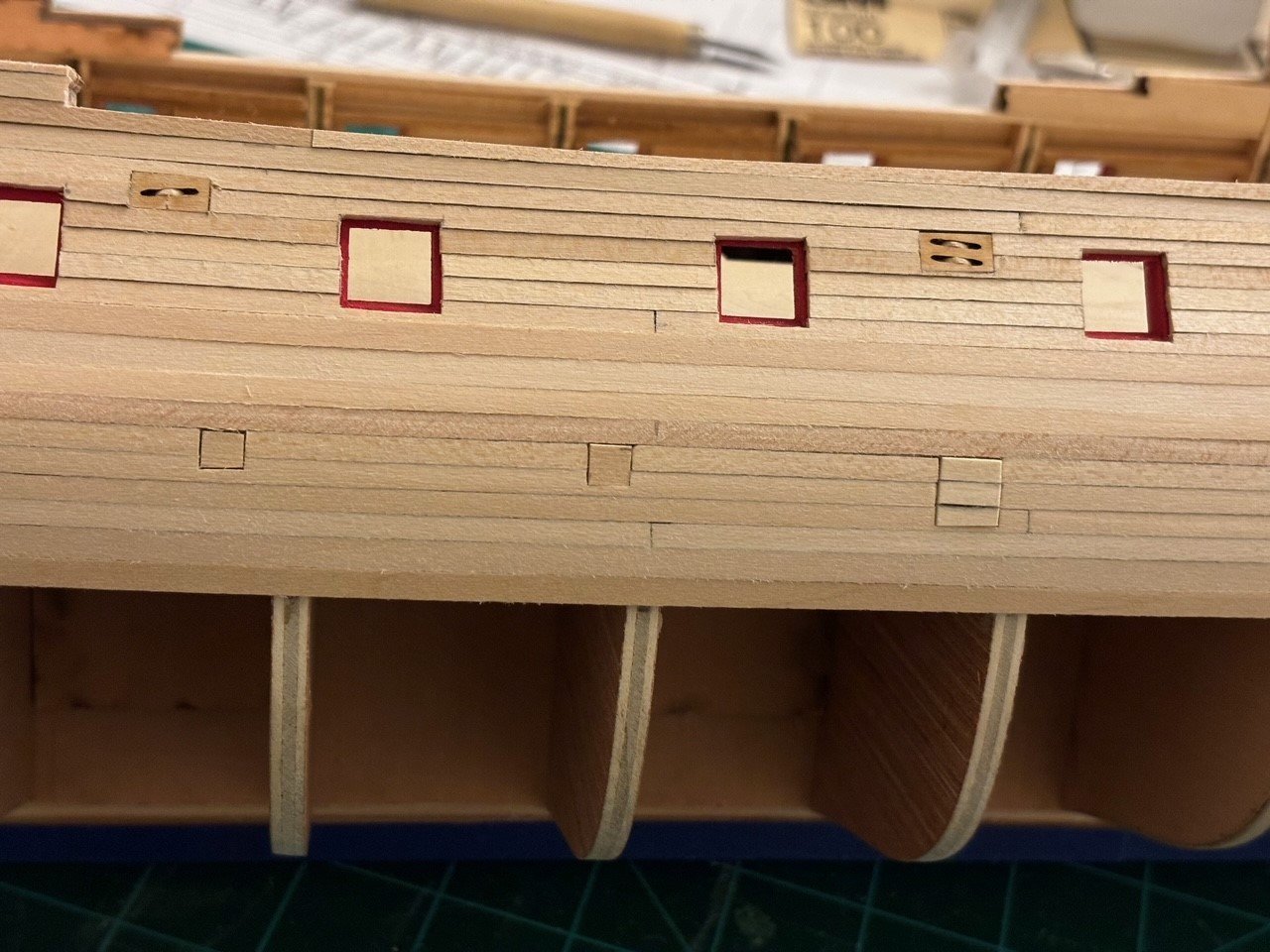

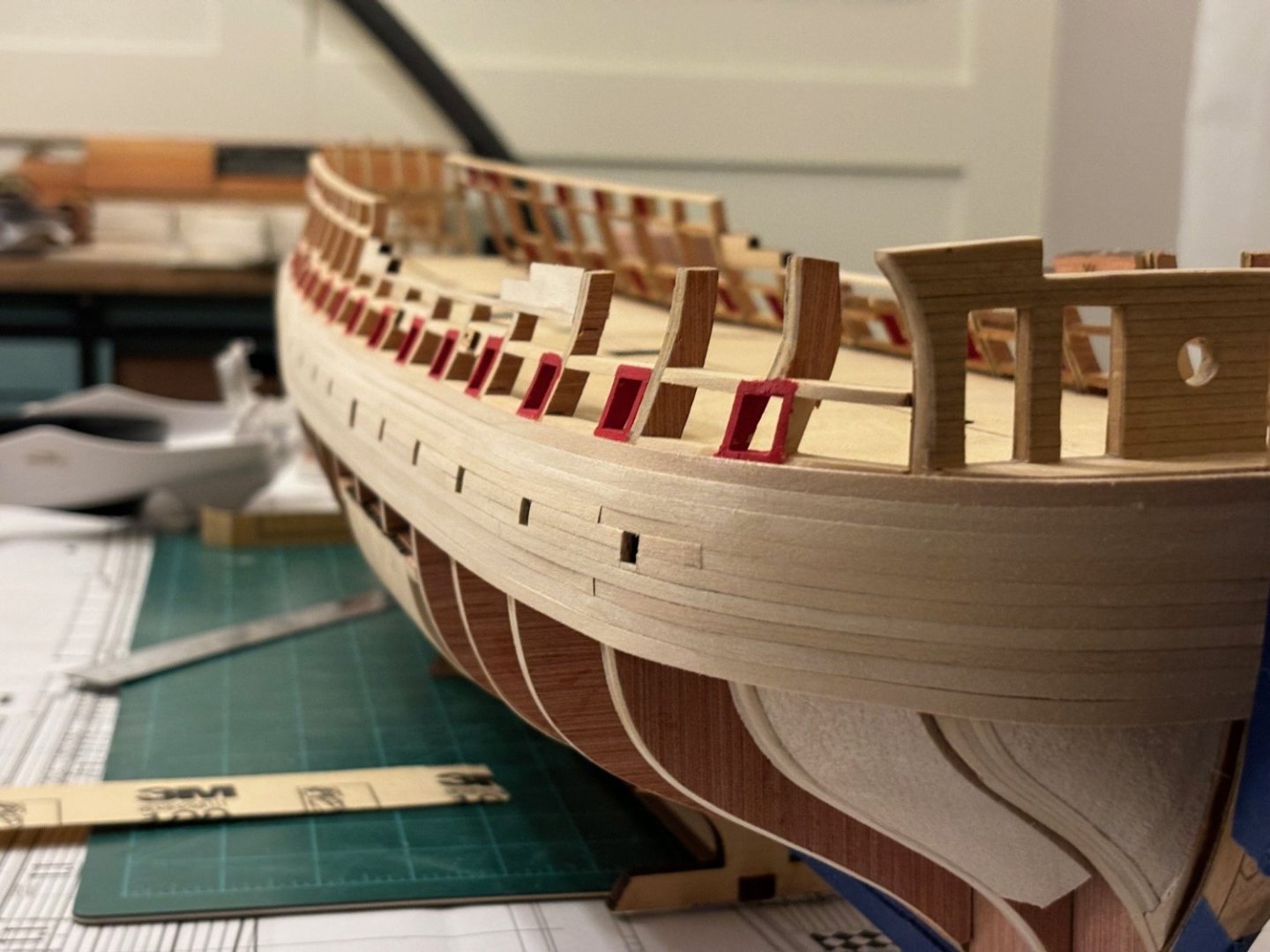

Starboard side is now planked up the sheer. The port sweep and ballast port lids have also been installed.

The port side sweep ports and ballast port lids have also been installed.

Next task is to do a rough sanding on the planks, install the remaining 3 blanks for the main wales on both side and then install the second layer on the main wales, channel wales and black strake.

- SighingDutchman, wvdhee and mugje

-

3

3

-

JJ, coming along nicely and I must second the comment by Allan on the attention to detail. Your model will look stunning next to your Winnie.

1 hour ago, scrubbyj427 said:stolen by my lovely neighbors

That really sucks, I hope that you are able to get your timber back. Seems like you just can't trust anyone anymore these days. That is why I have cameras set up all over the exterior of my house.

-

-

Looking great Chuck! She is going to be conversation starter for sure when on display.

- mtaylor, FrankWouts and Jack12477

-

3

3

-

-

Looking really good. Glenn. She is shaping up to be a very superb model.

- glbarlow and FrankWouts

-

2

2

-

1 hour ago, scrubbyj427 said:

What ply did you use?

The ply that I used is 1/4” basswood ply that I bought off of Amazon. I got 6 sheets of 12x24 for $36. So far I have had zero issues with it.

- FrankWouts and scrubbyj427

-

2

2

-

Thank you for all of the likes.

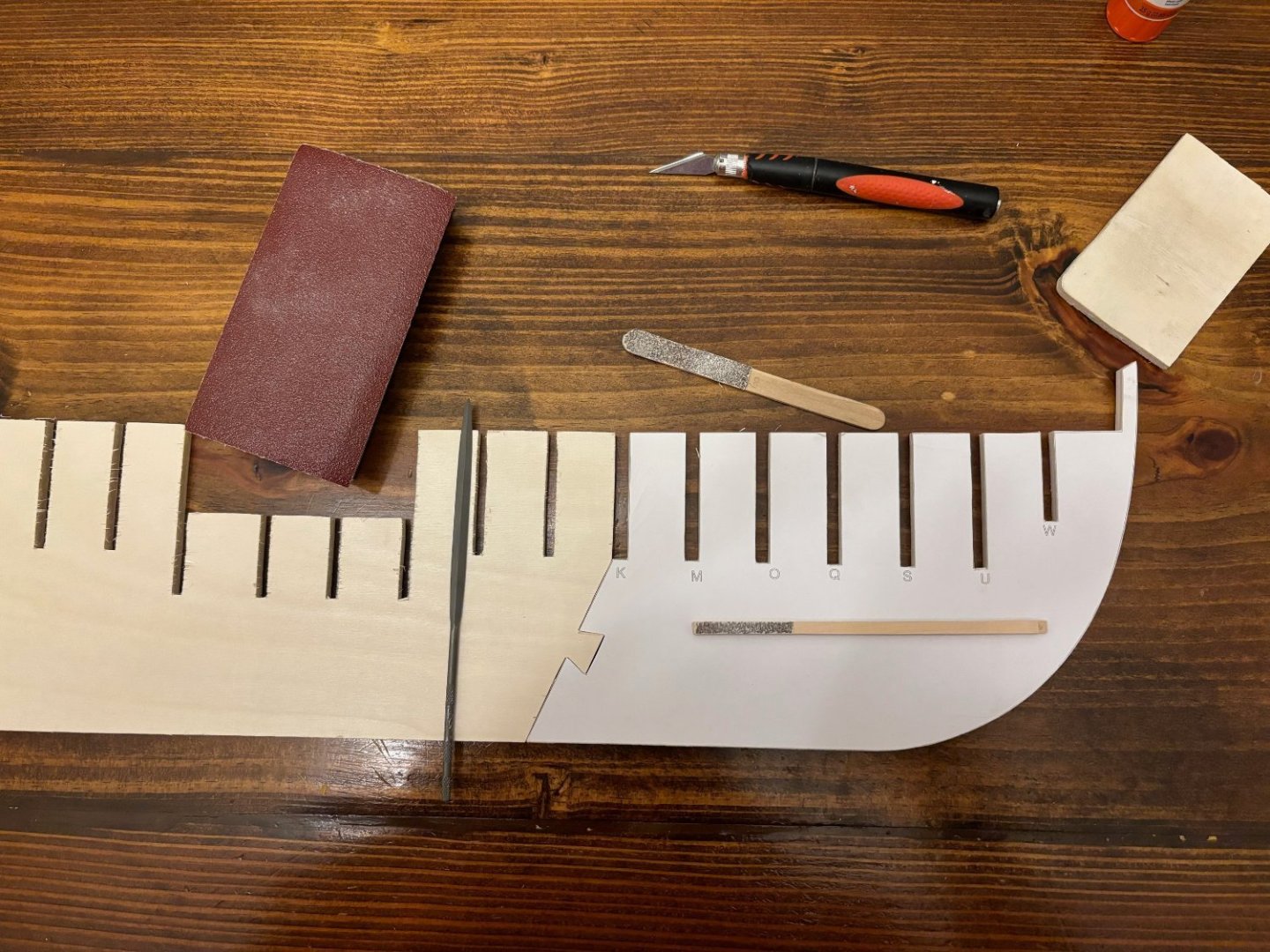

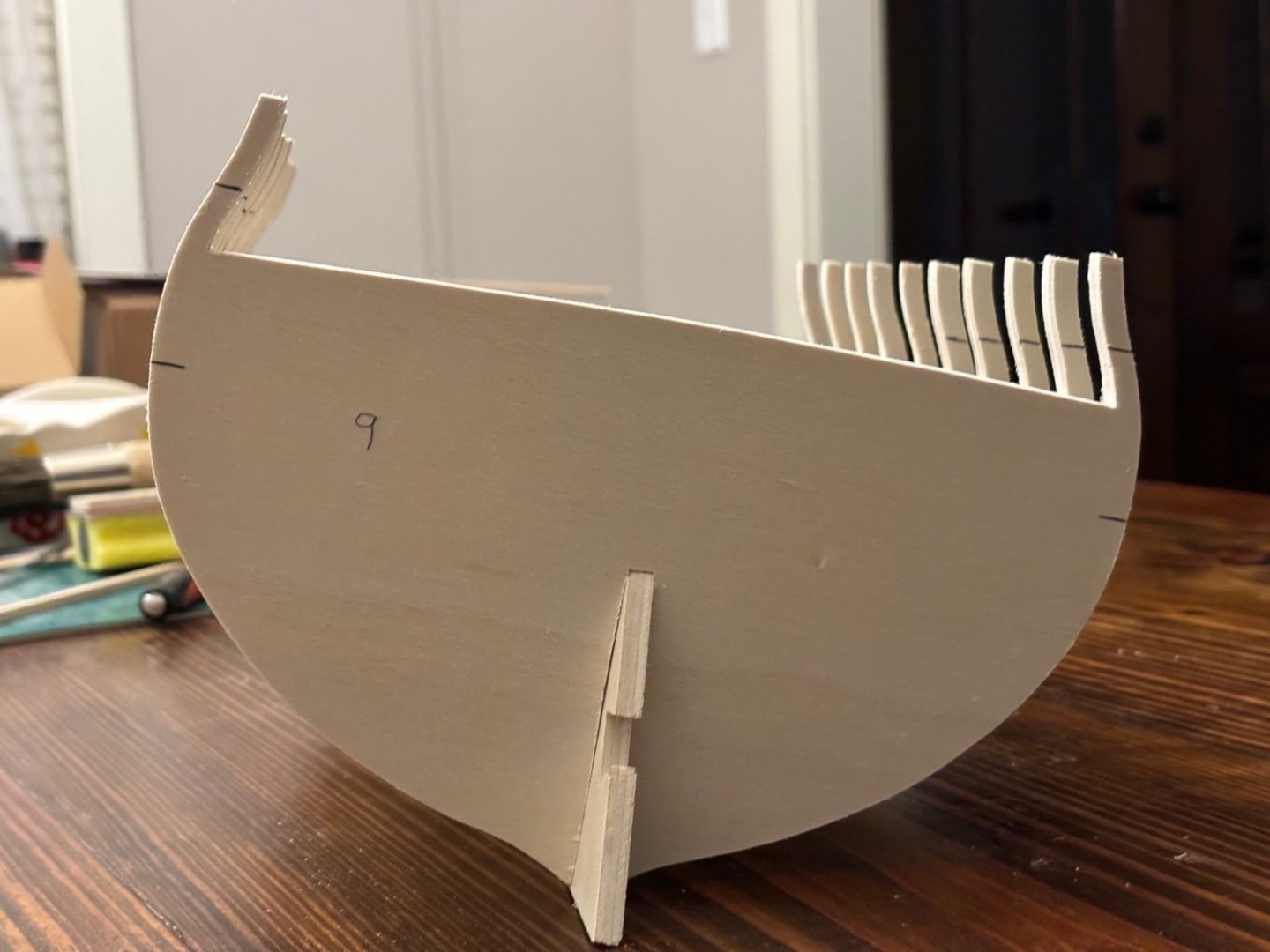

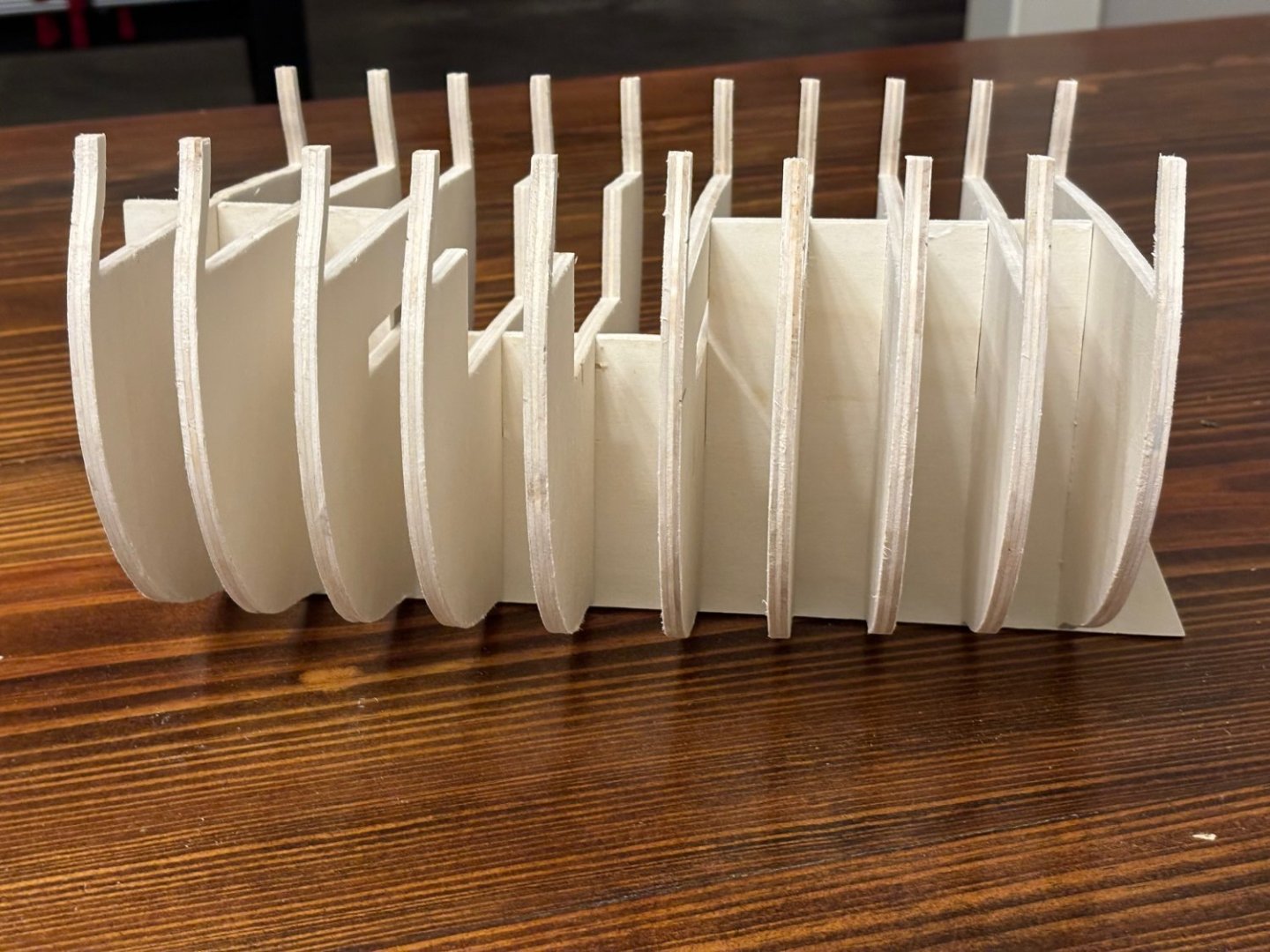

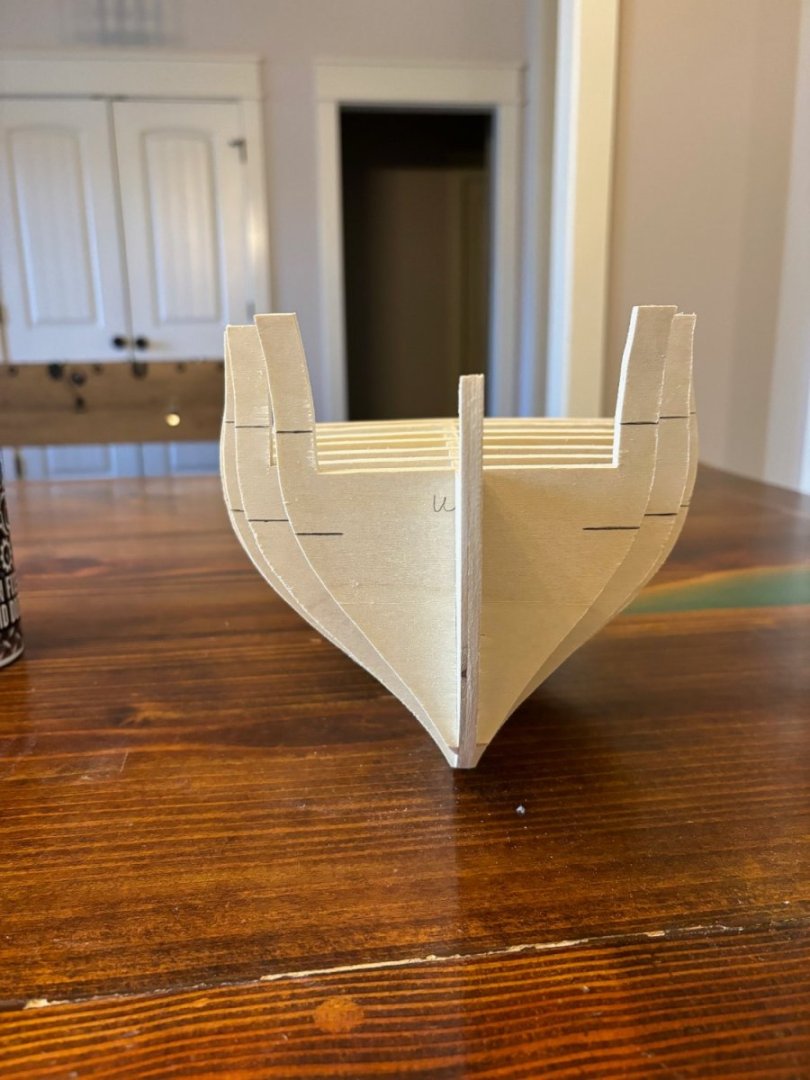

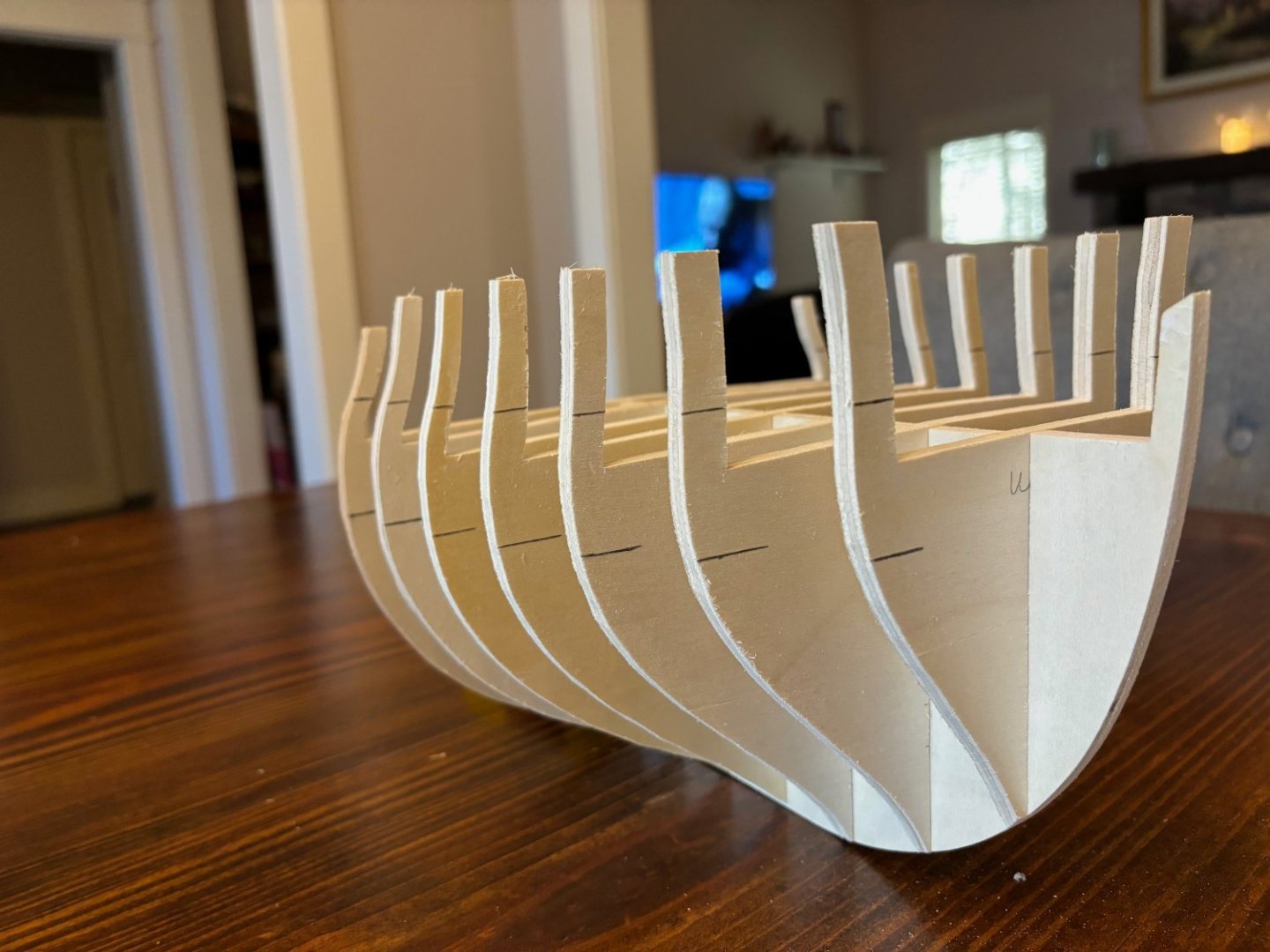

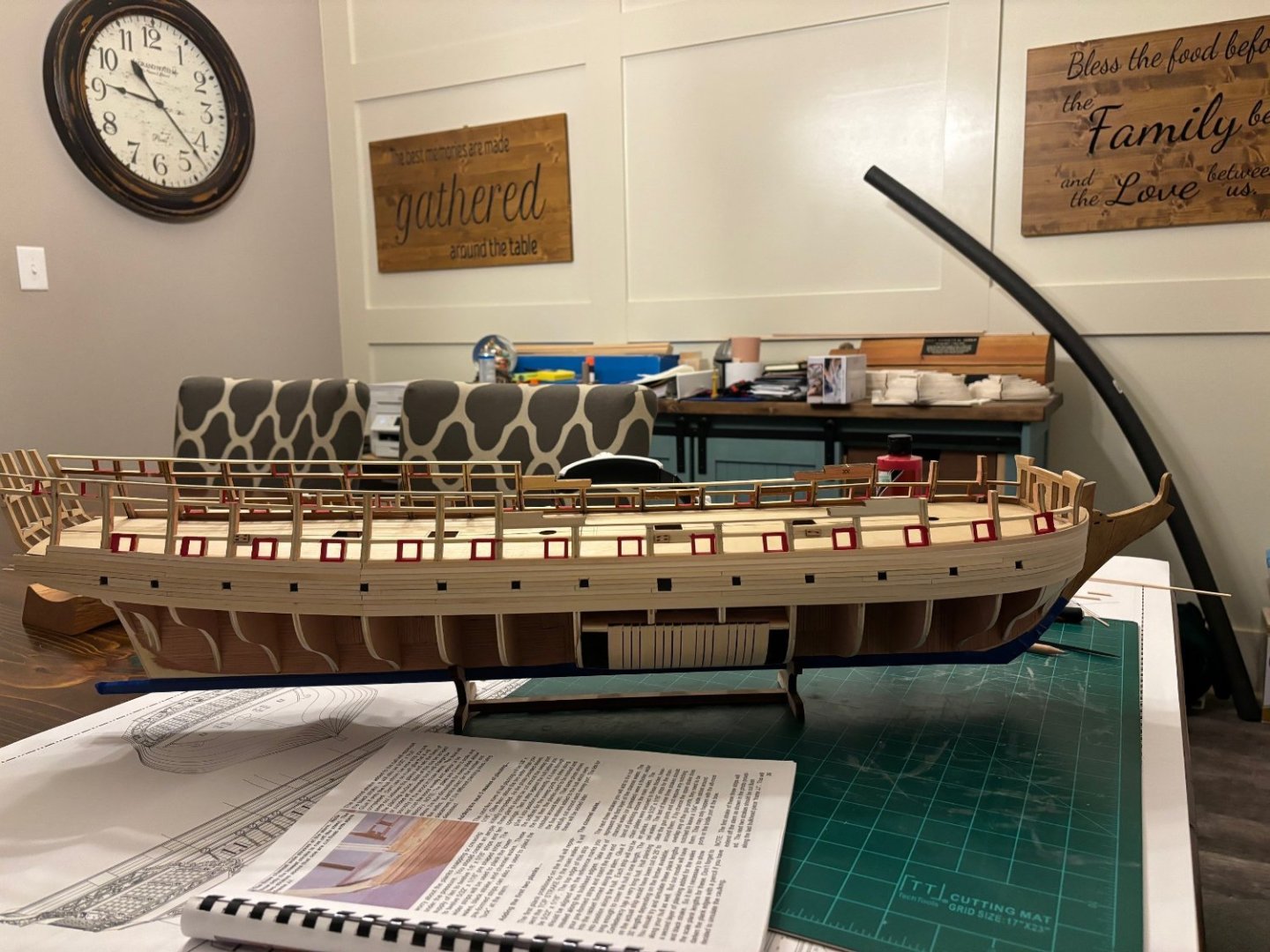

Progress is moving along, even if it is at a snail's pace. I got bulkheads K-W fitted to the forward former. The forward former piece is also fitted to the middle former piece.

The bulkheads are only dry fitted right now. Working on the middle former piece now along with bulkheads I through 9.

I also cut out the pieces for the skeleton hold up clamps on my X-Carve. So far I have 2 of them assembled; only 4 more to go. Once I get these all assembled and the bulkhead former completed, I will make the build board for the model.

As always, thanks for looking in on my log; any and all comments are welcomed.

- Chuck, FrankWouts, Freebird and 5 others

-

8

8

-

Why am I always late to the party? Simply amazing with the design and build so far, I will be following along intently with my bucket of popcorn and chair.

- mtaylor and scrubbyj427

-

1

1

-

1

1

-

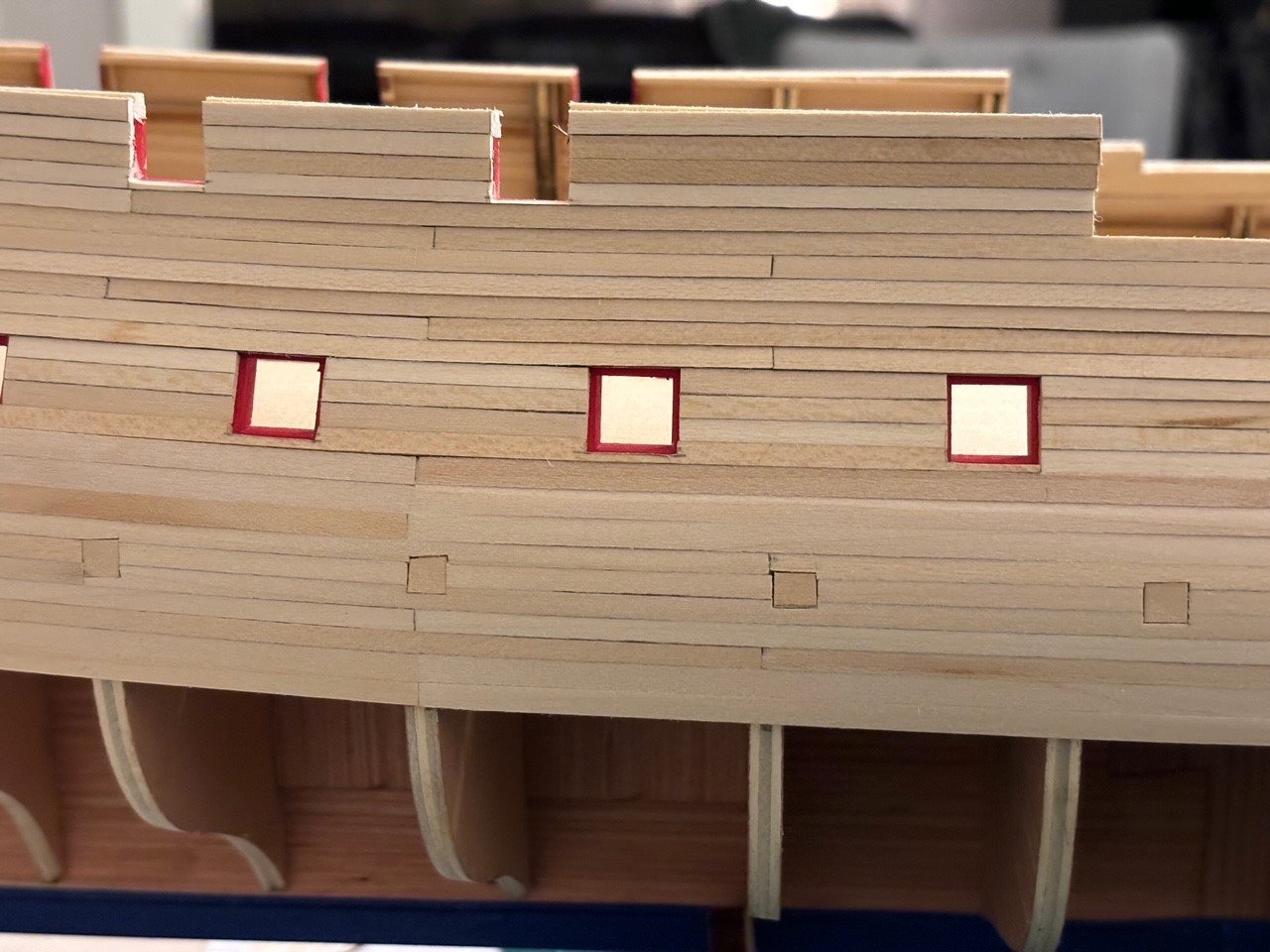

Finished up the planking above the wales on the port side. It just needs sanding to smooth it all out before adding the second layer for the channel wales and molding and sweep port covers. I'll sand it after I finish up the starboard side.

To get the rabbet consistent on the gun ports, I used my guitar string set up rule since it provides measurements down to 1/64 of an inch. I have also decided that I will be painting the hull the above the wales instead of staining it. I like the look of the painted hull better.

-

What an awesome technique for making the eyebolts look more to scale. I will be incorporating this way of making them for sure. Those lower platforms look absolutely amazing.

- mtaylor, scrubbyj427, FrankWouts and 1 other

-

4

4

-

That is one fine looking half hull merchantman model. I am currently planking mine at the moment to gain some experience. I started with planking the wales and up; and plan to use Chuck's method of planking below the wales.

Can't wait to see some more progress on your Winnie.

- James G and FrankWouts

-

1

1

-

1

1

-

-

-

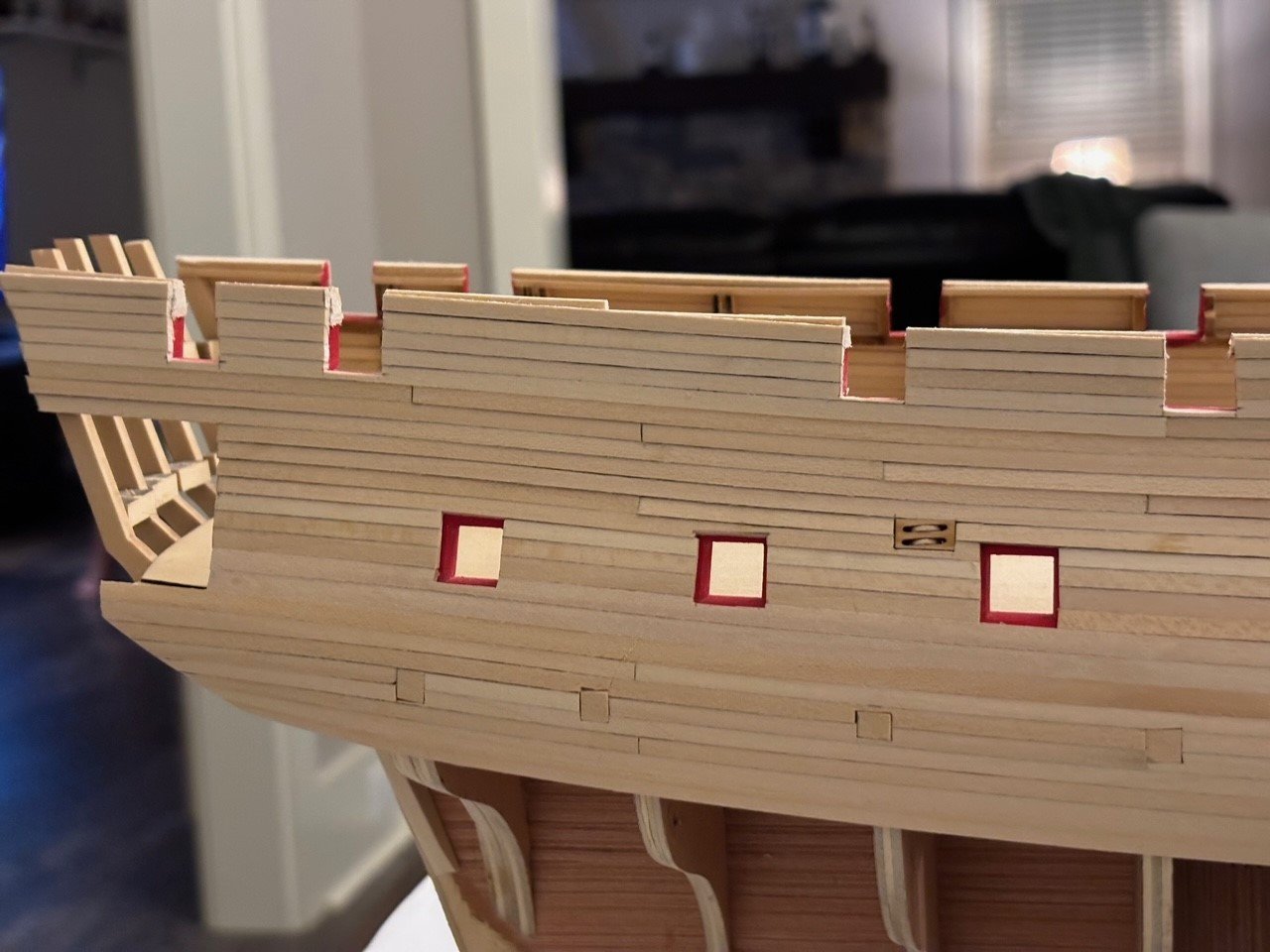

Had about an hour's worth of shipyard time today, so I decided to do a rough sanding on the planks that I already installed on her. I am very happy with how it turned out. I also cut some replacement 5/32 x 1/16 strips from some sheets that I picked up from Hobby Lobby (got tired of waiting on Model Expo to mail out the replacements I requested over a week ago).

As always, thank you for all the likes and all comments and critiques are always welcome.

- WalrusGuy and KARAVOKIRIS

-

2

2

-

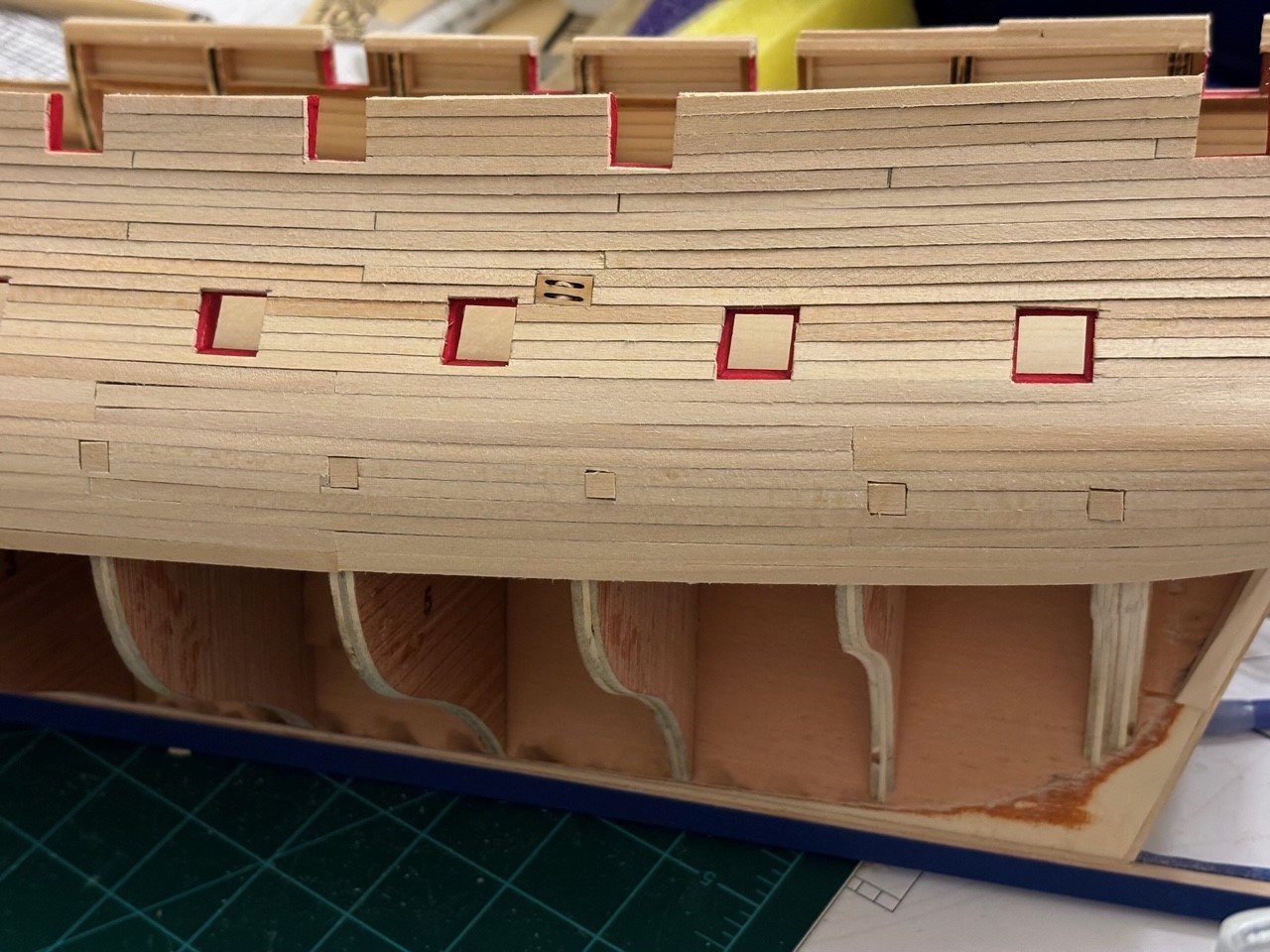

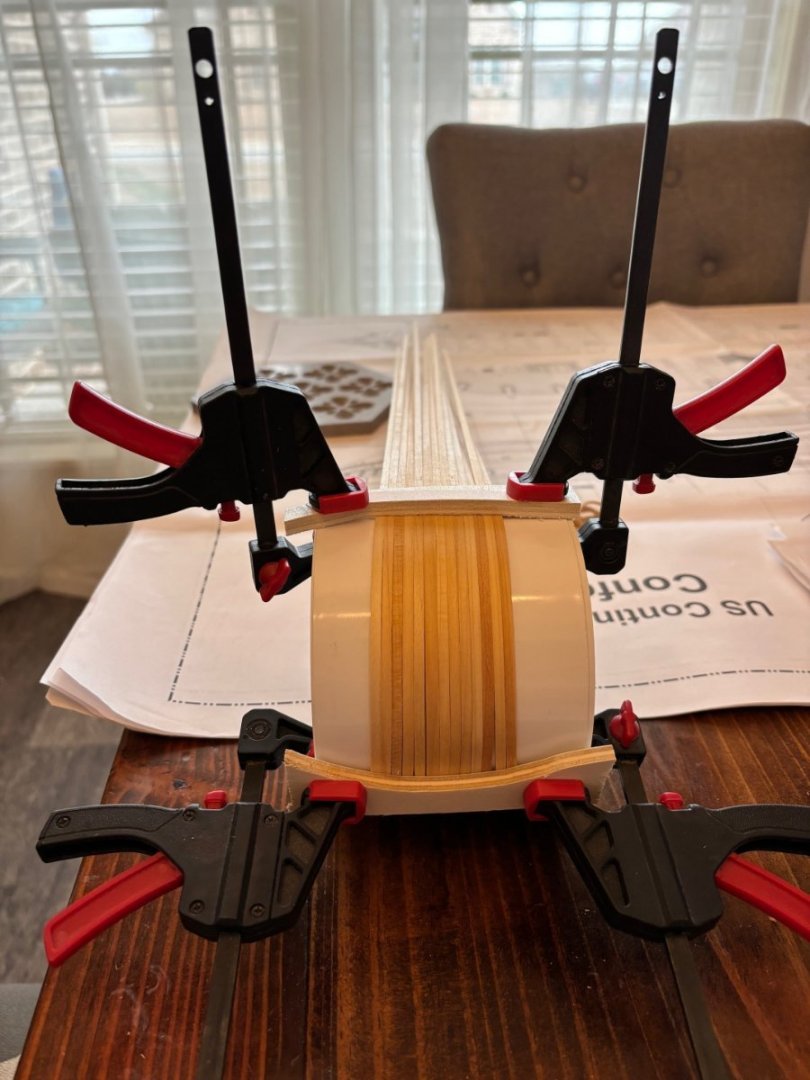

Still waiting on the replacement timbers from Model Expo; boy are they slow. I did get them to email me the templates needed for the sweep ports. I got those printed out and cut out and marked the hull with the locations of the sweep ports. Then I commenced to planking once again starting with the first layer of the top strake of the wales and black strake. Then it was 5 strakes of planking above that followed by 3 strakes of the first layer of the channel wales. Next step is to give all of these strakes a rough sanding before continuing on with the planking above the wales. So far I am much happier with the planking the second time around. Only time will tell if I will be painting or staining the hull.

Got the idea of using a piece of 4 in PVC tube to bend the planking material from another member's build log. I must say that it worked out great.

- TrunkMonkey, CiscoH, KARAVOKIRIS and 2 others

-

5

5

-

I have no words to describe your craftmanship, Chuck. Awesome work on the stove. Plus 1 vote for a mini kit.

- mtaylor and FrankWouts

-

2

2

-

A quick update to the build; all of the bulkheads and bulkhead former pieces along with the stern and stem filler pieces have been rough cut out of lite ply 1/4" thick. Next up is the tedious task of final shaping all the pieces per the templates. I will also take care to ensure that all of the bulkheads fit snugly into their respective slots on the bulkhead former and that all 3 pieces of the bulkhead fit snugly together. No power tools for this task, just needle files and 80 grit sanding sticks. Doing it by hand gives me greater control to finesse the pieces to their final shapes. I hope to be able to get this done in about a week or so, but am in no rush. It is clear that these initial steps in building the skeleton are a crucial step to having a great model at the end.

-

Just awesomely fantastic! Right on par with Chuck's prototype in my opinion. I will definitely use your log as one of my resources for my build.

- Ryland Craze, glbarlow and FrankWouts

-

3

3

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

in - Build logs for subjects built 1751 - 1800

Posted

As always, I have no words. Truly exceptional work! She is turning out to be a model that is worthy of display in the Smithsonian.