-

Posts

7,986 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Louie da fly

-

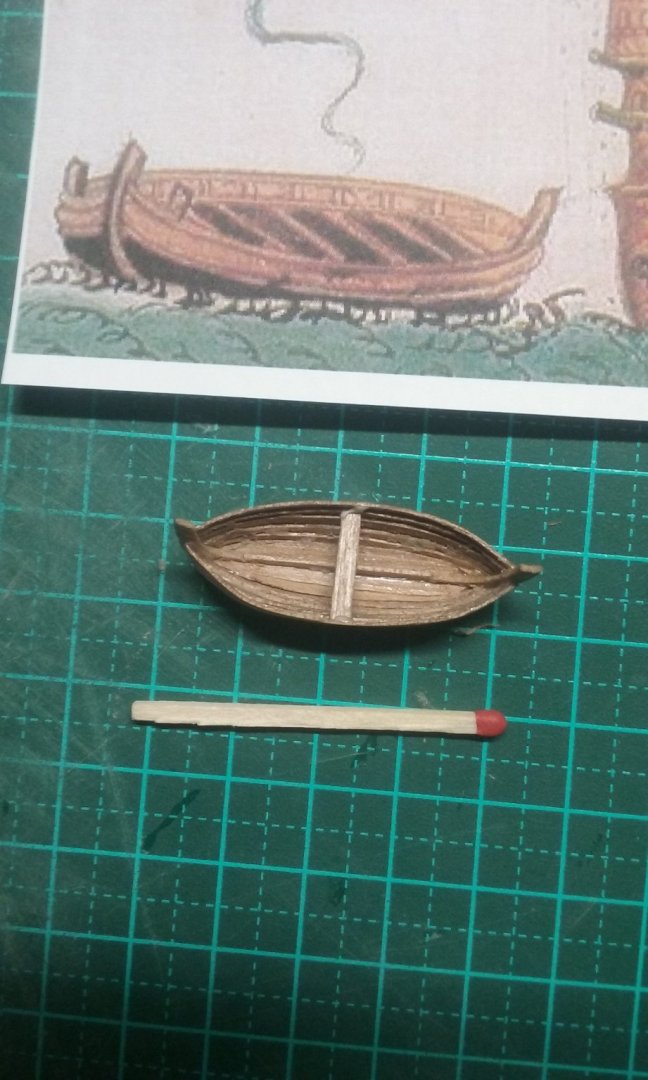

Thanks for all the likes and the nice comments. I thought I'd finished the boat, then realised I'd forgotten to add the gunwales. So here they are. I cut a sliver of wood for each gunwale, about 1/2 mm thick and just wide enough to cover the top of the planking and the frames. Then I bent it to shape gradually with a small pair of pliers - it would have been easier to bend it along the narrow dimension, but I needed to do it along the wider face of the sliver (if that makes sense), against the way it wanted to go. No heat or steaming used. Then glued it in place at one end and waited for the glue to dry. And then glued it, bit by bit, following the line of the gunwale. I had to hold it between finger and thumb till the glue dried. And did the same to fix the ends to the sternpost. I discovered that the "catheads" stuck out too far so the gunwale wouldn't connect with the stempost. So I moved them away a bit (PVA glue is nicely flexible) and tried again. I also realised one of the thwarts was not parallel to the others (see top views above) , so I tried straightening it - unfortunately it was too short now, so I had to make a new one and put it in place. And I've been experimenting with shoe polish (a mix of Dark Tan and Black) to darken the timber below the water line, as shown in the Anthony Roll. I don't want it jet black, just the colour a coating of pitch would be likely to produce. Not totally happy with it, but not bad. Note that the Anthony Roll also shows bottom of the Great Harry as black, so I'll be blackening that as well. But I need to do more experimenting with it, to make sure I have it right before I start. Equally, there's a sliver of wood I used to repair a gap in the upper works which really jumps out at you because it's so much lighter in colour than the surrounding timbers (just under the arched gunports) , so I'm hoping I can make it more in keeping with a bit of polish. Steven

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

Nice work, Lapinas. I like the boat especially. Steven

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

That's amazing. I take my hat off to you sir. Steven

- 132 replies

-

- charles martel

- battleship

-

(and 1 more)

Tagged with:

-

Hello from Northern California Foothills

Louie da fly replied to bobandlucy's topic in New member Introductions

Welcome to MSW Bob! Yes, by all means start a build log. The rest of us get to see your progress photos (and don't be too intimidated by that - everybody's very supportive and helpful, and there's none of us that haven't made mistakes - usually LOTS of them). Instructions are here. https://modelshipworld.com/topic/24705-before-you-post-your-build-log-please-read-this-starting-and-naming-your-build-log/ Good to have you aboard. Steven -

Written by W. W. Jacobs - 1863-1943, born in England - his father "worked as a dockhand and wharf manager on the South Devon Wharf. Jacobs seems to draw heavily upon his father's experiences working at the docks and his stories often feature the adventures of wayward seamen and mariners working themselves in and out of precarious predicaments." Most famously wrote the horror story The Monkey's Claw. Steven

-

Welcome to MSW, Michael! I used to have HO trains when I was a kid - the old Triang set. When I was thinking about what hobby I wanted to pursue as I got older, model railways was the other main contender. But I'm happy I went with ship modelling. I think it's more of a challenge to my creativity and manual skills. Good to see you've started your build log. Steven

-

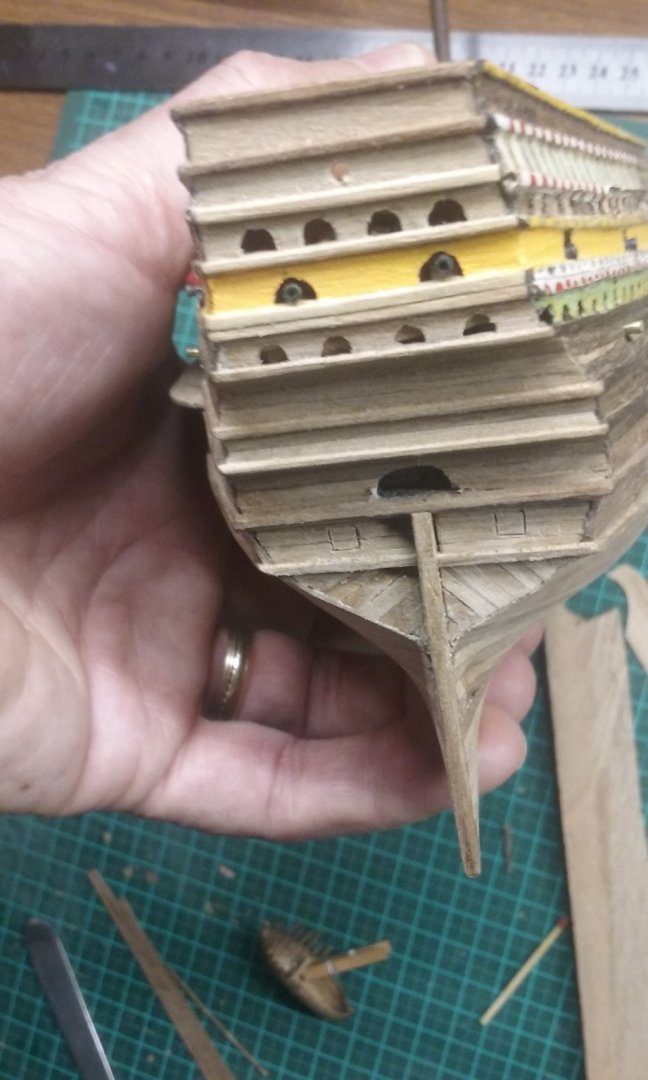

Painted Henry VIII's offsider: Cut gunports in the stern - seeing as the square gunports are closed, rather than make openings and add the portlids I just carved grooves around them. Cut semicircular gunports for the upper deck. And finished the longboat Steven

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

And over the low-pitched sounds of the oars grinding against the tholes, the creaking of the ship itself etc. According to the video of the Olympias sea-trials, they had hoped to try out various means of setting the time (presumably from contemporary records) but ran out of time and settled for the coach speaking through a microphone and a series of loudpeakers throughout the vessel. Steven

-

Not drumbeats - that's a Hollywood stereotype. Apparently low-pitched notes get lost among all the noise of rowing the vessel - what they used to give the time was flutes - this is a Byzantine representation, but as far as I'm aware the ancients used flutes as well. Steven

-

Yes, definitely. That's a field I have absolutely no knowledge of whatever, and would like to know about. Steven

-

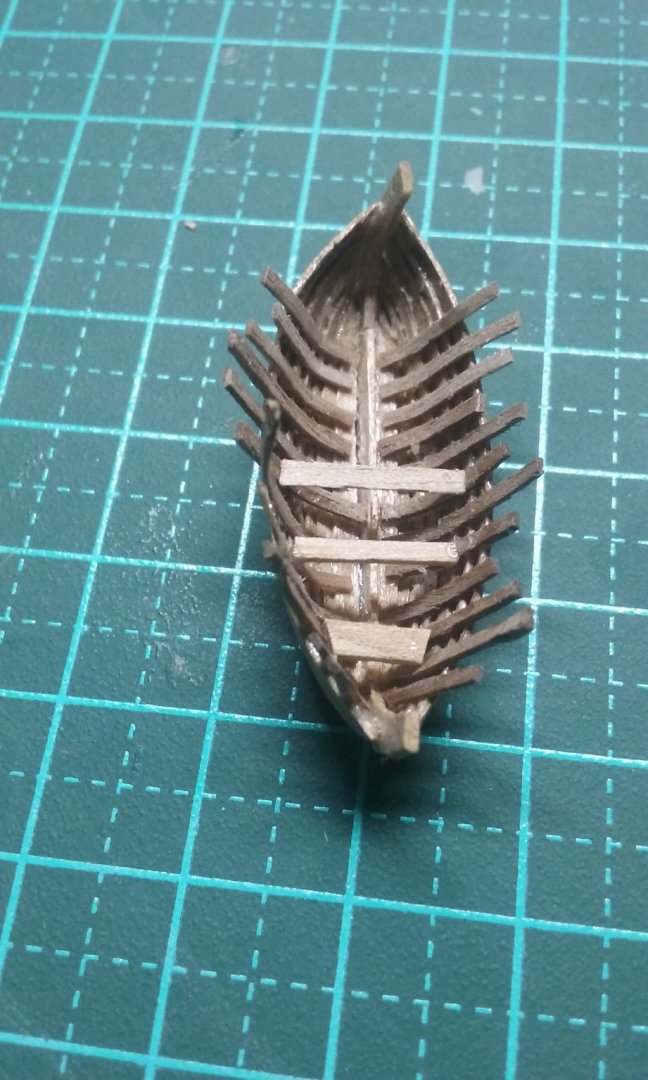

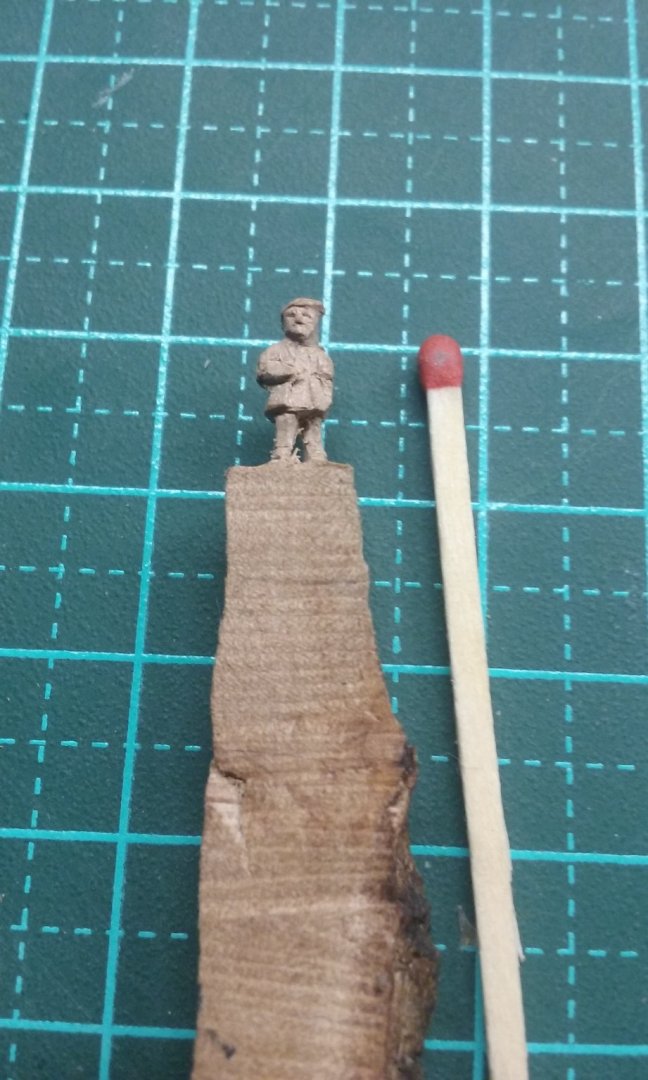

Adding frames to the longboat. And further work on the new figure to keep King Henry company - I think I've done a better job on him than I did on the king - except as I was trying to shape his Venetian hose (bloomers) I managed to break both his legs (they're VERY thin) and had to glue them back together. Steven

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

As far as I know, nobody knows what kind of cleats were in use at this time and place - so whatever you decide is probably ok. They look good. Steven

-

Ian, somebody's actually done it on MSW - see https://modelshipworld.com/topic/6207-greek-bireme-by-bensid54-radio-finished/page/16/ I think the rowing action on this one is particularly good. I don't know how it compares with what you had in mind, but Bensid explains his mechanism in some detail, and you might find this of use. (All W-A-A-A-Y over my head, I'm afraid). Steven

-

Welcome to MSW, Jeff! That sounds like a very interesting project. I built the Airfix Vasa about 50 years ago; I don't know if the kit has changed since then, but certainly a lot has been discovered about the ship itself in the interim. There are several wooden builds of the Vasa on MSW - if you use the search function (top right of this page) you should find them. Some are phenomenally good, and several incorporate a lot of the most up to date information on that beautiful ship, which may be of use to you. I'd recommend you start a build log and share your experiences with the rest of us. It's also a great way to get help and advice from the friendly and experienced builders here. Though you'll be doing a fair bit of scratch work on this, it probably qualifies best as a kit build - but bashed to make it better; something quite a few members do. The instructions are here: Good to have you with us. Steven

-

Welcome to MSW, Henry - from Oz, the land of the wombats. It would be good to see a build log of your HMS Fly, even if it started from your current stage of completion - though photos from earlier in the build would be even better. In case you haven't come across them so far, the instructions for starting a log are here: It's a great way to get help and encouragement (and the rest of us get to see the progress of your build). Good to have you on board. Steven

-

What a wonderful concept! I can think of a myriad of uses for insulting tape . . . All your ideas are inspiring, but i think mainly the problem would be the tight tolerances at such a small size - just not enough room to add another layer of something. I still think just soaking in oil might be the way to go at this size. I had great success with Gladwrap when I did the dromon, but that was of course much bigger. Steven

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

Thanks, Liteflight. I may still go with paper, my only concern is whether it's strong enough for the job. I finished the planking on the longboat: And then discovered the butter treatment wasn't adequate. The boat stuck to the plug and I had to rip it apart to get it off. Fortunately it mostly retained its shape, and all I really had to do was glue it back together again where needed. However, the strakes did lose some of their curve so the boat became considerably narrower. I fixed it by gluing in a temporary crosspiece - which might end up as a thwart, though I doubt it - it seems too big. I still have to add the frames, floorboards and thwarts, plus a triangular seat in the stern for the steersman, and those sort of cathead thingies in the bow, as shown on the boat in the Anthony Roll picture of the Great Harry (see above). Next time I do this kind of thing I may soak the plug in olive oil or something for a few hours, then wipe dry. I've done some investigation and transom-sterned ship's boats are about as common as double-ended ones in this period. The Embarkation at Dover shows double-ended boats with no steering oars, and steering can be done directly by the oarsmen, but for something of any size they really need to have a steersman. The majority of representations of double-ended ship's boats from this period show steering oars. Ordinances of Chivalry English, Late 15th century Morgan Library & Museum Bibliotheque National de France - MS Latin 6142 And a little more progress on the new crewman or whatever Steven

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

Looking for plans or possible models of Magellan's ships.

Louie da fly replied to J11's topic in Nautical/Naval History

Happy to be of help. Steven -

That's nice work, John. Yes, I can see a little more work is needed at bow and stern, but the planking (a very difficult task to get right) is very good and I'm sure you'll end up with something very attractive and worthwhile. Steven

- 48 replies

-

- dusek

- viking knarr

-

(and 1 more)

Tagged with:

-

As a reference in preparing your oars, you might be interested in this link, which I put together awhile ago. https://modelshipworld.com/topic/25729-oars-on-ancient-greek-galleys/?tab=comments#comment-752090 It contains all the contemporary pictorial representations I know of, of ancient Greek oars.

-

Wonderful work, Bolin. A pleasure to follow your progress! Steven

- 179 replies

-

- longship

- Helga Holm

-

(and 1 more)

Tagged with:

-

Not sure how strong they'd be if that's how the rudder is fixed to the ship.

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

I'm sending you a PM.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.