-

Posts

2,213 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GuntherMT

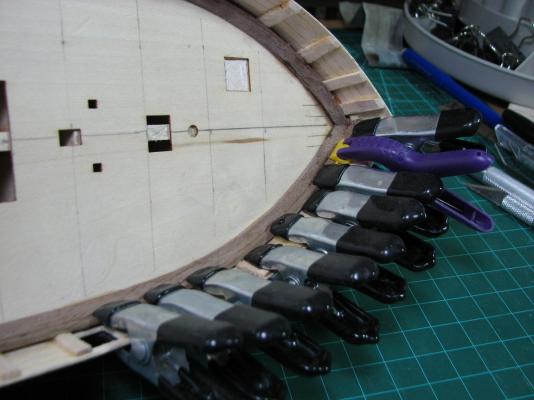

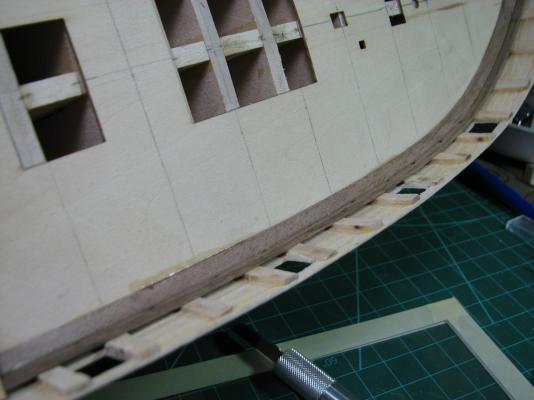

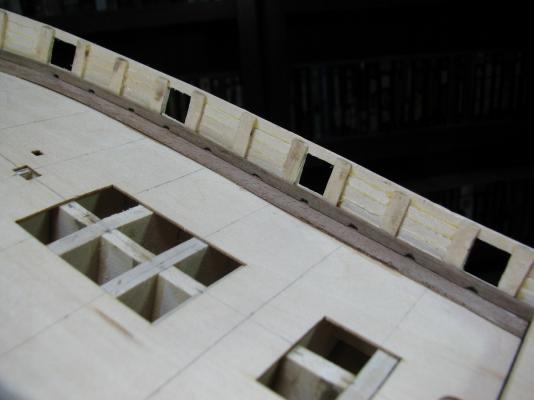

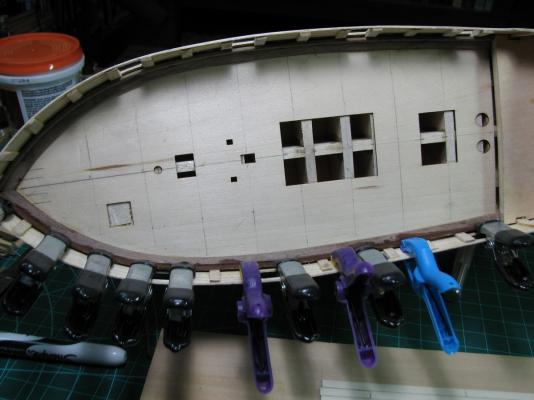

-

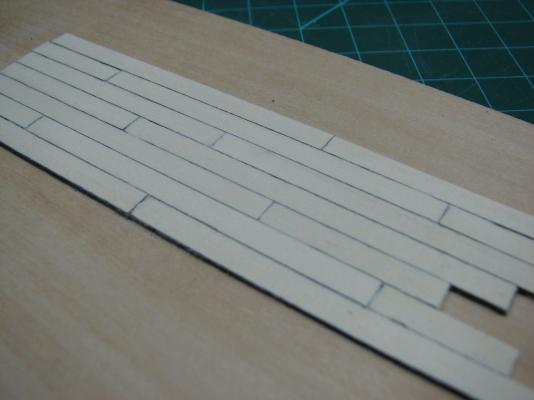

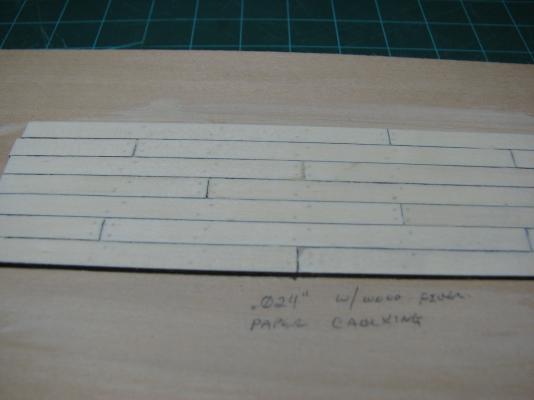

A little bit of progress. Moving quite slowly at the moment between work and some car trouble I just haven't spent much time working on the ship. I got the second wale on, and only after editing the pictures to post here did I see the gap I left at the stem. Close up photo's are the harshest critic. I used a batch resizer for this group of photo's, so hopefully they come out at least reasonably close to the previous photo's for quality. Next is the spirketing plank, which includes the scuppers that were discussed here over the last week. I've decided to just build them in per the plans and not worry about the water sloshing around on the deck for the non-existant tiny sailor-men. Given the type of ship, chances are fairly high that if it was taking enough water over the bulwarks to need the scuppers, it would be heeled over pretty good and the water would drain over the waterway anyhow. I started by fitting the wood to the top of the waterway, and getting it cut to size and sanded properly (rounded the inside edge, and put a slight bevel on the bulwark side for fitment, as well as getting the angle against the stem right). I clamped it down with a whole bunch of clamps after soaking it, and then continued to use an eye-dropper to add water in the areas that had the most severe bend, and then left it overnight. The next day while it was still in place, made marks in the center of each section where a scupper needed to go, and then removed the plank from the model and used a compass to mark the height of the scuppers, and marked 1/16" on either side of my center marks to define the basic location of each scupper. I was pretty worried about trying to trim these little guys out with a razor knife, as they are really tiny and I am not that great with depth control when using a knife - I tend to overdo it. Luckily, as I was playing with different tools I discovered that I had a small square file that was exactly 1/8" wide to the outside of the cutting edges. Bam, solution! I cut the basic rectangle to depth with the square file while the plank was clamped in a vise, and then used the smallest round file I have to shape the scuppers. Pretty happy with how they came out. Next of course, I had to get the thing back in place and glued. I used regular PVA from a syringe to get the glue along the back and edges of the plank without getting any into the areas of the scuppers, and then clamped the crud out of it again and left it to dry. After it dried, I removed the clamps, and it's pretty decent. I would have liked to have it fit perfectly against the waterway, but there is a small gap there. It snugs up against the bulwark extensions nicely though. I am now doing the same thing for the other side. I've got the plank cut to size, and it's currently soaked and clamped in place. I'll keep it wet for a bit longer until I head to bed. While I was waiting for things to dry (either water or glue) I also embarked on a bit of a planking experiment to try out two things: 1 - caulking with the method outlined in a thread by Nigel (found here: http://modelshipworld.com/index.php?/topic/7445-plank-caulking-using-tissue-paper-tutorial-by-nigel-brook/) using tissue paper. 2 - Tree nails. I made a huge mess with the tissue paper and glue, but the results were surprisingly good given my first try, and how much of a mess I made. Note that as can be seen in the photo, I didn't measure anything for this experiment, so the butt's don't really line up very well. Tree nails on the other hand, were a bit of a failure. I drilled 0.024" holes, which are about 1.15" in scale, and then tried to draw bamboo to the correct size, and failed badly at the hole 3 sizes above what I needed to get them down to. I don't know if the draw plate is bad, or if that's just the smallest I can get with the materials I have. The draw plate is from the Reno trip and I have no idea of it's source - the size that failed is the size he was using for his final size on the Hannah model, so maybe it's just worn out? I may get another plate (Byrns?) or try it with another material later. Since the actual tree nails failed, I fell back to the method that Alistair (I think) said he used, and tried my wood filler putty. It worked, but I'm not happy with how well it fades into the holly deck. I think I'll use larger holes than these, even though they are already slightly over scale, and then try to get real tree nails to work down to the size I need, or use a darker filler of some kind, or possibly go with the mono-filament line that's been mentioned by other builders here. Either way, I do plan to tree nail the deck, and while I don't want them to be obnoxious, I do want them to be visible when looking at the deck from a couple feet. Until next time, cheers!

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Welcome to MSW Fletch. I've only been here since the middle of August, but I couldn't agree more with your comments about build logs. I'm pretty sure I've learned more from the build logs than everything else combined since I started this hobby just over a couple months ago. I've also learned a great deal by posting my own log, where plenty of amazing people have given me excellent feedback, and also the simple act of taking the pictures, putting what I've done into words, and then looking at what I've done in the photo's (close ups are an unforgiving mistress) has been an awesome learning tool, so I absolutely recommend starting your own log whenever you get started.

-

Congratulations! Both the Agememnon and the Badger are fantastic looking ships, great work!

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Alistair - the strips are very nice, yes indeed. Lawrence - the boxwood pictured just above is from Jeff at Hobbymill. The boxwood that I used for the wales is from all the wood I picked up from the gentleman in Reno (a couple pages ago in my log) and I believe it was all sourced originally from The Lumberyard ( http://www.dlumberyard.com/). The Lumberyard wood is not quite as finely finished as the Hobbymill wood, but is a much nicer finish and more consistent than the kit strips. Neither the boxwood or holly from Hobbymill is exactly cheap, but it's not horribly expensive given the amounts needed for a kit like the AVS, when I am only using it for finish planking of the deck and misc. items like the wales or deck furniture. I wouldn't use it for the first planking of a double planked hull when the kit basswood is more than decent for that.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Actually Grimber, it makes me want to get busy and get to the point where I can use them. I'm looking forward to working with some of these planks for the decking. Still a ways off though.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Have had no time to work on the ship since I put on the starboard wale, but I did get a package left at my door today. So pretty.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

These are really neat to see. Thanks for sharing something that I've not seen as part of this forum before (as we all like to build wooden boats!).

-

Frank, I thought about your ink system, as the results were fantastic, but I don't have the ink and rather than waiting I just decided to try the sharpie and see how it came out. Worst case I would have wasted the plank, and I tried it on small test piece first, and thought it worked well. I did use boxwood, not basswood for the wale strip - it does allow the ink to soak in a bit, but probably not nearly as much as basswood would. Rich - enjoy your vacation! You might want to edit your email out of the post so it's not out in the public like this.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Ouch. It might actually be cheaper to buy a few bottles here in the states and ship it to you guys. Home Depot has the same size bottle of Original Titebond for $3.97, which is about $5.05nz. Or, after looking at shipping, maybe not. Shipping of up to 20 pounds to Auckland via US Postal Service flat rate box is $85 (108nz) so it wouldn't be worth it unless you wanted more than 5 of them I guess, and who knows what customs would do with a box full of glue bottles. Still, wow, is everything really expensive like that in NZ, or just certain types of things that have to come from overseas?

-

Someone posted some photo's somewhere in these logs last week of a picture of treenails on the deck of a real ship that currently exists, and those treenails are quite apparent, they don't blend in at all well, so I think there is quite some variation on how visible they might be, and that means you can make a reasonable argument that your visible treenails are also authentic if you choose to make them more obvious.

-

So putting off the scupper issue at least until tomorrow, today I filled and sanded. And sanded, and filled. And sanded. I am reasonably happy with the finish of the first layer, no big dips or swells, and only a few places where the filler is left to fill minor low spots. So I went to place the first wale. The kit provides some walnut strips for the wale, but the walnut provided in this size (1/16 x 3/16) is the most terrible wood. All the other walnut in the kit is fine, but the 6 pieces of 1/16 x 3/16 is a completely different color (very light) from the other walnut, and it's terribly brittle and splinters badly. I soaked a piece, and even with lots of water and heat, the edges would splinter terribly, and even after sanding it, I couldn't get the edges to clean up at all. So, I dipped into the Reno wood, and since the color of the wale doesn't matter (since it's going to be black), I found some really nice 1/16 x 3/16 boxwood strips, and cut one of them to size. The boxwood is actually harder to do the actual bend as it's a harder wood, but using water and heat, it does it just fine, but most importantly, it does it without any splintering at all, and maintains a beautiful surface. So I sanded the piece of boxwood and shaped it. I then decided to try yet another experiment that I saw somewhere on the forums in the last couple of months, and made it black before placing it, by the simple expedient of using a black sharpie permanent marker. It looks as good as the painted fashion pieces, was silly fast, and the black ink actually penetrates the wood. After I get the black strake on later, I'll seal it with some clear matte acrylic. So not much progress for pictures, as other than filling and sanding, all I did today was place the wale on the starboard side.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks for the feedback on the scuppers everyone. I'll think on it some more, and decide what I'm going to do with them when I get there I guess. Rich - your mailbox here is full, I can't send you a PM, so I'll just post this here! I forgot to mention at the meeting today, but there is a model show at Falcon Field in Chandler, in the Confederate Air Force hanger/museum next Saturday, November 1st. I plan to attend. The show runs from 10a-4p, and you have to pay the normal $12 admission fee for the CAF museum. Entries are open (I think they cost a few bucks per entry) so if you wanted to enter a model you could, although all the categories are for plastic, so you'd probably have to enter in the 'all others' category. I've considered entering the Carmen just for fun, although I know it would have no chance to win anything. If you are interested let me know and I'll see if I can find the link to the website, which is eluding me right at the moment. Shoot me a PM with your email address as well and I'll send it to you that way if you'd like.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Hi Russ, There are no pictures, as I haven't actually done anything yet. I'm reading ahead trying to formulate a plan for the next few steps, and it just seemed odd that the scuppers are above deck level both in the plans, and the instructions. The scuppers are also pictured at the top of the waterway on the practicum for the AVS on The Model Boatyard site. As I said, it's probably not a big deal to make it this way, and I probably will (as cutting into the waterways would be a royal pain to do at this point), but I was curious if this is a technical error in this kit and the plans or if I was missing something about how the scuppers were supposed to work.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks John & Len. So I have a question about the scuppers. Maybe it's just a design issue in the kit that everyone just builds with, but it seems to me that in order for the scuppers to do what they are designed to do, they would need to be at the deck level, not on top of the waterway which extends above the deck. What am I missing here? I'm fine with building it the way the practicum and the plans show, by cutting them in the spirketing plank, as if I cut them in the waterway they would cut into the wales, but it just strikes me that this design would allow quite a lot of standing water on the deck (the depth between the scuppers and the top of the deck) that would be unable to drain out through the scuppers until the ship was heeled over. The distance between the top of the deck, and the top of the waterway (and hence, the bottom of the scuppers) is 1/16", which in 1:48 scale means that the deck should be able to hold 3" of standing water under the scuppers. This seems.. wrong. Any thoughts on this?

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks Steve, Lawrence, and Greg. I don't really consider the Hannah to be 'my' build, as I've done nothing but pick it up and drive it home! No idea what will happen with it, but if I choose not to complete it, I'll try to find it a home with someone who will. Today and yesterday I did not touch the AVS at all due to taking care of other things. I do have a bit of update though, as I came home today to find I had an email from Jeff - my Holly and Boxwood planking has been milled and was shipped today. Sometime early to mid next week it should arrive, so my build will not have any sort of delay waiting on deck planking. Jeff shipped quite a bit earlier than I expected.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Very nice. I refuse to keep a log of my hours. As long as I am enjoying it, I don't want to know how much time I have invested in a little wooden boat.

- 708 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

I tried both beading needles and needle threaders and neither worked as they both required pulling a doubled over rigging rope through a hole that a single rope would barely fit through. I'll try to bring some examples with me tomorrow Rich and demonstrate.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Looking good Brett. Are you planning on fully rigging the guns or just going with the breeching line? Also I've seen a few people who have built this suggest leaving the bowsprit until after the mast is mostly rigged because of how outsized the bowsprit is, that way it won't be a pain to spin the ship around and risk breaking it off or damaging it or the rigging. I'm not nearly to that point yet, so not sure if I'll do that or not yet.

- 129 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

What manufacturer? Some of them may have the plans available to download - Here is a link to the plans for the Model Shipways Bluenose kit. http://www.modelexpo-online.com/images/docs/MS2130/MS2130-Bluenose_Canadian_Fishing_Schooner-Instructions.pdf

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.