-

Posts

685 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captain_hook

-

Hello and good luck with the build. If I remember correctly, the Caldercraft Sherbourne kit included 4x0.5mm Tanganyika planks for deck planking. I used 4x1.0mm holly for my Sherbourne, which simulates faded wood very well, basswood and maple would also be good options. Boxwood is certainly a more elegant option, but that would be expensive. There are many ways to simulate caulking. It also depends on how clearly you want it to be visible. A soft pencil would be a more subtile accent, but a more intense finish would be to paint the sides of the deck planks with diluted black acrylic paint (pre-treat with clear varnish and let it dry so the paint doesn't soak deeply into the wood later). I've also seen model ships where the deck planks were separated with black cellulose or paper. This also looks very good, at least at a larger scale.

- 21 replies

-

- Vanguard

- Sherbourne;

-

(and 1 more)

Tagged with:

-

It may be a bit smaller, but it looks great - it can even be placed on a desk. Great work.

- 117 replies

-

It really turned out to be a wonderful model. Thank you so much for the many photos; your work is truly inspiring.

-

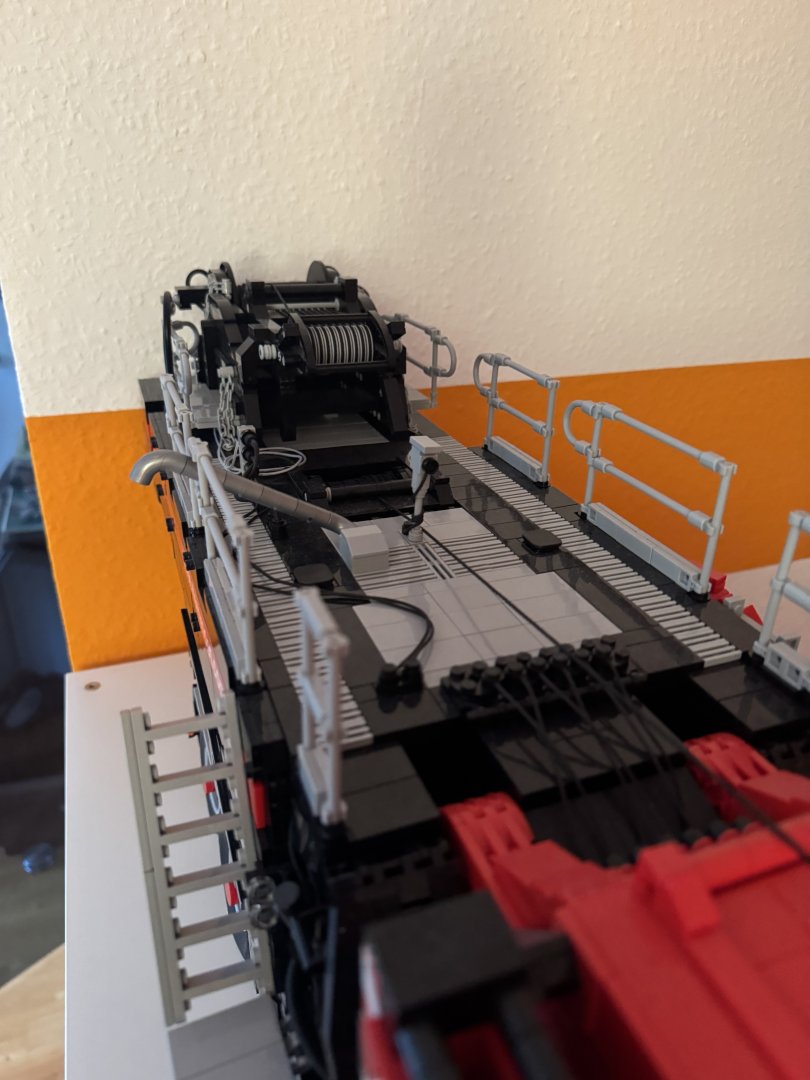

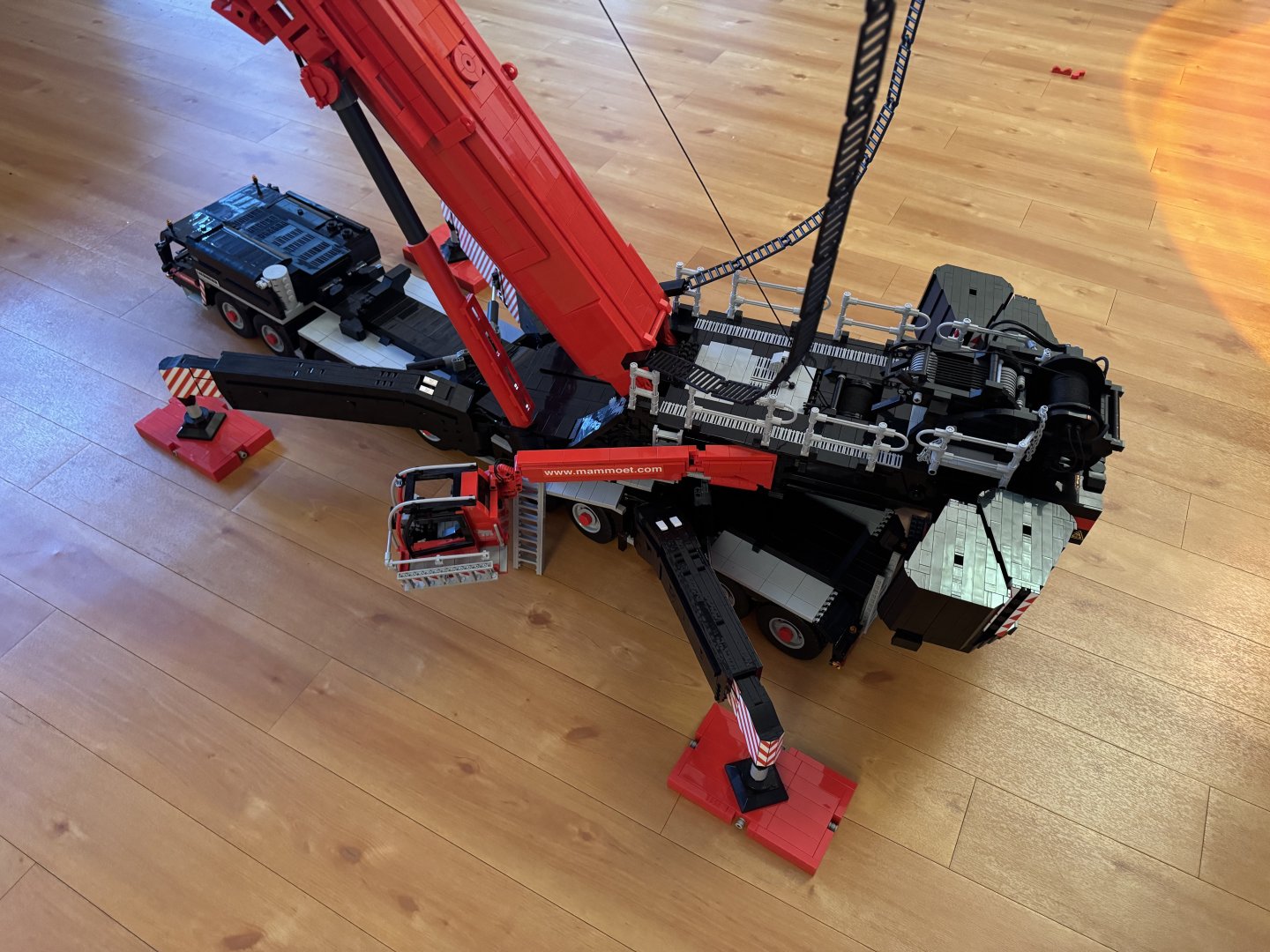

The model is largely a home-made construction, with the mechanics being a scaled-up version of a common MOC (a Technic Version of the Liebherr 11200). The model combines regular bricks and Technic bricks. However, the electric screw cylinders that lift the boom are not original Lego, but compatible accessories from another company. The stickers were designed with Corel Draw and then printed by a printer-company on commission. Here is picture of the real crane ..

-

Hello everybody. Since I couldn't get to my workshop in 2023 due to the installation of a solar system, I realized a childhood dream of mine – a scale model made of Lego. I chose the Liebherr heavy-duty crane, model 11200, as my motif. This crane can lift a maximum of 1200 tons, has nine axles, and a three-stage boom with a heavy-duty jib. The 1:18 scale model is built from around 14,000 bricks, 16 motors, and two battery boxes. It's basically remote-controlled, but due to its weight of almost 10 kg, it's not particularly stable when assembled – the limits of Lego's load-bearing capacity. The model was inspired by an earlier model by a Dutch hobbyist, although it was considerably larger. It took about nine months to build, with a few hours of work every now and then. I completely assembled the crane once and extended it for a photo shoot. Now it sits retired on my shelf. A model of this size was always my dream – but due to cost reasons, it wasn't realized until later. Now back to ship modeling; the next kit is already on its way … stay tuned.

-

Hello and thank you for your interest in my building log. Two years ago we installed a photovoltaic system in our house and I had to completely clear out my building room because the battery was being installed there. It was such a mess that it took me quite a long time to rearrange the room. There were also changes to my self-employment and I'll be moving into a different building soon. These things have distracted me from model building, and once I'm too far out, I can't get back in. Because of the long break, I've forgotten many details about ship modeling I’ve learned before and now I feel like I'm back to the start. To get back into it, I'm going to pause building the Coureur for now and look for an easier project, perhaps the Alert from Vanguard Models or something similar to start with in the next months …

-

That is a nice little boat, well done! And great photos too.

- 62 replies

-

- Saucy Jack

- vanguard models

-

(and 3 more)

Tagged with:

-

Thank you guys for the support. I don't want to give up but this task will definitely slow me down quite a bit and I have to move on carefully as I don't have much scrap wood for spare parts left. Precut-planking sucks! @Beckmann Yes, I use a heat-gun for pre-bending the planks. But clamping them helps a lot to fix them in the right position until the glue has dried. @Chuck Thank you. I will keep that solution in mind if I fail to use the precut-planking properly. @mtaylor Yes, you're right - per aspera ad astra.

-

Today I have started planking the outside with the first two planking rows on the starboard side. This is pretty much testing my patience and perseverance. No. 25 consists of four parts and no. 24 of three parts. No parts is fitting exactly from the start as they are longer and wider as needed. So you’re able to make custom adjustments but this takes a very large amount of time. As the cnc-milled rabbit is only about .5 mm deep you have to taper / flatten all parts of no. 25 to fit into that rabbit too. Took about 3 hours to finish one row and there are 23 more rows to go … I caught myself thinking about starting another project several times and this might be the final task to decide if I will continue building this model next year or just switch to a more suitable project like the Cheerful which has been waiting for me in the shelf for about 3 years now. As the cherry stripes are slightly rotated around their own axis from center to bow and center to stern to fit the hull several clamps are needed to fix them in position until the glue has cured. Another problem is that the plans do not show exactly where the overlap of the clinker-planking begins for each row - so it’s about 3 cm at the bow and 5 cm at the stern for no. 24. So that’s it all for this year, have to help my wife preparing the New-Year-Party. Stay tuned .. and happy new year! Andreas

-

As there were plenty of other things to do before Christmas I didn‘t quite find the time for modeling - but I will return to my build in a few days and start the planking then. Here in Germany there was some snow falling down last week but now it is just raining all day. But I heard a lot in the News about a heavy blizzard running through the USA and I hope all of you living there are ok and able to stay save until it is gone. Seems like Santa Clause has also visited my workshop and left a little Christmas tree there. I wish everyone on MSW a happy Christmas and - if you have any - a nice holiday. See you all here next year again ..

-

These VM kits are like some sort of 3D-puzzle. It is amazing how kits have evolved trough the years - compared to early Caldercraft kits like the Cruiser brig. Nowadays most of the hard work has already been done for the modeler. But James's skills may the building of the prototype look a lot easier than it actually is. BTW I liked the unpainted one a lot more - such a shame to cover all the nice wood ..

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Nice start! Good luck with your new build and hope you will recover soon. I also lost my modeling-motivation for about a year and still have to force myself to start the next intended step. But when the first 30 minutes have passed I‘m into it again for hours. But you‘re right - a small project is a good way to get experience of success and light the fire again ..

- 57 replies

-

- marisstella

- batelina

-

(and 1 more)

Tagged with:

-

I have done some more small steps that have to be done before planking of the ship will start. I prepared all supplied planking strips and removed all the laser char with 120 grit sanding paper. I had to exchange four planking strips as well because of small defects in the cherry wood and used them as templates for new ones made of scrap wood. There are 25 planking rows on each side and the planking layout used on one side is mirrored on the other. That is a lot of work ahead and I hope to finish both sides before Christmas. And I closed the gaps between the inner and outer planking left and right of the frames that are still viewable with small pieces of scrap wood. On the real ship this may have been done to prevent things falling between the planking sheets. At last I sanded the stern planking to the final shape. I‘m still a little scared about the clinker-planking but will start with that major step the next days. Stay tuned ..

-

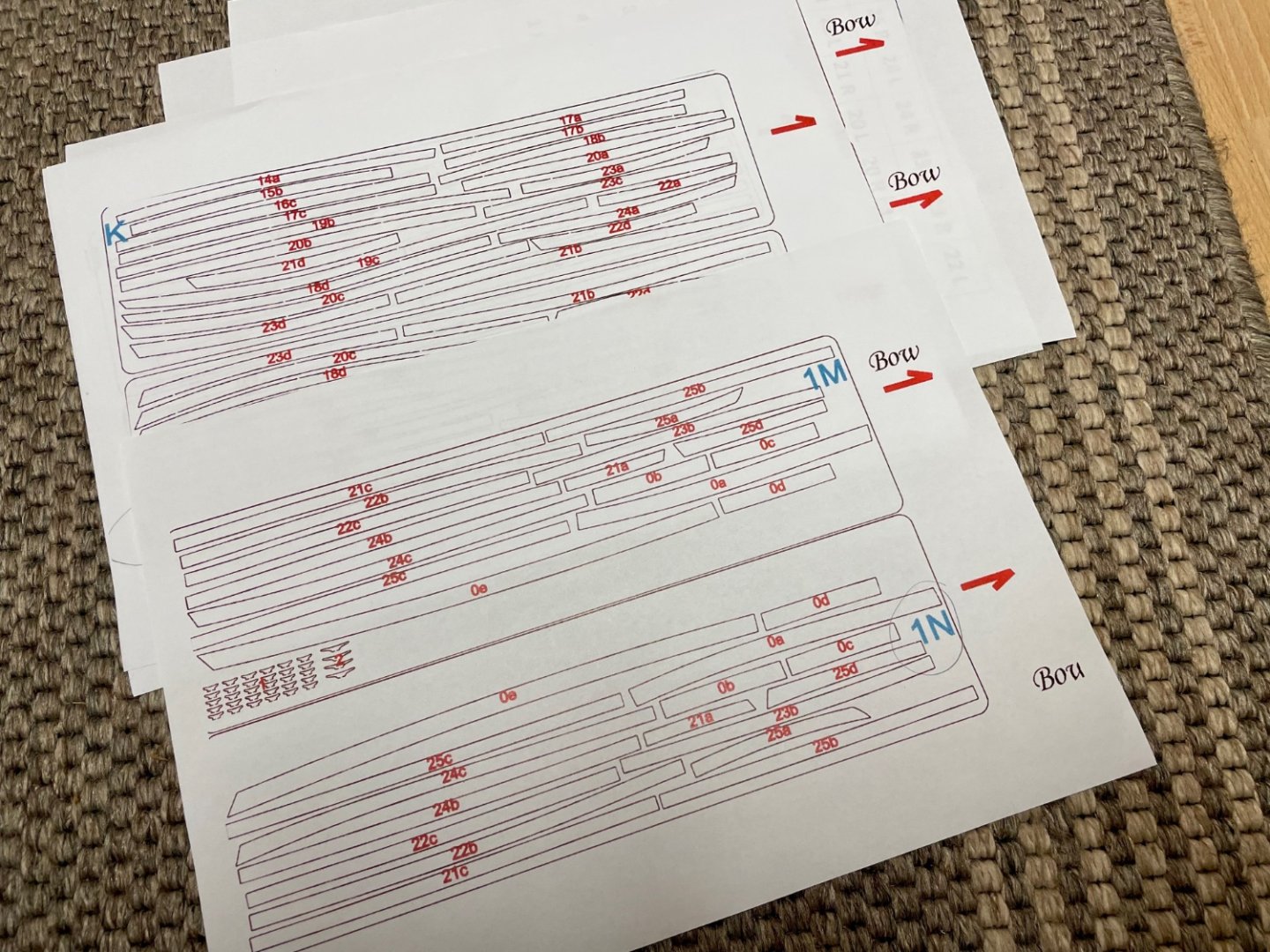

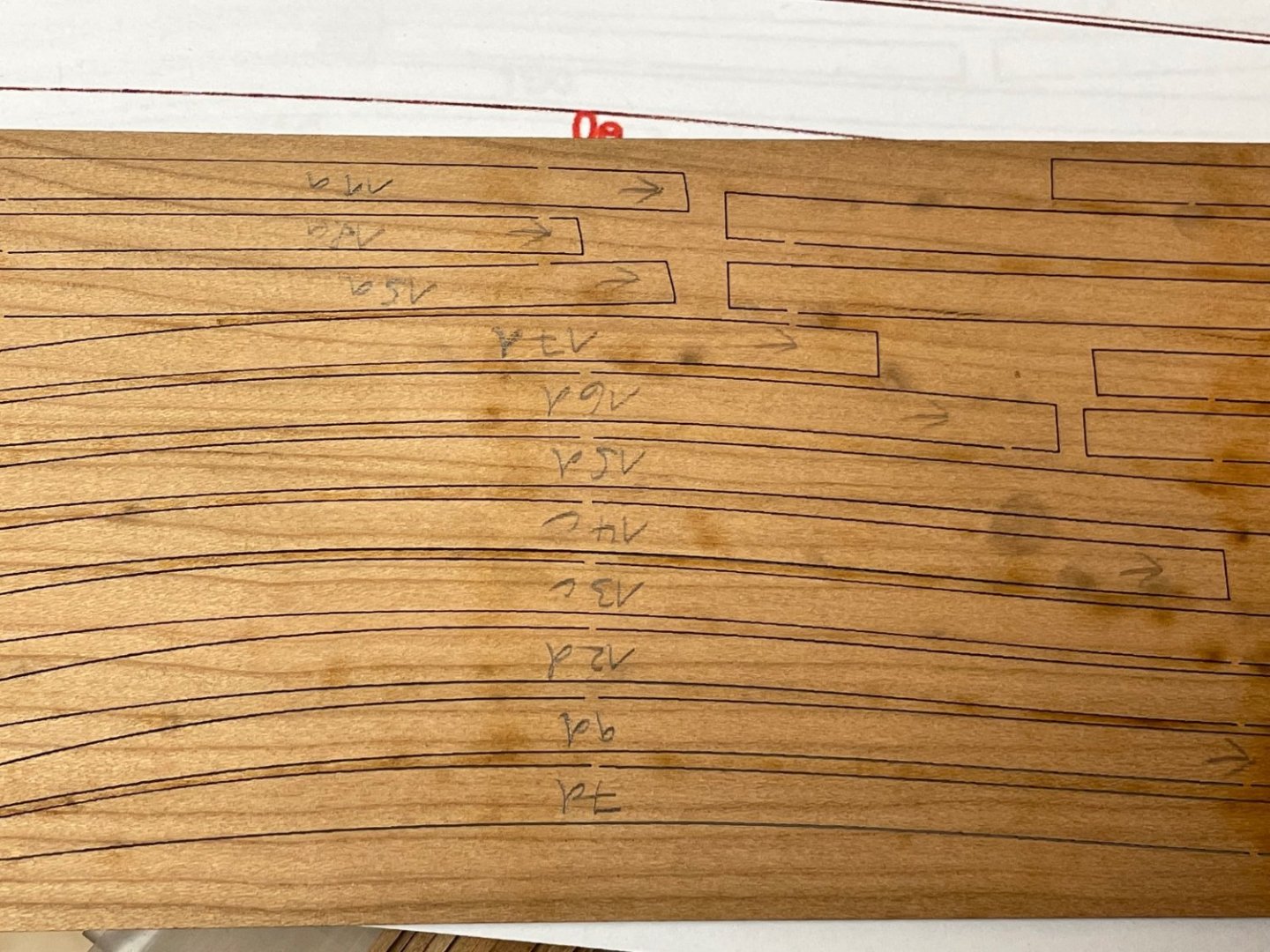

I did some preparation prior to planking the sides, this will help me ensure that the precut-parts are not mixed up later. I first enlarged all the precut-planking parts list pages from the manual for better reading the numbers and orientation, then transferred all part numbers and a small arrow to indicate the directions to the bow onto the lasered parts with a pencil. Then I carefully released all the precut-planking parts out of the sheets and selected them by the corresponding planking row, usually 3 or 4 parts per row. - starting with an A at the bow to C or D at the stern. These parts will need some cleanup, removing of the laser char as well as some adjustment to fit the hull later. And I may substitute strips with defects by parts made of scrap wood if necessary. As I have plenty of plastic bags laying around in my workshop I used them to group all parts of each row. I also scanned the plan showing the planking run on bow and stern with my computer, printed these areas on heavy paper, glued them temporarily onto the keel with some tape and transferred the planking run by pencil to indicate the width of each plank there. After this preparation I‘m now ready to start planking with the first 2 rows No. 25 and 24 bottom-up on port side. I‘m a little scared .. For me this will be the most difficult construction step as this will be my first clinker-planked ship, every part still needs to be brought to shape and there is little scrap wood for spare parts. I hope not to mess it up. Stay tuned ..

-

Ah, and I forgot to tell: It is far more easier to cut the hole for the rudder at this stage (before you plank the stern) than doing this as the manual suggests far more later. I did it using a drill and several needle files before planking the stern and reshaped the hole after I finished the planking. You can check the shape of the hole with a scrap wooden strip (4mm x 5,3mm) - if you can turn the strip inside the hole the shape is just right.

-

I have just finished planking the stern. The kit supplies some lasercut-parts for that but these parts are about 6.5 mm wide (at 1/4 scale that would be over 31 cm) and they are therefore difficult to apply properly. And their length is just too small to allow any adjustments. Instead of that I used the supplied 5mm cherry strips for planking as there are plenty of them available in the kit. I sanded the edges roughly to shape and will adjust the planking to final shape when I start doing the sides. Applied some WOP to protect the wood - at first I freezed for a second as the cherry wood has a very intense and shady colour. But the colour is already fading out as the WOP starts to dry - hopefully I will get used to that brown colour. I understand that cherry trees are a cheap wood source often found in asian countries - and well suited for furniture and other stuff. But if CAF is ever collecting feedback for a V2.0 of the Coureur then my second loudest request (well the first is a better manual) would be using pear instead of cherry. It is just more suitable for POF, has great colour and surface, doesn‘t burn as much as cherry when lasered and sticks well to wood-glue. Vanguard Models as well as Master Korabel have shown great kits using pear as primary wood. But anyway .. I will skip treenailing the cherry wood because bright treenails would look a little weird surrounded by dark wood (like an inverted photo). But maybe I will substitute the planking above the whale with boxwood stripes and show some treenailing there. I like the two colour-planking-setup (like seen on Alex’s HMS Sphinx). I haven‘t decided yet. I will then have to check all the steps for the planking first and make some adjustments where necessary to enable a smooth planking run for each row. Then I will start the clinker-planking botton-up. Stay tuned ..

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.