-

Posts

10,527 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ccoyle

-

That's beautiful, Tom! Congratulations!

- 144 replies

-

- HMS Speedy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

MV Mountwood by MikeBerk - FINISHED

ccoyle replied to MikeBerk's topic in - Build logs for subjects built 1901 - Present Day

Great work! -

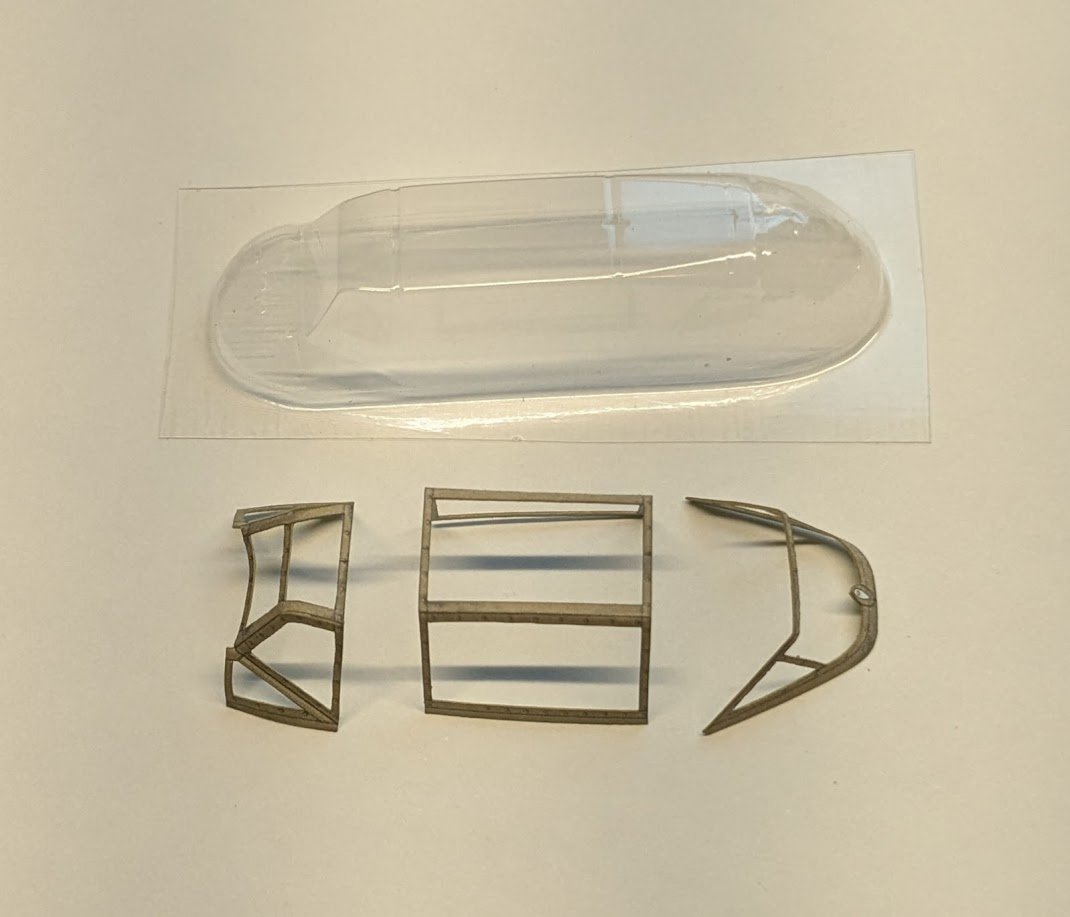

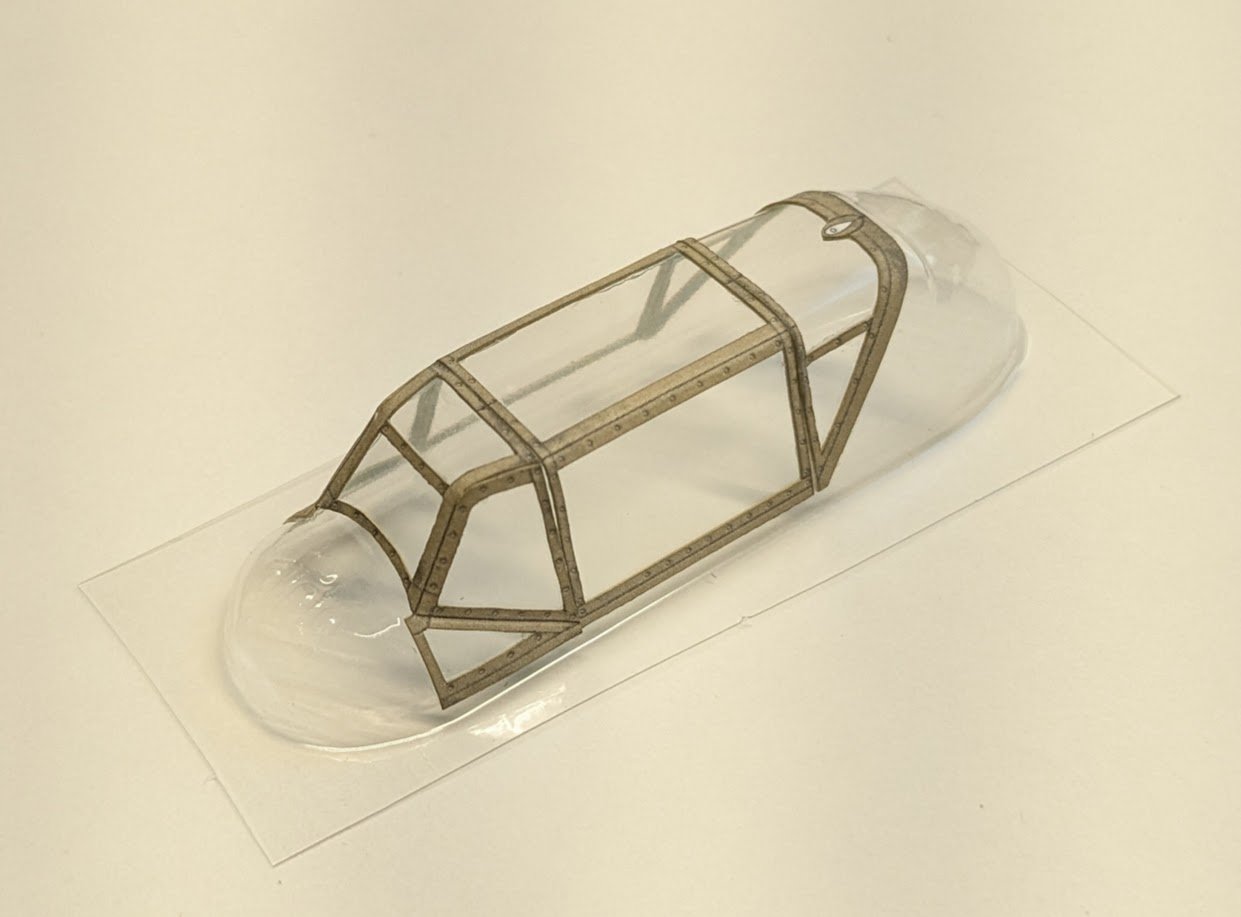

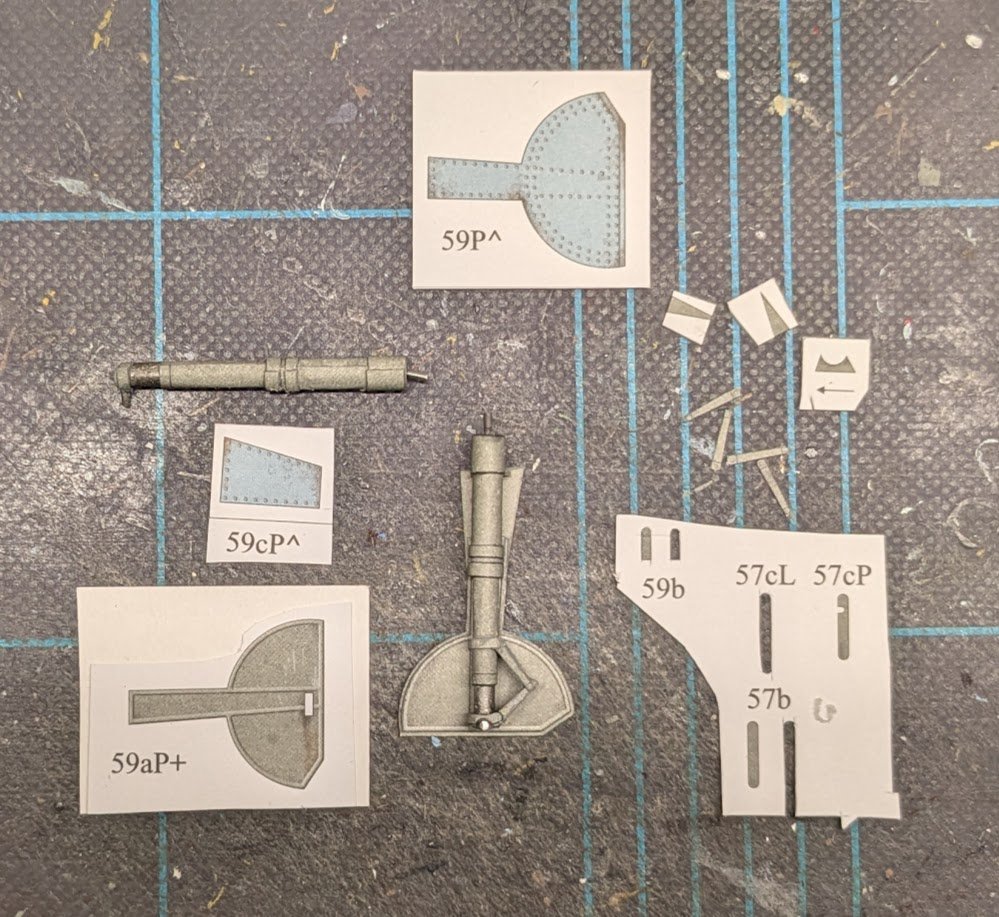

We are now into the home stretch. The major components are done, and there remain only a few bits and pieces. Some of it is tiny details that are easy to overlook, and others are not so easily overlooked -- like the canopy and propeller. Here is the canopy in progress. The kit includes both inside and outside frames. I have always found inside frames very difficult to do. Not only are they hard to position properly inside the molded canopy, but aligning them with the outside framing is nearly impossible, for me at least. And after all the effort, the interior framing is never something that stands out to the viewer. Solution: I use only the exterior framing, but I paint the interior color on the back side before gluing the framing to the canopy. This helps with the illusion that there is interior framing when in fact there isn't. And all glued up: Canopy glue requires 24 hours to fully cure, so I will resist the urge to mess with this until at least tomorrow afternoon. The canopy flexes quite a bit while cutting it out, so a full cure is required to help prevent separation of the frames from the canopy. Before adding the canopy I will need to build and install the gun sight as well as the armored headrest, which is a feature that was not found on the earlier E-4.

-

Finally, finally got around to having a base built for the dust cover, which I have had for at least a year, possibly more. With that, Fly is officially cased and done for realz now.

- 69 replies

-

- fly

- victory models

-

(and 2 more)

Tagged with:

-

Beautiful model, Rick! I have split your posts into a separate topic to avoid the misconception that this model is the same model as in the other build log. Cheers!

- 14 replies

-

- portland

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Mamoli's Blue Shadow rigging question

ccoyle replied to johnhoward's topic in Masting, rigging and sails

Hi, John. I have split your query off into a separate topic. I can't answer whether the Blue Shadow is over-hatted, but on the question of British vs. French practice, I would lean towards British, since she's a colonial vessel. -

Beautiful boat -- looks like a CLC Chester Yawl.

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

We can't stay mad at our fur babies forever, can we?

- 8 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Absolute beginner here - new to ship modeling

ccoyle replied to AlanR's topic in New member Introductions

Welcome aboard! -

Model builder's wife, upon viewing [insert name of junk item here]: "I think this needs to go (in the trash / to Goodwill)." Model builder: "But that could come in handy for a model some day!"

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

Just catching up on your project -- that's some exceptionally skilled craftsmanship on display!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.