Roger Pellett

-

Posts

4,519 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Roger Pellett

-

-

I would buy the auxiliary pack and extra belt although I have used my Saw for many years without having to replace the belt. The screws that hold down the insert plates are tiny and easy to lose. I have the micrometer stop and always never use it. I like the 3in 90 tooth blade for cutting wood. I also have a very fine, sorry, I don’t know the tooth count, blade for cutting brass sheet and tubing. I have a 10in table saw so don’t use the Byrnes saw for cutting heavy wood stock. Zero clearance inserts are easily made from thin craft plywood.

Before you use the saw- Paint the miter pin a bright color! Mine is painted Day-Glow orange. I have dropped it many times and would have lost it if it was not painted.

Roger

-

The catapults were not the steam catapults used on the Forrestall and Nimitz class ships. These were developed by the British and began to be used in the 1950’s. The catapults used on the Essex Class carriers were hydraulic-pneumatic and according to Wikipedia, Lexington used flywheel powered catapults. So, Enterprise would fit in between.

There is a copy of a US Navy technical manual on the internet describing the Essex Class hydraulic-pneumatic catapults. The system used pumps to pressure a non-flammable liquid that in turn compressed air stored in large flasks. Upon release, the rapidly expanding air provided the impulse to launch the plane.

Roger

- mtaylor, mtdoramike, Canute and 1 other

-

4

4

-

-

A couple of thoughts. I believe that the Model Master paints were enamels- thinned with solvents. The Badger paints. Are they acrylic and compatible with over painting or touching up Model Master paints.

In matching colors, I would suggest comparing the two when both are dry. Some paints change color slightly when drying.

Roger

- Ryland Craze, mtaylor and Canute

-

3

3

-

Old NRJ issues, those published approximately before the year 2000 contain a wealth of information similar to that now found on MSW. Fortunately, much of this is included in the two volumes of Shop Notes available from the NRG office.

These are an invaluable resource for those of us wishing to handcraft models using “old school” methods.

Each volume includes an entire chapter relating to finishing; paint, varnish, etc. volume I includes mixing paints using Japan colors and volume II color charts for commonly used Nineteenth Century paints. This might be your nest resource for matching your grey paint.

Roger

- Ryland Craze, Canute and mtaylor

-

3

3

-

-

-

-

An interesting project Eric,

I am surprised at the availability of maple on your farm as I associate it with more northern locations. In Ohio, it tends to be found in the Lake Erie watershed with Oak and walnut in the Appalachian region of the state further south. Here in Minnesota we find maple also in a narrow band mostly in the Duluth area, but evergreens, birch and poplar (aka Aspen) dominating not far north of town and oak and walnut further south. Is the maple on your farm the Sugar Maple or another species that likes a warmer climate.

Roger

- Cathead, Keith Black, Jack12477 and 3 others

-

6

6

-

Beautiful work, up to up to your usual standards!

Can anyone explain how the drag chutes work? It would appear that they need to be ejected against the slipstream to then wrap themselves around the wing. Or, do the pods swivel?

On a slightly related note, Duluth is home to the Sirius Aircraft Company. Their production facilities are located at the Duluth Airport about 5 miles from my house. Sirius is supposed to now be the largest producer of general aviation aircraft in the US. Their composite fuselage high performance aircraft feature a parachute that can be deployed to float the plane back to earth in an emergency.

While the system works, in the hands of an inexperienced pilot it can be dangerous. My wife’s distant cousin owned one of these planes. Taking off from an airport, the plane’s engine apparently faltered and he deployed the chute at low altitude. Instead of floating the plane to a safe landing it dragged it into a tree line killing him and two passengers.

Roger

-

-

After reading Rob Napier’s excellent book about caring for ship models, I thought that it would be fun to restore a well made but abused model to its former glory. When I have nothing better to do I sometimes browse EBay for a suitable candidate.

There is one one major roadblock (pun intended!); shipping. Not wishing to make a road trip to the East Coast where most worthwhile projects are, getting the model moved without further damage made things impractical. Likewise, IMHO by rigging the model, Elmina has reduced the market for it.

Roger

- mtaylor, GrandpaPhil and Keith Black

-

3

3

-

6 wives; 2 beheaded, two divorced, and he almost had #6 killed. There was no shortage of people who would want to do away from him. He had reason, of his own making, to be concerned with his security.

Roger.

-

Very detailed and interesting work upgrading this kit.

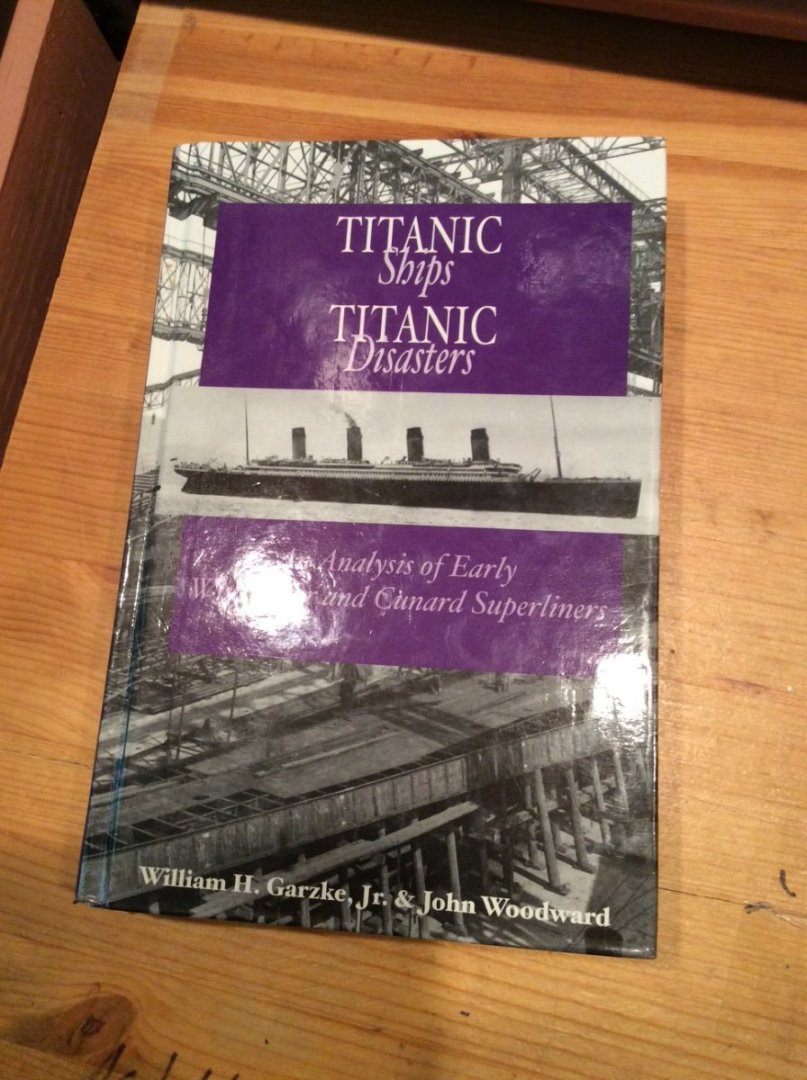

If this effort has piqued your interest in things Titanic, the book below written by a Forensic Naval Architect and a professor of Marine Engineering at the University of Michigan discusses the design of Titanic as well as Lusitania and Britannic without the sensation usually associated with these vessels. I took Marine Engineering courses from one of the authors, the late Jack Woodward. The authors’ conclusions about the three ships are most interesting.

Roger

- bridgman, Canute and scrubbyj427

-

3

3

-

-

An interesting project. 1/16in basswood scales 2in at your scale that might be about right. If you need thicker you could laminate two pieces together. If you can get basswood sheet, does your source also stock craft plywood? This is handy stuff usually available in millimeter thicknesses that approximate fractional thicknesses 1/64in, 1/32in, 1/16in, 1/8in, 1/4in. Either basswood or craft plywood would be preferable to balsa. I assume that you plan to paint the model.

Roger

- Glen McGuire, robert952, mtaylor and 1 other

-

4

4

-

Shields as discussed above: I would make them from .005in thick brass sheet. I would first sand it with 220 grit sandpaper to give it some tooth then lightly spray the sheet with Tamiya primer. The shields can then be painted with acrylic or oil artist’s colors. The brass is easily cut with a pair of ordinary scissors.

Roger

- mtaylor and Snug Harbor Johnny

-

1

1

-

1

1

-

Luis,

I have a whole collection of models that I am thinking about building. In my head I solve all sorts of problems when I have nothing better to do.

My current project is a steel hulled vessel with overlapping plates. I tried using double sided transfer tape to secure brass hull plates. I could not get an acceptable bond to the hull. In my opinion the longevity of any pressure sensitive tape is suspect.

If I were to build a model with a copper sheathed hull I would use paper glued down with ordinary PVA adhesive. I would paint the paper using an airbrush. It should be possible to spray different shades to give a subtle appearance. It helps to seal the paper beforehand with shellac.

Roger

-

-

It’s my understanding that Douglas Fir was used for the masts on the large American Schooners built in the early 1900’s. It was shipped all the way from the Pacific NW to shipyards in Maine on special Railroad cars. These masts were made from a “single stick,” not built up.

Chapelle writes that the RN refers to American “fir built frigates,” not a complimentary term. On the other hand, it is well known that The US Navy used Live Oak shipped from Southern States to Northern shipyards for structural members, so I don’t know what the RN is referring to

It would seem to me that Teak would not have made an appearance until the Nineteenth Century when the British began to build vessels in Indian shipyards. I have a 2”x 4” piece of Teak that I bought many years ago during a business trip to Taiwan. In it’s uncut state it a light brown. I don’t know what it would look like if it were to be exposed to weather and wet sanded on a daily basis (holystoned). It certainly is not a candidate for a ship modeling wood. It has a coarse distinct grain and an oily texture. It works great for glass cases as it is very easy to finish.

Roger

- Canute, michael mott, mtaylor and 1 other

-

4

4

-

-

Railroads or boats! Both are interesting which is enhanced by your lovely workmanship. Wether in our shop actively building or just “lurking” here it’s great to know that you are well.

Welcome Back!

Roger

- FriedClams, Keith Black, druxey and 1 other

-

4

4

-

Internally stropped blocks became common in the late 1800’s. Chuck used to sell kits for these.

Roger

- mtaylor, Ryland Craze and Keith Black

-

3

3

-

The transverse stability of a floating body is directly proportional to the cube of the breadth (BxBxB) at the waterline at which it floats. For most hull forms, beam decreases as draft decreases. In other words, the hull becomes narrower as you move closer to the keel.

It was, therefore, probably not necessary for the Archimedes Claw to completely lift the bow from the water for it to work. By raising it to the point where the waterplane became narrow enough to reduce stability the hull would tip and fill with water through various openings.

Less dramatic, but more likely.

Roger

- FriedClams, Ian_Grant, mtaylor and 3 others

-

6

6

Byrnes Table Saw Configeration

in Modeling tools and Workshop Equipment

Posted

Thanks Bob,

I had no idea that these things existed. With nerapathy in both hands and consequent loss of grip strength I am constantly dropping nuts, bolts, and washers

Roger