Roger Pellett

-

Posts

4,519 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Roger Pellett

-

-

If you look closely at the pictures that Bob posted, there is a round collar just above the chuck. This collar is threaded onto the spindle. Unscrewing the collar pushes the chuck off of the Morse tapered spindle. They used to sell collet chucks that would fit the Morse taper. These collet chucks had their own threaded collar that screwed onto the threads on the spindle to lock the chuck in Place. This allowed the drill press to be used for routing. I have one for my drill press and it works well.

The higher end Rockwell Delta drill presses had interchangeable spindles. One for drilling, another for routing.

Actually, I almost never use the drill press for routing. I much prefer another vintage method: Sears Craftsman moulding heads mounted on my table saw.

Roger

-

This is an open ended question depending on where you live, how much you are looking to spend, and how much room you have.

So: Assuming that you live in the US, are not intending to spend $1500 or more on a professional quality model, and are considering a bench mounted model, I would head to the closest big box home improvement store and check out their proprietary brand. I would consider these factors:

Ball or roller bearing supported spindle with Morse taper. The Morse taper is an industry standard so you can change chucks if needed.

Belt driven motor with stepped pulleys. These can be changed if the motor dies. If Integrated variable speed motors die that’s a problem.

Adequate distance between spindle centerline and column. This determines the “size” of the machine.

The largest table possible.

The fewest plastic parts

The drill presses that I have seen at our local Menards are surprisingly cheap- $100- $150.

If you can find an older used one, it will probably be a better built machine that meets all of the above criteria. Mine is a 50 year old Toolcraft, made in Springfield, MA it literally gets used every time that I’m in the shop and is still going strong. The same criteria would apply to a used machine, plus of course the spindle needs to rotate freely without play in the bearings.

You will have a hard time finding a bench top machine with a 1/2 in chuck and especially one with a chuck that will close to zero. This doesn’t have to be a deal breaker. If the spindle has a Morse taper, you can replace the chuck. You can also buy Drill bits larger than 3/8in diameter with reduced size shanks. The chuck on my drill press will not close on a drill bit smaller than 3/32in. I chuck bits smaller than this in a pin vice and mount it in my drill press chuck.

Roger

- JeffT, BenD, thibaultron and 4 others

-

7

7

-

During the depression my father, a recent aeronautical engineering graduate, and my mother started the short lived Viking Aircraft Co to supplement his meager salary. My father designed model air craft, drew the plans, and produced the kits; balsa sheet, strips, and tissue paper. The kits included a bottle of model airplane Dope, homemade by dissolving celluloid in acetone. When painted on the model, the acetone evaporated leaving the celluloid. Model airplane cement was supposedly a thicker version of the same stuff.

Roger

- thibaultron, mikegr and mtaylor

-

3

3

-

In my (not so humble) opinion, the model is later than the 1920’s. Maybe c 1930-1050. In the mid 1930’s, L. Francis Herreshoff designed a double ended yacht to contend for the America’s Cup. She was eliminated in the trials. Maybe she or one of Herreshoff’s other double enders inspired the model.

Roger

- Keith Black, mtaylor, Dobro23 and 1 other

-

4

4

-

For those not familiar with the Lake Freighter Model that I am currently building, inspired by Wefalck (impregnated paper) and Bob Cleek (shellac) I plated the hull with shellac saturated paper, glued on with common Titebond woodworking glue. Primed with several coats of Tamiya spray can primer, the result has been a surprisingly durable surface. I recently managed to set the plated hull down on a on a blob of glue left on a piece of cardboard. When discovered, the glue had grabbed but not completely hardened. The cardboard peeled right off without damaging the surface.

mikegr could cover his balsa hull the same way.

Roger

-

It would seem that much of the reason for these early tanks would be in their shock value. Why then would you be worried about hiding them from the enemy with camouflage?

- Canute, lmagna, Edwardkenway and 5 others

-

8

8

-

Ship model building flourished during the 1930’s and 40’s encouraged by serialized articles published in Popular Mechanics and Mechanics Illustrated Magazines and probably because it did not require a lot of expensive materials in depression era America and later during WWII. These models featured hulls carved from solid blocks or laminated pieces of pine.

During the 1970’s there were a number of articles published in the Nautical Research Journal and Model Shipwright Magazine advocating use of today’s classic ship modeling woods; Boxwood, Pear, holly, etc. This was in connection with making built up or Admiralty style models. About this same time, POB model kits began to be imported into the US. Heavily marketed, they displaced many of the traditional American solid hull kits. Hooking on to the desire of the uninformed to build a “museum quality” model these kits often feature deluxe sounding but unsuitable Woods like a brown wood marketed as walnut.

I have two models built by my father with solid pine carved hulls. One is over 70 years old and one is over 80, even though adhesives used today are much better than those available to him. Both are in perfect condition. The solid hull construction method using readily available inexpensive pine lumber should not be overlooked by scratch builders wanting to build a model that can be passed along to grandchildren and great grandchildren.

Roger

- mtaylor, Jaager, thibaultron and 2 others

-

5

5

-

I have had a long term ambition to build a series of 1:32 scale warships boats. After finishing three boats, I decided to finish my Benjamin Noble model, but I have done considerable research on Civil War era ships boats.

The City Class gunboats were an early Civil War project involving three organizations: The Army that “owned” the boats, the Navy who provided one or more constructors to supervise construction, and Samuel (?) Pook who designed and built them. As the need to secure the river’s was urgent I don’t believe that anyone waited for generation and approval of formal specifications and these backwoods boatyards were used to building river boats with minimal paperwork.

From the photos that you posted these appear to be typical US Navy small boats and could have been requisitioned from East Coast Naval Shipyards, assuming that rail connections were available to the Ohio or Mississippi rivers. They could also have been built onsite from drawings provided by the supervising Naval Officer. Drawings for typical Civil era boats are published in Chapelle’s American Sailing Navy Book.

Antebellum US Navy specifications specify that boats’ interiors be painted in either Straw or Lead colors. Instructions for mixing these colors can be found on websites dealing with antique paint colors.

Roger

-

I never thought that I would see a crescent wrench used to build a model ship!

Nice work!

-

Scratch building model ships requires ingenious use of the materials at hand. It’s the results that count, and no one can argue with the quality of the model in your photo.

I think that we’re trying to say that by using balsa you’re making life hard for yourself. As a very soft porous wood, it is hard to hold crisp clean edges, it dents easily and is difficult to finish. It is commonly used to build model aircraft because it is light, a property unimportant to ship modelers.

I’ve never been to Greece but I believe that it has a robust wooden boat building industry. See if you can track down one of the penetrating epoxies that I mentioned above.

Roger

- mtaylor, thibaultron and mikegr

-

3

3

-

It’s impossible to answer your question without a photo of the boat that you’re trying to restore. There are just too many variables. For example, a 1920’s vintage boat could be either gaff rigged (square sails) or Marconi rigged (triangular sails). Each has different rigging. Pond yachts could be either free sailing or self steering.

There are some web sites that deal specifically with pond yachts. You might find photos there to compare with the boat that you are working on. Google “Pond Yachts.”

I’m sure that if you send us a photo It will generate plenty of replies.

Roger

- Ryland Craze, Keith Black, Dobro23 and 1 other

-

4

4

-

If you are building modern steel hulled ships, this means that you’re going to be painting the wood so appearance is not a factor. Thin craft grade plywood is readily available here in the US. It comes in fractional inch thicknesses down to 1/64in which I believe is less than .5 mm. A higher grade material in the same thickness range is also sold for model aircraft use. It should be available in Europe and will work for structural applications.

- thibaultron, mtaylor and mikegr

-

3

3

-

Ras,

Small hole saws for cutting holes in wood can be easily made from K&S brass tubing sold in better stocked hardware stores and on line. The saw is made by filing teeth into the open end of the tube. Accuracy can be improved by epoxying a wood dowel in the tube upstream of the teeth. A much smaller pilot drill can then be epoxied into the center of the dowel.

Roger

-

The answer to your specific question might be a product called “git rot,” sold here in the US by marine supply houses to salvage rotted wood (it would be easier to answer questions if you guys would give us a rough location of where you live.). This is a very thin epoxy resin intended to penetrate the wood. In the last few years there has been an explosion of other specialized epoxy resins intended to solve various problems, and you might find something that meets your needs, sold by companies like WestSystem and System 3. Intended for use by wooden boat builders and repairers, they can be expensive for modeling applications.

I second, Jaager’s suggestion to solve your problem by substituting a different species of wood, IMHO, in the rush to build a model from what is considered to be “museum quality lumber, ordinary construction grade pine, not spruce or fir, is overlooked by many modelers. If you sort through wood at your local lumberyard or big box home improvement store you will find a nice piece of pine for a fraction of what it will cost you to salvage the balsa. Since most of our applications require small pieces, we can generally work around knots and checks. This means that less select grades can work fine for us.

Roger

- mikegr, mtaylor, thibaultron and 1 other

-

4

4

-

-

Wefalk,

I like your grooved board idea. This could be used in conjunction with my Sherline lathe to taper a stack of telescoped tubing. The two masts for my lake freighter Model will be thin in relation to their length. The trick is to avoid whipping of the stick while getting a smooth taper.

This problem is is at least a year away so I still have plenty of time to mull it over in my head.

Roger

-

This looks like a huge job! Well done.

- mtaylor and FriedClams

-

2

2

-

Gary,

These tiny LED lights open all sorts of new modeling possibilities. Having been disappointed by all of the Out Of Order signs on mechanized exhibits in museums, however, I am concerned about longevity. I would assume that these are battery operated, and I know that LEDs are very efficient.

What kind of batteries are you using and what do you expect their lifetime to be?

Roger

-

I have thought about this since the model that I am building has steel masts, and for some reason modeling a metal object from metal always looks better.

My idea would be to stack telescoping sizes of brass tubing soft soldered together, and then taper them. I am not nearly to the point where I need to try this.

1:700 scale? That’s a whole different world!

Roger

-

-

I continue to make progress on the Benjamin Noble. I am currently working on the poop deck, a silly term, but that’s what it’s called on the drawings. With its open curved bulwark, I have not been looking forward to tackling it. I will post pictures soon.

Since he has not posted a build log, I will wander a bit from my topic to comment on Feathermerchant’ s build of Margaret Oilwill, another Lake vessel.

In the late 1800’s, there were three painters who have left us with visual records of Great Lakes vessels; Vincent Nickerson, Howard Sprague, and Asa Whipple. As each specialized in selling paintings to the vessels owners, their work is considered to be accurate. There are a number of paintings here in Duluth by Howard Sprague, as he was commissioned by the American Steel Barge Company to paint pictures of their whaleback ships. Two of his pictures hang in Duluth’s historic Kitchi Gammi Club, a great place to hold a future NRG Conference 😏.

My painting of Western Reserve was painted by Vincent Nickerson in 1890, and sometimes when I have nothing better to do, I surf the web in search of other Nickerson paintings. The other day, I found a painting by Nickerson, of Margaret Oilwill, Feathermerchant’s subject that had recently been sold by a Cleveland, Ohio art dealer. I found it by googling Vincent D. Nickerson. Not exactly a Van De Velde, but an exciting find neverless.

Roger

- mtaylor, KeithAug, Keith Black and 4 others

-

7

7

-

Claire,

Very nice work, and an interesting subject.

What wood are your models made from? It certainly results in a crisp, clean appearance.

Roger

-

While I don’t doubt that the Archimedes drills are not intended for use with standard twist drills for the reasons given by Wefalk, I have not had a problem using small wire sized twist drills in mine to drill hard woods like pear and box. I have also used it to drill holes in brass. In all cases, holes drilled have been thin materials where the drill bit does not bind.

Roger

-

I was given this kit as a Christmas present in 1964. It is the 1 :144 version. It is the only kit that I ever built. Although fine details do not stand up to close scrutiny, it looks great in its case sitting on top of my bookcase.

William H. Webb’s folio of plains, published in their entirety in a 1990

issue of the Nautical Research Journal includes a detailed drawing of a nearly identical vessel named America, sold to the Russians. It could be used to add detail to this nice kit.

Roger

Florida Sharpie Fore Stay Sail Rigging

in Masting, rigging and sails

Posted · Edited by Roger Pellett

Joe,

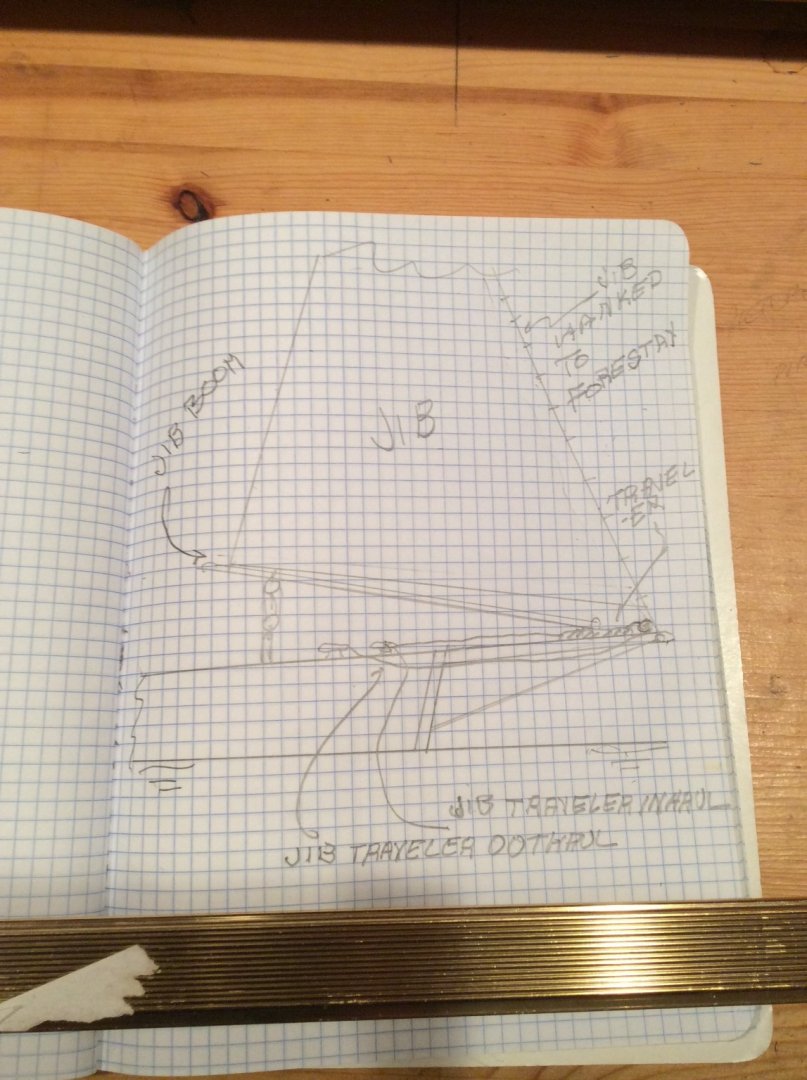

My very crude sketch below is based on a design from Reuel Parker’s The Sharpie Book. It fits the lines, blocks and attachment points on your model. I believe that the line attached to the haulyard is actually the traveler outhaul. While I show the jib hanked to the forestay, there are also some photos that jibs could be set flying.

Roger