Roger Pellett

-

Posts

4,519 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Roger Pellett

-

-

-

The ultimate wood for the fine detail work that you anticipate doing is Boxwood. You live near a wonderful source of this for most of us ultra rare wood- the formal gardens of large country homes. Sadly, many of these shrubs are dying from an invasive blight. If you can connect with the gardeners that maintain these estates you should be able to get some of this wood that would otherwise be burned. You would then need a small bandsaw to break it down into billets suitable for your Byrnes saw.

Roger

-

Hi Dave,

It sands and paints well and doesn’t interact with paint, acrylic or otherwise. It’s an odorless powder and mixes with water. I just put some in a small container and add water. The amount of water added does not seem to affect its curing. If it’s too runny, I just add a little more powder.

Roger

-

Once you learn to use it, the table saw can be very versatile. Different thickness blades can be used to make different width grooves, and the saw’s blade height adjustment allows different depths. If you buy one of Jim’s saws he also sells adaptors so that you can use blades with different diameter arbor holes. Figure our where you are going to buy your blades, see what diameter arbor holes they offer and then order the necessary adaptors with your saw.

Roger

- thibaultron, Canute, mtaylor and 1 other

-

4

4

-

I grew up building balsa tissue model airplanes. 10 years before I was born my father and mother started the “Viking Aircraft Company” to produce and sell model aircraft kits to supplement my father’s income during the depression. This short lived Company was closed down by their landlord who objected to balsa dust and acetone fumes. My mother saved advertising and price lists but unfortunately no kits.

Building these stick and tissue models many years later my father taught me to first fly them as a glider to get them balanced correctly; they were always tail heavy. If they would glide, the rubber band power would be sufficient for them to fly. If the model was to fly, we often used clear dope to finish it as it was lighter in weight than pigmented colors.

Roger

- mtaylor, pjofc4, Old Collingwood and 5 others

-

8

8

-

To make the items listed above, either a model maker’s table saw or a milling machine can be rigged up to produce them. Looking forward to more projects, I would choose the table saw. The Byrnes saw (Byrnes Model Machines) is considered to be the gold standard.

- thibaultron, Slowhand, Keithbrad80 and 3 others

-

6

6

-

-

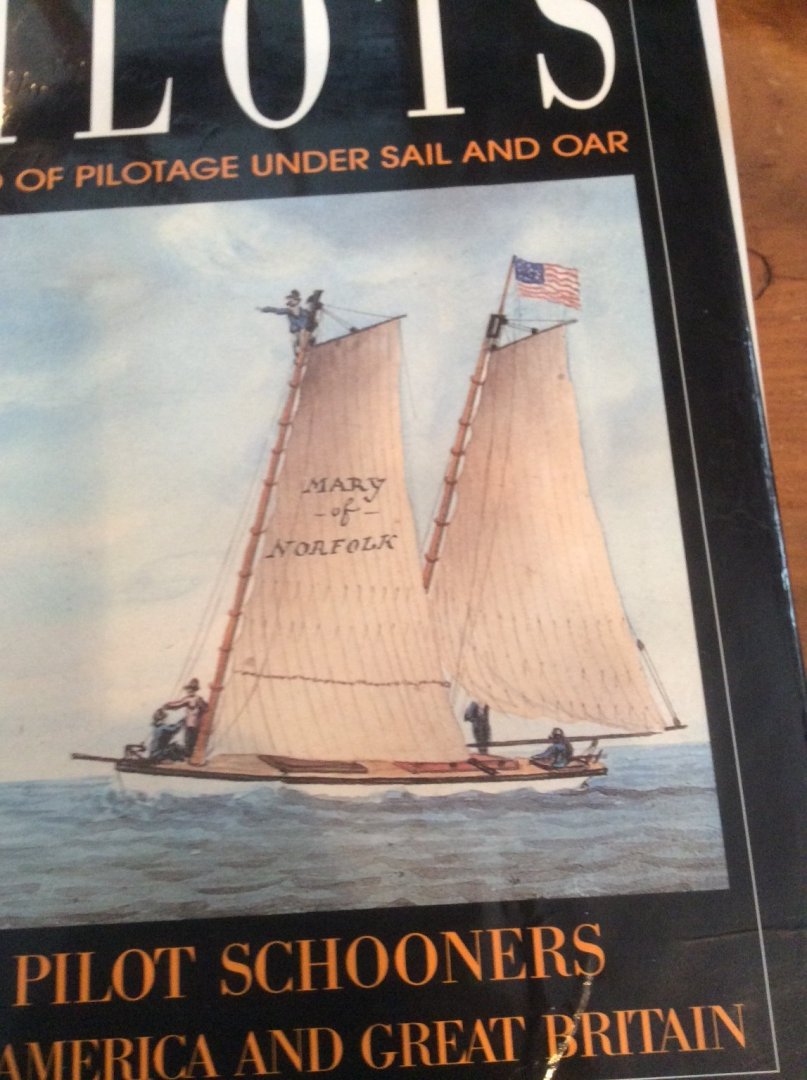

In 1794 Royal Navy Officer George Tobin painted a number of real life pictures of Virginia Pilot Boats operating off the Virginia Capes, the entrance to Chesapeake Bay. These boats not only didn’t have ratlines, they didn’t have shrouds or stays. Neverless at least one of his pictures includes a lookout at the masthead looking for an arriving ship to pilot. Maybe he used the mast hoops as ladder rungs?

- Larry Cowden and mtaylor

-

2

2

-

If the kit manufacturer spent even a slight bit of time doing research before they offered the kit for sale, they would have realized that the “restored” vessel in Baltimore Harbor was an historic fraud. Noted American maritime historian and naval architect Howard I. Chapelle had been writing about the impossibility of the ship in Baltimore Harbor being the same vessel as the frigate launched in 1797 since 1946. His books discussing this have been readily available. Finally, the US Navy published “Fouled Anchors” and convinced the Baltimore City father’s to restore her back to her 1953 appearance.

Roger

- Canute, thibaultron, Antti and 1 other

-

4

4

-

Sailing rig nomenclature is regionally dependent. Names, like the rigs that they referred to were invented by those who used them, without reference to a nautical dictionary. For example, can anyone explain what a “square rigged bugeye” is; or a “three sail bateau”?

The term “Tall Ship” that I agree is meaningless was taken from John Masefield’s poem: “I must go down to the sea again, to the lonely sea and the sky, and all I ask is a tall ship and a star to steer her by.”

-

Nice work Steven. I think that you have copied her look nicely. The Mary Rose and the 120 years later (give or take) Red Bay Galleon are really still the lower “boat shaped hull” with separate fore and after castles built atop. Your model clearly shows this.

BTW: I wish that I had your model building skills when I was at the age that you were when you started this. Your model started so many years ago was clearly worth restoring and completing.

Roger

- mtaylor, Tony Hunt, Old Collingwood and 3 others

-

6

6

-

-

I have a pair of ear muff hearing protectors that I bought many years ago for target shooting. These do a great job of blocking out sound, even that from a full sized table saw or a noisy air compressor. While not a solution for apartment dwellers, they in my opinion solve the problem in my basement workshop.

- Canute, thibaultron and mtaylor

-

3

3

-

My Byrnes saw was purchased prior to the “high fence” option. Before beginning a new project, I would like to add the higher fence.

I notice that Jim’s site includes an option for a extended fence. Can this be purchased separately and be added by the user or does the saw have to be sent back to Jim.

I am naturally concerned about correct alignment.

Roger

- mtaylor, thibaultron and Canute

-

3

3

-

Wise guy? No! Not at all. Your construction of this beautiful model is evidence of your research. Thanks for sharing it with us.

Roger

-

A wonderful model! You have nicely captured what I think that one of these ancient vessels should look like- Light and Graceful.

Roger

-

-

Anyone know what happened to the guy aboard South Dakota with the 3/4in bolt?

-

Thanks Keith, it looks like a separate distilling plant was state of the art in the mid 1860’s. Good research!

- mtaylor, Keith Black and FriedClams

-

1

1

-

2

2

-

-

I certainly cannot argue about buying high quality tools but I also remember trying to outfit a shop as a newlywed on a beginning engineering salary. In that case, it was either do without or buy what I could afford. Some, but not all of which I have later replaced.

As a 45 year NRG member I fully support and have contributed to the organization’s research mission through articles, book reviews, and letters that I have published in the Journal over the years. I believe that support of this mission includes encouraging others to move beyond building tried and true HMS Victory or USS Constitution models by tackling more adventurous projects.

If we promote the message that the only way to move beyond a kit subject is to set up a shop full of top of the line tools the barrier for expanding horizons will be too high for many aspiring modelers. While a name brand swiveling base/ rotating head vice may be nice to have, a Harbor Freight model serves the same purpose. With dimishing supplies of cut-to-size specialtized lumber, milling our own will become the norm. A high quality 14in bandsaw sells for about $1500 plus freight, specialized blades, etc; more than many may be willing to pay.

Harold Hahn built his remarkable models with an 8in table saw and Sears hollow ground veneer blades. While not ideal, tools like this can still produce outstanding models.

Roger

-

-

Did these ships have separate fresh water distillers? Reciprocating steam engine cylinders were lubricated by spraying liquid tallow into the steam. After passing through the cylinders and condensing the condensate was filtered in an attempt to remove the tallow. Even so, it would seem that this “fresh water” would be nasty stuff to drink.

At least this is how the steam cycle worked on Great Lakes vessels. I don’t know the details for these ships.

- Keith Black and mtaylor

-

2

2

-

I prefer the yellow paint job to the red and white shown on the box art. It looks more businesslike.

- popeye the sailor, mtaylor, Canute and 3 others

-

6

6

Improving a Homemade Thickness Sander

in Modeling tools and Workshop Equipment

Posted

Having finished up a number of non ship model projects I’m ready to get to work in the new year. I have two boxwood planks that are begging to be used while I still have my wits about me, so I decided to build a “natural finish” model featuring this beautiful wood. Before starting I decided to overhaul my Byrnes Saw and get a better thickness sander than my homemade one.

Before writing an order for a new sander I took a second look at my old one.

The more that I looked at it, the less inclined that I was to replace it.

It’s a heavy duty floor mounted machine. The need to glue the sanding medium on is a pain but cloth backed belt sander belts last a long time. I also like the 12in did sanding disc mounted on the left side. The main thing that I don’t like is the gymnastics involved with having to get around the back of the machine to pull work out while not letting go altogether and launching a missile. While the Byrnes sander looks like an excellent machine, I decided that before buying one I would try to add a feeding mechanism to my homemade sander. This would let me feed material in from the front without the need to pull it out of the back. I also enjoy the satisfaction of using tools that I have built myself.

I have a simple crank operated feeding mechanism roughed out in my mind and intend to post progress as I go forward.

Roger