-

Posts

797 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Seventynet

-

Thank you for the kind words and looking in Shihawk, Don and Greg and for the likes ianmajor, Mort, Hexnut and others. It makes me feel like I have high expectations to fulfill as I inch along at a snails pace. Best, Ian

- 191 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Mike those bulkhead filler blocks are going to make life easier when you get around to planking. Thanks for sharing. Best, Ian

-

Greetings, again, I really have very little to report since last time except I have applied wipe-on-poly (WOP) to the hull below where the lower wale will be fixed. I just wanted to seal the hull. As I explained to Don I had a challenge with residual PVA. I thought I had scraped/sanded the hull down to bare wood everywhere but the WOP revealed its presence. Although I simply had to scrape/sand off the poly to get at it, it did result in several re-applications. Not much of an issue really. Put it down to inexperience and declining eyesight. My pictures now suffer from light reflection. No idea how to fix this. Best, Ian

- 191 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Sorry Chris, that's way out of my knowledge base. However I wonder if it would be logical to assume that the maximum width of the real stock would be controlled by the length of the plank. IOW if the curve for a 20 foot plank required a plank wider than they possessed, the plank length would be limited to something less than that. Maybe a serious spile would be addressed by a less wide 10 foot plank. Does that make sense?

-

Hi Chris, I think the only thing that will tell you how wide the plank needs to be is the curve itself and the length of the plank - revealed through the many techniques used to define the spile. I use transparent tape. Anyway, the wood I used (mansonia aka African walnut) became more conducive to edge bending through two approaches - tapering (and there's where you can do a semi-spile by cutting/sanding part of the curve into the plank you are tapering) - and steaming/soaking the plank, then prebending and clamping it into the actual bend (let it dry, refine the fit and then glue in place). I do not think you risk a plank popping later on if you follow that method. However, there is a limit to how far you can edge bend and the wood will tell you that (it will fold in on itself). Again, IMHO, spiling is the preferred way if you can get the stock. Best, Ian

-

At the risk of stating the obvious, a drop plank is used to reduce the number of planks running forward (e.g., at the bow). In other words if the tapering is making the plank too thin (like Mark says, less than 1/2 the plank width), you may need to reduce the number of planks by dropping one out - a drop plank facilitates that. A stealer is used to fill out a space that cannot otherwise be filled by the normal plank width (e.g., typically at the stern).

-

Since I just finished planking my Victory I will wade in with my 2 cents on spiling. When I second planked the starboard side I spiled about 6 planks at the bow. The planks were very happy and a perfect fit was obtained (IMHO). The trouble was that to effectively spile I had to start with a wider piece of wood than the kit supplied. In my case I used some wider planks that didn't quite match the rest of the planks. So on the port side I edge bent the supplied planks. More effort, more strain, but with steaming and prefitting it ended up looking just as good (I show some examples on my log). The edge bending was also facilitated by spiling standard planks to the extent the existing width would allow - not insignificant at the bow where you are typically tapering to a narrower width anyway. Anyway, if I was to do it again I would have ensured I had wider planks of the same stock to begin with. Even though the end result was the same I enjoyed spiling and it is the correct way to do it. Best, Ian

-

Ok, thanks for your patient explanation Heinz. I was overthinking things. Best, Ian

- 191 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi Robert, I just discovered your Bluenose build. Gorgeous! Fabulous workmanship. Ian

- 66 replies

-

- bluenose ii

- artesania latina

-

(and 1 more)

Tagged with:

-

Thanks a lot Heinz. I guess I am mathematically challenged. Your stated dimensions of 1000 mm x 16 mm x 2 mm - are referring to the stock with which you cut the individual planks right? If I work with the dimensions provided by Longridge: 5/16 in. is converted to 7.94 mm and 5 in. is converted to 127 mm. I think you have written that in your notations as well. It seems to me that I should then take the ratio of these two measurements (I guess that doesn't require a conversion does it) and multiply that by my desired plank length to get the widest dimension. So if I take the ratio of 7.94 to 127 (0.0625) and multiply it by 85 mm (this would be 20 feet at our Victory scale) I would get 5.3 mm for the widest height (and 2.7 mm for the narrowest height using the same approach). Does this sound right? It doesn't seem wide enough to me. Is it reasonable to assume the anchor stock length should be the same as the normal planking length? In any case thanks for the advice on individual plank treatment - I was suspecting that would be the case and it is good to hear you confirm it. Best, Ian

- 191 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

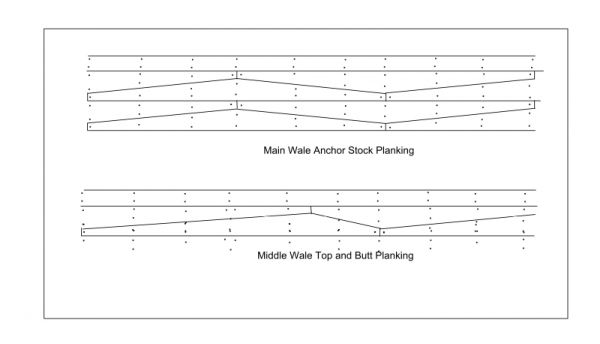

Hi Heinz, Thank you again for following my build and encouraging me. While I have you I thought I'd ask a question. I plan to use what the literature calls "anchor stock planking" for the main and middle wales. I notice you followed this approach as well. I have been looking for dimensions of these planks and found a picture that Ed Tosti provided in his excellent Victory scratch build in the "modelshipbuilder" forum (hopefully this link will work: here). I reproduce his picture below hoping I am not in contravention of posting laws (if so anyone let me know and I'll remove it): Can you suggest to me the dimensions you used and the technique you used to cut them? I was otherwise going to use the Byrnes saw with the taper jig. Thanks, Ian

- 191 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks Michael and I look forward to meeting you and Rob as well. It will be good to hear what's happening in your neck of the woods. I remember buying a second hand laser back in '79 when I first moved to Edmonton and putting it in Lake Wabumun. Best, Ian

- 191 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks for your kind if not exaggerated words Arthur, Alan, and Don and others for pushing the like button. I would be lying if I did not admit how much I appreciate the encouragement! Best, Ian

- 191 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Good day, Well I've finally finished second planking on both sides below the wales anyway. I'll get the hull ready for the wipe-on-poly tomorrow except where I'll be fitting the wales. I can say without any reservations that I am ready to move on .

- 191 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Looking really good Robert. I highly recommend filler blocks at the bow and stern. I wouldn't use balsa though - too much bending torque from the planks and it won't hold pins well in those areas. Best, Ian

- 527 replies

-

- caldercraft

- victory

-

(and 1 more)

Tagged with:

-

Well done Marcus, it's looking nice. Ian

- 165 replies

-

- cape cod catboat

- Finished

-

(and 1 more)

Tagged with:

-

Love everything you've done on this ship Boyd. I have learned and copied much from your build and will continue to. I personally like the way you've gone with the masts and rigging and may yet go that way myself. Keep up the splendid work. Best, Ian

- 413 replies

-

Hello Robert. Another Victory build, yay! It looks like you are doing a very careful job. You will not regret it. I think the lighting on the Vic is very cool and would suggest that you'll get all the help you need from Rob (robipod). There's also lots of other Victory builders ready to help on this incredible site. Anyway if there's anything I can help you with planking wise don't hesitate to call on me. Similarly, I may just be asking you for help soon at the pace I'm going! Best, Ian

- 527 replies

-

- caldercraft

- victory

-

(and 1 more)

Tagged with:

-

Thanks a lot for the encouragement Rob. No I'm not in the wood business but I'm not a stranger to basic woodworking either. My dear old father taught me many things about woodworking and small dinghy making when I was a kid that stuck fast. But really I just take the time to read, figure things out and copy what people like you have done. I am blown away by the innovative work you have done on your Vic. Best, Ian

- 191 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks so much Corey. I am obviously a glutton for punishment. I never really thought too much about how much work this would be. But I find immense pleasure working away on the Vic while listening to tunes and checking out the amazing builds on this site. Best, Ian

- 191 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi Corey, You are doing a fine job. Just take the time you need to figure things out and it will pay off (says a fellow first time builder ). I was admiring the rabbit in your stem. Nice work. That's a good solution for a movable lamp post. Those things take a lot of torque and this looks like the ticket. Happy New Year! Ian

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.