-

Posts

9,724 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

New 1:48 scale POF kit of the Cutter Alert from Trident Models in China

Chuck replied to MSW's topic in Wood ship model kits

They dont have a website to my knowledge and usually sell through EBAY and Amazon.....as well as some other similar sites. They dont have any available at the moment but should have some soon. -

Justin.....I am actually cutting more Medway longboat kits this week. I am already about half way done with another six kits. So sooner than later..... Chuck

- 66 replies

-

- Finished

- Model Shipways

-

(and 1 more)

Tagged with:

-

It looks really great actually. I wouldnt worry about the lower counter. That looks really good. The curve of the upper counter can be adjusted visually by slightly tweaking your molding so the upper counter is consistent in width and the curve on top and bottom is the same.....or at least closer to being the same. So dont worry about that too much. You need to buy chapter 3 of the project in Cherry? Of that is all you need to buy at the moment I may use you as a test to see how the international mail is running. If you want to give it a go....send me a PM so we can discuss the details.. Chuck

-

Looking good so far!!!! Take your time with those qgalleries. They are tricky buggers.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

really nice work.....I am glad you enjoyed the project. You did an exceptional job on it!!!

- 46 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

ancre Coureur by cafmodel - 1/48

Chuck replied to cafmodel's topic in - Build logs for subjects built 1751 - 1800

Beautiful work Tom!!! -

Posting kit instructions?

Chuck replied to Gaffrig's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

I just looked and the other ship in bottle instructions are there but unfortunately not for this particular kit. So yes by PM only please. -

Posting kit instructions?

Chuck replied to Gaffrig's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

No I dont think so.....Amati is still around. I am sure they have it on their website. Chuck -

Looks great Mike. That is coming along wonderfully.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Very well done. Keep using the better camera!!!

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

Well done. But just as an FYI, that molding across the transom, it really shouldnt be there. That was never a detail on these small boats. In fact.....take a look, the rudder cant actually move now. And internally strapped blocks....probably not used. Just a stropped block with a thimble. But you did a fine jon making them. Chuck

- 87 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

-

ancre Coureur by cafmodel - 1/48

Chuck replied to cafmodel's topic in - Build logs for subjects built 1751 - 1800

Tom that is looking really good. Nice touch on the triangular eyebolts. -

I am sure you can make another. Rich that looks pretty darn good. Those came out great. I know how tiny they are and that makes it even more impressive.

- 109 replies

-

- model shipways

- kate cory

-

(and 1 more)

Tagged with:

-

Its always open.......still time to jump in.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

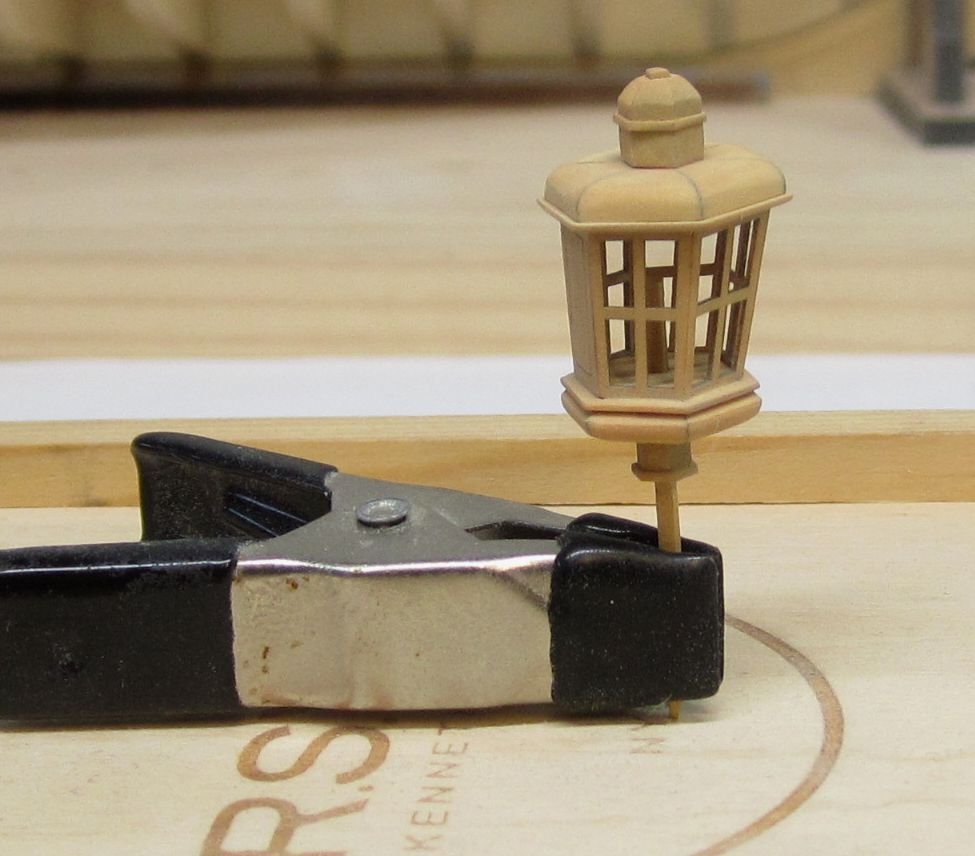

Capstan experiment one. I got bored and burnt out making inventory items. So I decided to test out my parts for making the lower capstan. I have had the parts laser cut for a while. I didnt take any construction photos as this was just a test but keep in mind this is way before we will actually need it. I am always just a little ahead with the design stuff. So I will make another and document each step. I want to make the center spindle a bit heavier that goes between decks above the capstan drum. So I will tweak that before I make a new one. But what I wanted to show you guys is how I did it. I tried a new design for fitting the chocks into the whelps. Below you can see my very first proof of concept testing to see if I could laser etch notches on both sides of the whelps. It worked beautifully. So all you need to do is slide the chocks in after test their fit. This was a challenge even at this scale because these parts are still pretty tiny. The other parts including the capstan drum are all built as usual in layers on a 1/16" x 1/16" stick to register them. Very similar to the way I designed the stern lantern mini-kit for the winnie. This was a fun mini kit to build and will look great painted or left natural. I will detail its construction in Chapter 5.....sorry to jump the gun. I couldnt help myself. These will be made available as stand alone mini kits in 1/4" scale and 3/16" scale as well.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.