-

Posts

9,693 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

For those reference lines for the port framing and wales....just use a sharp xacto blade and score the lines through the paper sheet with a straight edge and into the wood. Its permanent that way. If they dont show up enough after for you to see them.....use some poly over the cut line and they will be. Dont be afraid to make these cuts real cuts....no reason to be delicate with them. Its actually more precise and thinner than a typical pencil line.

-

Nicely done. Just remember to go slow and have fun.

- 217 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

No need. I already waxed your rope. Its good to go right out of the package. You can add more if you want to but I wouldnt recommend it. Chuck

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks great!!!! I have everyone home also.....I hope we dont kill each other. I will just hide in my shop until its over. Chuck

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looks great Mike. Exactly as it should at this stage. Well done...

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Michael...that is looking really fantastic. Nice work. The scary is part is now done with. The remainder of the build is lots of fun. I hope you enjoy it!!

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You are very welcome Glenn. Enjoy the project. Its a real fun model to build. I am looking forward to seeing your progress. I cant believe how quickly you got those packages. Chuck

-

Dont worry about the bollards. Just cut the planking around it. Remember...the bollard timbers will be painted black anyway.... Any of the bollard timber that may show will be unseen deep within the head timbers. Just leave it as is. With the planking...small gaps and or small changes in beveling will give you that tiny difference. It is also not wort over thinking and worrying about. If you want to cut down a wider piece so it fits and matches the bottom layer that would be fine. I do however think it is a mistake to add the second layer of wales now. You should wait until the planking above and below the wales is completed first. The whole reason for two layers is so you can micro-correct the run of the wales should you need to and this becomes more evident only after having the topsides planked.....and the drop plank in position. In addition, there is a strong possibility that you will chip or dent and damage the edges of your wales while planking everything else. Then you cant really fix that. You can build in any order you like but if you are curious as to why I selected the order and why I use 2 layers.....those are the reasons. Chuck

-

Thank you....yes some of those parts were tricky to mfg. Just be careful because some of them are fragile.

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

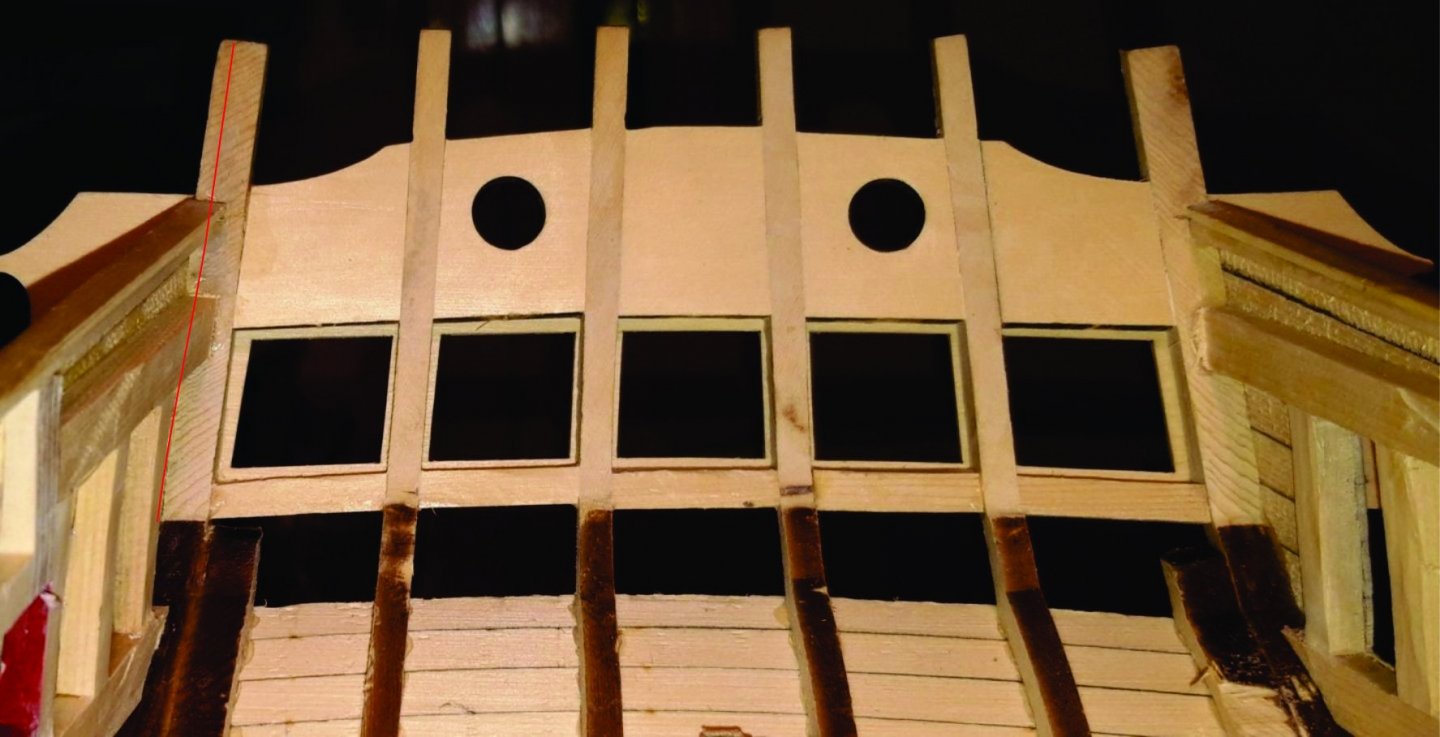

I am sure you can fix that right up. The windows do look good and they fit really well. For everyone else, have a look below. You can tell pretty easily if you havent faired the outside stern frames enough. Notice how the outside stern frames are nearly the same width as the four inside frames when viewing the stern head on. This is important and everyone should correct this if they can before they start chapter 3. Those outside stern frames should be thinned down considerably. Compare these to the width of Matthias' outside sterm frames. I would say probably in the neighborhood of 1/16" too wide....give or take. I have drawn a red line to show you guys. Its also shown on the plans.

-

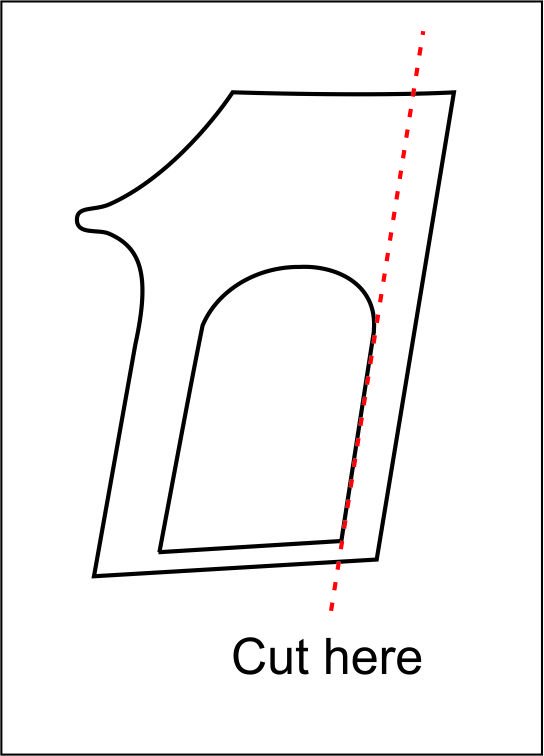

Its not a huge issue but yes it requires a fix. You can simply cut a bit off of your filler like this below. But also carefully slice a bit from your window on the inboard side as well. As long as it looks centered when you view the false window from the other side. But in addition....you might consider chiseling some of that planking away. The filler is 3/32" thick. So draw a line that represents this on your hull and chisel away some of that planking. Maybe another 1/32" or even all of the planking. But remember to glue a filler block on the inboard side of your planking before you start chiseling. You will need a backer there for your planks.....between the stern post and that qgallery door. These are all things to consider. You can do a combination of all three. Its up to you. I hope that helps. Yes most folks underfair the hull back there.

-

Looking great Mike. Yes the friezes for the lower and upper counter are a great way to check the curves. They will also help you get a consistent width for the upper counter. In Mike's photo below....the space between the two friezes is where the 1/8" wide molding will go. So align the upper counter frieze with the bottom of the transom and that should leave 1/8" between the lower counter frieze. Perfect!!!!

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Beautifully clean model. The finishing techniques are superb.

-

Yes but the washer was already on it....but it doesnt have to be. Just use these....after the bit breaks of course. The kind with the 1/8" shanks.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks pretty good to my eye. Well done!!!

- 126 replies

-

- Finished

- confederacy

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.