-

Posts

9,711 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

Thanks Jim....It was a pleasure and loads of fun. I dont know how I missed your post sorry for the delay in responding. I am cutting new barge kits right now.....then longboat masting packages....then a bunch of serving machines and ropewalks.... After those are all done I will start another batch of longboat kits. I just have resock everything else first. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Grant Welcome yo the group......I am so happy you are having fun with the project. Nicely done joints. And yes, Its so important to keep your area clean and your hands too. It keeps the cedar looking vlean and crisp. Enjoy the kit!!

- 109 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Beautifully done. It looks fantastic unrigged. Maybe add a small jolly boat or cutter with the display which would be very interesting on the unrigged version. I do hope you enjoyed building her!!! I thought she was a delight to build.

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

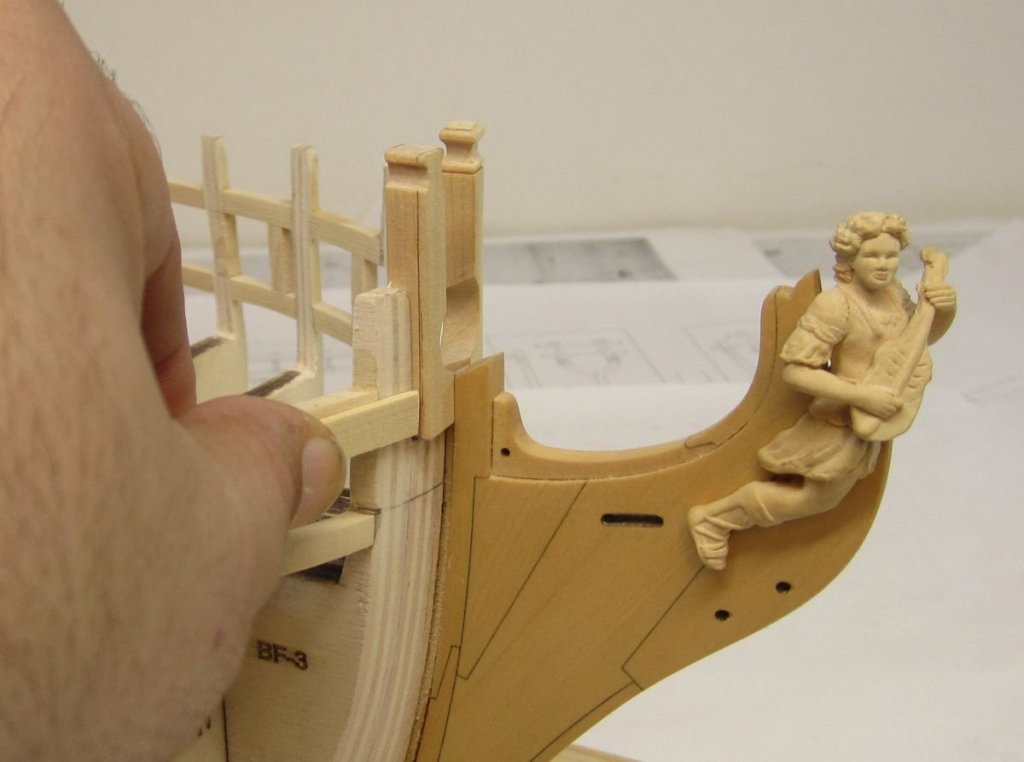

Thanks for saying... For those who asked, here is a non blurry photo of the figurehead. It was getting dirty do to handling with dirty fingers. So I cleaned it up and applied a coat of sanding sealer. It looks really good in person but is surprisingly hard to photograph in focus. The color matches the stem quite well and its still hard to believe this was carved by machine. I didnt use wipe on poly because I dont want it to darken too much. The stem where it sits will be painted black eventually. Compare with the contemporary model. You can see how crude it was carved, I dare say that Jack did an excellent job improving its appearance. Actually the knee is painted blue and black below it. I am not sure if I will do the same. I may just go with black. Note the headrails. They are not carved. Instead there are friezes painted on them. That will be an interesting detail to replicate. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

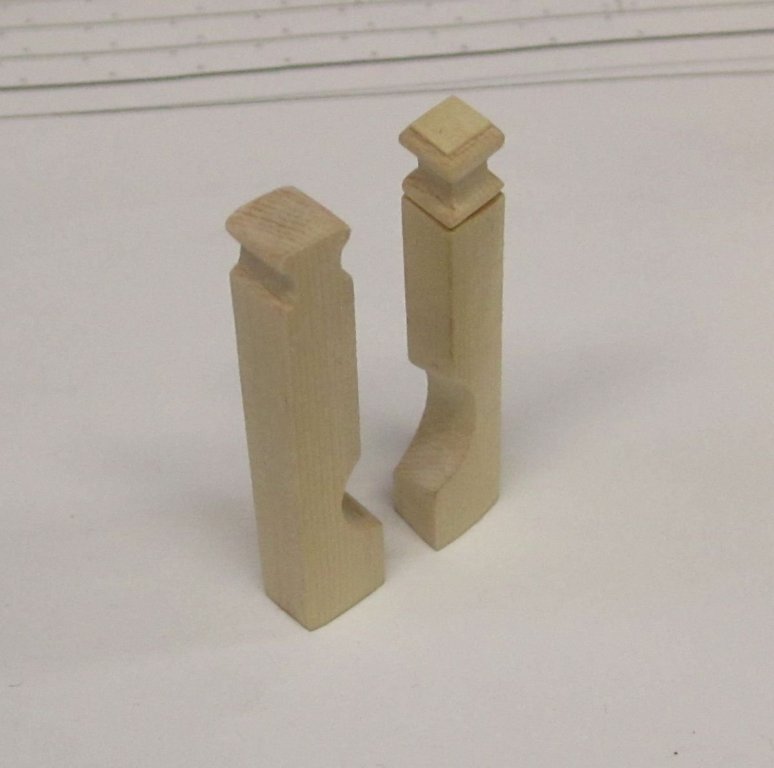

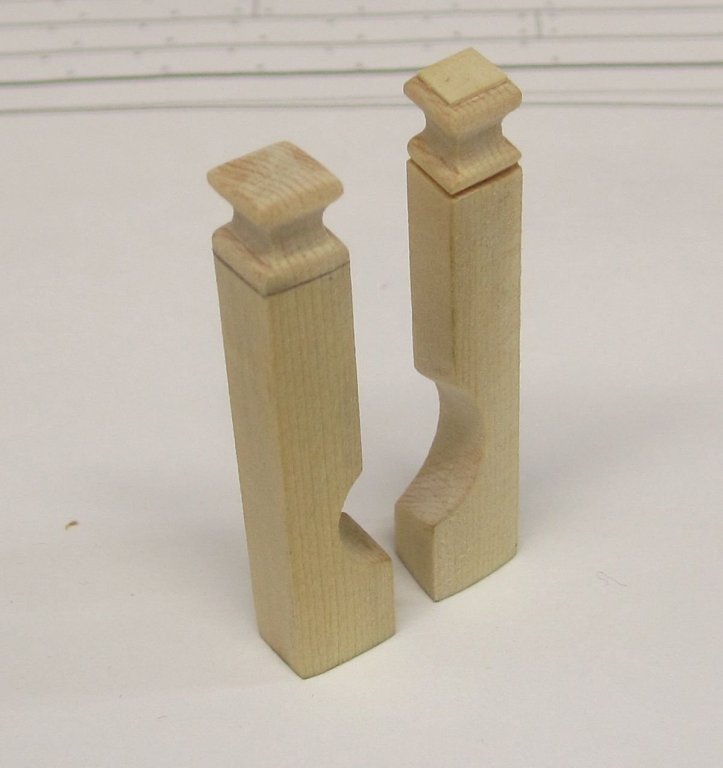

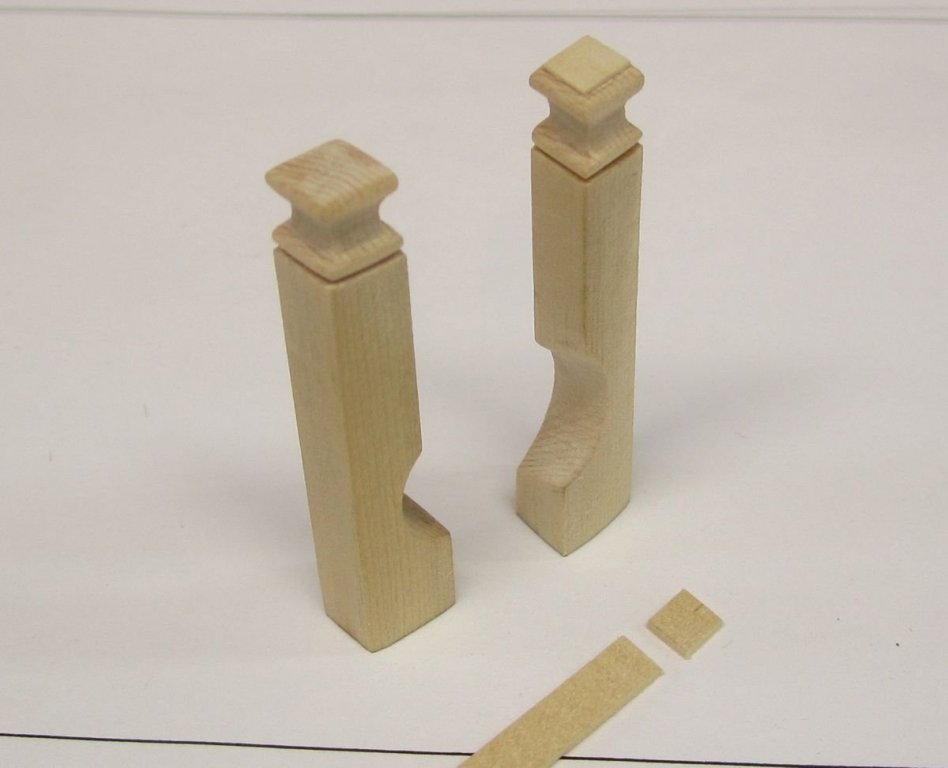

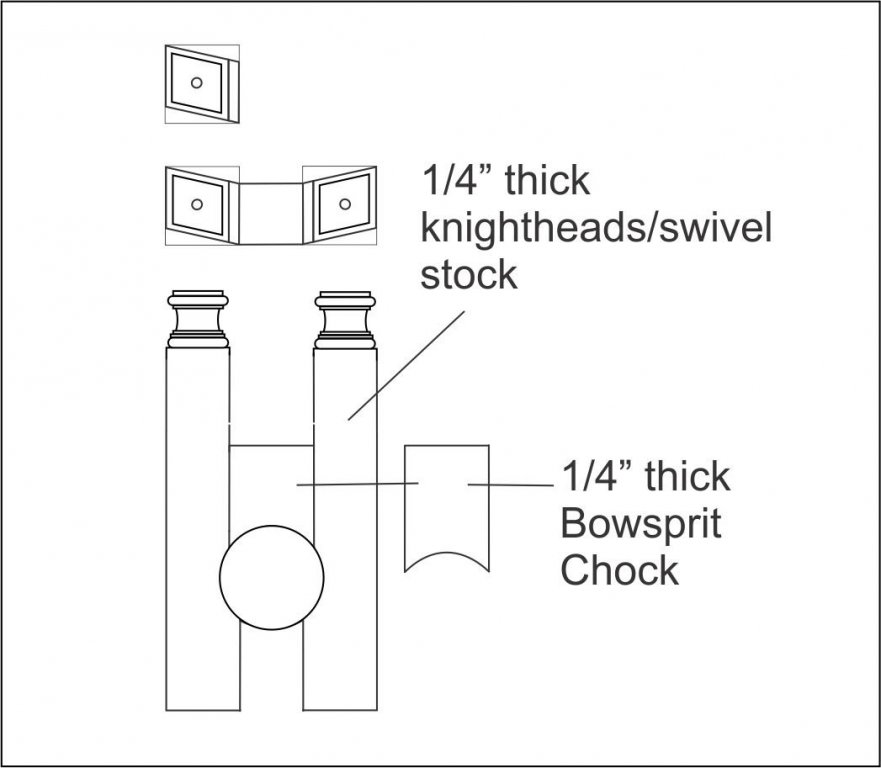

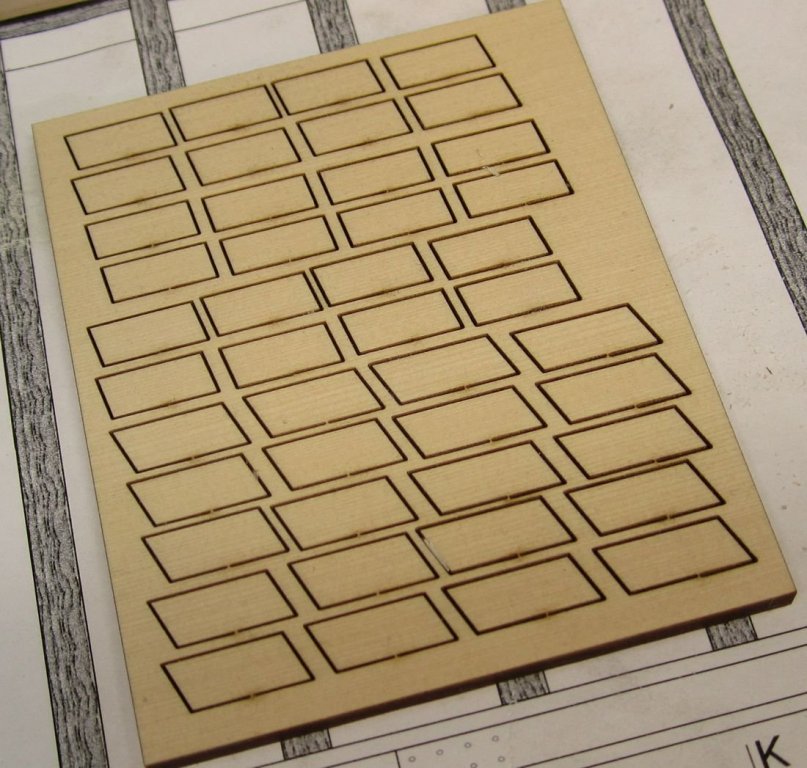

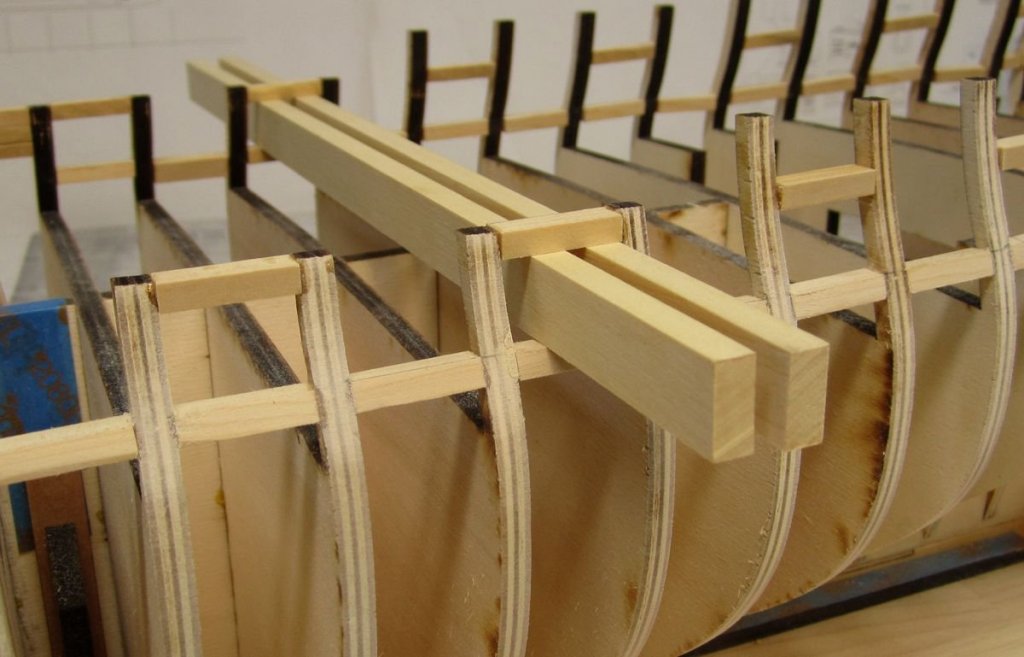

Thank you very much!!! And happy Easter!!! I didnt feel like actually working today so I finished the starter package. The last items to be completed were the bollard timbers. Just like most projects, there is at least one item that will prove very tricky and challenging. The bollard timbers arent too bad though. They are similar in difficulty to making those "bolsters" at the bow of the longboat. Every model has at least one or two complex parts to shape. Its not unusual but most kits usually drop the ball on how these items are presented. I believe its just a matter of breaking the process down into many steps ahead of time so mentally it becomes a lot easier. Each individual step is not very difficult and once completed, you have shaped a very complex piece of modeling. The bollard timbers at the bow are laser cut as blanks. You need to make a pair of these that match as mirror images. In the center, a chock spans the gap between them. Here are the blanks which are 1/4" thick. Before you begin, it is important to fair the inboard side of the hull. The bulwarks and stem need to be reduced to 1/8" thick. You dont have to fair the entire hull inboard....just up towards the bow. Its easier to shape the bollards after fairing and having the bulwarks thinned down. Then place the bollard timber in position so the inside edge sits flush with the rabbet as shown. But make sure you sand all of the laser char off first. This will help keep the piece clean as you shape it. In fact your hands should be washed and super clean once you get the char off. You will be handling these pieces a lot and they will get dirty otherwise. This piece will stand proud of the bulwark framing so that the exterior planking will be level/flush with it. Therefore, you must create a bevel on the front and back sides. Once placed in position, use a 3/64" thick plank that has been beveled (just like you would when planking) and position it along the bollard. Then draw a line down the edge which will determine the bevel needed. This needs to be done inboard as well. Note the bollard timber on the port side is already completed. I will attempt to make a mating pair. There is a very detailed drawing on the plans for these parts. The photo below shows the bevel completed on both sides.....note the finished example which I keep handy so I can make a matching pair. Next, file the round cut-out that forms the top using a round needle file, sandpaper etc. You can use the shape created by the laser on the other two sides to guide you. Then draw a line just below the where you filed. Do this on all four sides. You will be filing a groove all around the piece. I actually used a #11 blade to make a stop-cut on the line. Then I chiseled a bit off towards the line on the top side. I then rounded it off so it looks like the plan. This is what it looks like completed. But you will also notice that I cut a little skewed square from a 1/64" thick strip. Its very thin but still not thin enough. This should be glued on top of the bollard timber to "simulate" a nice carved detail. This detail would be much harder to carve and file into the top so I cheated and glued a separate piece on top. After I glued in position, I sanded it even thinner to about half its original thickness. This is what it looks like....below...but we are not done yet!!! The circular slot for the bowsprit still need to be filed on an angle to match the stem. You can position the bollard on the model and draw a line to follow when you start filing. This is shown below. Once that is completed the bollard timbers are finished. They can be glued on the model and then the cross chock positioned between them. Sand the char off before you do this. You will also need to sand the same angle into the bottom of the chock so the circular opening will accommodate the bowsprit. The photo shows this all done and the chock glued into position. It was sanded flush with the bollard timbers inboard and out. Remember that I am making this model out of Yellow Cedar. You can see how well it holds an edge with these tricky timbers. No finish has been applied yet. But the softness of the cedar made it very enjoyable and easy to sand, file and carve.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Queen Anne Barge by Beckmann - 1/24

Chuck replied to Beckmann's topic in - Kit build logs for subjects built from 1501 - 1750

Just beautiful!!! 😃 -

Thank you very much. It will be a while yet. I dont want to release the starter package until I am well ahead of folks. Not until at least the planking is completed. I did however finalize the starter package parts and I will probably start laser cuttinf them next month. I just want to start stockpiling them for the eventual release. But yes it will be a first come first serve sort of thing.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

At 1/4" scale the hull will be 38" unrigged. Its a big model and you will be able to show some great detail. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

When I get the outboard planking completed I will start selling the starter kits. I want to get ahead of everyone so nobody has to wait for the next installment....I have no idea when I will finish planking but I will start planking the first week of May.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

My head hurts just reading through that stuff. I am probably just going to stick with sanding sealer or wipe on poly!!! 😁

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

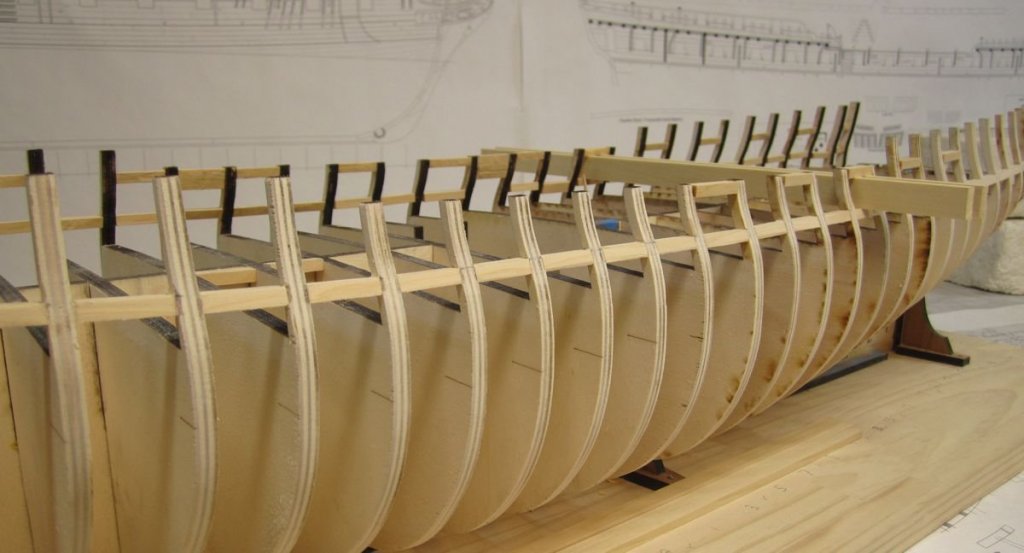

Thank you guys. I finished the quarter gallery framing....I will skip the details on this here. I also added the laser cut hance pieces. Except for the bollard timbers at the bow, all of the framing is completed. The bollard timbers are tricky so I will wait until I get back from the joint clubs show next week to make those. Once they are done it will be time to start planking. Here is what the framing looks like completed....basically this represents all the parts for the starter package including the bollards that I will make next week. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Really looking good!!!

- 103 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Rusty, You might be getting a care package in the mail of sorts for this project very soon. Greg, I would love try a varnish but never did it before. I would need to experiment. I dont even know what a good brand would be for that to start with...but I will see. Work is progressing quickly now. The stern frames were added after I placed the last "bulkhead 29" piece in position. They were glued into the many slots for them which should position them close to the angles we need....but not perfectly. Then I taped some tick strips to the frames using a stern framing guide I developed for the project. They were taped to each frame as shown to locate where the stern lights (windows) would be located. The locations for the top and bottom of the windows was transferred to each frame. I then inserted some stern window guides laser cut to shape between each frame. These are the exact shape and size for the windows. I didnt glue them in at all. They are just pushed between each frame and they stay in position really well. We will be removing them after the sills and framing for the windows is completed. It doesnt matter if you add the top or the bottom framing (sills) first. They were all laser cut but still require some beveling on the sides to conform to the curved shape of the stern. I just used a 3/16 x 1/4" strip to make the lower sills. Its tricky getting the angles correct so I had a few do-overs. But this is a crucial part of the build so I was very careful to get a good fit. They were thicker than what was needed so I could fair them once they were glued in position. The window templates were a godsend!!! If my sills were too wide they spread the frames apart and the template fell out. This is a good indication that you still need to sand them a bit more for a perfect fit. Only when after positioning the sills and they didnt make the window templates fall out did I glue them in permanently. Then I started fairing the fore and aft sides to thin down the transom framing to about 3/32" thick along the top edge of the upper sill pieces. This is the time to do the inboard side because you have good access to it before the quarter gallery framing is added. This is what it looks like after the fairing was completed....I still have to fair the port and starboard sides and bulkhead 29 to conform to the shape of the hull....I will do that later today or tomorrow. Then its time to do the quarter gallery framing.... So close to finishing the skeleton framing now!!!! I left the center window guide in position to show you guys how well they worked. This was a much easier way to align and frame the stern than the previous methods I have used.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Queen Anne Barge by Beckmann - 1/24

Chuck replied to Beckmann's topic in - Kit build logs for subjects built from 1501 - 1750

I have no idea...could be a few things. My guess is the frames were not securely glued into the keel allowing for some movement. Or the base was warped from the beginning and and just not noticeable. There isnt much you can do about it at this point though. I am sure nobody will notice. Impossible to tell in the photos. Chuck -

Queen Anne Barge by Beckmann - 1/24

Chuck replied to Beckmann's topic in - Kit build logs for subjects built from 1501 - 1750

Really fine work. The guilded carvings look fantastic. -

I have been making some steady progress on the framing. I just didnt want to bore you guys with this part of the project. Building the skeleton and framing is not that fun to look at. But here is the quick run down.... The bottom port sills were added first. Even though you really only need them where the gun ports are, I recommend that the bottom sills are placed between every bulkhead. It really makes everything solid. If you cut the sill to the correct length it also squares up teh bulkheads really good. Even the best attempts at squaring them to the false keel doesnt work. You might note that the three sections at the bow for the sills are laser cut. That makes it much easier. You may be tempted to measure the length off your model where the port sill is going to placed. This is the worst thing you can do. It is too easy to push the bulkhead one way or the other which of course forces the other side of the bulkhead in the opposite direction. This will really screw up your gun port placement. You could also measure off the plans....this is better but still not ideal. The best place to check the length between two bulkheads is on your model BUT....up against the false keel. This will give you the best results. If you do this for both sides everything will be really square and symmetrical. See below. Once done this was repeated for the upper sills or lintels. I used a spacer the correct height to place them all easily without measuring. I only did these where the actual ports were and a few other important locations. These are all shown on the plans. Then the port sides are added.....I have laser cut these. There are many shapes and angles to choose from. You still have to bevel the top and bottom where needed because they must be perfectly vertical.....just like the bulkheads. I used a spacer for these too so the ports were all the same width. This is what it looks like with all the port framing finished. Pretty boring stuff. I am about to start on the stern framing. I should be planking before very long. The outside was faired smooth. I wont bother with fairing the inboard side of the bulwarks yet. Its better to wait until after the hull is planked above the wales for that. Although I will probably rough chisel some heavy stuff away a little at time inboard when the mood strikes me.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looking real good so far. Well done. Happy you joined the group.

- 87 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.