-

Posts

5,198 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

I always wonder when I do something that causes me to step backwards to repair something that was damaged by doing something constructive with the wrong bit. Sounds like you have moved on now, I am looking forward to some pictures. Michael

-

Dan the thumb stuff doesn't sound very pleasant. the lion is looking much more interesting, I agree with you about the narrowing of the head, it looks much better, I would be inclined to make it even a smidgen narrower perhaps 16 or 16.5% spitting hairs I know. Ill just quietly go back to my corner now. your carving is better than any I have done. Michael

- 241 replies

-

- queen annes revenge

- pirate

-

(and 2 more)

Tagged with:

-

Hi Popeye, thanks for the commendation on the brass work. regarding the eyelet, I noticed on a lot of the pilot cutters and smacks that they just went through the wood, but knowing the owner and what a finicky task master he is it will likely not be his cup of tea to leave it sort of unfinished. Somehow I think he will have me conjure up something appropriate. Michael

- 2,215 replies

-

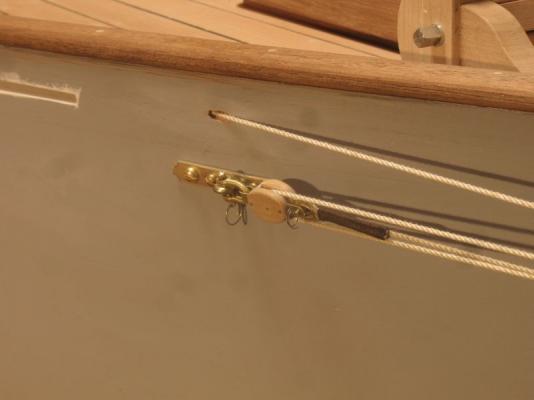

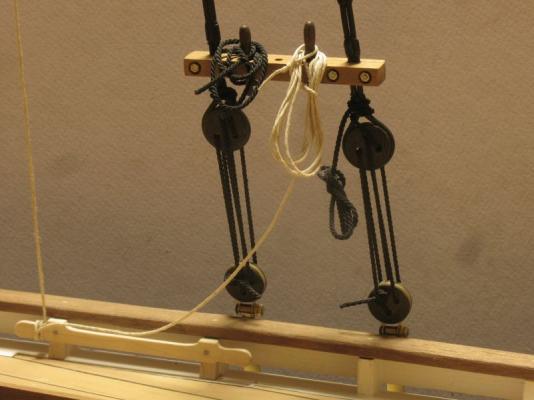

John, if you do eventually get here, there are some great views in the Rockies not too far from here just three hours away. and we do have a spare room. Joe thanks for the kind words. well the bowsprit shrouds were a bit more fiddly than I thought they would be, Had to make a few more thimbles and shackles I decided on the dark rope for the shrouds and a light rope for the tackle. I need to make some cleats now so that I can tie ropes and lines off better, just need to sort out where to put them and what type to make, they will probably be brass. Michael

- 2,215 replies

-

Good to see an update Lextin, she is coming along, michael

- 366 replies

-

Hi Rusty Just checking in for the first time, very nice workmanship That is a large cross section. Michael

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

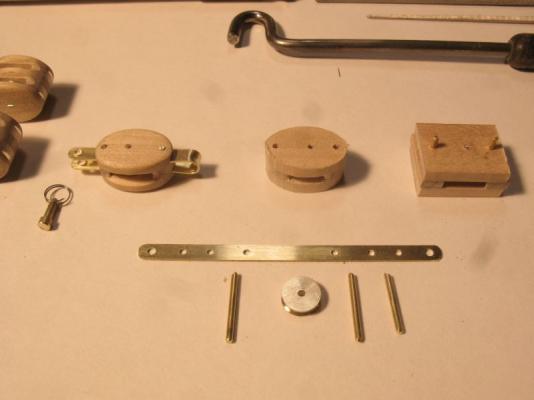

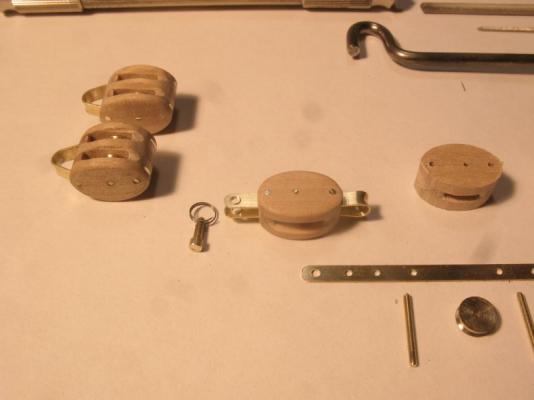

John, Andy, Bob, thanks for checking in. Yesterday afternoon and today I worked on some more rope on the ropewalk. I used some Guttermann 100% Egyptian cotton Ce 50 to make up some more standing rigging parts I used 39 strands to make some 5/8' scale rope and 27strands for some1/2" and also some more blocks for the bowsprit shrouds the rig will use a single block with a becket and a double block on each shroud, tomorrow I will finish the second single block and make the brackets for the hull and drill the holes through the bulwarks. This series of shots shows the parts of the block and the sequence of the gluing and shaping. The brass bars were originally drilled inside all the previous blocks but I have refined the process a little and now am drilling them in a flat jig first The top and bottom pins are .437" apart and the sheave is 1/4 inch diameter the wood is hard maple. I keep thinking about Remco's byline about treating each part as a complete model and it is really helping me with this build. The port side belaying pins Michael

- 2,215 replies

-

Hi John thanks I just have to round off the corners a little more for it to fit back in the bottom of the cockpit. After supper I made a little block that fits to the shrouds to hold some belaying pins, I have seen this arrangement on a number of the pilot cutters and Smacks seems like a good way to deal with lighter lines like flag pennants and getting rope off the deck. The wood is mahogany and the plank was split and bolted back together then the shroud holes were drilled at a slight angle right at the split line and the three holes for the pins were drilled in the wider section. the bolts are 2x56 cap screws I made the nuts. This is so much fun I am really enjoying myself. Michael

- 2,215 replies

-

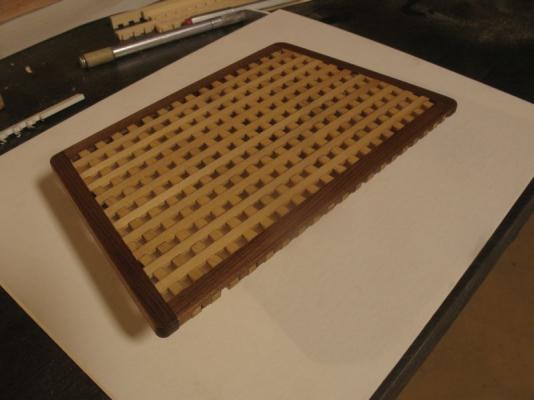

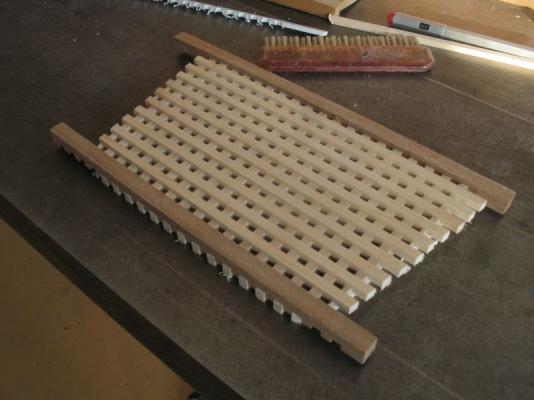

John, Jay, Carlos, and Bob thanks for you continued support it means a lot. Popeye the snow is likely going to stick around the temp is dropping to -16c tonight. Today I worked on the grating and chose some dark coloured Cedar for the frame. Using the same mill to also create the correct spacing for the short slats. reassembled with the correct spacing in both directions now. The top surface sanded down with some 220 then 600 oiled with some teak oil. Michael

- 2,215 replies

-

Thanks John I must admit I am leaning that way myself, all I need to decide is just what profile to make it, I think that it should be of a slightly larger section than the 1 1/4 stock. Michael

- 2,215 replies

-

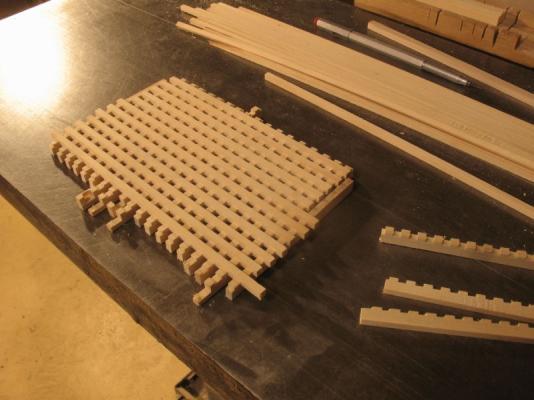

John I'm retired This evening after supper I finished off the rough fitting of the grating in the bottom of the cockpit. it still needs the edge wood and I'm not sure yet whether to use a contrasting wood or to go with some more of the Yellow Cedar that the grating is made of. I cut a slab of 3/4 x 3 1/2" yellow cedar from a 4x4 of it that i have had for a while now. Then stripped it up into some scale 1 1/4 inch thick boards and made a couple of passes to create the square stock and the wider stock was milled with a "19 modified twist drill into an end mill The drill is .166" diameter this gave a nice snug fit to the square stock when it was assembled. checking the size to mark out for sanding. next the assembly was rough sanded to fit into the cockpit on the disk sander. Michael

- 2,215 replies

-

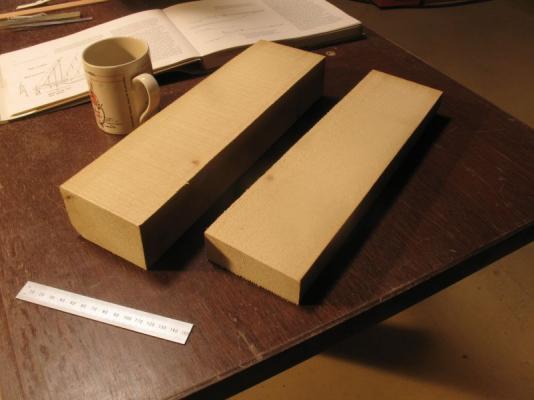

Many years ago I was commissioned to make a special bulkhead piece as a gift for a chap who owned a 65foot swan sailing yacht, showing a section of this wood the piece was mounted on two brackets that were fretted out with the profiles of the hull of the swan. it was mounted in the main cabin on one of the bulkheads. I was given this piece of wood as payment for the piece that was prepared and mounted. Michael

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.