-

Posts

5,195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

This almost seems to be the case on any body of water these days. Michael

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Hello Dan I just finished reading through your entire build, I am impressed and admire your skill and tenacity on your task at hand. I agree with you on the lighter boat I like the look better. I am curious about the wire you used to hold the ribs to the formers, what type and what diameter? Michael

- 241 replies

-

- queen annes revenge

- pirate

-

(and 2 more)

Tagged with:

-

Ilhan, your model looks very fine, it looks like you are closing in on a finish. Michael

-

Antony, it is so neat to see the level of detail that you are putting into this section, I can see that making these sections has a particular appeal and they are more educational than some models because they really draw attention to the methods of construction. Michael

- 209 replies

-

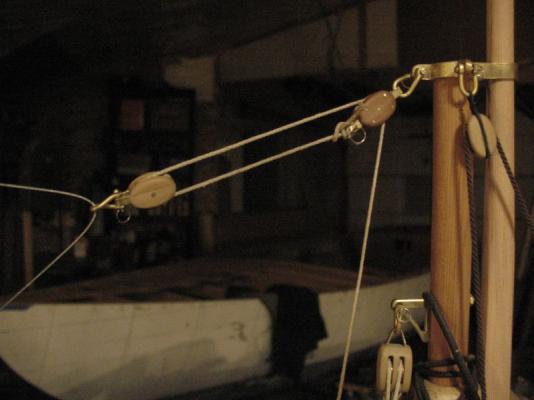

John, thanks. Popeye, glad you are finding it interesting. Joe, thanks it seems that sharing how we do things is what makes this site so enjoyable, i have learned so much from all the great work and Ideas that make up the bulk of the posts here on this forum. Bob, yes answering those questions seems to be a never ending task. Today I did some major reorganizing of the shop, and finally got the pilot cutter off the floor, and opened up some room to work on both models;>) Then this evening I redid the block set up at the end of the bowsprit I used a new twisted shackle and a single block with a becket for the arrangement. I glued the rail posts and knees down to the deck at the base of the mast. It is so much easier working on the deck hardware and woodwork at desk height. Michael

- 2,207 replies

-

Very clean way to do this part of the build I like the way it looks. Michael

- 86 replies

-

- schooner

- effie m morrisey

-

(and 1 more)

Tagged with:

-

Randy it is good to hear that the tribulations of life are resolving well and that your mind is at a level of peace that you can again focus on your model, Michael

- 384 replies

-

- san francisco ii

- artesania latina

-

(and 1 more)

Tagged with:

-

Hi Richard first time visit, these J class yachts were most elegant I will be following along now that I have found your build. I have admired this yacht for a long time. There is a chap in France who built a giant one here Michael

- 162 replies

-

I am really enjoying your build Ed, I am learning a great deal and storing it up for my next build. Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

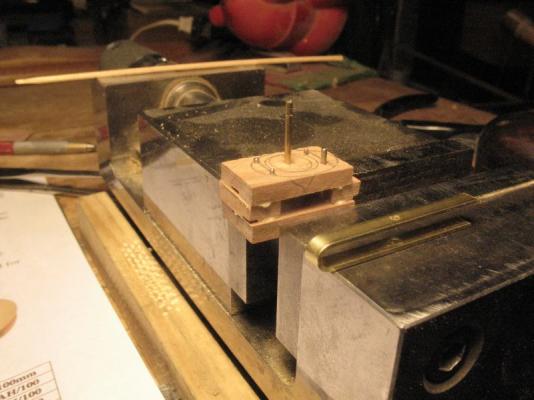

John yes that would be a problem. today I made a new eye-bolt for the mast for the topping lift. and added the small block. Also made a .156 mill bit for slotting the inside of the block shell cheeks, basically I snapped of the bottom part of a .156 drill bit and reground it on the bench grinder it works like a charm. Also today I worked on a jig to create the small curve at the bend of the metal frame of the block, I basically used the same method as for the thimbles for the eye-slices. I cut a slice of 1/8th gauge plate and filed it smooth then rounded the end and filed in a small groove using a needle file. Next I bent some 1/8th diameter hard steel rod (heated it to cherry red) into a sort of hook and attached a handle so that I could keep my fingers away from the hammer. After removing from the form. I did anneal the very middle section before bending it to fit over the form The new 6 inch block I made today with maple, I like the look of it as much as the apple and I have lots of strips of maple so I will probably use it for the rest of the blocks. Michael

- 2,207 replies

-

Hello Antony, just visiting your build for the first time, Very nice work I will follow along. Michael

- 209 replies

-

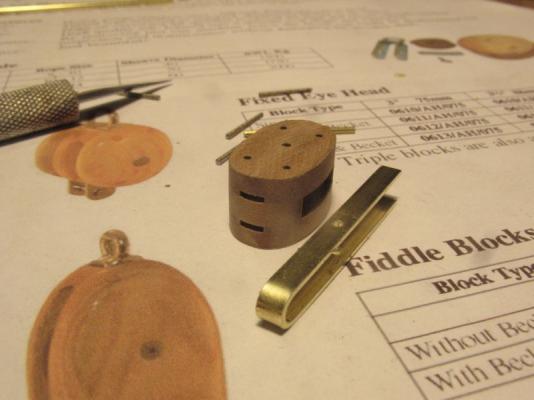

I had a go at a smaller block today out of Maple. it is the front one, the brass is .015" x .125" the pins are .031" the shell length is .45" width .33" and thickness .25" which all translates to a block in scale just over 3 1/2 long x 2 inches thick good for scale 3/8 rope. I think that most of the blocks will be bigger than this one but at least I know I can make them this small and still have them functional. most of the blocks will be as big as the rear one which is the same size as the apple one. I'm really glad this is not a fully rigged ship of the line, or I would go bonkers. Michael

- 2,207 replies

-

John, I suppose that's alright. Mick, thanks for the kind words, I will look and see what I have regarding Hilda, I would love to see a picture of your blocks, what scale are you thinking of building Hilda? Michael

- 2,207 replies

-

Hi Popeye Thanks we must have been posting at the same time. as I noted above the proof will be in the pudding. Michael

- 2,207 replies

-

Thanks Druxey, yes it was a bit nerve wracking, the village administration was on standby all day Saturday just in case. Regarding the block I think I will pursue this way of making them and develop some jigs to make it a more smooth flow of tasks. I am also curious as to how small I can make them this way. the new block is .71" long which scales to 5.7 inches and .45" wide scaling to 3.6 inches and .4" thick. These sizes are a bit random I admit, now comes the serious task of making some blocks to an accurate size, as per the information on the Davey Ash Block specification sheet. typically 3 Inch shell length for rope 8-10mm 3 1/2 inch shell length for rope 10-12mm 4 inch shell length for r0pe 12-14 and their larger blocks 6 5/16 shell length for rope 16-18mm 7 3/4 shell length for rope 20-22mm 8 3/4 shell length for rope 24-26mm These particular blocks were inspired by their 1928 range of ash blocks, I am sure there are all sorts of other manufactures who make similar blocks but for my purposes these give a good range and I like the way their blocks look. were I making a model of a particular working boat I would be more particular. Michael

- 2,207 replies

-

John yes it does seem that way, the lake is still open, we have had some very nice warm weather this last month. After supper I managed to nearly finish the new block , I like this way of building them much better than the earlier method , perhaps because it is the way the full sized ones are made. using the new twisted shackles as well, I like the look and texture of the apple block. Michael

- 2,207 replies

-

Wonderful step by step of your building process, your comment about Cad and being able to print the flip side is one that I have known but not applied so thanks for the reminder. michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Evenin' all back at the workbench today for a bit more mucking about with block making. I was given a very nice antique block when I was on the west coast in the early part of September, so I am modelling the new block sort of along the same lines, rather than machining the block out of a solid piece I thought I would have a go at fabricating it in the more traditional manner. the locator pins are tapered watchmaking pins pushed into a .040 holes. The brass insert frame is .031" x .125" The wood is Apple. We have had a little excitement round these parts the last week, the train derailment at Gainford is 2 miles from my house these shots were on Sunday night the smoke is from the controlled explosion! freaked us out , it would have been nice if they had told us they were going to do it. the level crossing I have to cross to get to the highway 16 right after the explosion. its all "quiet now on the western front" Michael

- 2,207 replies

-

Hi John, you must be very pleased with your finished model she really is a work of art! so much fine detail and superbly crafted. Congratulations on the completion. Michael

-

Late to the show as usual but I have a reclining rocker dragged into position for the comfort and enjoyment of watching the show. Michael

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.