-

Posts

5,200 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

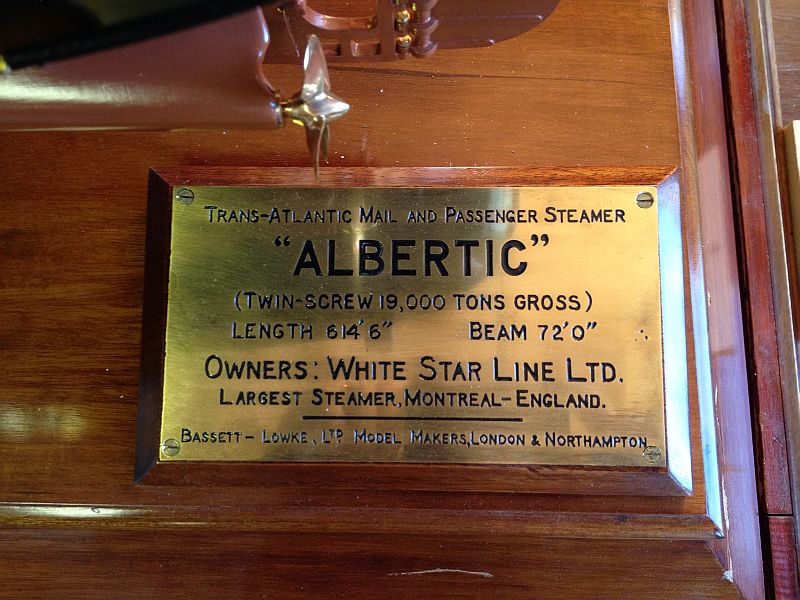

I was recently commissioned to restore to "Original Condition" A 1:100 model of the steamship Albertic. The model was knocked over and sustained considerable damage to the port side lifeboat deck Funnels and railings along with vents and all sorts of lines and wire stays. I have made extensive photographs of the condition as I received it, and have begun recording the removal of the damaged parts that were still attached, A few surprises that were not evident when I viewed it at the clients premises have come to light. I cobbled together a quick trolley so that I can move the model around, I will make a lightweight dust cover to keep the dust off the model. I will no doubt be calling on the expertise of the membership for advice as I move forward. As tragic as the damage is I am hoping that this will be a good experience and that I rise to the occasion with a smile as things become repaired. here are a few pictures to show the extent of my task. Builders Name plate Port side sustained the most damage Starboard side suffered mostly inertial damage The funnels took a beating because they are heavy and brass A lot of loose parts were piled on the deck in front of the bridge The stern end of the port lifeboat deck is badly bent and twisted The stairs didn't fair too well either Below the port lifeboat deck is the most damage on the hull I am really hoping that this area can be reworked without having to repaint the entire side, we will see? A box of the loose pieces now lifted off the ship Ouch This will keep me busy over the next couple of three months. As I was removing all the big loose parts I was noticing how much of the fine lines and wire cables have also been damaged. many of the parts were attached with micro brass pins, all the lifeboat davits for instance. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Thanks for you quick answer Chuck. OK I looked up Albion tubes Are these the tubes you are referring to? and that of course leads to the next question what type are the ones you have used because your results speak for themselves. Michael

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi glen that makes sense, It also occurred to me that you can also thin the inside edge before rolling so that the entire length of the seam looks thinner as if you had used a thinner material for the tube, while maintaining the serviceability of the thicker material. Michael

-

Hi Chuck, Very nice work on the bowsprit rigging. Regarding your method of making the thimbles, did you use the tube straight from the raw stock, or did you anneal the brass sections before you used the punch to shape them? I am assuming that you did not anneal them from the colour but just looking for a confirmation. It occurred to me that one can shape the punch so that it acts as a self regulating one by varying the length of the tip so that you cannot over do it, just musing about the possibilities of making consistent multiples of various sized thimbles, triggered by looking at those you made. Michael

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Glenn I have been off line a while myself and am also in catch up mode, Nice work on the chimney, ouch on the situation of having to do the rework on the paddle wheel. I am curious about the thickness of the chimney though, It seems to be a little thick would the actual chimney have been 1/4 inch thick? or did you choose that thickness for a different reason? Michael

-

Hi Jond, an enjoyable journey. I am glad to see that i am not the only one who works in odd fits and starts. It is also encouraging to see how you were able to persevere and get to the place you are now at with the Bluenose. There is a great satisfaction working at a large model for the reason you mention about getting your fingers into the work. It also require a different mindset because you can't hide anything. I will be following along. Michael

-

Nice work Mark, you must be looking forward to getting her out of that straight jacket. Michael

-

Hi Denis just catching up a bit, nice progress on the ship, curious about the gears in the one pic, what is your source for them? Michael

-

Hi Druxey, yes the owners insurance will cover the cost of repair work, it will also give me the opportunity to make a couple of modifications to the area where the mast and coaming go over the fore-deck. It just was not something I was planning for the early spring. The boat is now cocooned for the winter under tarps. Michael

-

Doing a little catching up Ed. As always it is such a good thing to visit your build. A nice touch on the milled cleats, and also the pins in the tiny shackles. The thing that always gets me is how clean you manage to keep everything looking. Wonderful workmanship. Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Lovely work Nils. The focus and attention you put into your work is enviable. Michael

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Don, I struggled getting info about the engine, This website Has some useful info, it took a little digging but there is a lot there. Regarding the builders of the era you mention, again I had spent a great deal of time searching The wooden boat forum was a good resource. Lawrence, thanks for your compliments, I'm down with a flu like cold right now and managed to get my big boat out last Sunday, after a San Juan 28 mast crashed onto the fore-deck punching a hole and smashing the mahogany Coaming....my sailing season ended with a bang as they say. It looks like we will be here for another winter, so I hope to get some time in the shop again soon, I have a project coming up that involves a restoration, it will give me a little pocket money and I will start a log of it when I pick it up next week. Now back to bed. Michael

-

Ya know y' just can't go buildin' 'em that quick! There was not enough time to savour the steps over a few weeks. Lovely boat and equally lovely model. Michael

- 24 replies

-

Keith a beautiful job on the foot. I also liked the clear step by step sequence of photographs of your construction method. I was surprised that such a large piece of bronze or brass was used on the original. Michael

-

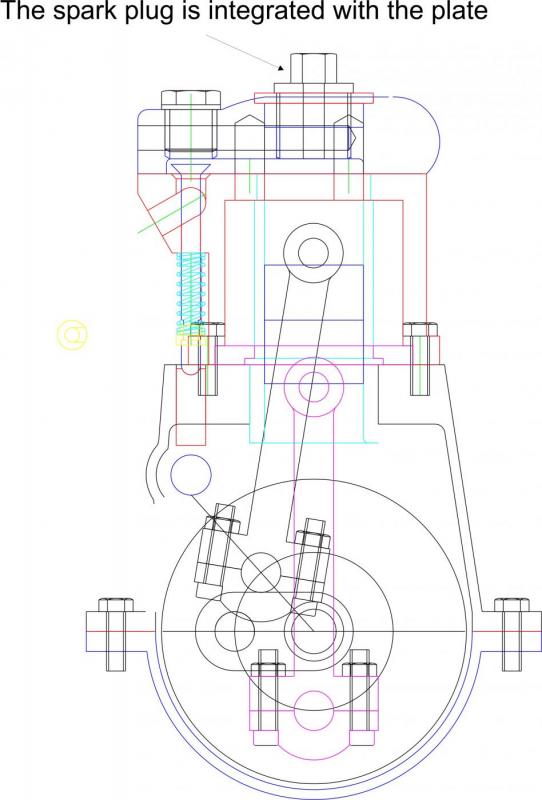

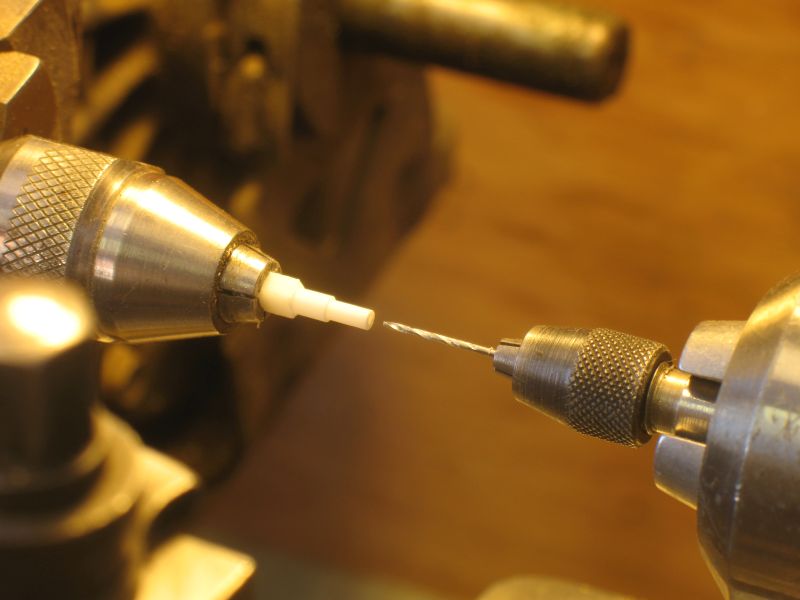

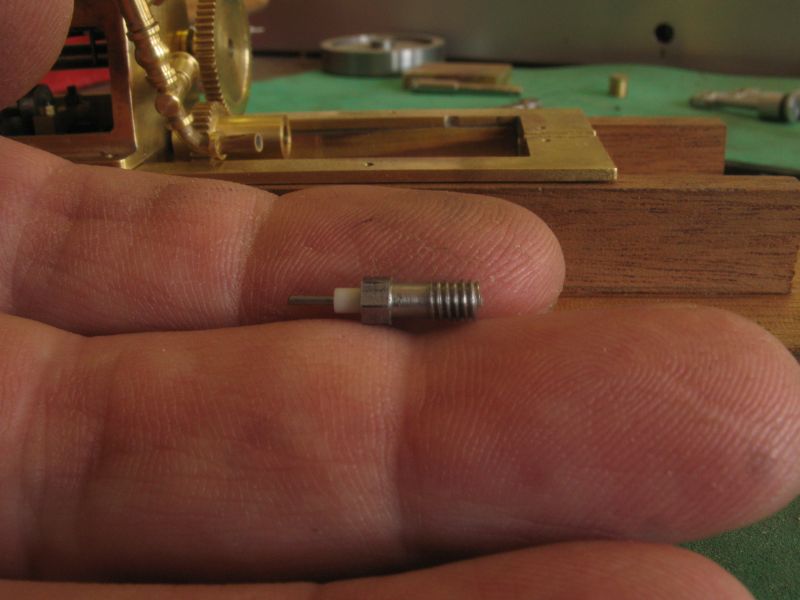

Sam the brass pieces are part of the cylinder head that form the section that the spark plug threads into this cross section shows the brass insert the comment that the spark plug is integrated is wrong. The steel plug threads into the brass one which is part of the head. Druxey yes the Corian is an insulator I have tested the plug using a Piezoelectric current it sparks very well across the core to the case at the business end of the plug. Moxis there is a comprehensive description of the engine here Michael

-

The mahogany does look rather spiffy on the hull keith, and interesting solution for the tapering of the planks. Michael

-

Great progress since I last checked in Glenn. It just occurred to me that this is basically a three dimensional history text, following the adage "that a picture is worth a thousand words" There must be a great deal of satisfaction in piecing together a story about the detail of vessel from a few remains. Michael

-

Hi Bob and Lawrence, Thanks for your thoughts and concern. With so many different avenues of interest I sometimes feel a little divided, Almost like a lack of focus. I can focus intensely for a period on one project, then get sidetracked and follow its course before remembering something on the original project, and so go back to it and the cycles repeat, and so it goes. If only there were 48 hours in each day.... Then there is house maintenance, and visiting, the afternoon nap... you understand. Michael

- 2,215 replies

-

Russ, Albert, Patrick, and Kees thanks for your kind words, i have been busy this summer sailing my yawl on the lake, working on some watercolours and other summer related activities. I will be back on the model soon enough. Michael

- 2,215 replies

-

Congratulations on the book Druxey a fine compliment to the exquisite model which was not only a joy to watch develop but educational as well. Michael

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.