-

Posts

3,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dgbot

-

Great way to recycle a shirt. David B

- 60 replies

-

- muscongus bay lobster smack

- first build

-

(and 2 more)

Tagged with:

-

He soaked his planks in vinegar and used CA for the glue. If I can find them I will post them. David B

- 241 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

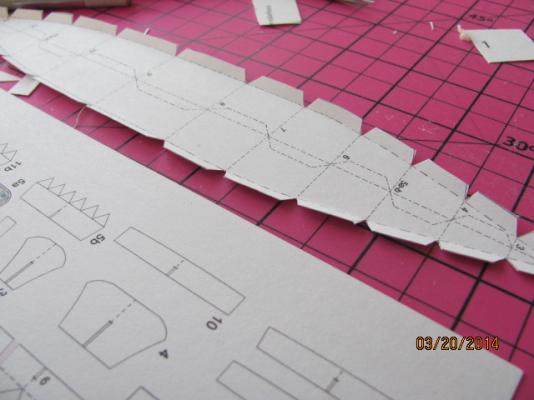

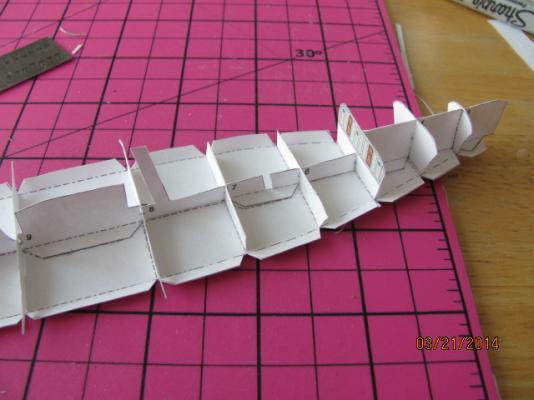

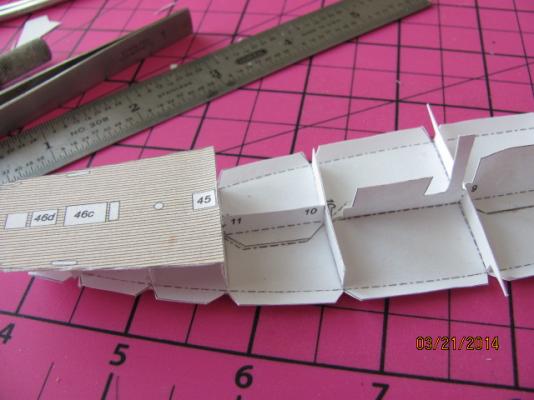

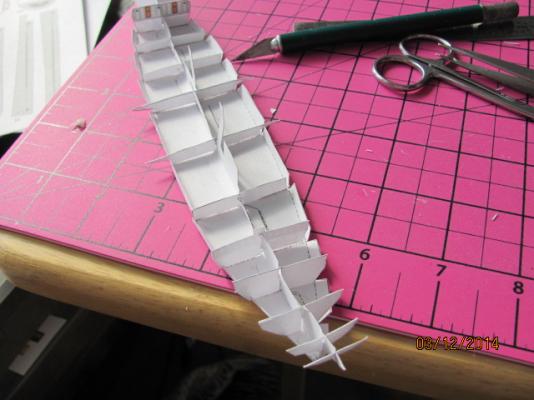

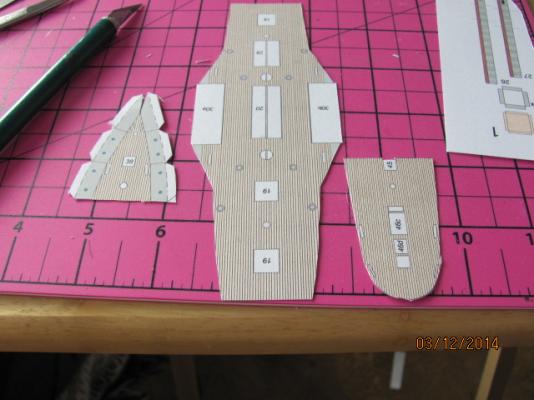

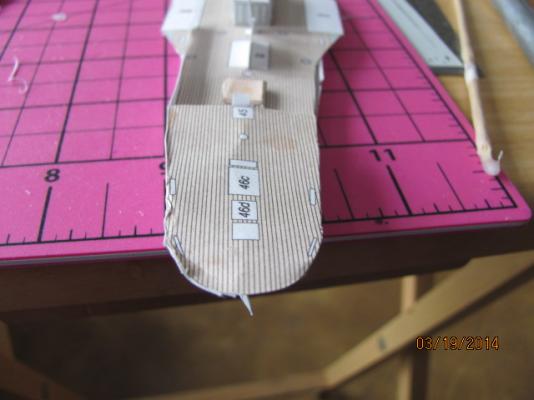

This time I had to make syre the forms were seated proper and square. Then test fit the decks before I go any further. So far everything seems okay and aligned properly. David B

- 27 replies

-

- teazer

- blockade runner

-

(and 2 more)

Tagged with:

-

Robert I just found your log. I find it fascinating. One of the members of my club built a bone model of the Friesland and your log brought back memories. You are doing a great job in a very difficult material. The main broblem he had was bending it for the planking. How did you bend your planks? David B

- 241 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

One of the things you have to remember is that back then glass was blown. The size of the panes were limited. I would go with the first photo but use the profile of one of the other photos. David B

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

I still think you are doing a fine job and you are taking your time to try and do everything right. David B

- 94 replies

-

- robert e lee

- amati

-

(and 1 more)

Tagged with:

-

Great idea. You are making good progress. David B

- 94 replies

-

- robert e lee

- amati

-

(and 1 more)

Tagged with:

-

Congratulations on a job well done. David B

- 60 replies

-

- muscongus bay lobster smack

- first build

-

(and 2 more)

Tagged with:

-

Holding tool for holding small parts

dgbot replied to Tarjack's topic in Modeling tools and Workshop Equipment

Great idea. The human mind is capable of creating many things. David B -

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

dgbot replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Marvelous. Great looking figures. David B- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

Beautiful planking job Dan. Question, why did you use birch veneer? David B

- 241 replies

-

- queen annes revenge

- pirate

-

(and 2 more)

Tagged with:

-

Some of the best wood for bending I found was apple. Beech does a nice job to if you can find it. David B

- 625 replies

-

- bounty launch

- model shipways

-

(and 1 more)

Tagged with:

-

Steve, most of the severe bends I have done usually was by wetting the pank and putting some heat to it. A curling iron, a modified soldering iron or a planking iron. I have also made male/female fixture as well. I never found the need to use ammonia. It also depends on the type of wood you are using as well. David B

- 625 replies

-

- bounty launch

- model shipways

-

(and 1 more)

Tagged with:

-

Ouch I hope you did not lose to much. David B

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Spiderpig how much experirnce do you have modeling? The kits you put down are all nice but you should try something a little easier first. I have found many nice kits over the years cheap because the owner bit off more than he could chew. David B

-

Great hinges. Your idea of using the left over plating is a stroke of genius. David B

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

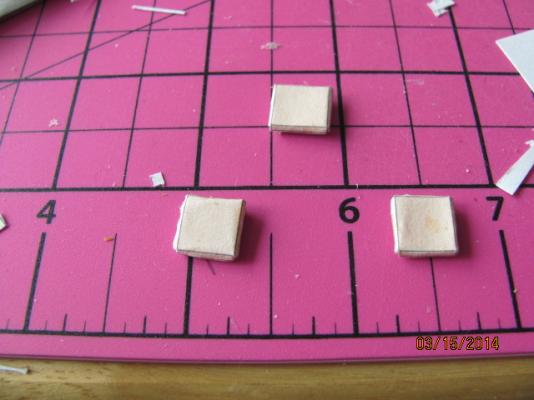

Nice work. When using my Preac I would gang different blades together to get the correct width. David B

-

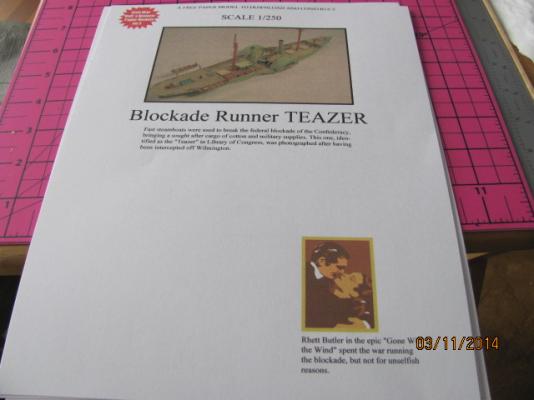

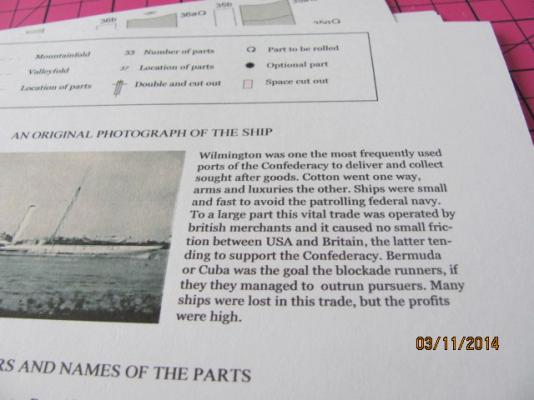

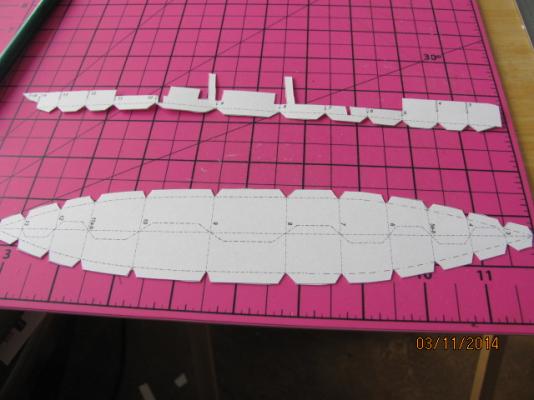

I have started my next model. It is the Blockade Runner Teazer. It was part of fleet of steamboats used by the North during the Civil War to blockade Southern harbours and ports, The scale is 1/250. I started the model the same as the last one using what I learned from the last one. However this kit is far more advanced and as a result it is easier to make mistakes. Everything started out okay but after awhile as you will see I have decided to start over.

- 27 replies

-

- teazer

- blockade runner

-

(and 2 more)

Tagged with:

-

Bob, I think your paint scheme is perfect. David B

- 277 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.