-

Posts

3,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dgbot

-

You have nothing to be sorry about Toni. Your work is a pece of technical perfection. I wish I had half the skill you have. David B

- 1,449 replies

-

You did a nice job your carving is good too. David B

- 1,449 replies

-

I have alway been interesred in SIBs I will be watching thid build. Davd B

- 36 replies

-

- black pearl

- bottle

-

(and 1 more)

Tagged with:

-

In that case go for any of them. David B

-

Good idea Bob. I was wondering how you were going to plank the inside. David B

- 277 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

Your doing a fine job on your deck planking to me the rough part is always the scraping and smoothing. What a mess. David B

- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Looking good so far. However I would fill in the spaces between your bulkheads. This will help in prevent you planking from buckling and give you more surface to glue. I have seen quite a few pinks built. It is a nice lokking model. However the hull can be a little tricky to plank because of the curves and the bow. David B

-

Remindes me of a great lakes oar carrier. But whick one. David B

- 382 replies

-

- stadacona

- sylvan scale models

-

(and 1 more)

Tagged with:

-

Nicely done . However I thought the paddles on the Robert E Lee were articulated. I could be wrong though. David B

- 94 replies

-

- robert e lee

- amati

-

(and 1 more)

Tagged with:

-

Metal bars or some other form of protectionwould be used. Glass owuld be expensive and hard to replace . David B

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Harriet McGregor by Boccherini

dgbot replied to Boccherini's topic in - Build logs for subjects built 1851 - 1900

I like your build great joinery and very neat. Keep up the good work. David B -

I bet you were not happy about having to rework the entire assembly over. This took a lot of time. David B

- 241 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

Nice soldering Bob. If you go to Michaels you will find metal leaf kits at a very decent price. David B

- 420 replies

-

A feather board would be easy. But I think making the Byrnes saw with a tilting arbor would take away what to me is one of the most important features. A permanantly aligned 90 degree to table blade. I could be wrong though. David B

-

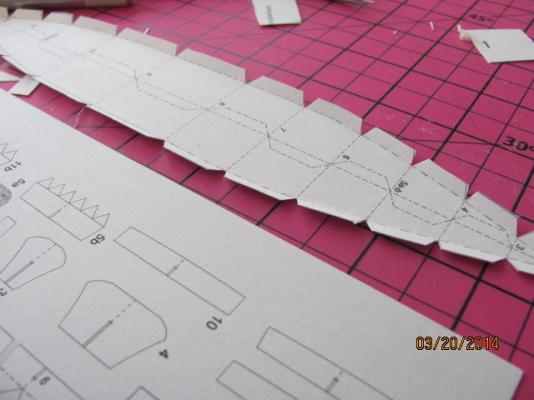

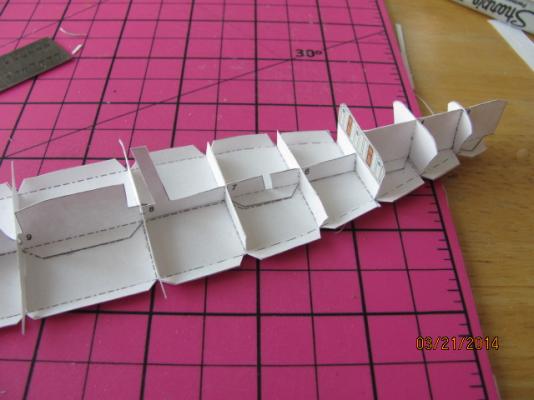

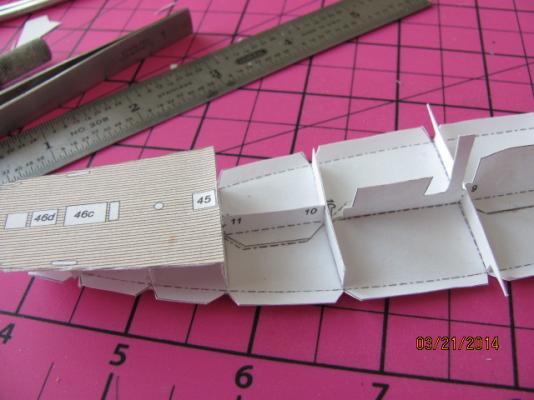

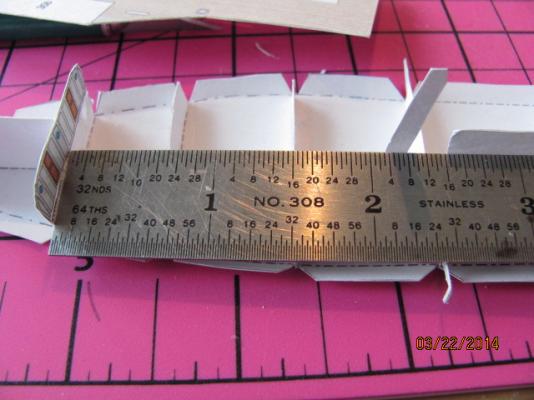

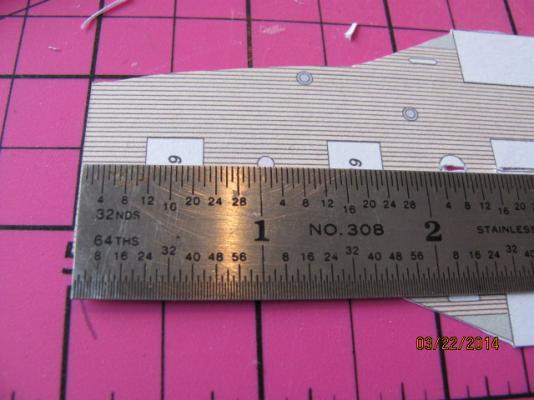

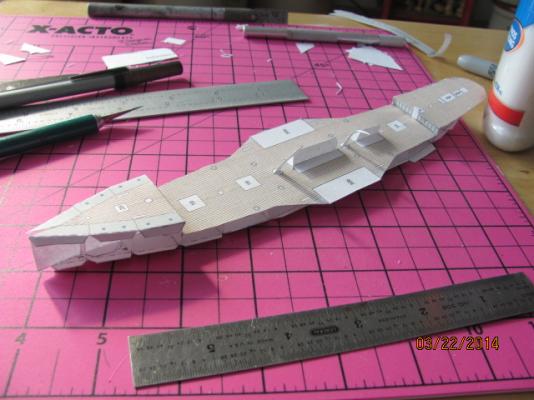

My second try at this kit proved to be interesting in that I learned several new things. The first thing was to cut out the hull and the backbone and make sure they they fit perfect. Once I was sure of everything they were glued together. Then I cut out the bulkhead formers and dry fit each one before they were permanenly seated. I made sure the aft deck was perfecly aligned. Thi took some time and playing with. Paper unlike wood is flexible and you have to double check every joint. The main deck was cut out oversize and length was measure to insure a proper fit once all the slots and holes were cut out. I am glad I did this. Note to self when printing always double check the dimension, you could always be off. Even 1/64 could mean serious trouble. The for deck was added and I am happy so far. Once more several lessons were learned and one is alway double check everything and take nothing for granted. David B

- 27 replies

-

- teazer

- blockade runner

-

(and 2 more)

Tagged with:

-

I think you are doing a fine job. Keep up the good work. David B

- 86 replies

-

- muscongus bay lobster smack

- Midwest Products

-

(and 1 more)

Tagged with:

-

They did not like the smell of a slughterhouse that had not been cleaned for several years. His own wife would move in with the kids when he sarted cutting. David B

- 241 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

I am sorry to say that this was before digital and I do not have a phoot of on my computor at the moment. That does not mean I wont stop looking. I will ask fellow club members if they have any. In Buds case the association where he lived threatened to throw himout of his condo. David B

- 241 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.