-

Posts

4,825 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by gjdale

-

-

Can’t wait to see your interpretation of Chris’s design B.E. I’m sure it will be something special, so I’ve pulled up a front row seat to follow along.

- Blue Ensign, mtaylor, BobG and 1 other

-

4

4

-

Thanks Nick. Paul is another of the YouTubers I quite like and that is quite a good demo he does in that link. He also mentioned Yellow as a primer under Red, which is going to be my next test as I’d read somewhere, sometime that this was a good combo. Waiting on the next paint delivery now……

- mtaylor, Canute, popeye the sailor and 4 others

-

7

7

-

Glad to see you back at it Bob. I look forward to the next update.

- Ryland Craze and BobG

-

2

2

-

Thanks Ken.

And thanks Ron - that’s one of the guys I’ve been watching. I think he’s pretty good.

-

Thanks Wefalck for that info. I hadn’t considered not using primer on the metal parts - painting is certainly not my forte! I think I’m going to stick with the primer though.

Egilman - thanks for the Desert Cart link but at $91 a can, I think I’ll pass. That is the first time I’ve seen it offered for shipping to Australia though - I wonder if it would actually let me order it if I went through with it…..I’ve seen similar adds like that and when you go to checkout, suddenly it doesn’t ship to your location. The second link is not for the Foil paint - that’s the Premium paint that I already tried and didn’t like.

I’m pretty happy with the Alclad colours so far. They are reasonably obtainable, a fair price and have had some very good reviews.

Thanks everyone for the input - much appreciated.

-

-

It's been a while since my last post. Not because there has been no progress but because I have been waylaid doing some Paint trials...

Paint Trials

The instructions call for the use of Krylon Foil Paints. This is particularly important for the appearance of the (simulated) Brass and Copper parts. Unfortunately, this range of Krylon paints is not available in Australia. I therefore decided that it would be sensible to do a series of trials to find a paint solution with which I would be happy. I initially tried the Krylon metal finish range but quickly decided that these gave nothing like the finish of the foil version of these paints. I had some previous experience with the Vallejo Metal Colour range but was concerned about the durability of these, being an alcohol-based acrylic.

I spent some time researching options on the internet and watching a bunch of YouTube videos. The first conclusion I came to, was that there is a lot of crap and misinformation out there, posted by people who really don’t know what they are talking about. The good news is that I found a few whose opinions and advice I felt I could trust.

The next conclusion I came to was that I wanted to try Lacquer paints. It seemed to me that they would give me the durability I sought while also being quite easy to airbrush. The only downside of Lacquers is that they contain “nasty” stuff. Given that one should really wear a respirator and use a spray booth even when spraying acrylics, it didn’t seem to me that this was a big deal (as long as I managed not to stink the rest of the house out). One big tip I picked up from YouTube is that you can use ordinary hardware store generic Lacquer Thinners for cleaning up. It can also be used for cleaning up after using acrylics if you wish to avoid confusion when using different paint types – one cleaner to rule them all. For thinning though, a branded Thinner such as Mr Hobby Levelling Thinner is recommended (if needed).

For metal colours, I decided to give the Alclad range a try. They have quite a line-up in their range but again availability was to prove an issue. I would have liked to try their colour “Polished Brass” but nowhere in Australia seemed to have it in stock. Instead, I went with their “Pale Gold”. I also bought some of their Copper and Gun Metal. These all come pre-thinned and airbrush ready straight from the bottle.

For the red painted sections, I decided to give Zero paints a go as I plan to use these for my next Pocher car model (in due course). These also come pre-thinned ready for airbrushing straight from the bottle. There is only one importer of these paints in Australia, and once again availability has been challenging. I did manage to find a colour called “Fire Engine Red”. It is supposed to be an exact match for a Mercedes Benz 300SL. I figured with a name like that, it would have to be a good choice for a fire engine.

Then came the choice of primers. If you thought that it didn’t matter what colour primer you use, then think again! It’s usually a good bet to match the primer from the same brand as your colour coat – usually….

My previous experience using Metal Colours (Vallejo) was that they require a Gloss Black primer. So I ordered the Alclad Gloss Black Base when I ordered their other paints. Turns out that this is only required for their “high shine” range. For the “standard” metal colours, the instructions on the bottle say to use either their white, grey, or black (standard) primers. More testing to do. The good news is that the instructions also note that no clear coat is required to seal these and that they may be buffed with a micro-mesh cloth for a greater shine – just what I was looking for.

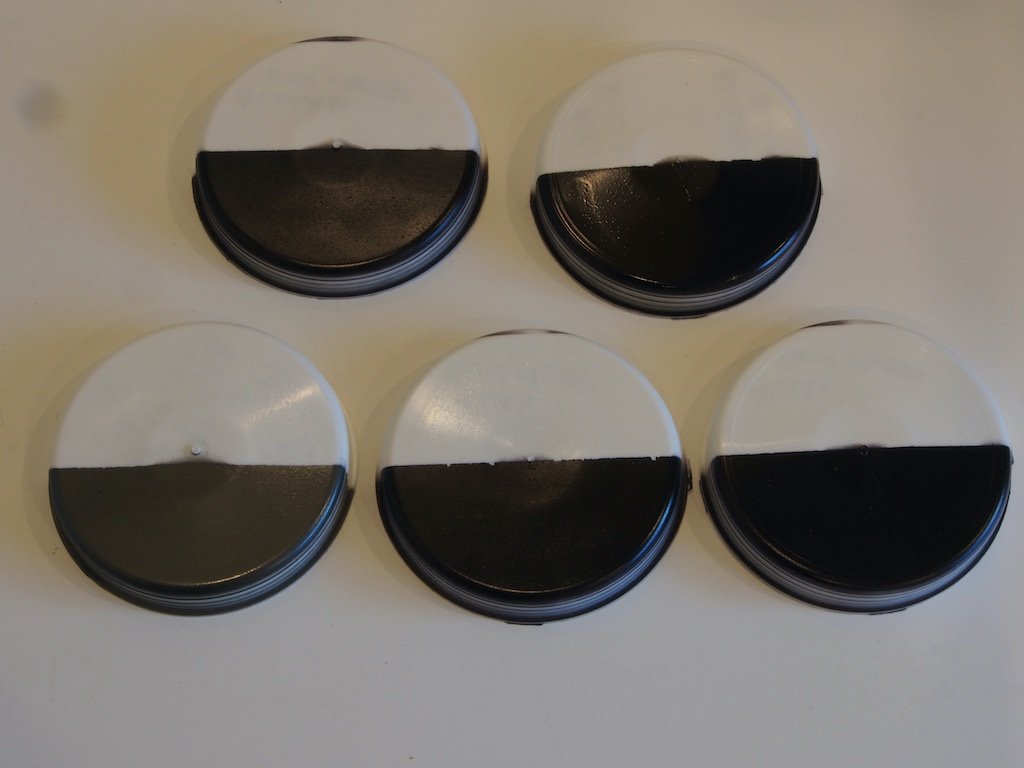

Here are some test swatches of the Pale Gold using white, grey, black, and gloss black primers (no buffing here).

It’s hard to tell from the photo, but the bottom left proved to be my favourite. It’s on a white primer, although at this stage that’s a Tamiya white primer (I’m still waiting on the Alclad one).

And here are the same tests with the Copper.

This was a close call between the white and grey primer, so to keep it simple I’ll stick with white. The gloss black (top right) was a long way last.

The only Alclad metal that I didn’t like was the Gun Metal. Regardless of the primer used, it just looked black to the naked eye. So I decided to go with my Vallejo Gun Metal (bottom left in the picture) as there are very few parts that use this colour.

When it came to the Red paint, I was really surprised at the difference the primers made. I was also really disappointed with the Zero white primer. I had been warned by one of my YouTube videos that the Zero white primer laid down “hairy” and that’s exactly what it did, giving quite a rough texture. I tried the red over Zero White, Tamiya White, Zero Light Grey, Stynylrez Grey (slightly darker than Zero), and Zero Red Oxide. Here are the results. The Greys and Red Oxide are along the top, the two whites are on the bottom (Tamiya white on the left, Zero on the right). The differences look much greater in real life.

I was quite surprised that even the light grey primer gave a very dark and dull red. Only the white gave the brightness of colour I was after, although it did need more coats to gain the required depth of colour. This will eventually have a satin clear coat over the top.

Following the paint trials, I am awaiting a further order of primers, including both Alclad and Stynylrez. I really liked the way the Alclad sprayed for both the primers and the metal colours. I’d heard good things about the Stynylrez, so wanted to try it too. So far, I have only tried the Grey. It is much, much thicker than any other primer I’ve used and the instructions on the bottle say to use a 0.5mm or larger needle when spraying it and to use a higher pressure (20-30 psi). That said, it does self-level beautifully, despite its initial appearance when first sprayed. I particularly want to do a side-by-side comparison of the Alclad and Stynylrez white primers under the Zero Red colour coat.

More trials to come….

-

Always wanted to try one of these, so I’ll follow along with interest.

- Keith Black and Ian_Grant

-

2

2

-

Neat solution Dave - looks great!

- Canute, Edwardkenway and mtaylor

-

3

3

-

I’m in too. Should be an interesting build. I’ll join Mark at the bar for this.

-

Nice recovery Tom. As Toni said, we’ve all been there, done that - some of us more frequently than others!

- druxey, usedtosail and mtaylor

-

3

3

-

Great job Kevin - and amazingly fast too! Well done.

- Egilman, Edwardkenway, Kevin and 6 others

-

9

9

-

-

That is looking great (and huge!) Yves. You must be well pleased with this.

- lmagna, mtaylor, popeye the sailor and 3 others

-

6

6

-

A good question Kevin, and Wefalck has provided a great answer. Thank you both for exploring this.

- Old Collingwood, Egilman, mtaylor and 4 others

-

7

7

-

At last, I have managed to make a proper start on this project after a few distractions!

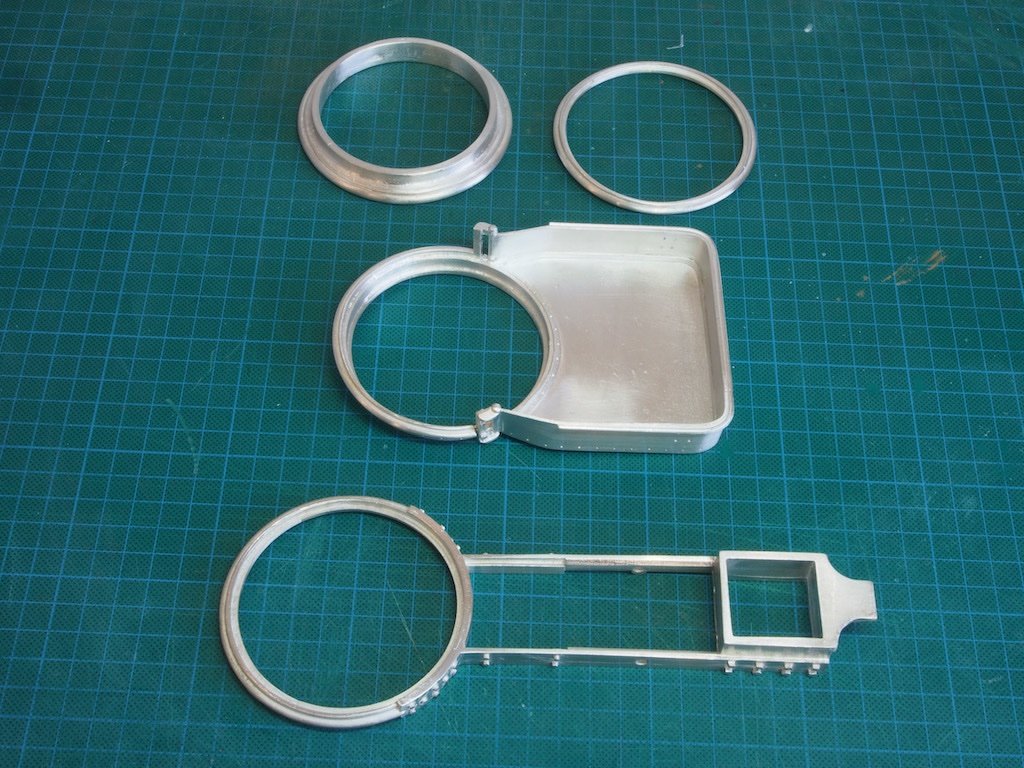

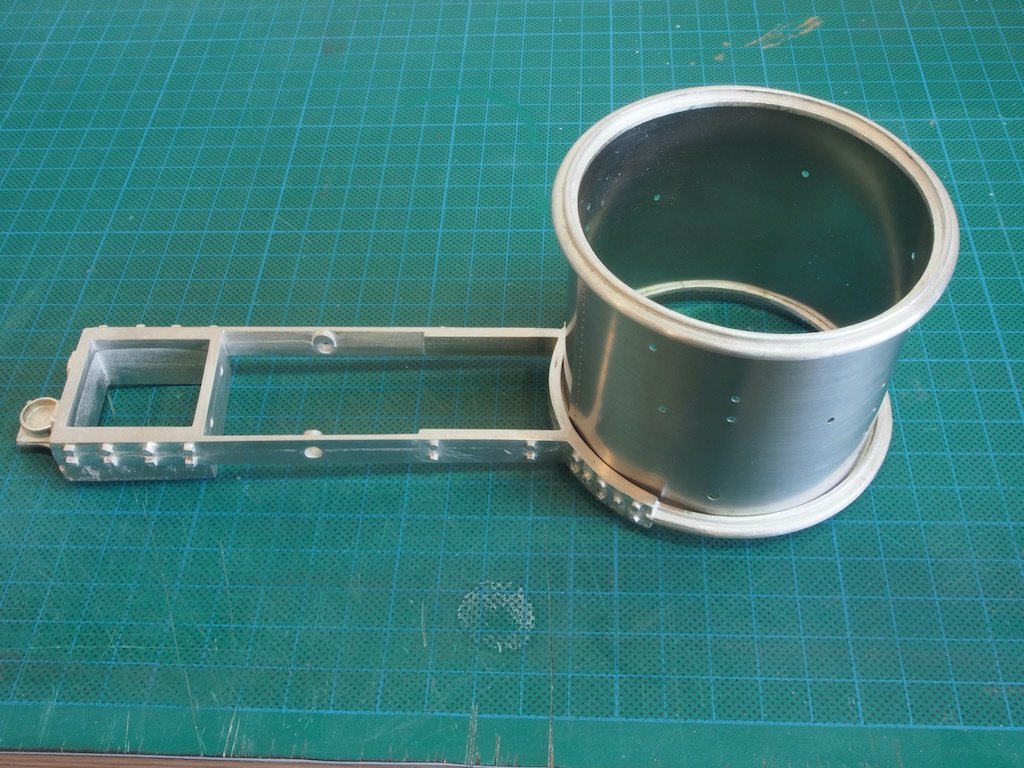

Construction: Main Frame

Construction begins by checking the alignment of the Main Frame Boiler Ring, the Boiler Ring, the Coal Bin and the Boiler Cap Ring. The Boiler Cap Ring (upper left in the photo) is used as the reference for all other rings. It is important for these to be as round as possible as the boiler walls index from these. The parts were then scraped, filed, and sanded of all extraneous casting imperfections (there were many!).

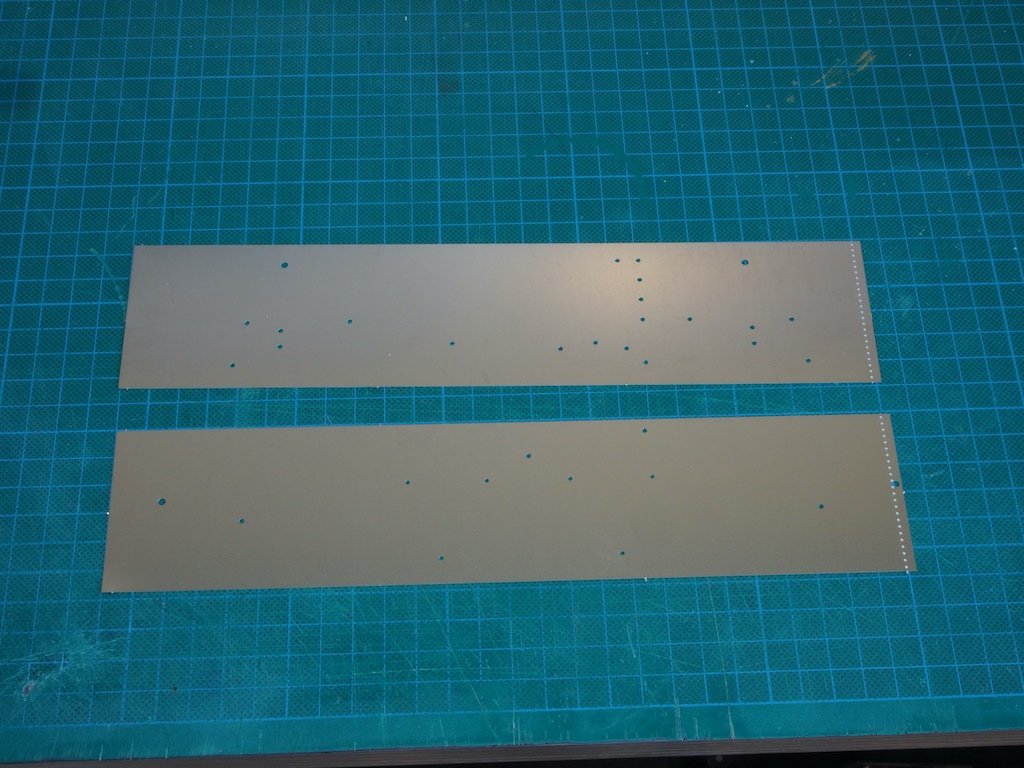

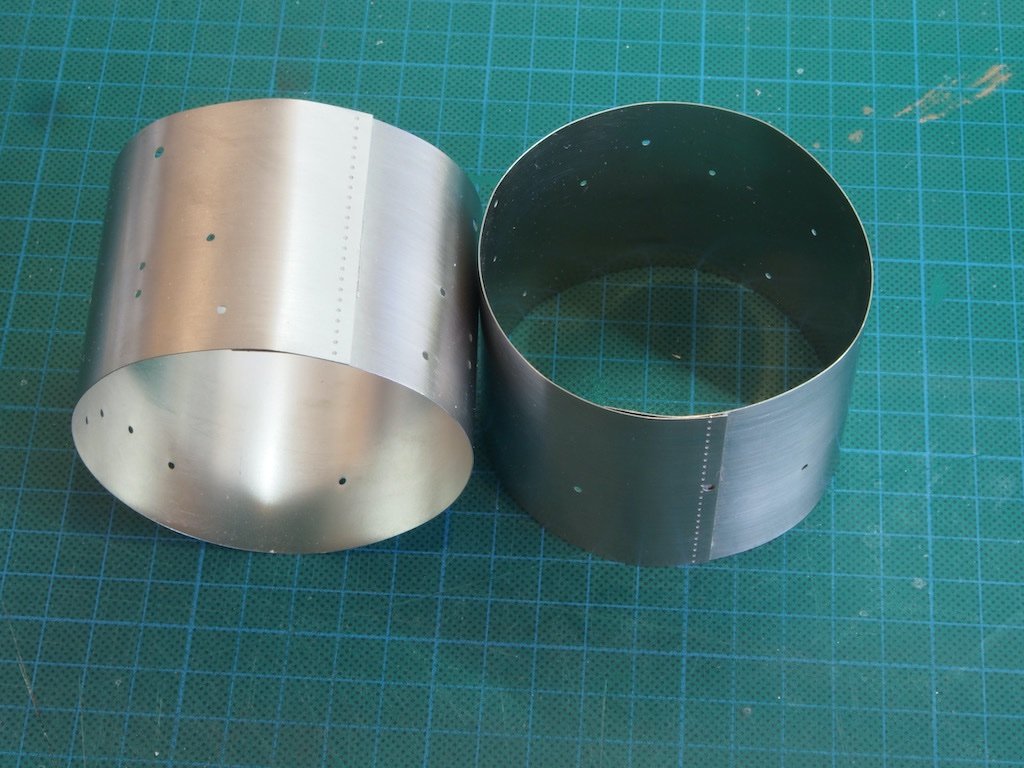

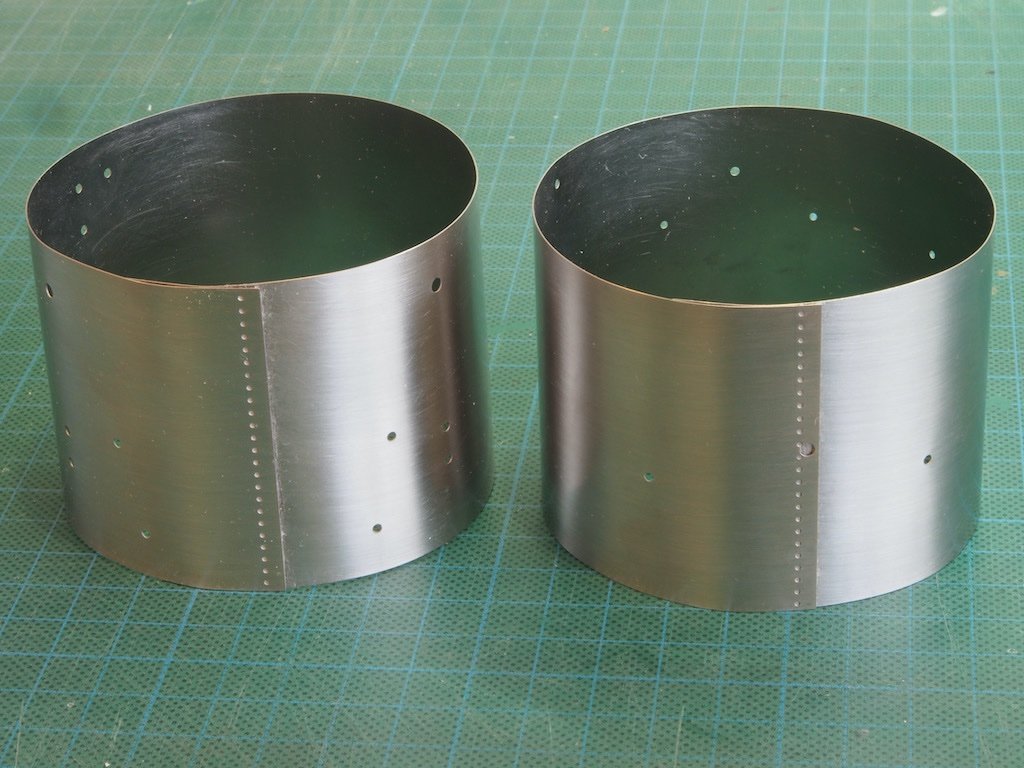

The boiler walls are comprised of two sections, both formed from photo-etched stainless-steel sheets. The outer faced of these are first scrubbed in a horizontal direction with a Scotchbrite pad to simulate a brushed surface.

The sheets were then slowly formed into cylinders by bending by hand and using the mainframe / coal bin along with the boiler ring to get them to the right size. Once they were the right size, I held them temporarily with masking tape and miniature clamps while medium viscosity, gap filling CA was applied on the inside surface of the joints. Once that had set, the clamps and tape were removed, and more CA was applied under the overlapped edges on the outside face. Masking tape was reapplied to hold everything in place while the glue set, and they were left overnight. The next day the tape was removed, and excess glue cleaned up with Acetone and cotton buds (Q-tips). All in all, this was a lengthy and difficult process – far more so than the description suggests!

Lower boiler wall being formed using Coal Bin and Boiler Ring for index:

Upper boiler wall being formed using Mainframe and Boiler Ring for index:

And the finished boiler walls:

These are now set aside until much later in the build. The reason for forming these now is so that subsequent paintwork on the other parts does not get scratched in the forming process.

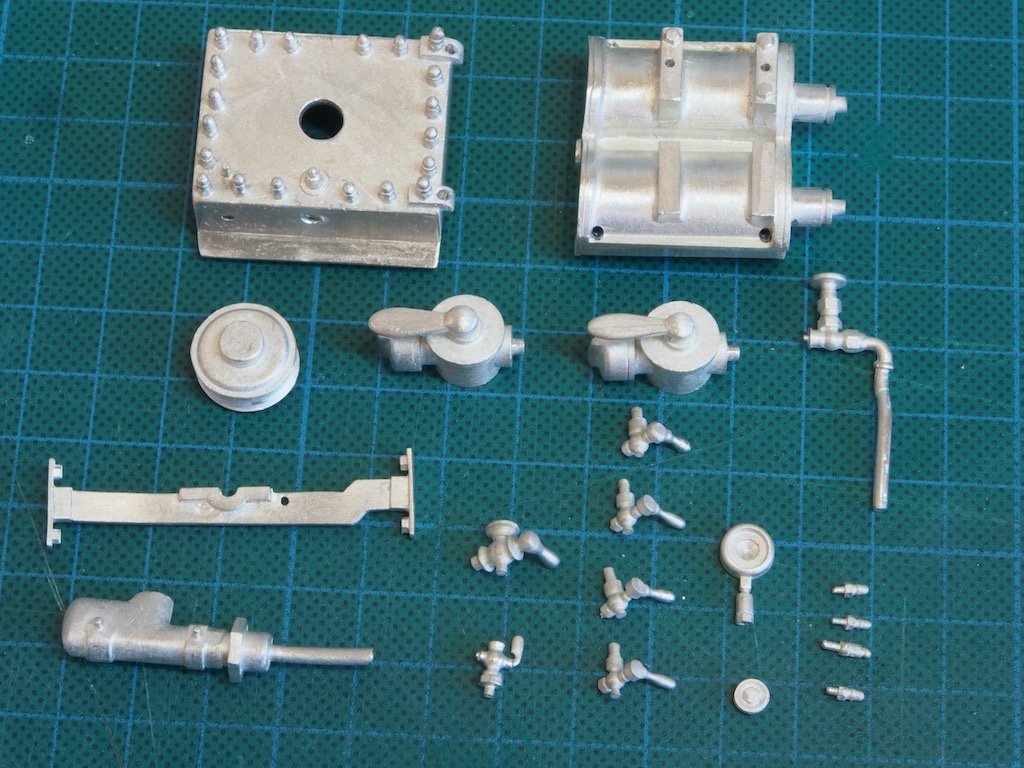

Attention is now returned to the mainframe and some initial components – the Lower Steam Box and the Upper half of the Water Box, along with various attachments. Locating and identifying some of these parts is a real challenge. Although the drawings are very good and the instruction manual has a lot of photos, some of the smaller parts take a while to positively ID. And although the instruction is very good, it is not perfect, and I’ve already found a couple of inconsistencies that it took a while to nut out. It is important to scrape, file and sand the casting imperfections and then dry fit everything prior to painting and assembly. All the locator holes had to be re-drilled to accommodate the indexing pins as well. Once all of these parts looked like they would fit in the appropriate place, they were scrubbed with a toothbrush in some warm soapy water before being set aside for painting.

Here are the parts ready for the spray booth (along with the main frame – not pictured):

It may not seem like much, but there is two full days work to get to this stage!

-

Outstanding B.E. - but then again, we have come to expect nothing less from you! 👏👏👏

- Ryland Craze and Blue Ensign

-

2

2

-

This is certainly coming together quickly Kevin - looking good.

- mtaylor, Kevin, popeye the sailor and 5 others

-

8

8

-

He’s also a member of this forum Kevin - goes by the screen name “Xken”. He also designed the Allerton Steam Pumper kit I’m just starting. You’ll see some similarities in design principles between the two.

- Canute, popeye the sailor, mtaylor and 4 others

-

7

7

-

I see that this kit is another Ken Foran design, so I expect it will be a good one. Nice start.

-

I’ll be interested to follow along too. Looks like you’re all set for a great start.

- mtaylor, Ryland Craze and usedtosail

-

3

3

-

-

Looks superb from this distance Mark!

-

1869 Allerton Steam Pumper by gjdale - Model Trailways - Scale 1:12 - Finished

in Non-ship/categorised builds

Posted

Thanks Popeye. Yes, I’m fast becoming a fan of lacquer paints, and Alclad in particular. I’m also experimenting with Stynylrez primers. Although they are not a lacquer, they seem to work well with everything. Unfortunately, every time I decide to try something else, I have to wait for the postal system to catch up ‘cause virtually none of it is available locally these days.