-

Posts

4,825 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by gjdale

-

-

Looking great Sea Hoss. She really does have elegant lines doesn’t she?

-

Wow! That’s a really nice build James. Looks like the modern equivalent of a Pocher model, only the parts actually fit properly! Now where’s the challenge in that?😉🤣

It also looks like there’s no painting required - is that correct?

All in all, a very, VERY nice model.......

- Egilman, mtaylor, Old Collingwood and 3 others

-

6

6

-

Thanks Ryland,

It feels good to have reached this point after so long. By the way, your own excellent build log is serving as a key point of reference for me - invaluable!

- Canute, BobG and Ryland Craze

-

2

2

-

1

1

-

Thank you for your kind comment Merriann and welcome to MSW. As Bob has said above, the most valuable tool in your toolbox will be your build log. I would encourage you to start one for your current build - it doesn't matter that you are already well into the build.

A small update...

Having decided to go ahead with the Naphthol Red colour, many very thin layers were applied to the top of the cap rail and the inboard sheer strake. Having not used this painting method before, I was somewhat apprehensive to begin with but quickly overcame that as I saw the colour building up with a very smooth finish, free of brush strokes. I lost track of the number of coats, but it was somewhere between 12 and 20-ish, with light sanding every third or fourth coat. Special thanks to Chuck and others who have described this painting method in some detail in various logs.

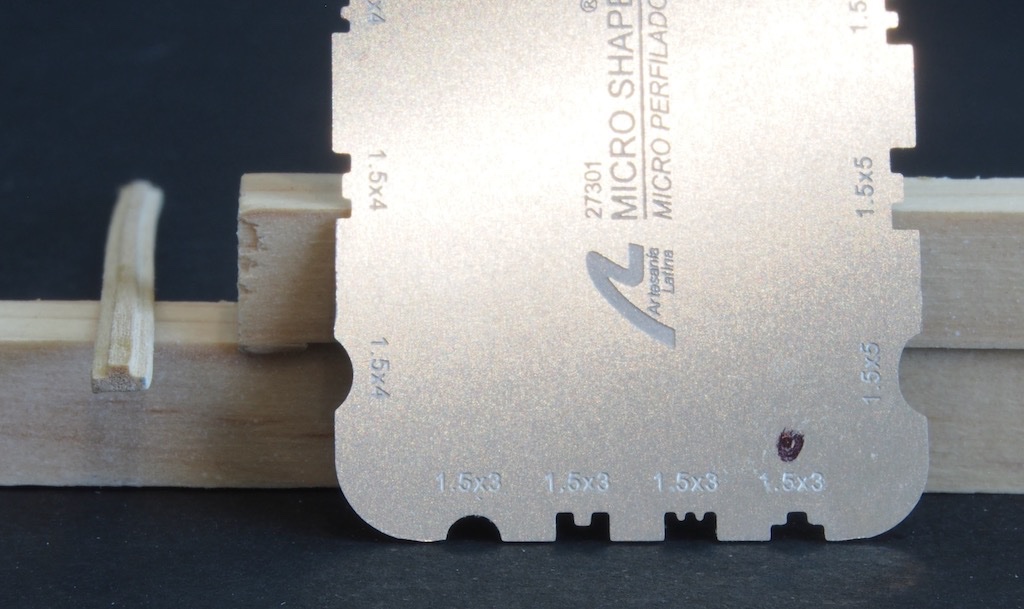

While waiting for the paint to dry, I prepared the molding strips. To create the profile, I used a set of profile scrapers that I purchased some time ago from Artesania Latina. They come in a set and cover a range of sizes of stock material and profile shapes. I found the 1.5 x 3mm fitted the supplied boxwood strip quite nicely and in no time at all produced the desired molding profile. Picture below shows the scraper and the end result.

Once the paint had dried, I applied the friezes along the sides and bow. I cheated a little here by printing them on sticky label paper on my laser printer so that I could just peel and stick. This worked well. The molding strips were then applied, the hull given another coat of WOP and the transom frieze applied. The only tricky bit here was choosing and then tailoring one of the five options to fit my transom. To assist in this, I used some tracing paper to trace the outline of my transom and then transfer this shape to the closest fitting of the supplied options. A little further trimming and a good fit with a relatively even border was achieved. That completes Chapter 3. Here are a few photos of the current state of play as I start work on the floorboards and platforms.

- Nunnehi (Don), GuntherMT, oneslim and 9 others

-

12

12

-

Thanks very much Ryland. The paint is looking quite nice as is, so I'm reluctant to do anything to it that might change that!

I'd been thinking along the same lines regarding the friezes. I just did a test on them with WOP and found that it did smudge the colour. Then I found a can of spray matte finish in the cupboard - the can says it is specifically designed for "all papers & boards, drawings, layouts, artwork, prints, photographs and maps". That will be my next test.

-

Thanks for the kind comments and opinions on colour choice. I've almost finished painting the cap rail - lost count of the number of coats, but it's somewhere between 12 and 20..... I would never have thought of this painting technique before but it certainly works well and is not at all hard to do once you get going. I've been using a "wet palette", which I think really helps as well.

I have a quick question (actually two questions) for Chuck and/or any of you who have been down this path already.

1. Once the cap rail painting is completed (using acrylic paint), is it necessary to use a clear finish over the top of it (for protection)? If so, what do you recommend for this clear coat?

2. In applying WOP to the exterior of the hull, is it advisable to put this over the printed frieze (again for protection), or will the WOP likely destroy the frieze?

Thanks in advance for any and all advice.

-

Sorry to hear about the health issues Bob - particularly with the whole COIVD thing happening in the background around you as well. Take your time coming back - we'll be waiting when you're ready, some of us more patiently than others.....😉

Glad to hear you've picked up your guitar again in the meantime. One should always have music in one's life.

-

-

Thanks Rusty and Bob, and also all of the likes.

The new stock of monofilament fishing line has finally arrived, so I’ll now be able to complete the “nailing” of the hull. While I was waiting for the post to arrive, I went ahead and completed the bolsters and the thinning of the cap rail and frames. The bolsters were quite tricky, as anyone who has reached this point before me will attest. Chuck even went so far as to provide six blanks in the kit to make the two bolsters required – and it’s just as well that he did. I started on the starboard side and blew two attempts before getting the third to a point that I was satisfied with. The port side only took two attempts, so learning clearly took place! I even had one blank to spare!!!😁

Here’s what they looked like after I glued them in place initially.

I then realised that the lower edge should have been tapered/bevelled considerably, so was faced with the challenge of achieving this with the bolsters in situ. Fortunately, with the assistance of Mikhail’s wonderful micro chisels and some sandpaper, this actually turned out to be easier to achieve than I’d first expected. Here’s the subsequently modified bolsters.

With the bolsters in place, I was then able to go ahead and thin the cap rails. Using the technique described by Rusty in his log, I used a scrap of 1/32” material to guide the formation of the outboard edge to a uniform overhang, then using a pair of compasses marked a line 5/32” from the outboard edge to guide the thinning of the inboard side.

At this point, I had to wait for the fishing line to turn up before going further, so my final task here was to decide on the paint colour for the cap rail etc. I had remembered reading somewhere what brand/colour Chuck had used but couldn’t find it again, so I PM’d Chuck and asked him directly. Chuck said that he used the Winsor and Newton Galeria Acrylic range of paints and the colour was Crimson (for anyone else wondering). I also noted that some others had chosen slightly different variations. For example, someone (can’t remember who) used Cadmium Red. There is an art supply store nearby, so I popped out and bought some of the Galeria Acrylic Crimson, and some Cadmium Red (Winsor and Newton Professional Acrylic range). I also had a couple of other reds in my existing range, including Naphthol Red (medium hue) and Permanent Alizarin Crimson – both from the Winsor and Newton Artists’ Acrylic range. I then did some test swatches on some art paper for comparison. The results are below, and I’d appreciate any thoughts from others on my eventual choice.

What I noticed straight away was that the Artists’ Acrylic / Professional Acrylic range behaved very differently from the Galeria range – they mixed with water on the wet palette in a very different way that is hard to describe, and also laid down on the surface material quite differently, going on with much more even coverage and also seeming to dry more quickly. I guess there’s a reason this range is double the cost of the Galeria range.

I quickly discarded both the Cadmium Red (too orange) and the Permanent Alizarin Crimson (too purple) from the choices and was left with the Crimson (Galeria) or the Naphthol Red (Artist’s Acrylic). The Naphthol Red appears slightly darker and more subdued than the Crimson and I think I like that colour tone slightly better, though it’s a very close race in my mind. Being much nicer to work with tipped the balance for me in the end, so my current choice is the Naphthol Red. I know that photography and computer monitors will impact the way things appear on screen, but I’d appreciate any thoughts on my colour choice.

Now I’m off to finish the “nailing” and prepare the inboard sheer strake…

-

-

-

-

-

Sorry to hear of your accident. Always remember that every power tool in your workshop is actively trying to murder you!

- Ferrus Manus, Kevin, Matt D and 1 other

-

4

4

-

-

Nice to see you start on this one Ken. I’ll follow along too as I’m not too far ahead of you - at my usual building pace, you’ll overtake me in no time!

- Old Collingwood, BobG and Canute

-

3

3

-

Sorry to hear of your personal troubles Tom - hope things get sorted soon for you. On the CA glue side of things, try using a respirator with an organic vapour filter - it’s about the only way I can use the stuff without making myself seriously ill for several days.

- MadDogMcQ, popeye the sailor, Canute and 1 other

-

4

4

-

-

The best laid plans....

Having intended to complete the monofilament nails prior to removing the hull from the build board, I found I only had enough monofilament to complete one side. Perhaps I drilled the holes waaaay to deep…. I thought I had previously tracked down some more monofilament but what I had in the drawer turned out to be a braided line and of no use at all. For some reason, black fishing line does not appear to be a popular choice in Australia as I could not find a single supplier of it within Australia. I did, however, manage to find a shop in New Zealand with an online presence, who happened to stock exactly the right stuff. I’ve ordered that, so hopefully I won’t be faced with the two-month delay I’ve been experiencing with other international orders lately.

So here’s where I got to before exhausting my kit supply:

A quick re-think of the strategy and I decided to go ahead and remove the hull form the build board. This I did following Chuck’s instructions and encountered no problems. Similarly, I removed the frame centres following the instructions and again encountered no problems.

Next up was to install the cap rail. The only issue I ran into here was that according to the instructions, I should have been left with a 1/16” gap between the upper strake of planking and the “ears” on the transom. For some reason my planking went all the way up to the ears on both sides. After fairing the sheer, I simply cut a notch out of the lower part of the ear to make room for the cap rail. The cap rail then went on easily. While I was fairing the sheer, I also did an initial clean-up of the frames – really just removing the laser char.

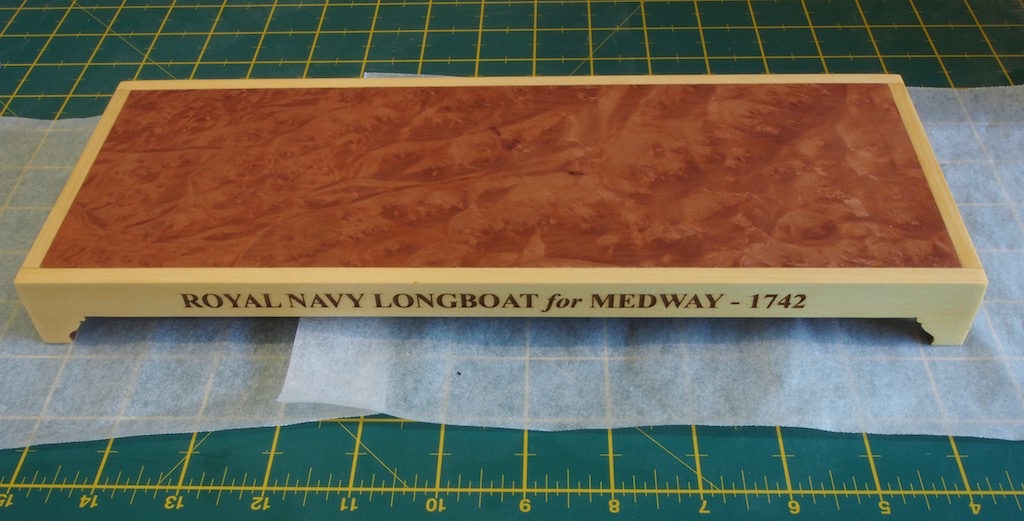

Ryland kindly gave me a tip to fit the pedestals to the hull at around this point as well, noting that this would be much easier at an early stage of the build – a point well made. So, I decided to make up the display base this weekend. I initially thought the substrate for the burl veneer was undersized, but after a quick PM exchange with Chuck realised that I was over-thinking things and there was no problem at all – in fact, it’s designed this way. Makes perfect sense when you actually put it together….

Anyway, here’s the display base completed with just one coat of satin WOP at the moment. Will apply further coats in due course. The pedestals have also been assembled and coated. I’ll fit them properly to the hull once the finish is dry.

I’m now officially past the point where I canned my first attempt. While this one is not perfect, it is so much better at this stage than the first one, that I’m really pleased I decided to bite the bullet and start over.

Next up will be the challenge of the bolsters…next weekend….

-

-

-

Thanks Ryland, and thanks for the tip re the display pedestals - I hadn’t even considered that aspect!

- Canute and Ryland Craze

-

2

2

-

Thanks Mike,

I'd be very interested to hear/see how you go with the Zero paints and 2k clear.

-

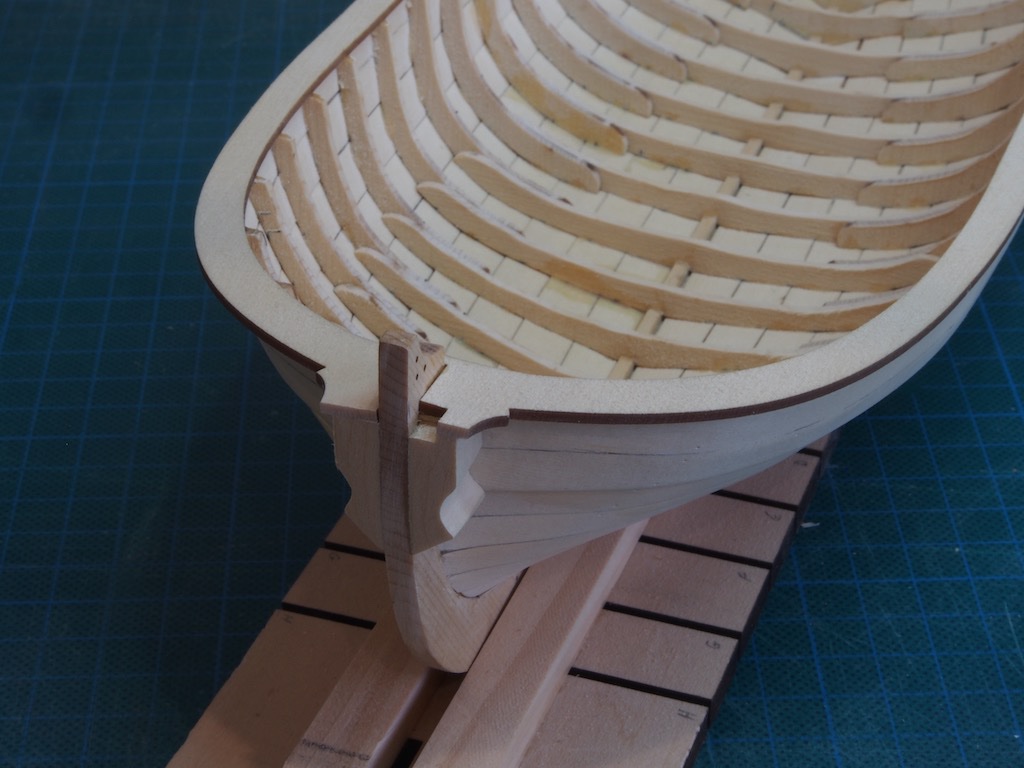

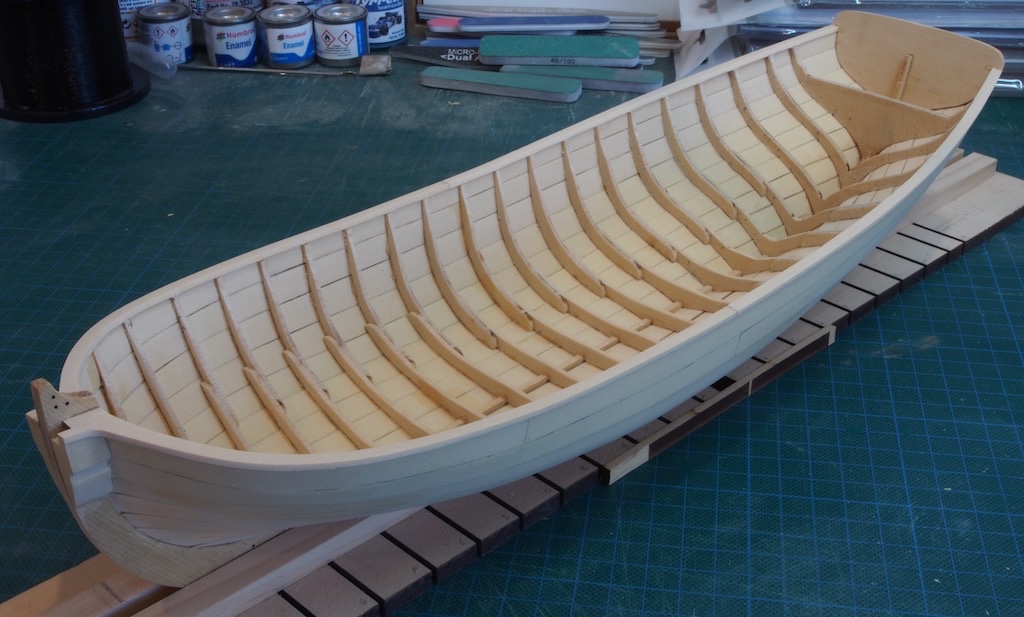

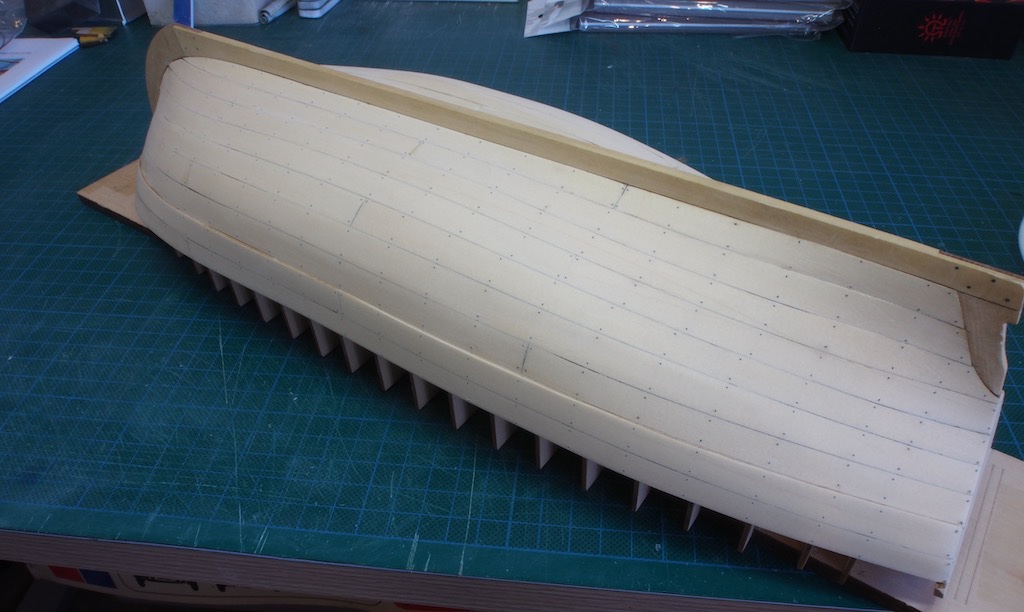

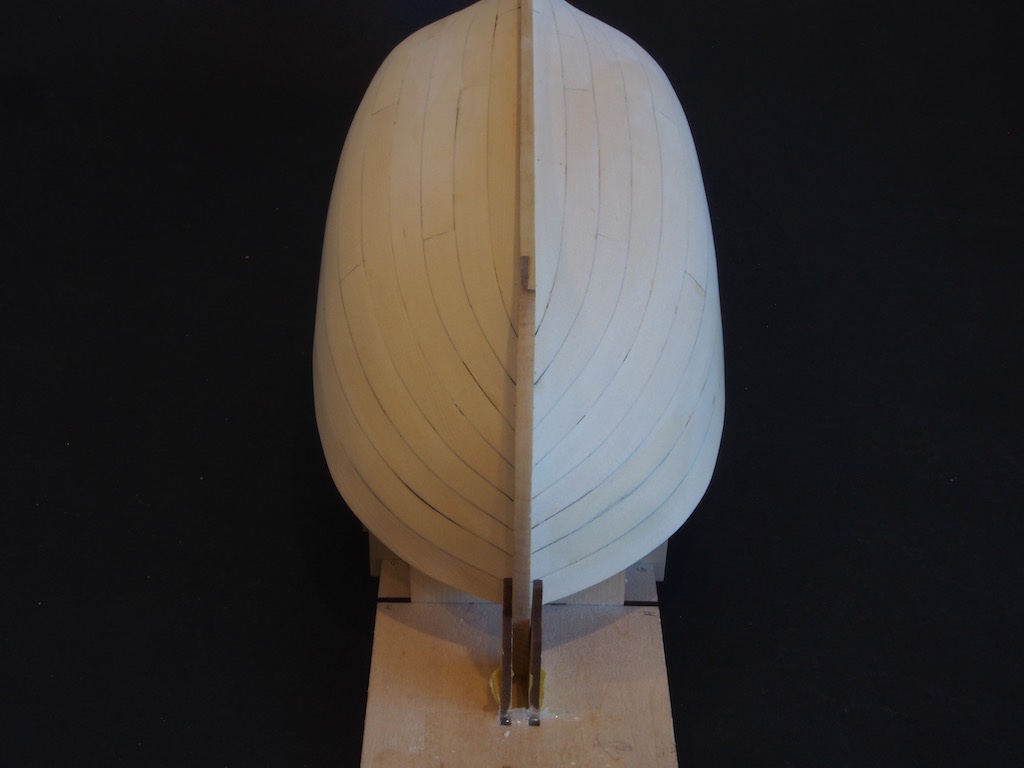

Planking has been completed. Although this was much easier using Chuck’s methods for bending and gluing, I still had some very minor “staircasing” at the bow, although this was nowhere near as bad as on my first attempt. Here is the first layer completed after an initial light sanding:

The whales were then added. I did these in reverse order, working down from the gunwhale in order to correct any minor misalignment at the bow. Following Chuck’s advice, I used a sharp chisel to pare down the forward end as it approached the rabbet. The aft end was simply sanded thinner for the last half inch or so. All of the holes have been drilled in preparation for the monofilament “nails”. I think I will complete this task and do a final sanding before removing the hull from the build board.

Muirneag 1903 by Blue Ensign – FINISHED - Vanguard Models - 1:64 scale - A Scottish Zulu Fishing Boat Based on the Vanguard Models Zulu Kit

in - Kit build logs for subjects built from 1901 - Present Day

Posted

Glenn,

1:64 is a ratio - it is independent of unit of measure. So yes, 1 inch equals 64 inches AND 1mm equals 64mm.

It gets confusing when scales are expressed in inches, eg 1/4”. In this case we are saying how many inches equals one foot, so in this example, we are saying that 1/4” equals one foot. This is the same as expressing the scale as a ratio of 1:48 (ie 1/4” x 48 equals 12” (or one foot), or put another way, 12” divided by 1/4” equals 48).

If we were to express the ratio scale of 1:64 in the inch format, it would be 3/16” (ie 3/16” equals one foot) - you can do the math.